2.1 First tutorial: ESP user interface

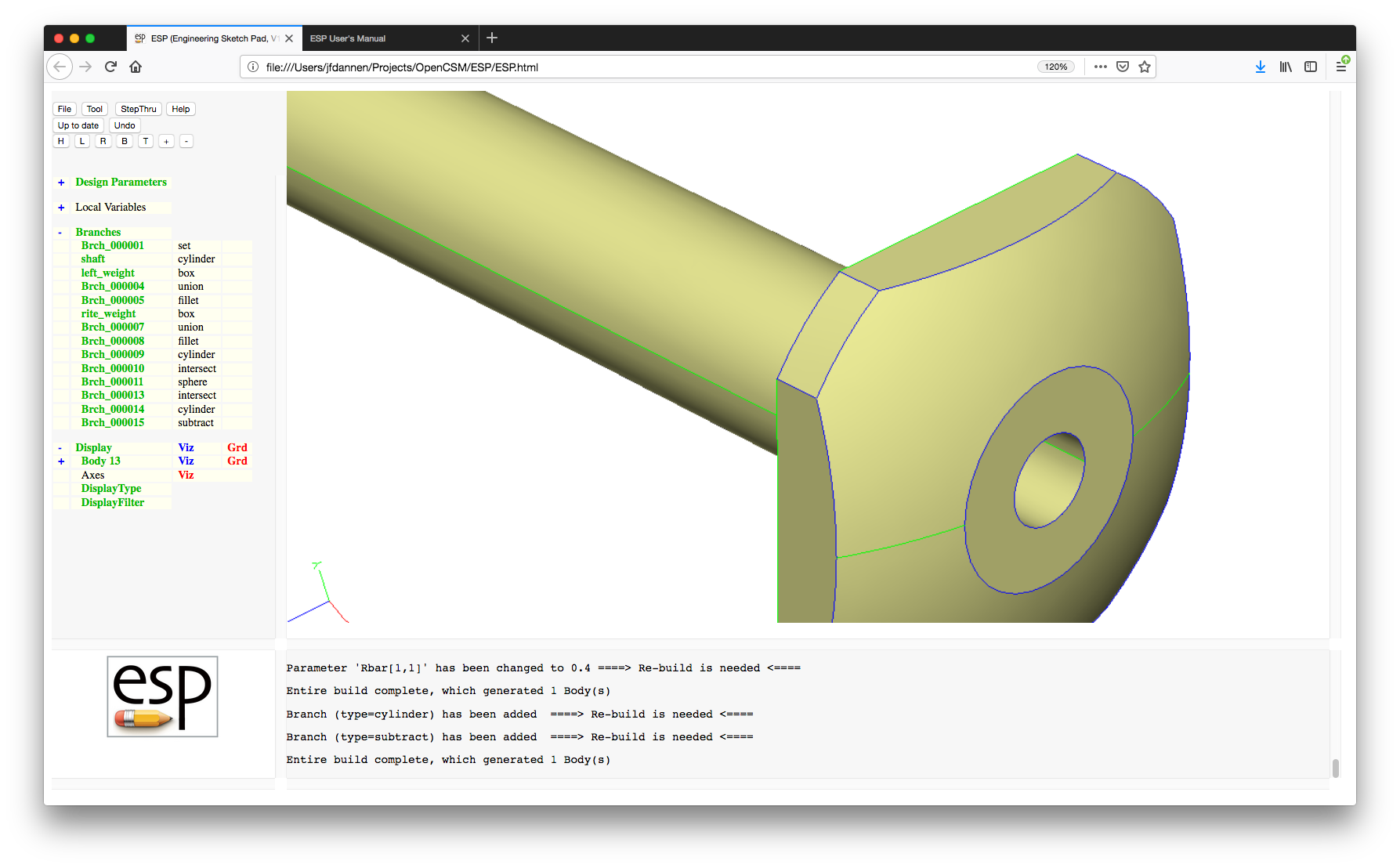

2.2 Second tutorial: Base ESP model

2.3 Third tutorial: Using the sketcher and adding spokes

2.4 Fourth tutorial: RULEs, BLENDs, and error checking

2.5 Fifth tutorial: Multi-models

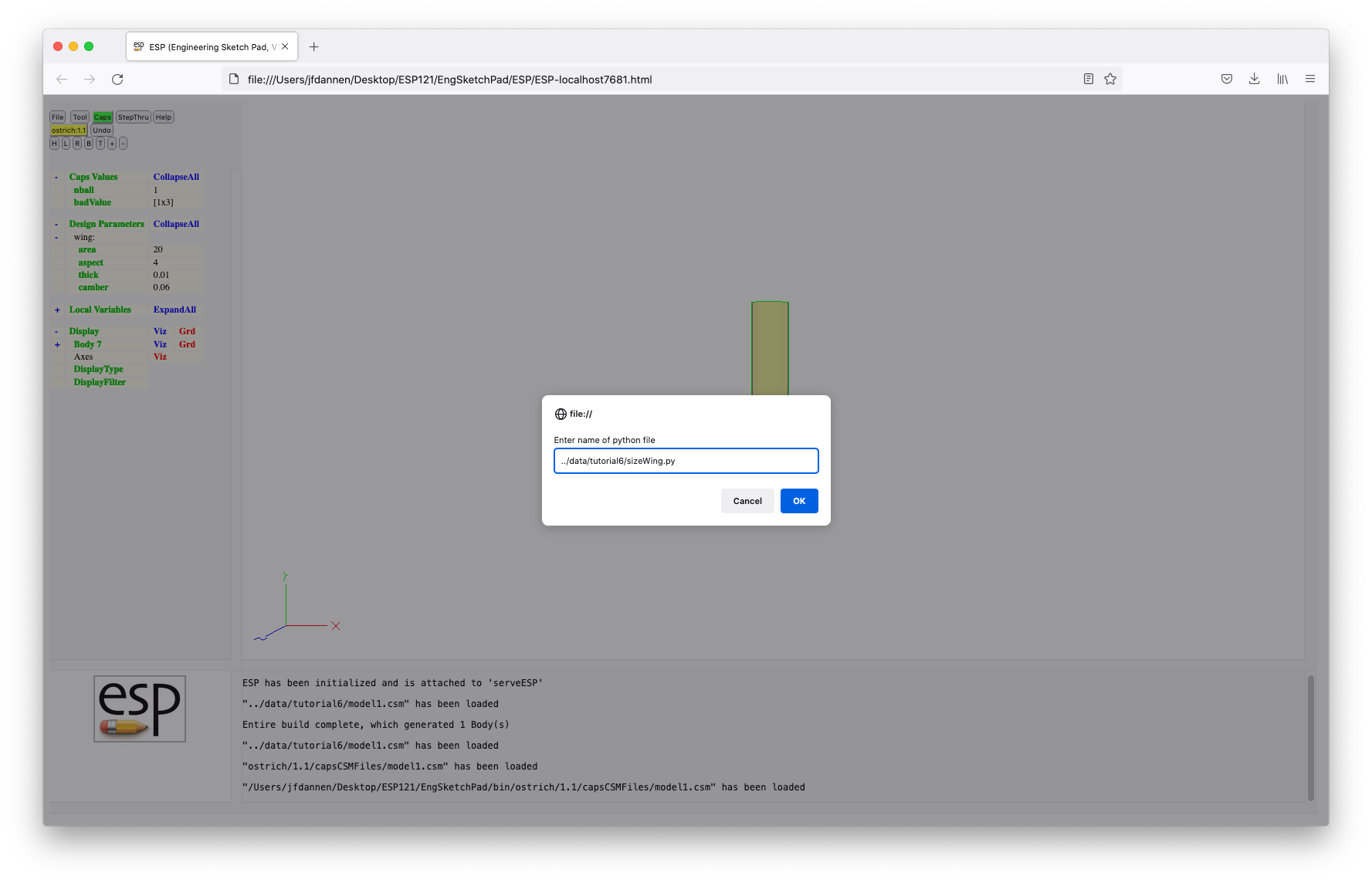

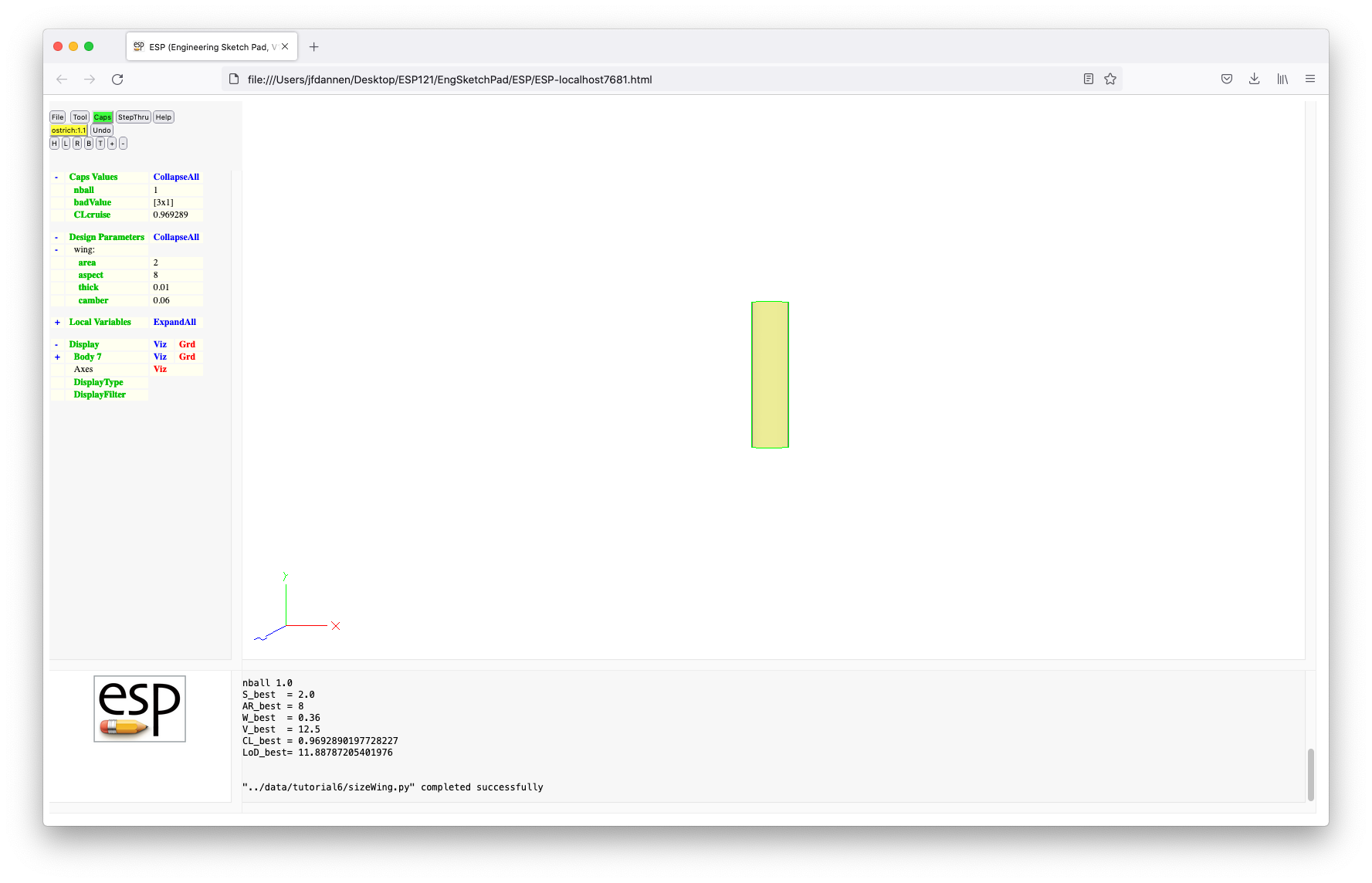

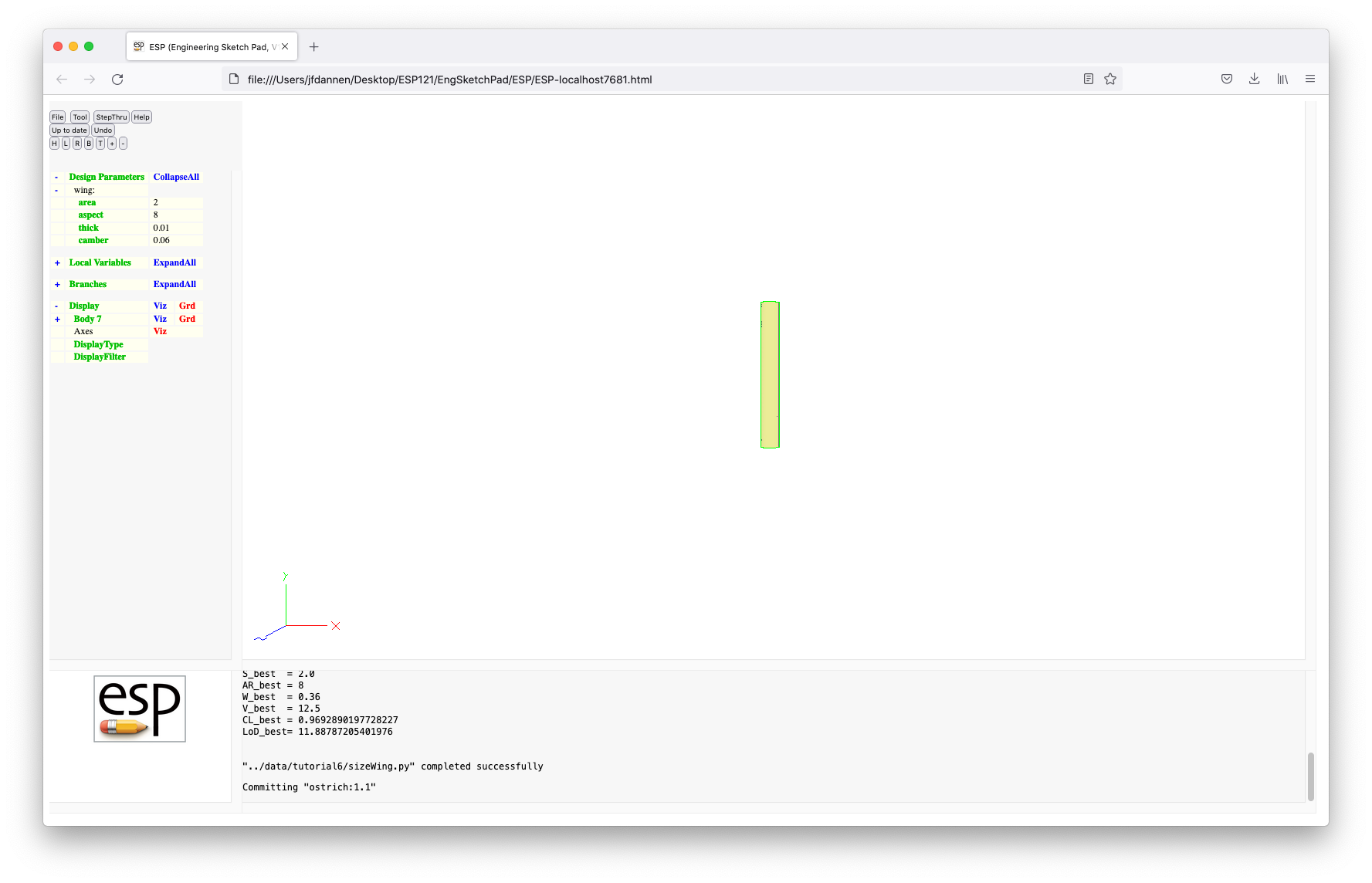

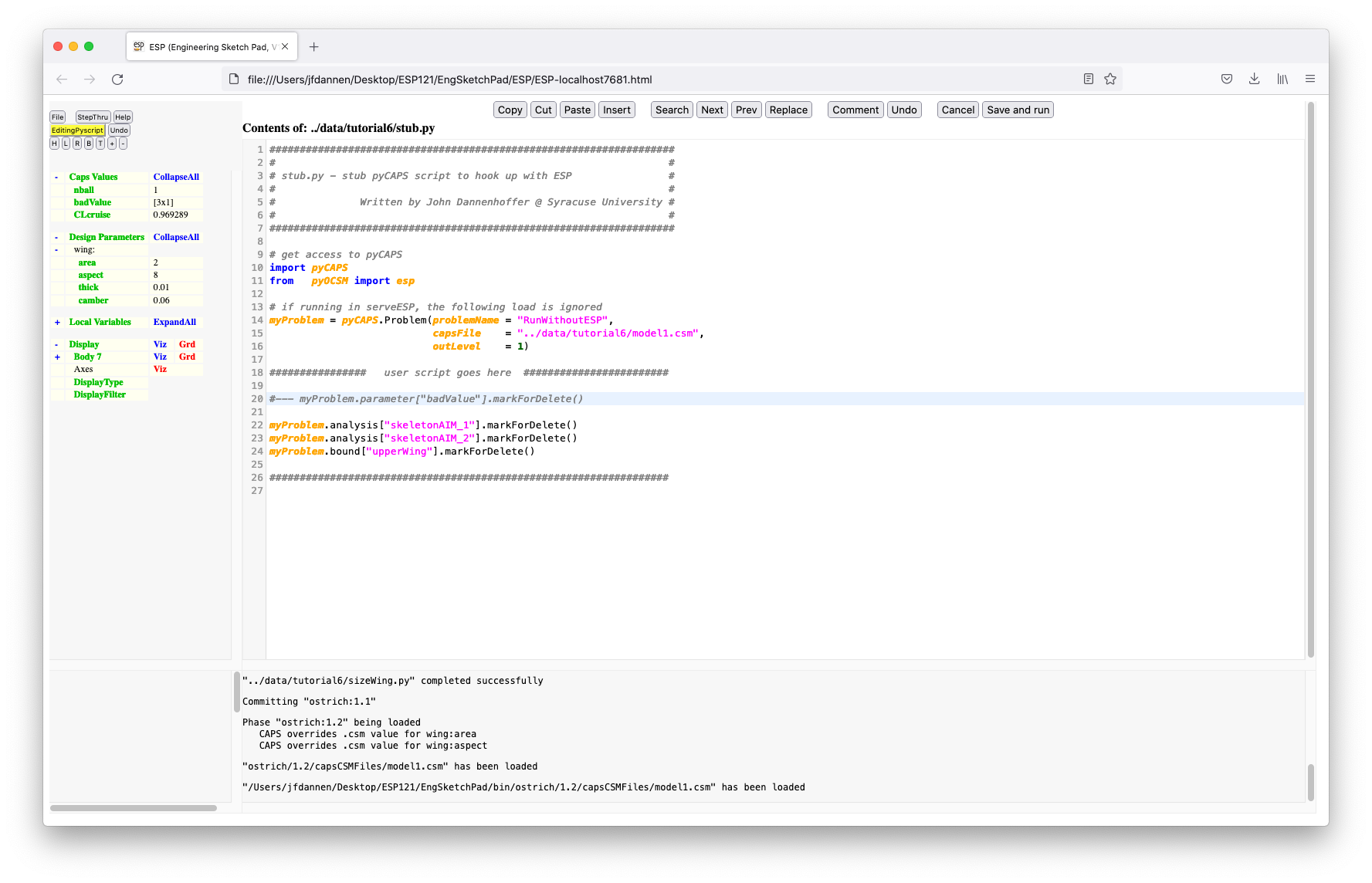

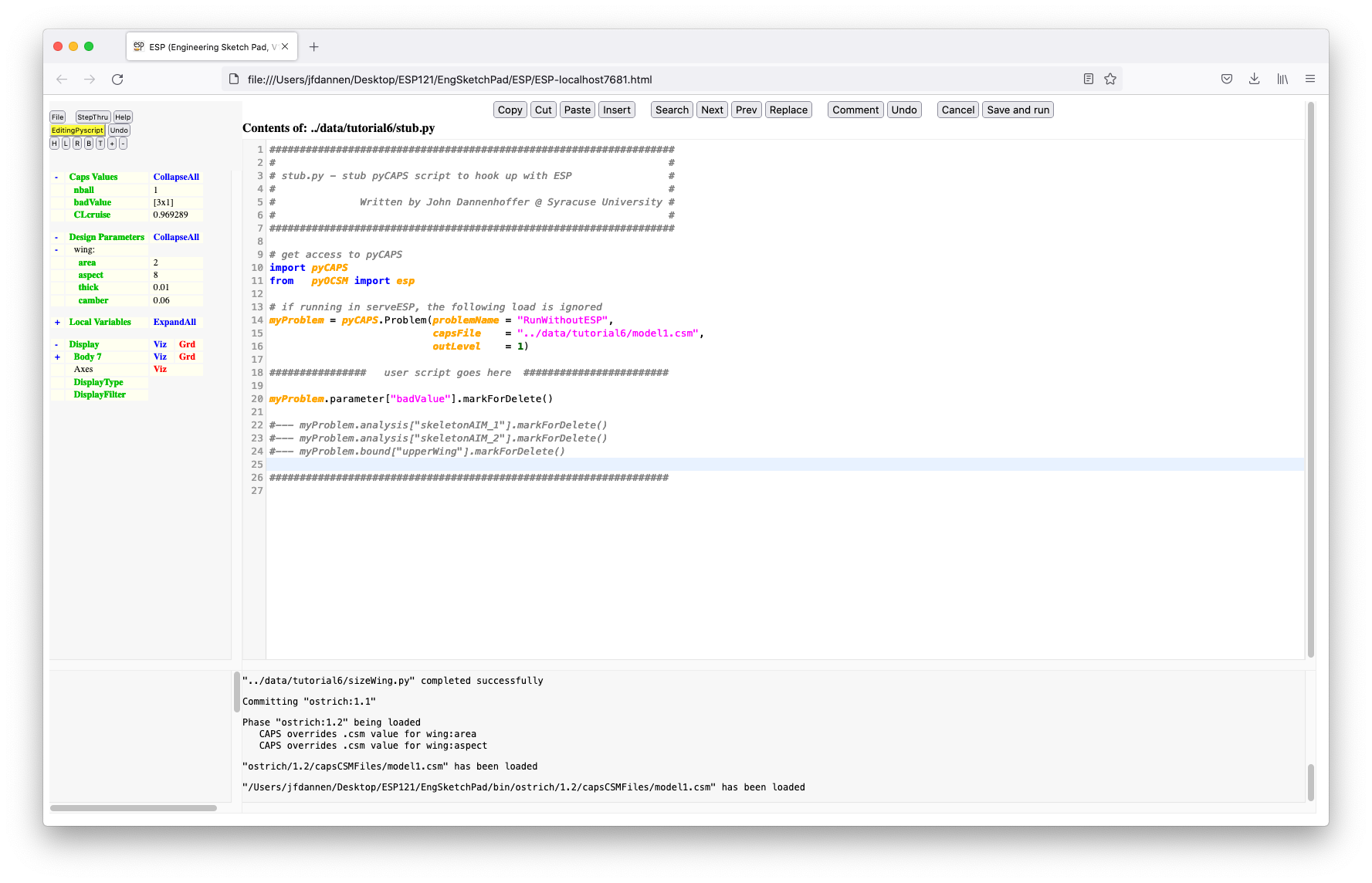

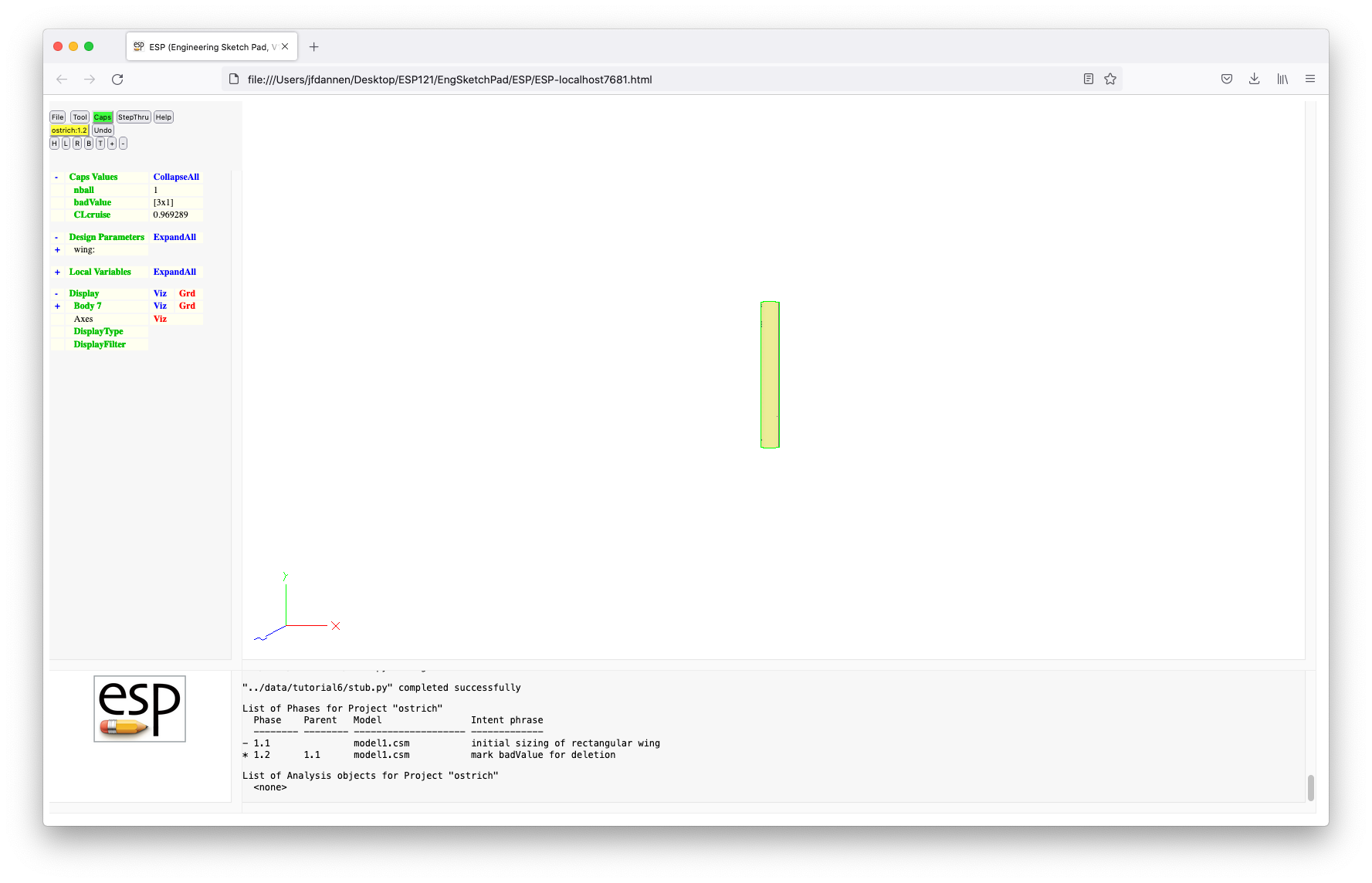

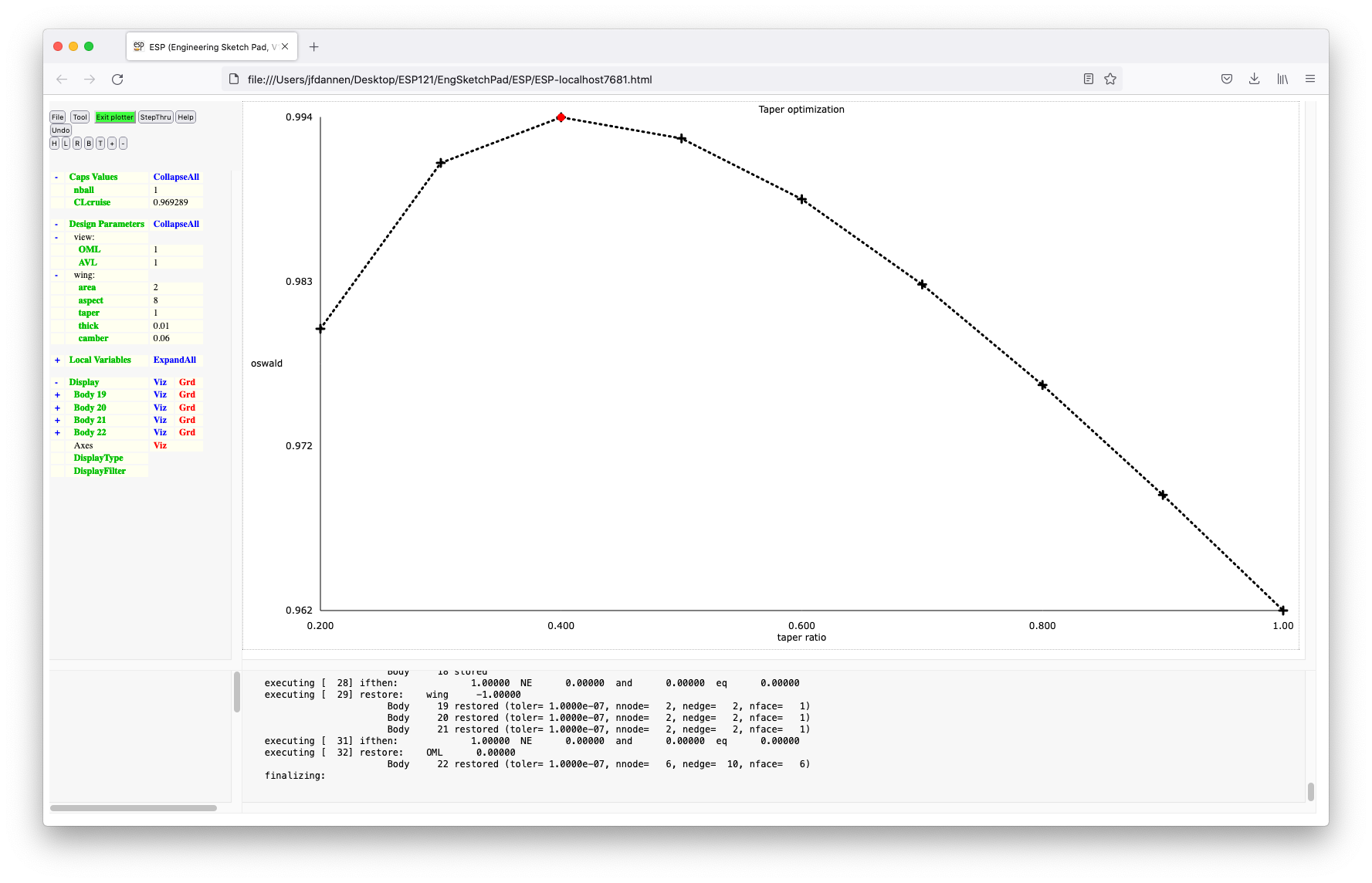

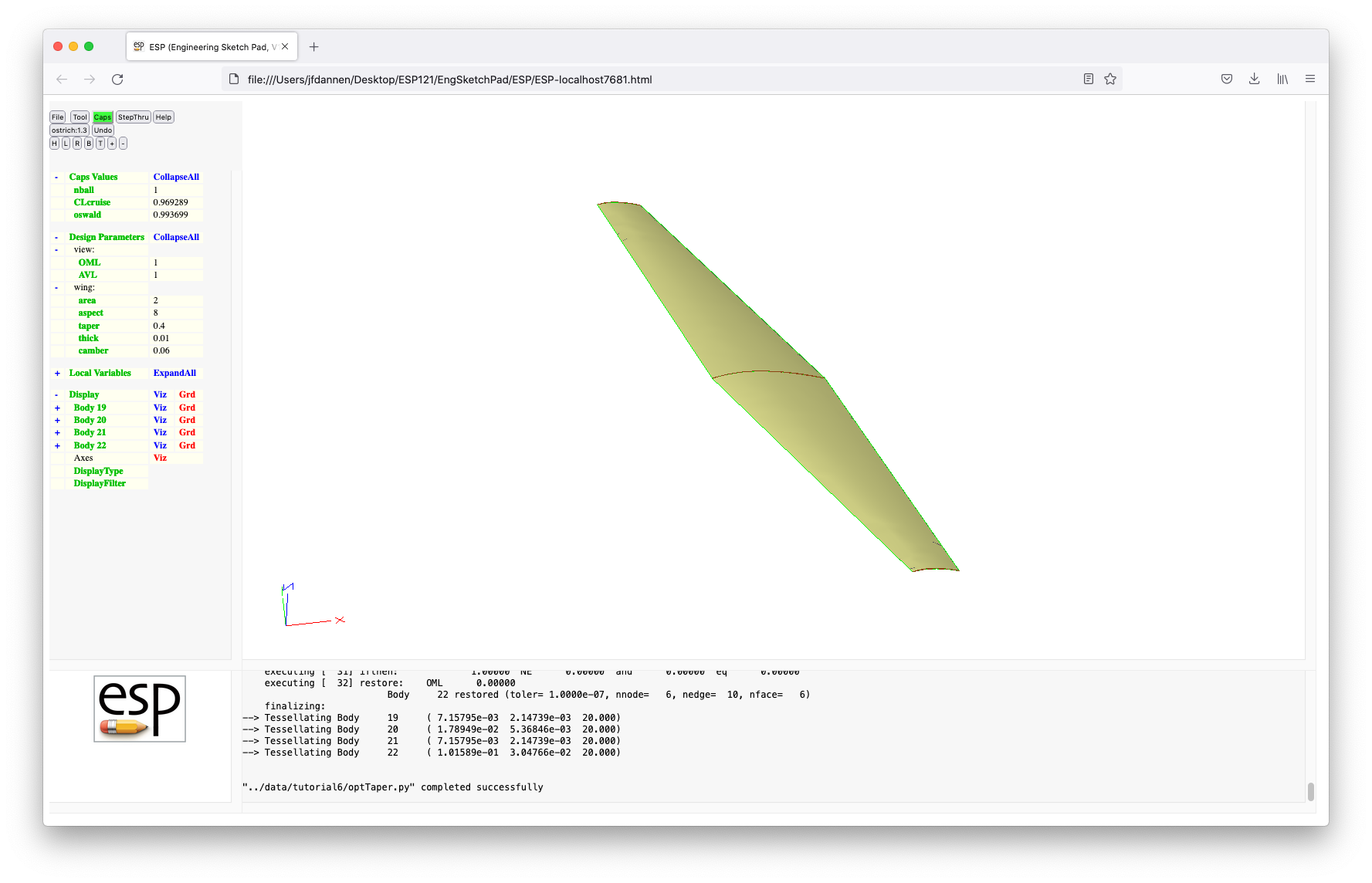

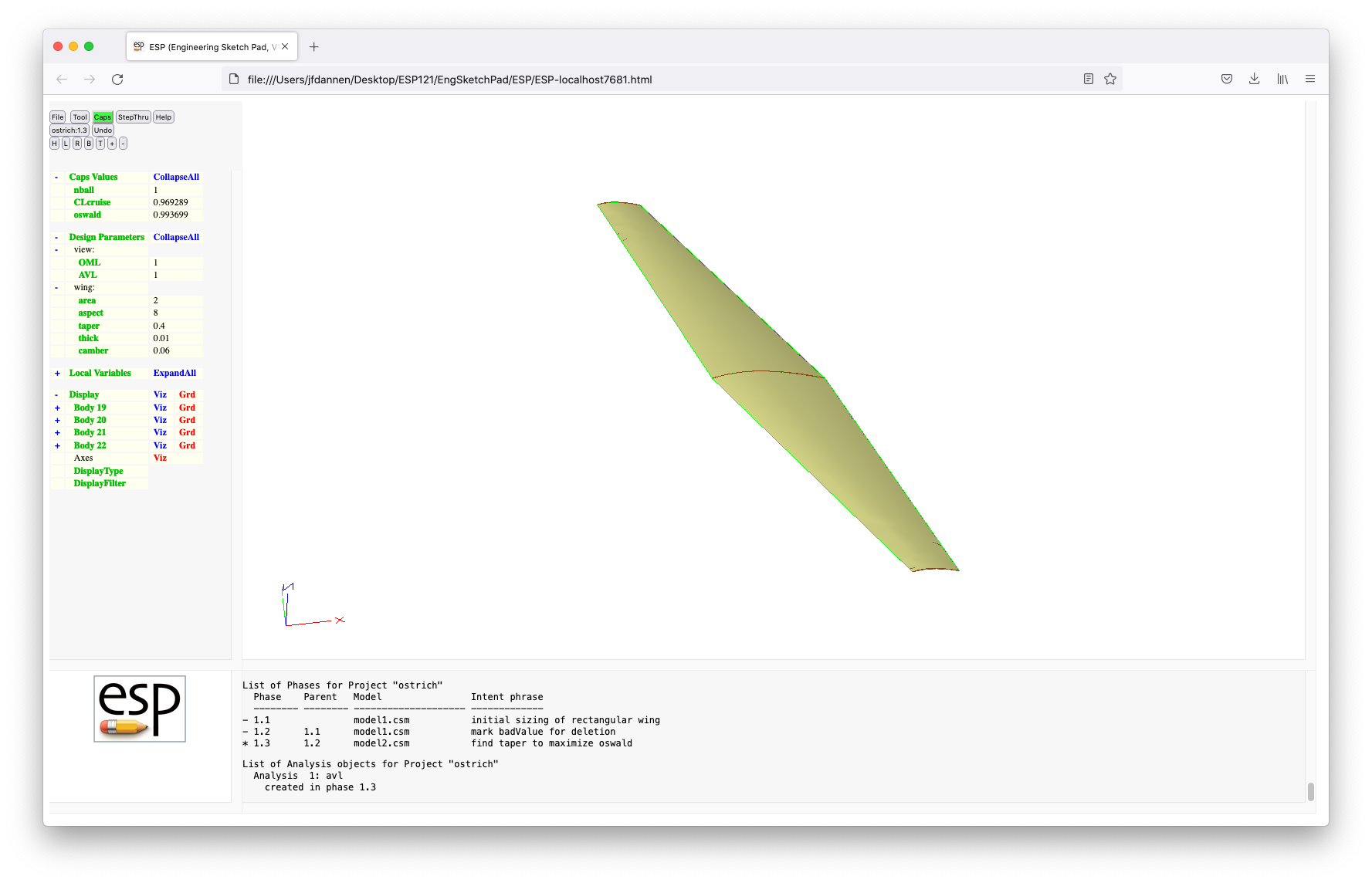

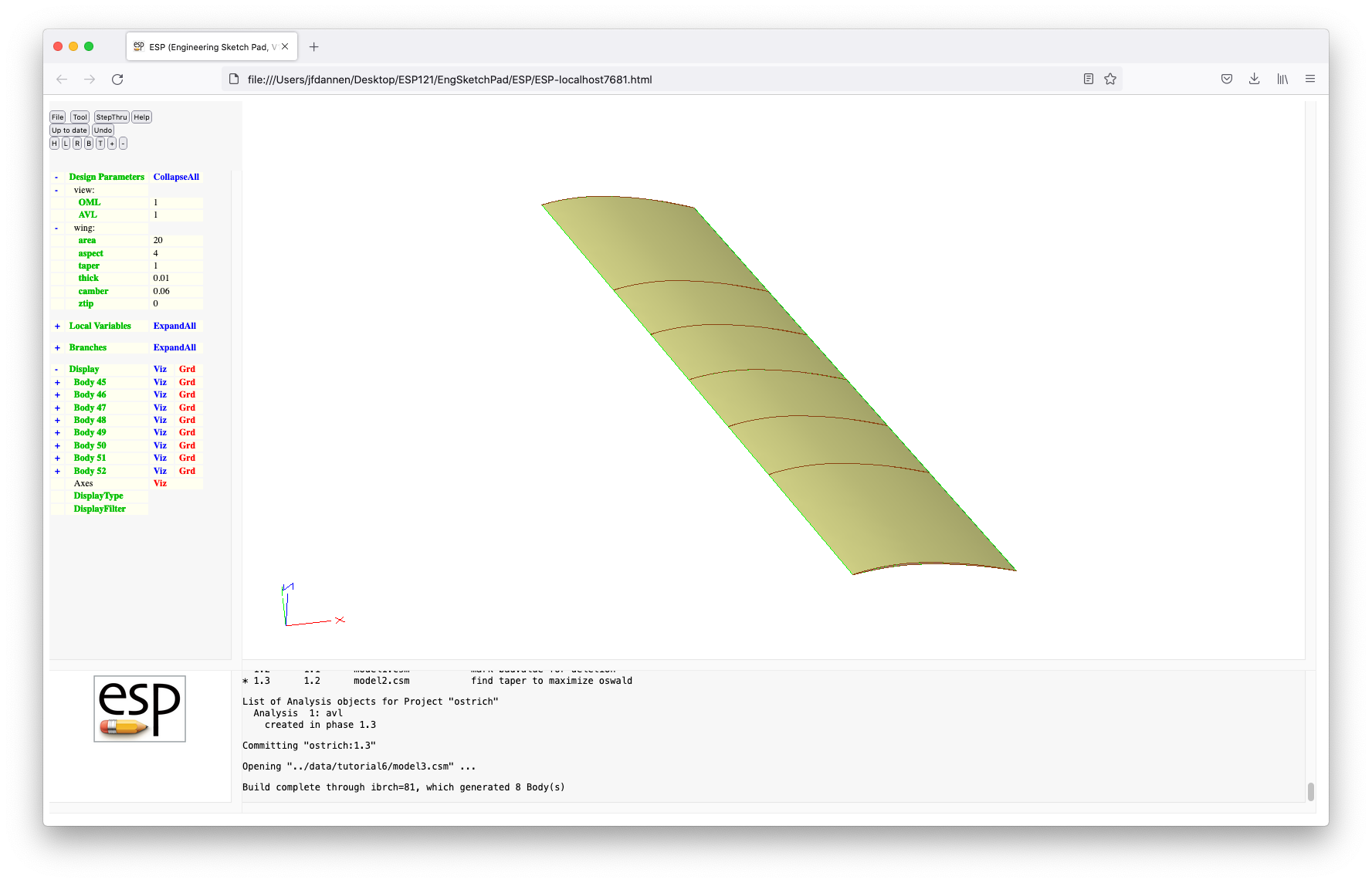

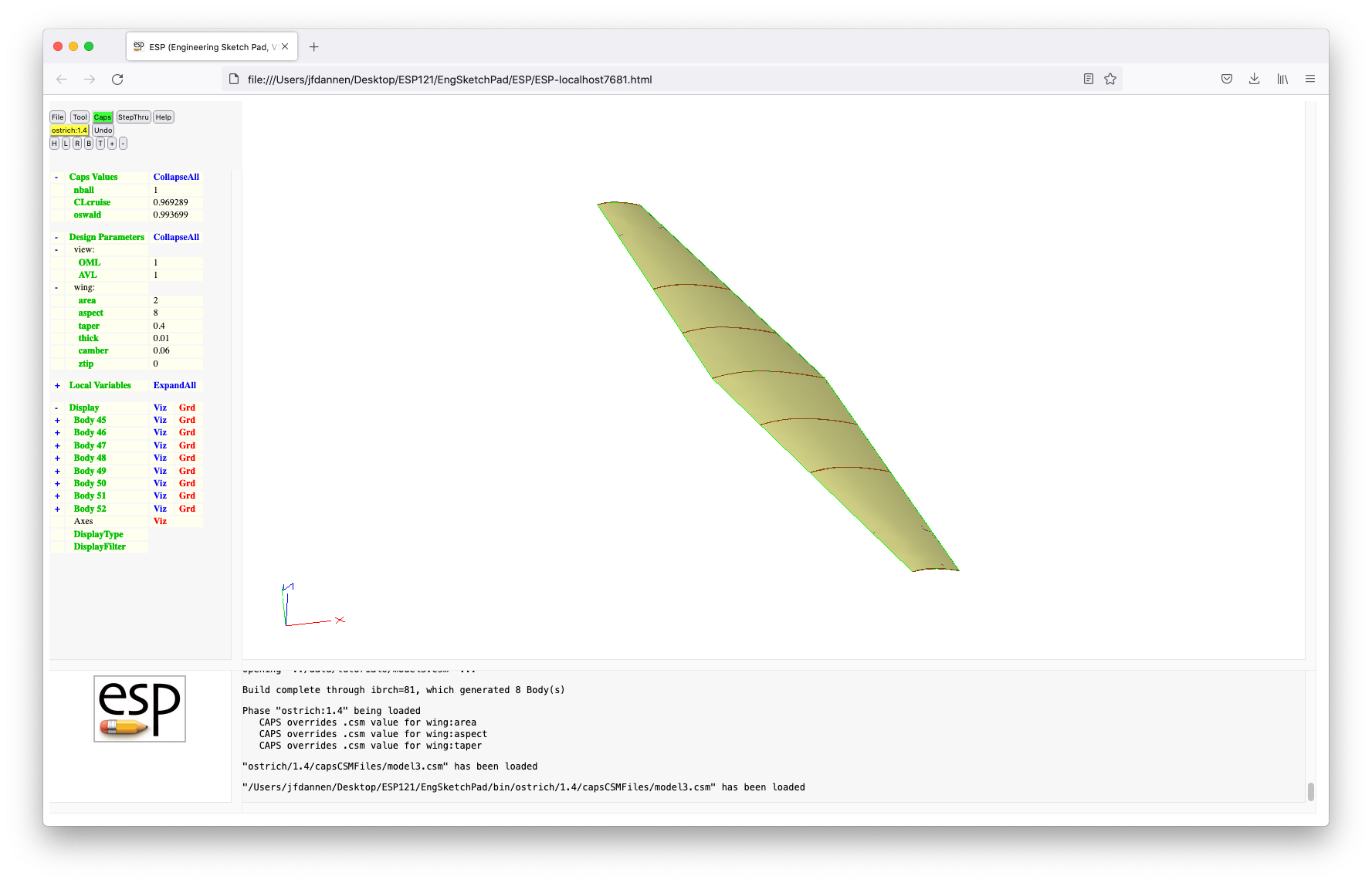

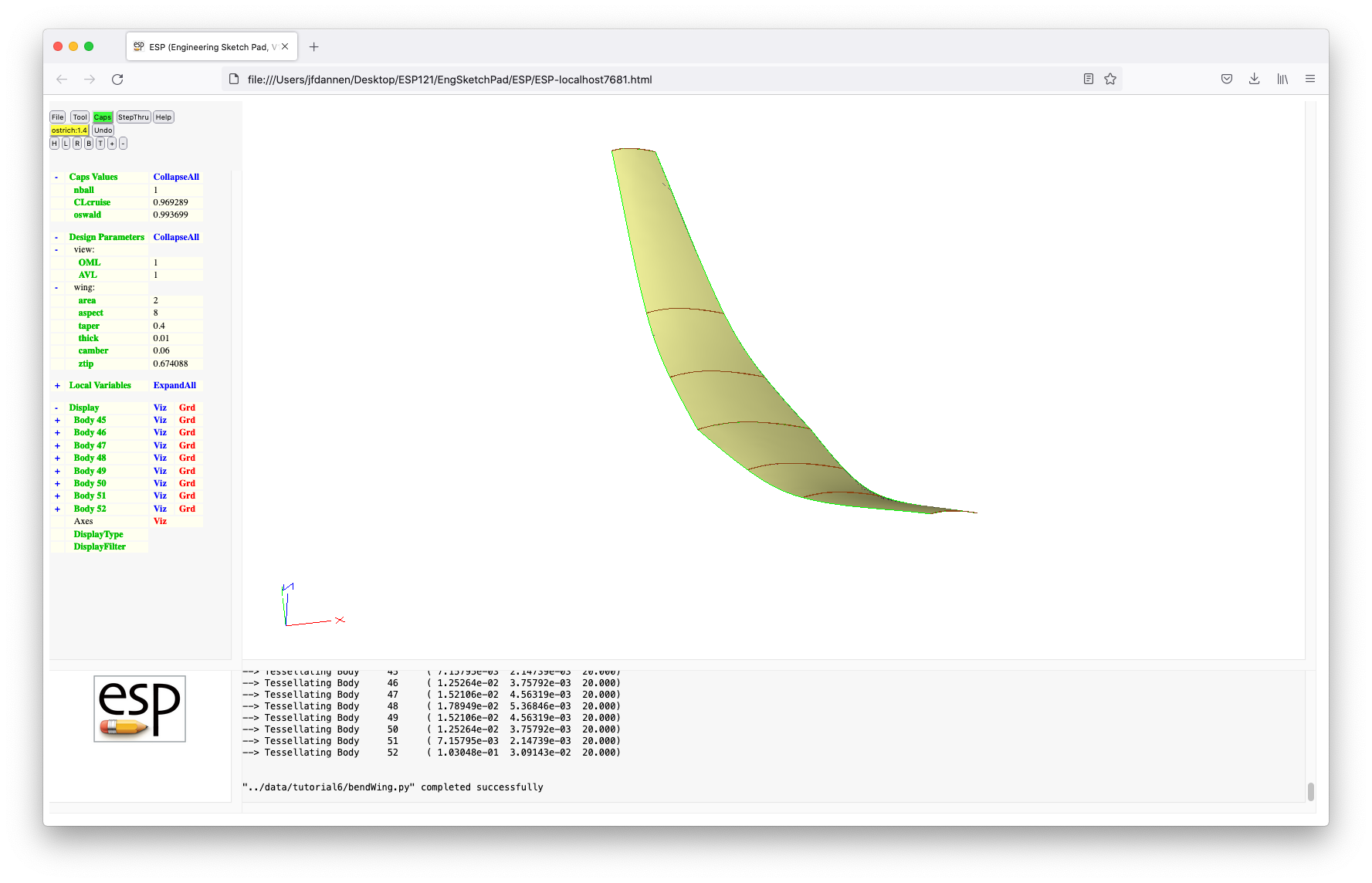

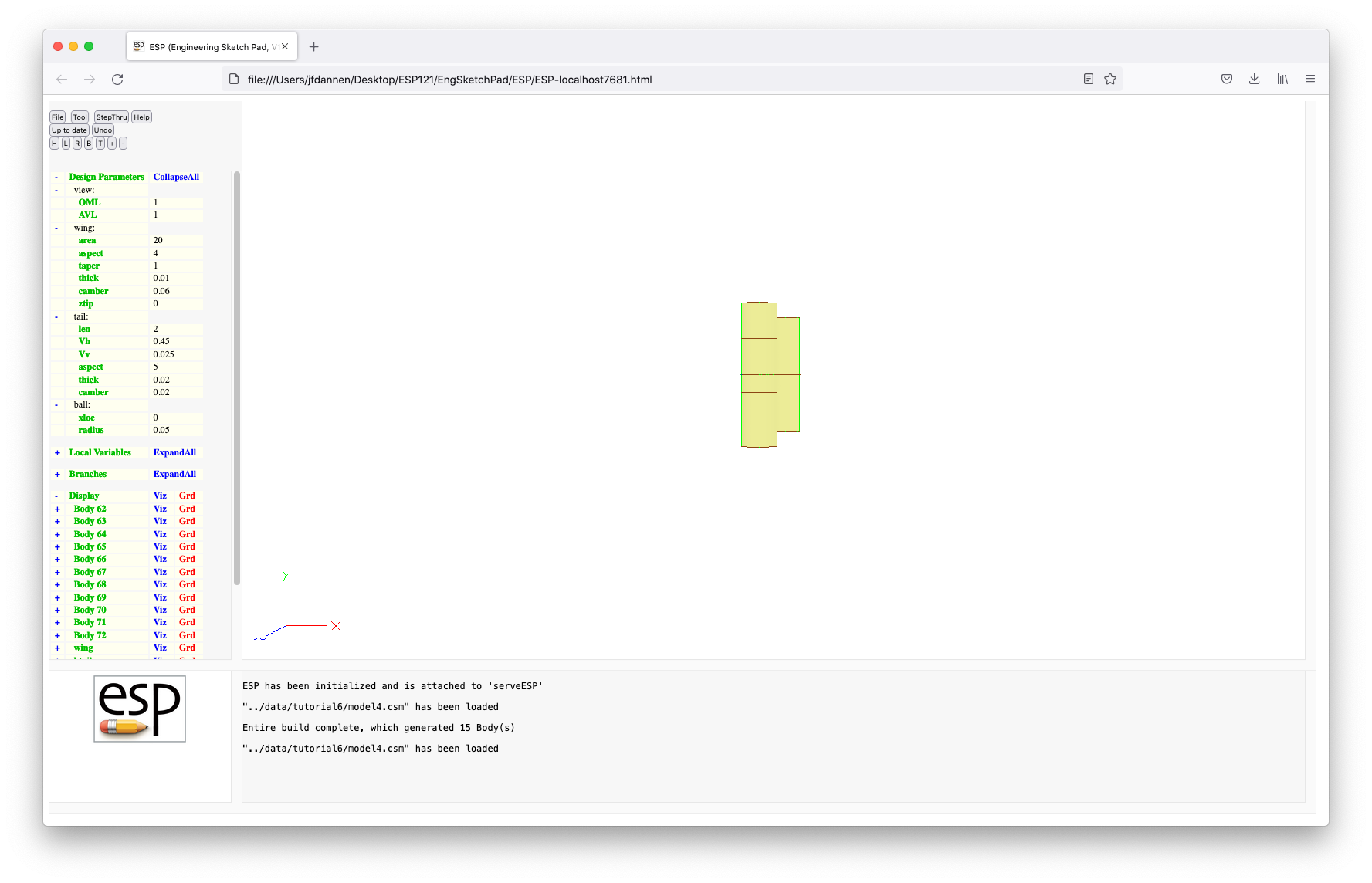

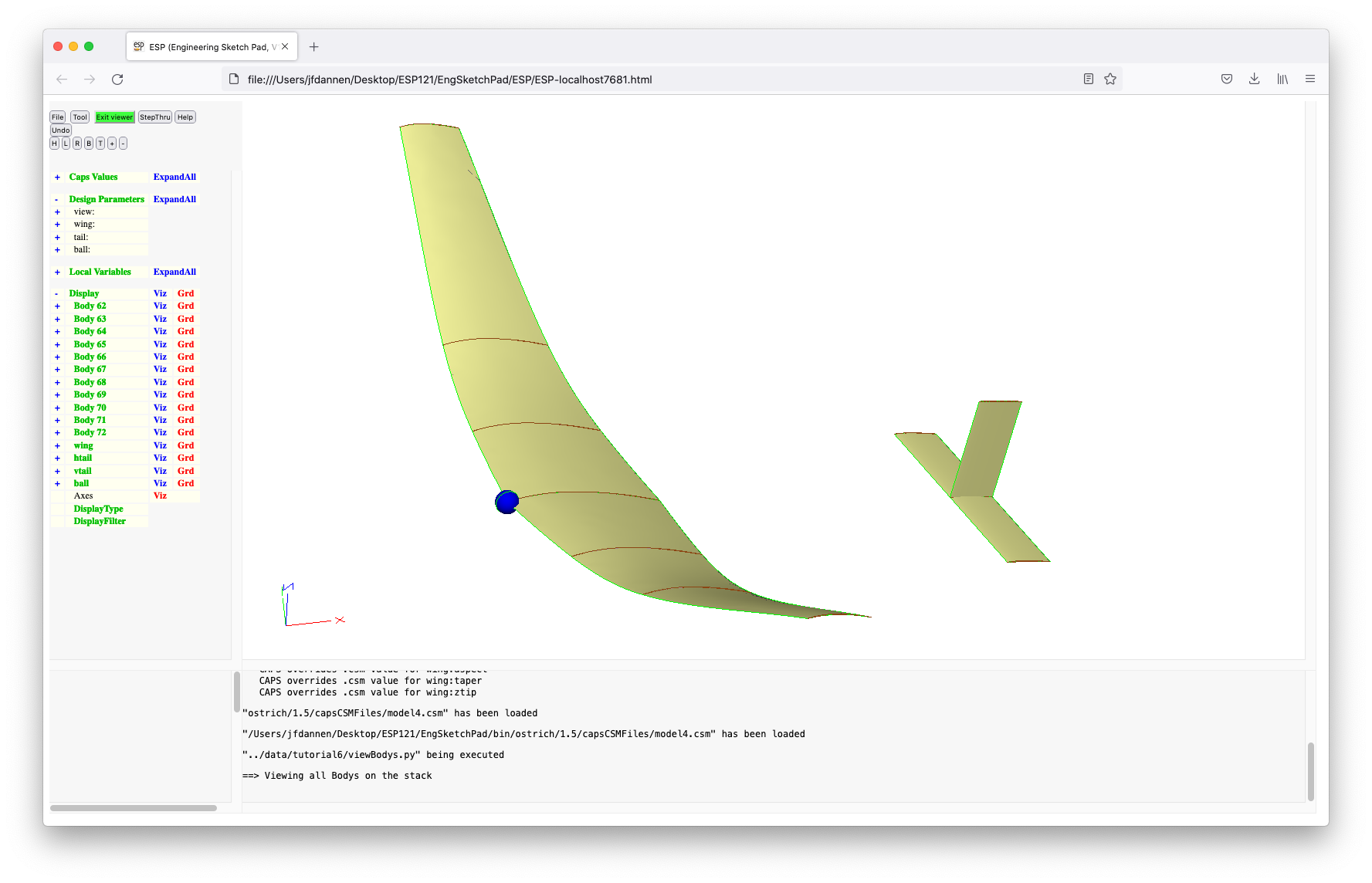

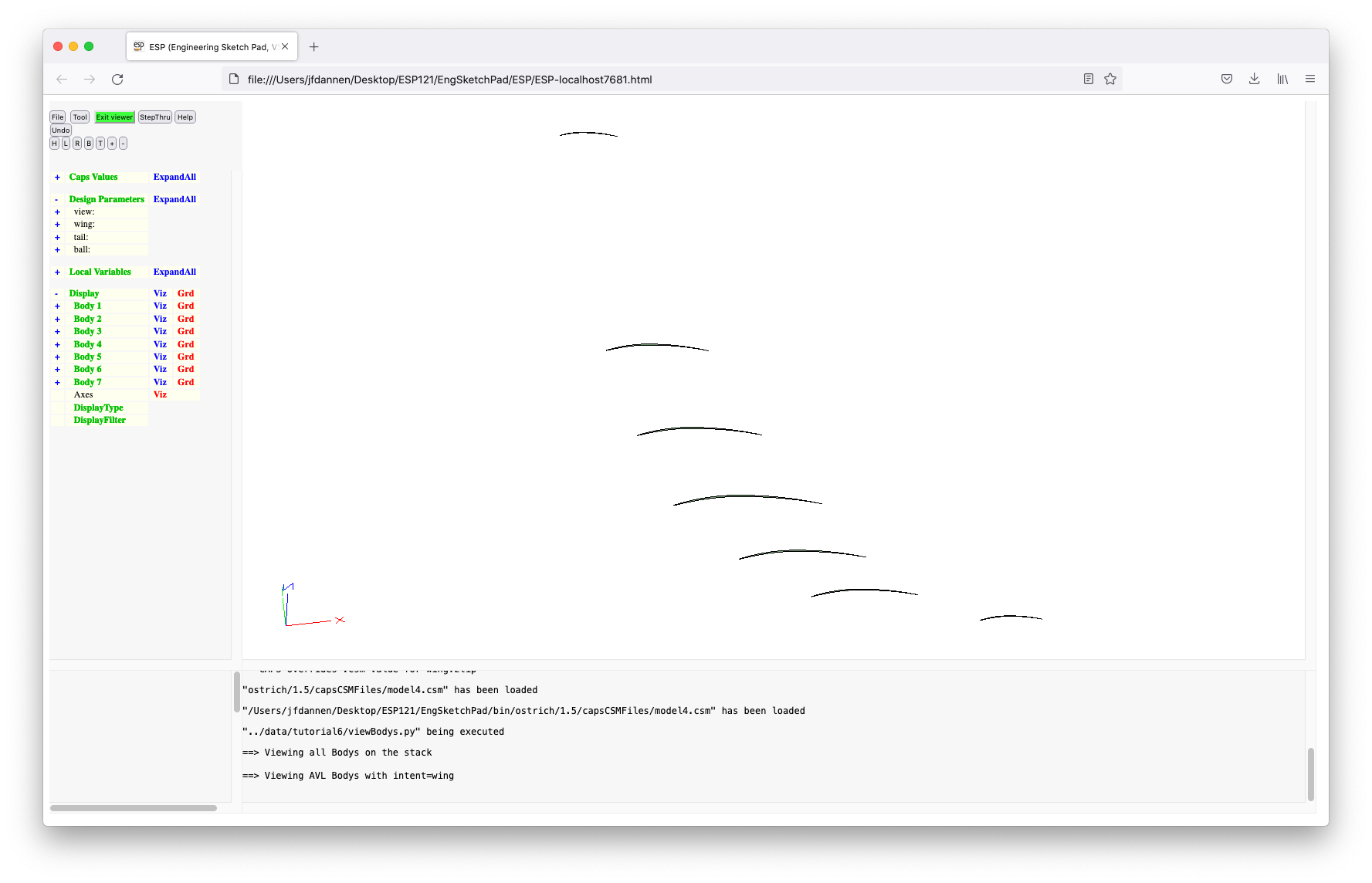

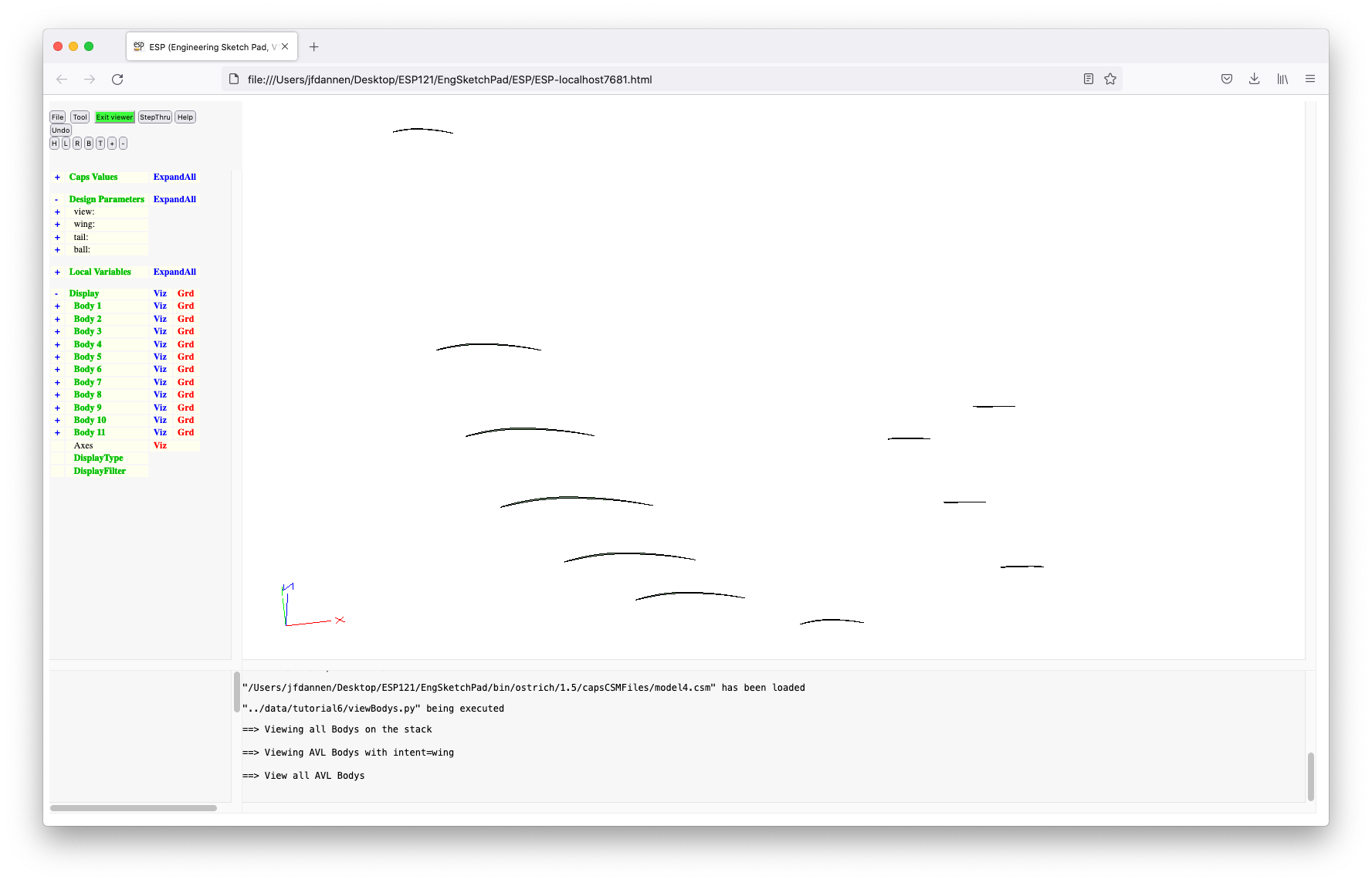

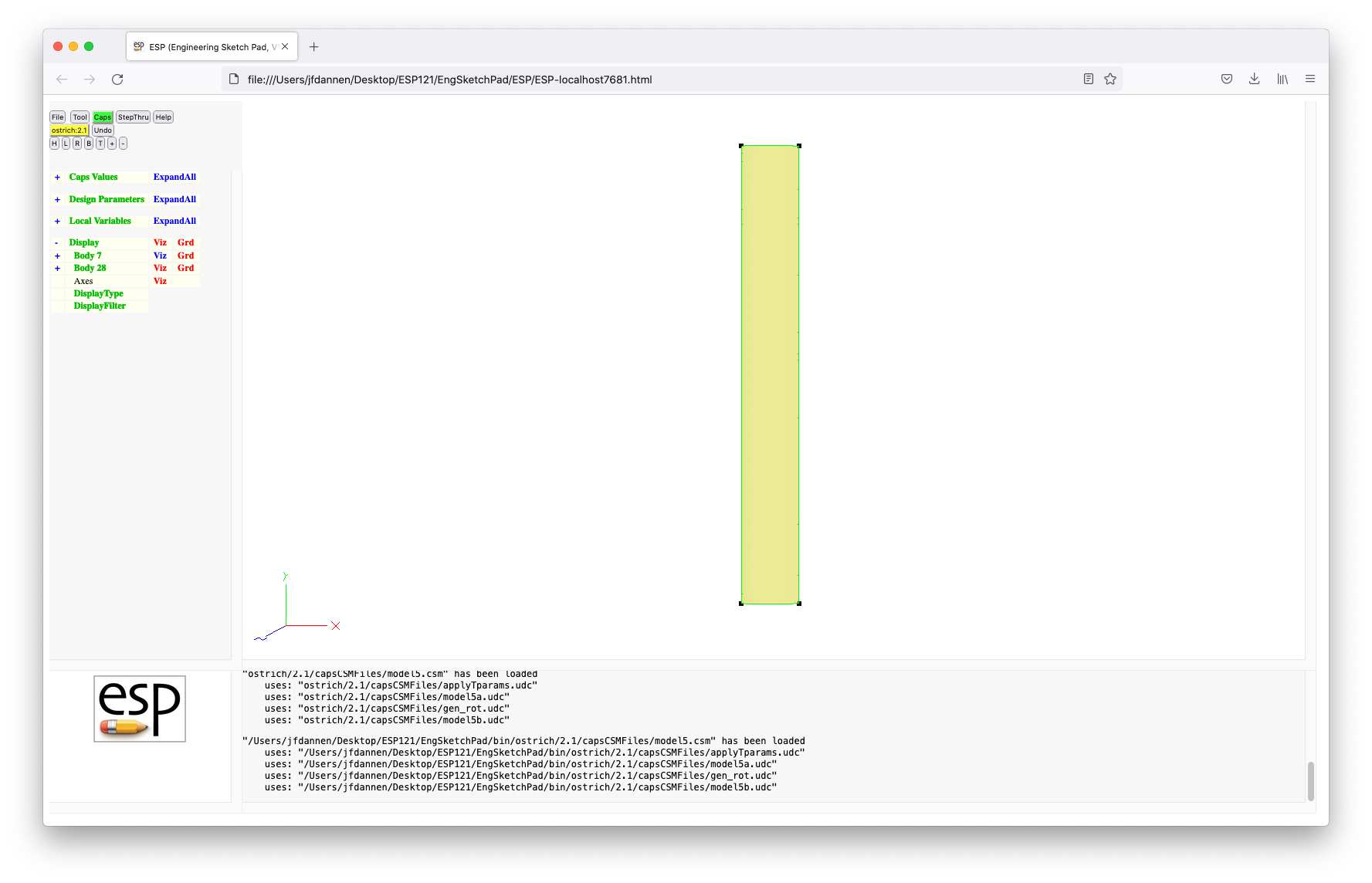

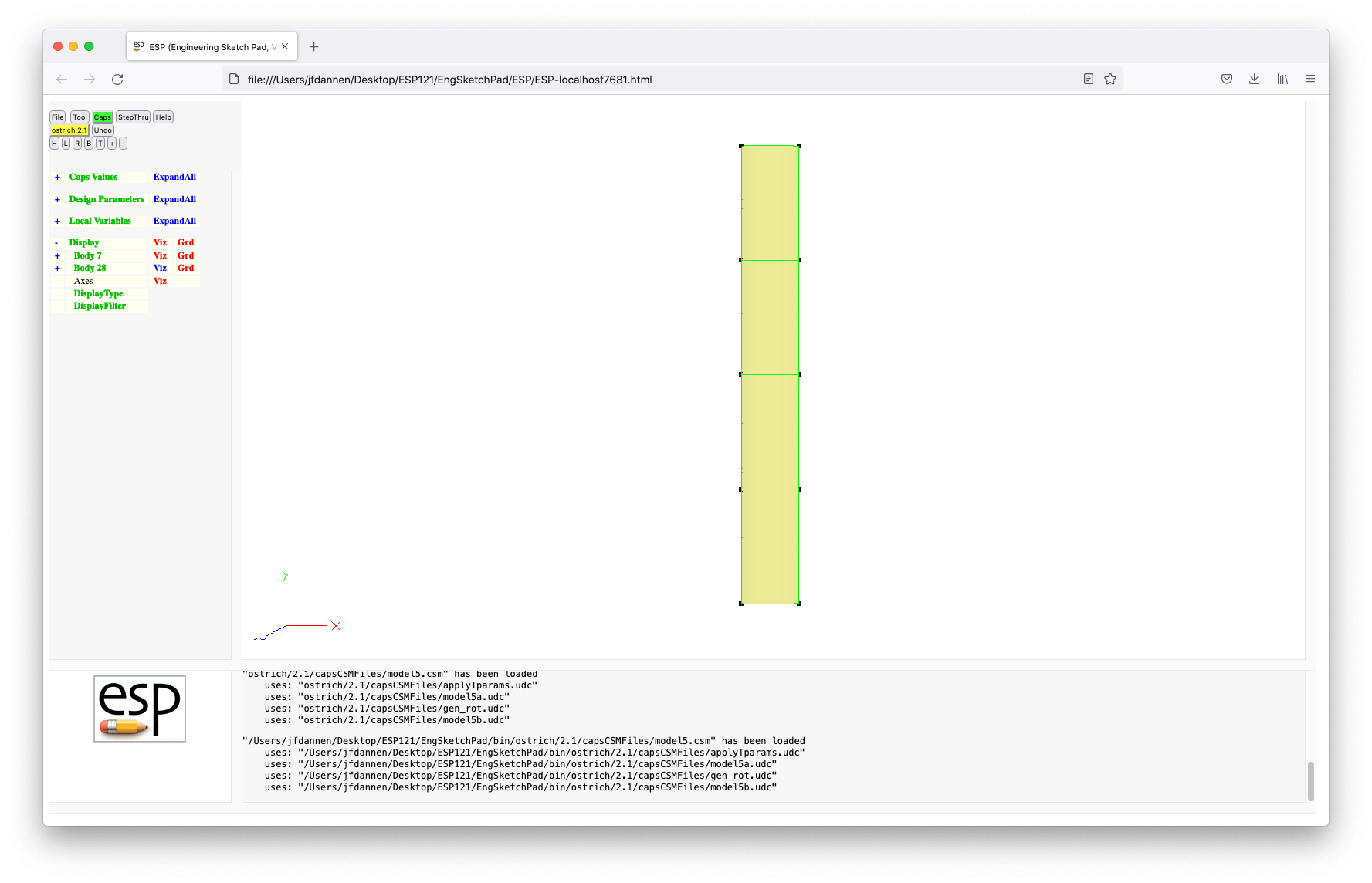

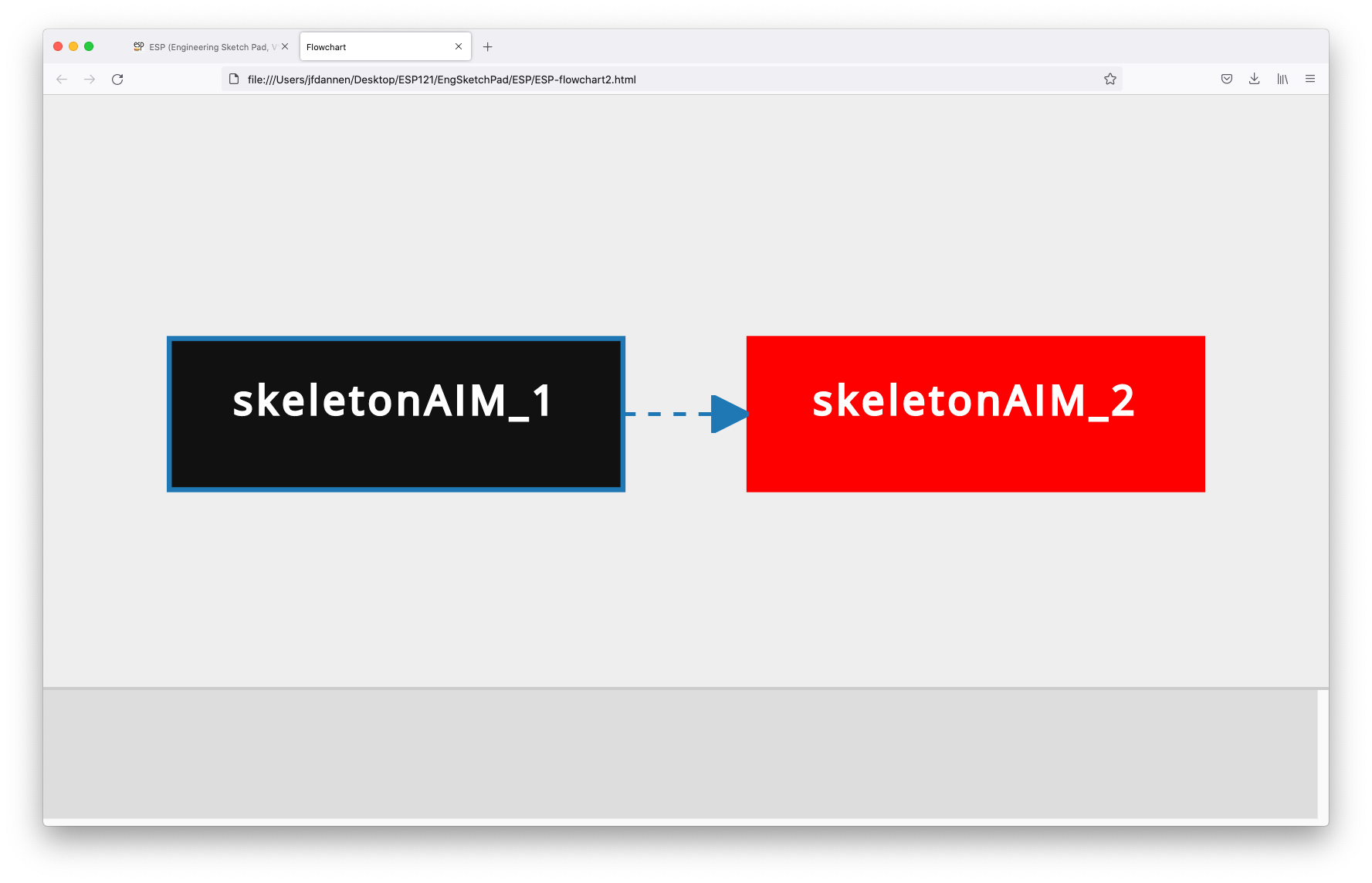

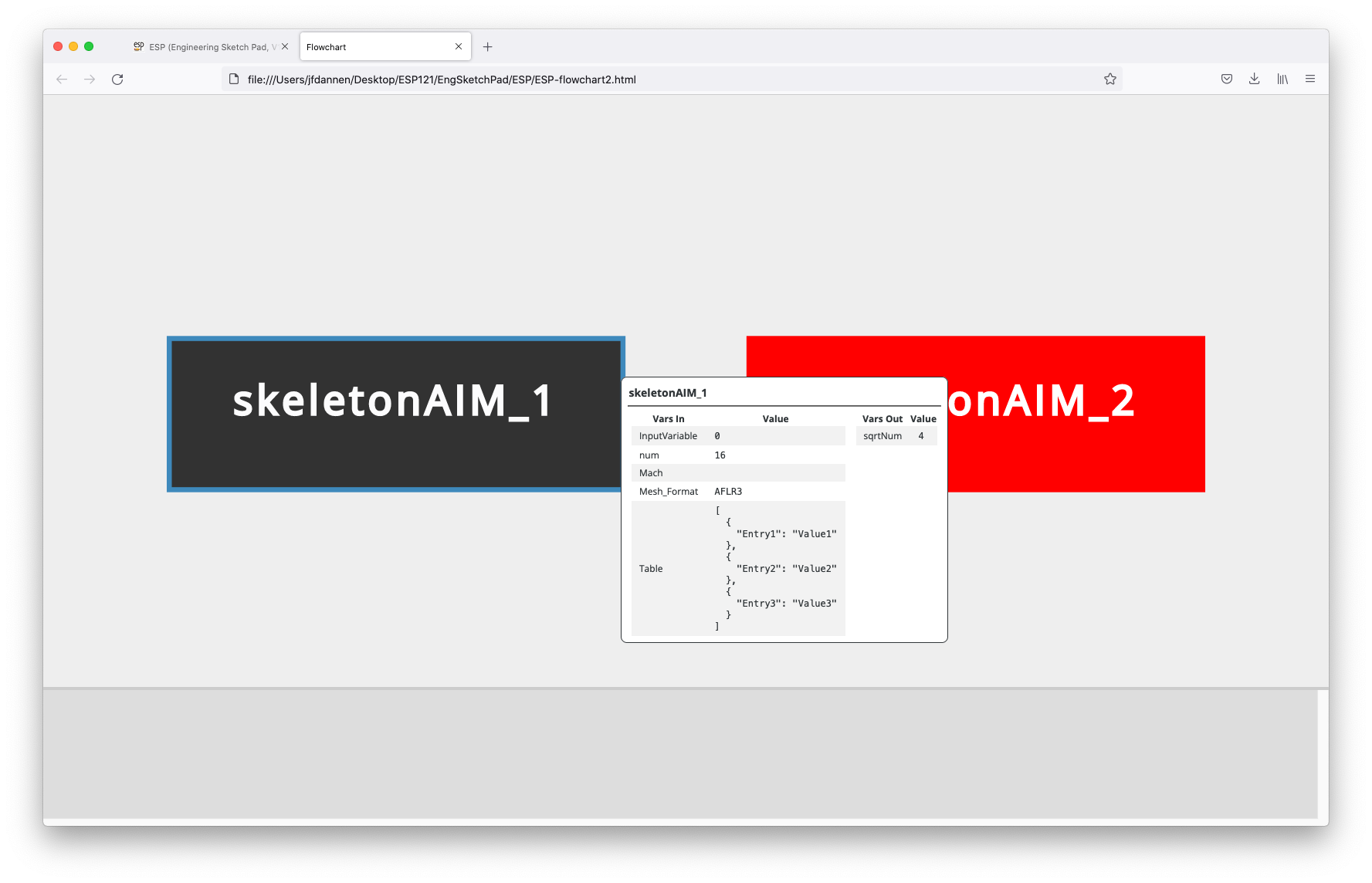

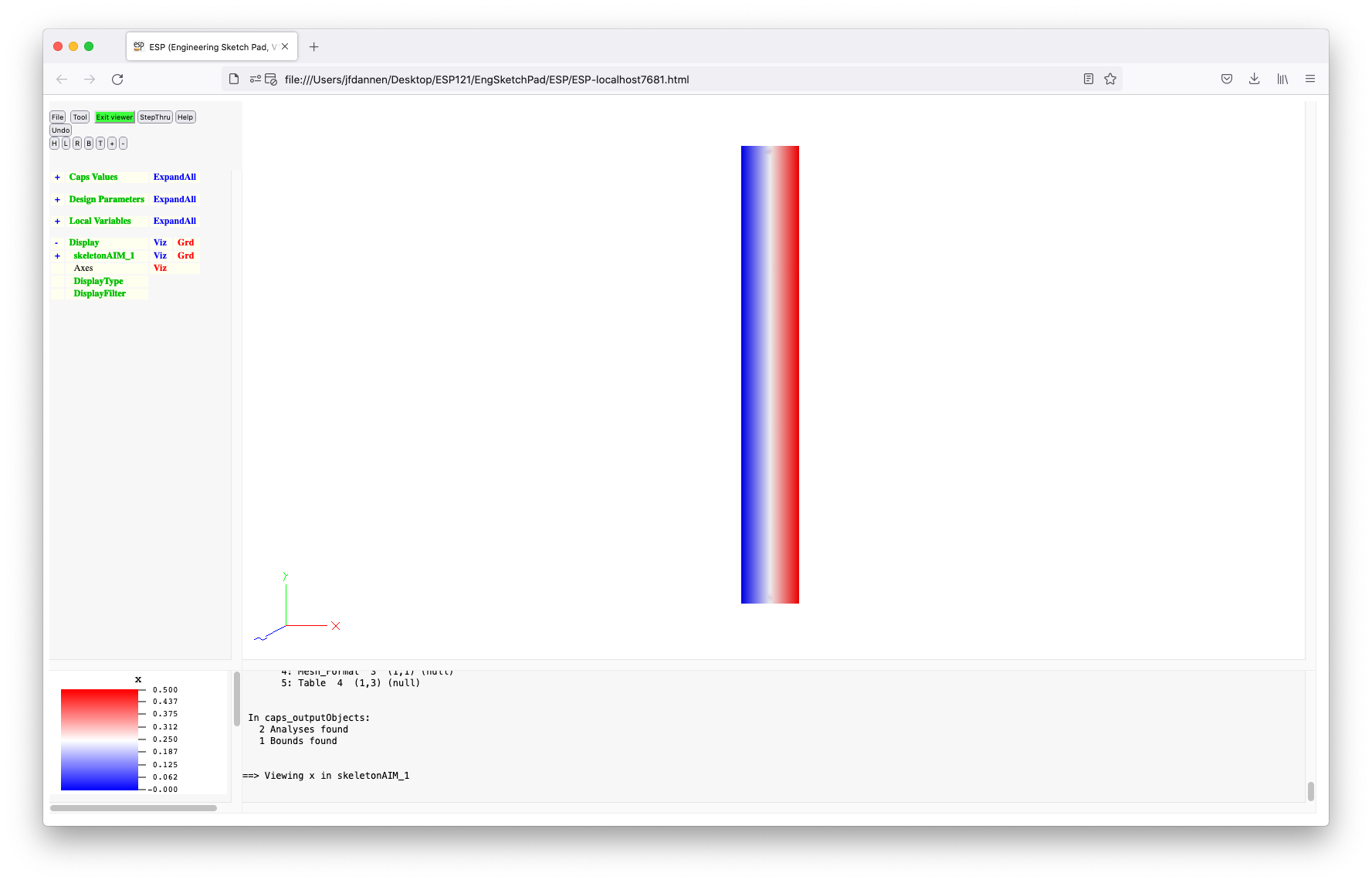

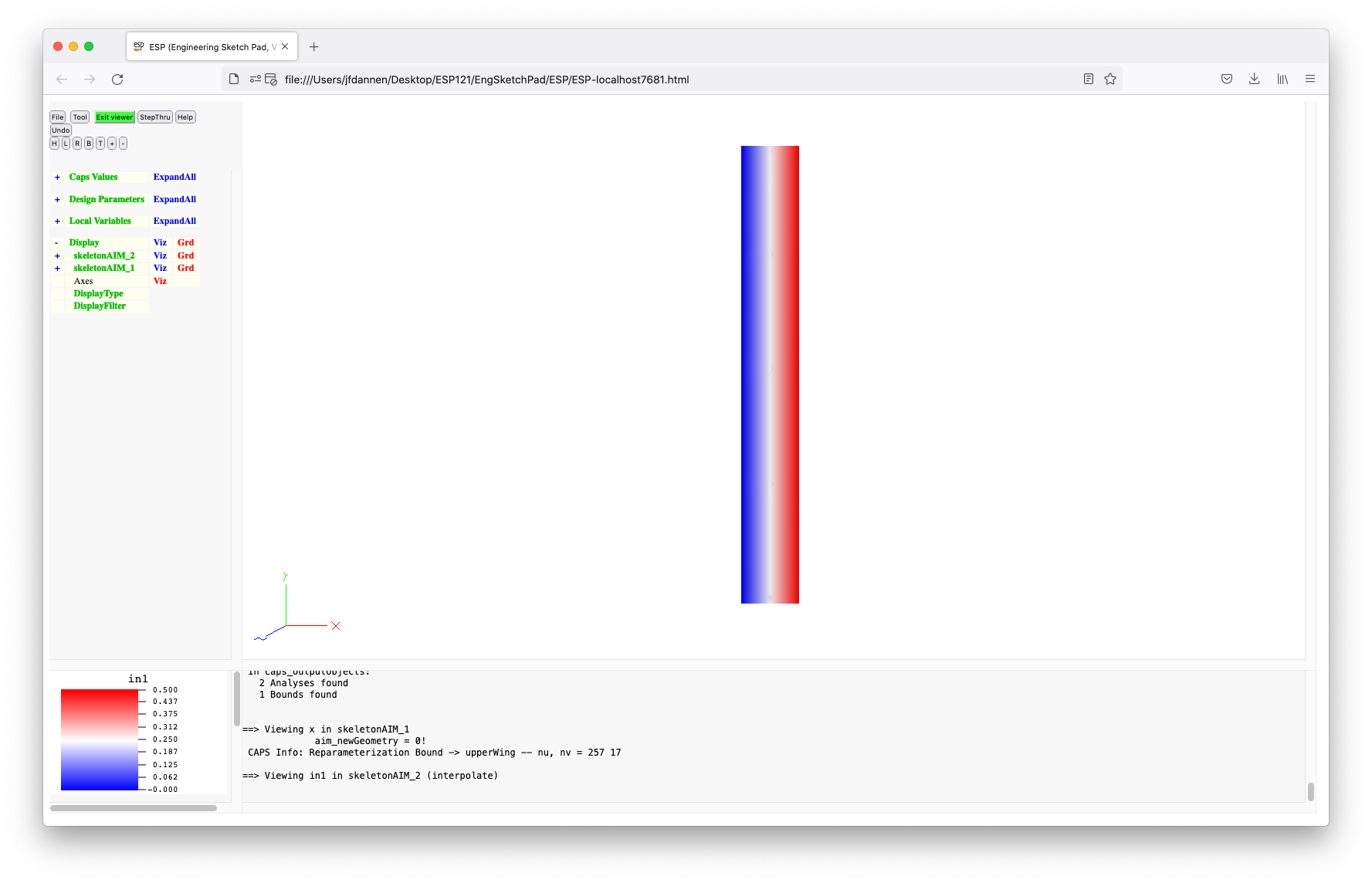

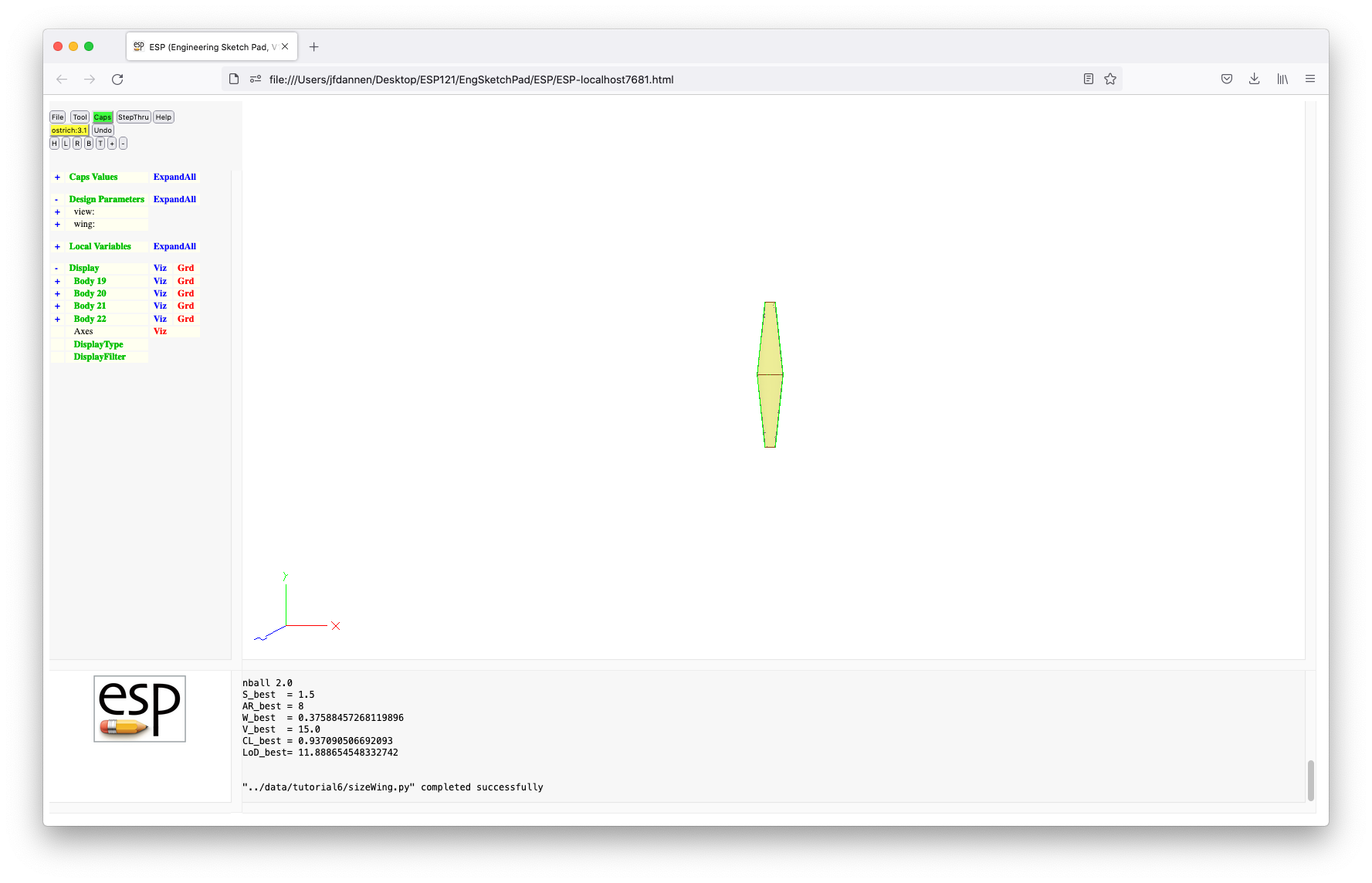

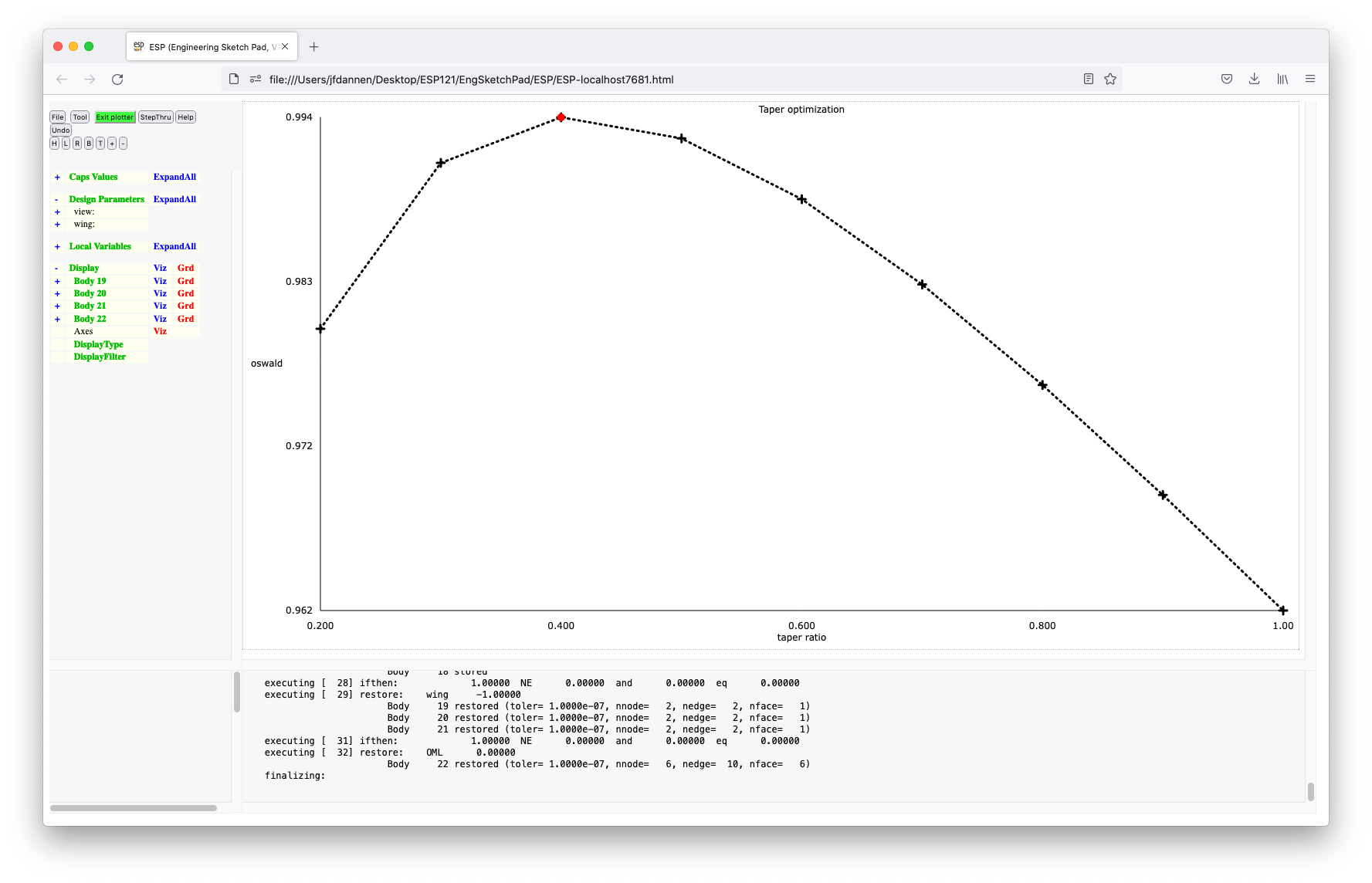

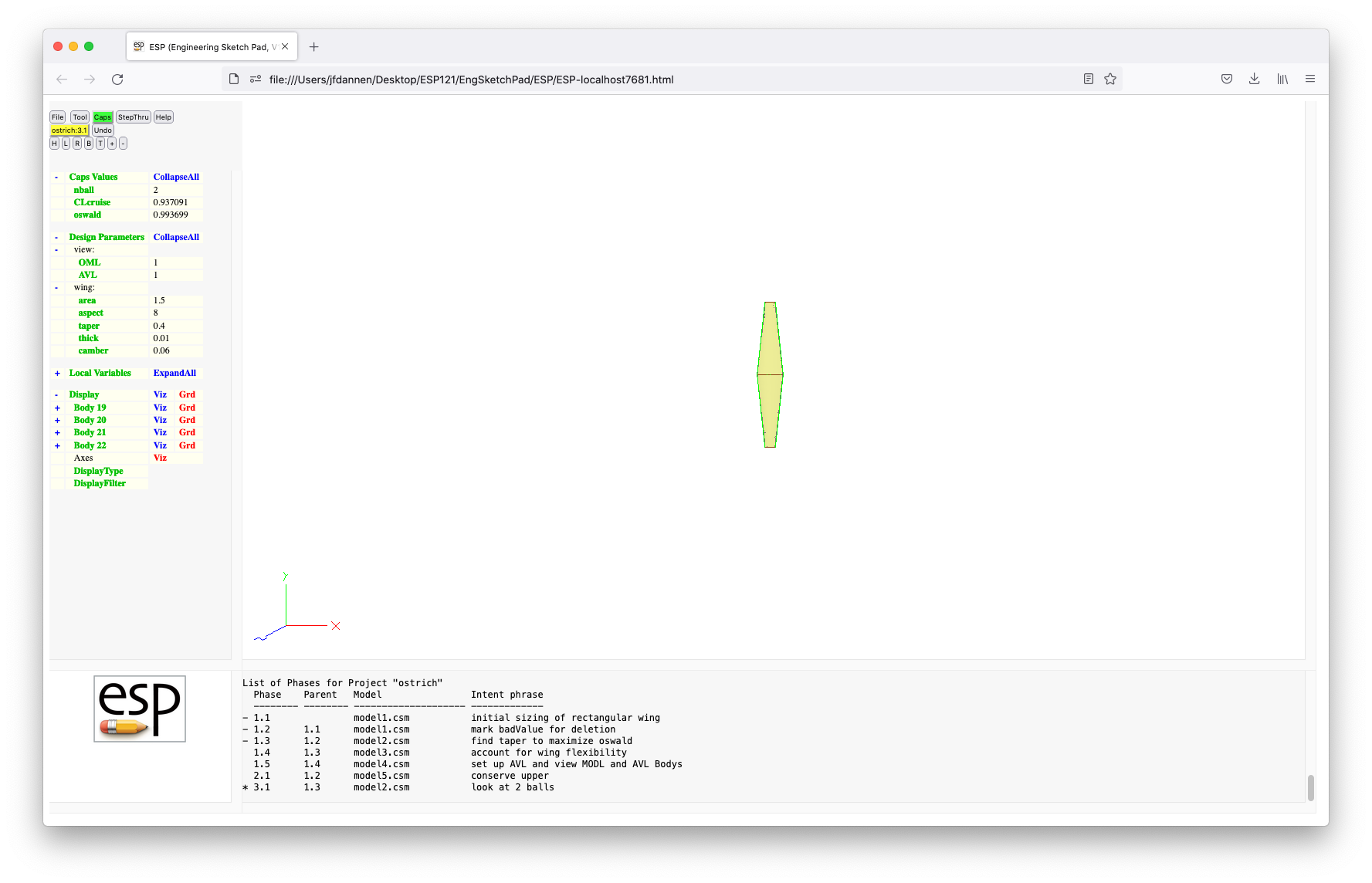

2.6 Sixth tutorial: Integrated Design Environment

2.7 First legacy tutorial: Basic usage

2.8 Second legacy tutorial: Sketcher

2.9 Third legacy tutorial: Aircraft example

5.0 Format of the .csm and .udc Files

5.5 User-defined Primitives/Functions shipped with OpenCSM

5.6 User-defined Components shipped with OpenCSM

7.0 Frequently Asked Questions

10.0 Bug Reports and Other Feedback

The Engineering Sketch Pad (ESP) is a

browser-based program for creating, editing, and generating

constructive solid models for use in the multi-disciplinary

analysis and optimization of engineered systems. It is built

using a client-server architecture.

The server consists of a back-end program

(serveESP) that performs the majority of the

computational work; the server has been designed to work on a

variety of compute platforms, including UNIX, LINUX, OSX, and

Windows. As will be described below, the user

of ESP typically starts a session by starting the

server.

The client, which is built within a web browser, provides the graphical user interface with which most users will provide inputs and receive outputs. The supported browsers include recent versions of FireFox, Google Chrome, Safari, and Edge. (Internet Explorer is not supported because of a bug within the WebSockets layer provided by the browser).

ESP is technically just the user-interface to a

system of software packages, including:

WebViewer is a package for generating complex

three-dimensional representations of geometry within a web

Browser. It consists of software that is incorporated

into the server as well as a series of JavaScript

functions that operate in the web Browser via

WebGL.OpenCSM is a feature-based, associative,

parametric solid modeler that supports manifold solids

(the typical output) and non-manifold sheets and wires

(such as may be needed for representing wake sheets and

antennae). The inputs to OpenCSM is an

ASCII, human-readable .csm file, in which

the model is described by a series of design Parameters

and a Feature Tree (or build prescription). The Feature

Tree consists of a user-specified series of standard

primitives, Boolean operators, and transformations.

OpenCSM also includes the ability for users

to define their own user-defined primitives (via compiled

code) and user-defined components (via scripts). The

persistence of Attributes, even through regenerations,

directly supports the use of OpenCSM within

multi-fidelity and multi-disciplinary analysis and

design. OpenCSM also provides the ability for

a user to compute the geometric sensitivity of a

configuration with respect to (any combination of) the

design Parameters, often without regeneration; these

sensitivities can then be used by a grid-generator so that

the sensitivity of the grid with respect to the design

Parameters can be computed.EGADS, the Electronic Geometry Aircraft

Design System, is an open-source geometry interface

to OpenCASCADE, in which the functionality

in OpenCASCADE that is needed for

construction of typical applications is incorporated into

about 70 C-functions. These functions support a "bottom

up" approach to configuration construction, in which the

boundary representation (BRep) is built up from nodes, to

curves, to edges, to loops, to surfaces, to faces, to

shells, to bodies. EGADS also supports a

"top-down" approach, which directly maps

to OpenCSM's Feature

Tree. EGADS provides persistent user-defined

Attributes on all topological entities.OpenCASCADE is a large, openly-available

geometry engine on which the rest of the system is

built. OpenCASCADE is the only part of

the ESP system that needs to be acquired from

an outside source. See the README.txt file

associated with the ESP distribution for

details.All the parts of the ESP system are distributed as

source code that is licensed via the LGPL 2.1 license. See

the Copyright section below for details.

In most cases, a user will start with a configuration that is

described in a .csm file and then modify it and/or

build it via OpenCSM's various commands.

For a convenient Quick Reference,

see $ESP_ROOT/doc/ESP_QuickReference.pdf, which is

a two-page summary of the various .csm commands,

built-in functions, dot-suffixes, and the ESP

character set.

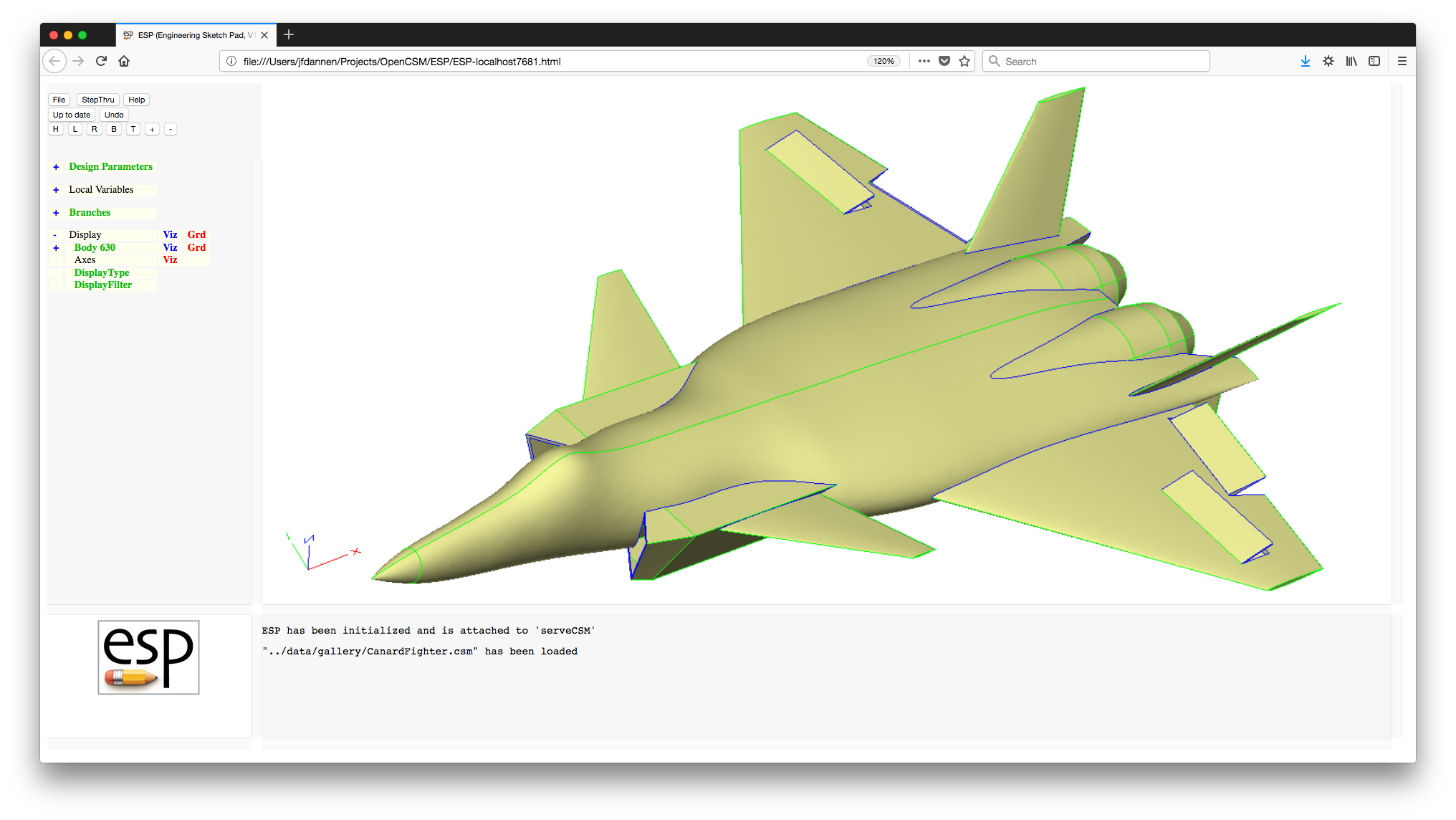

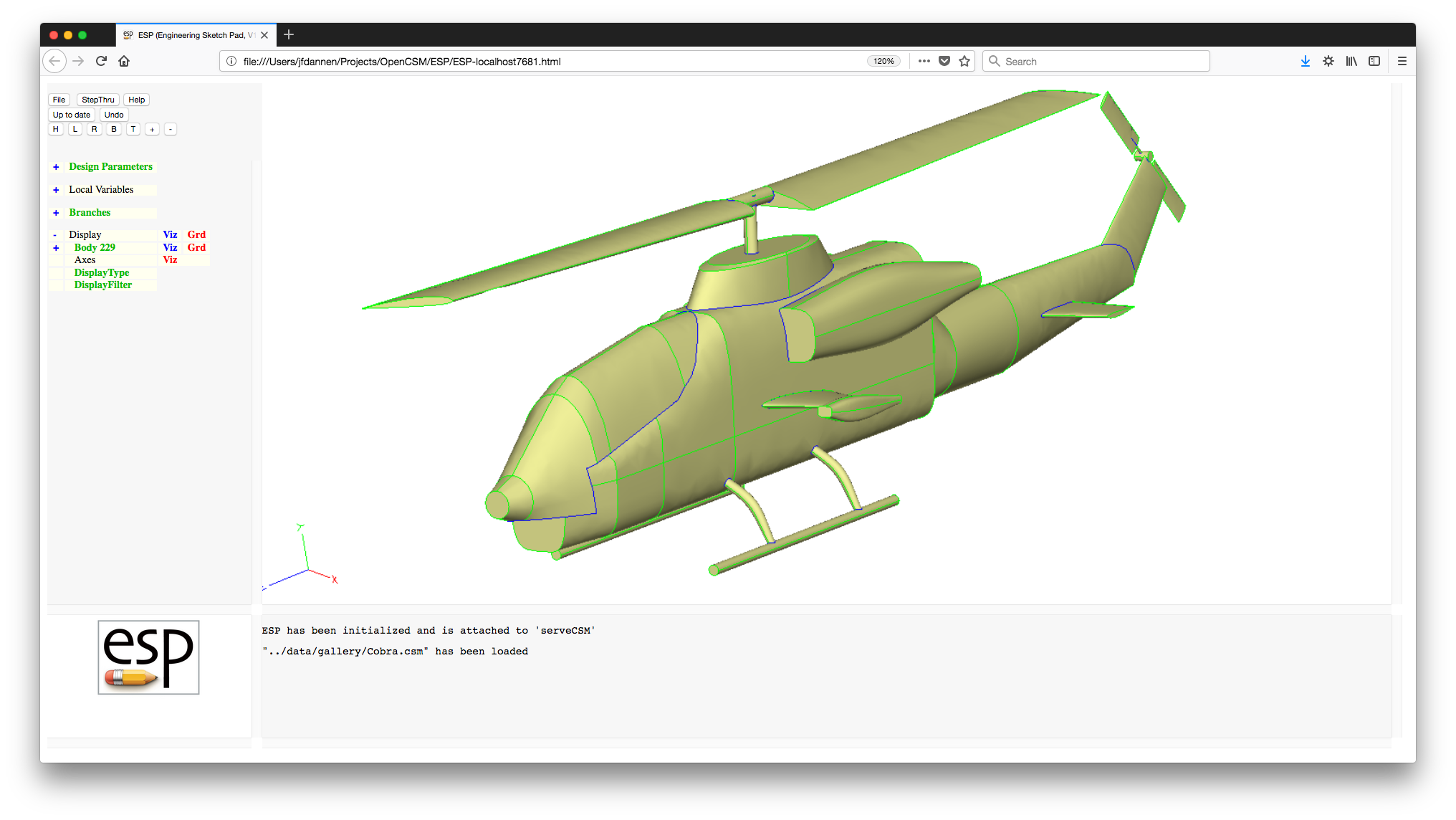

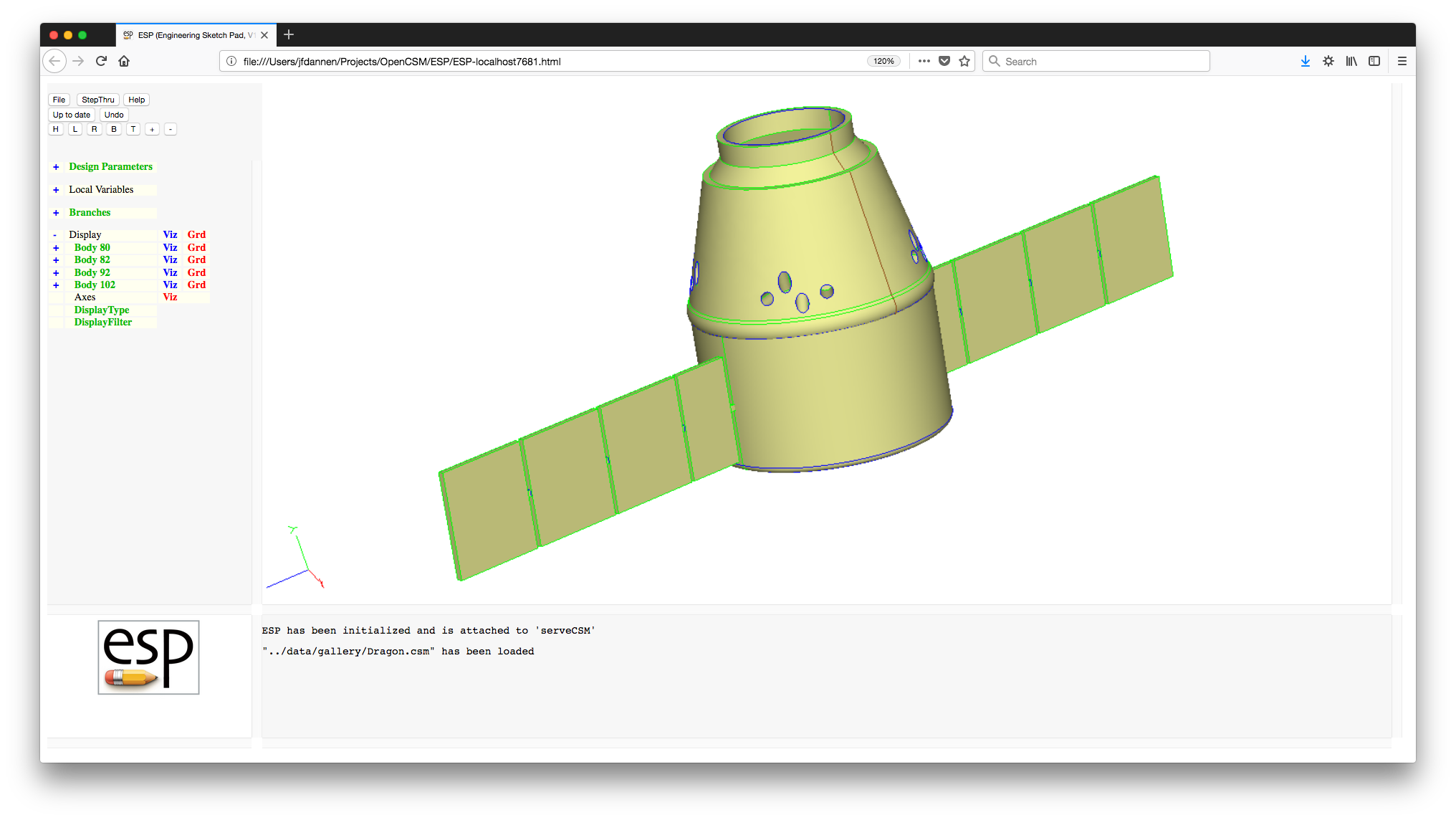

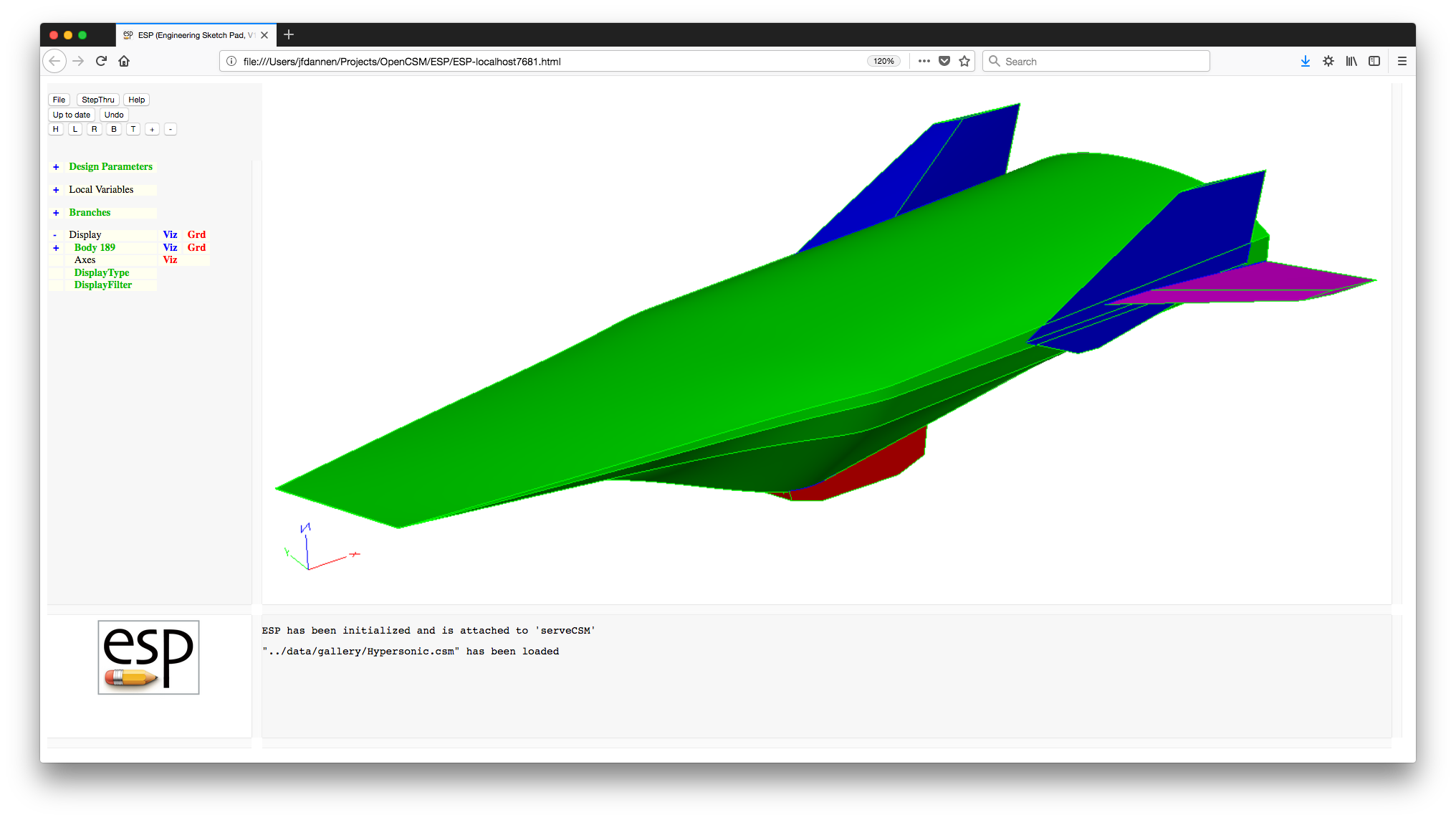

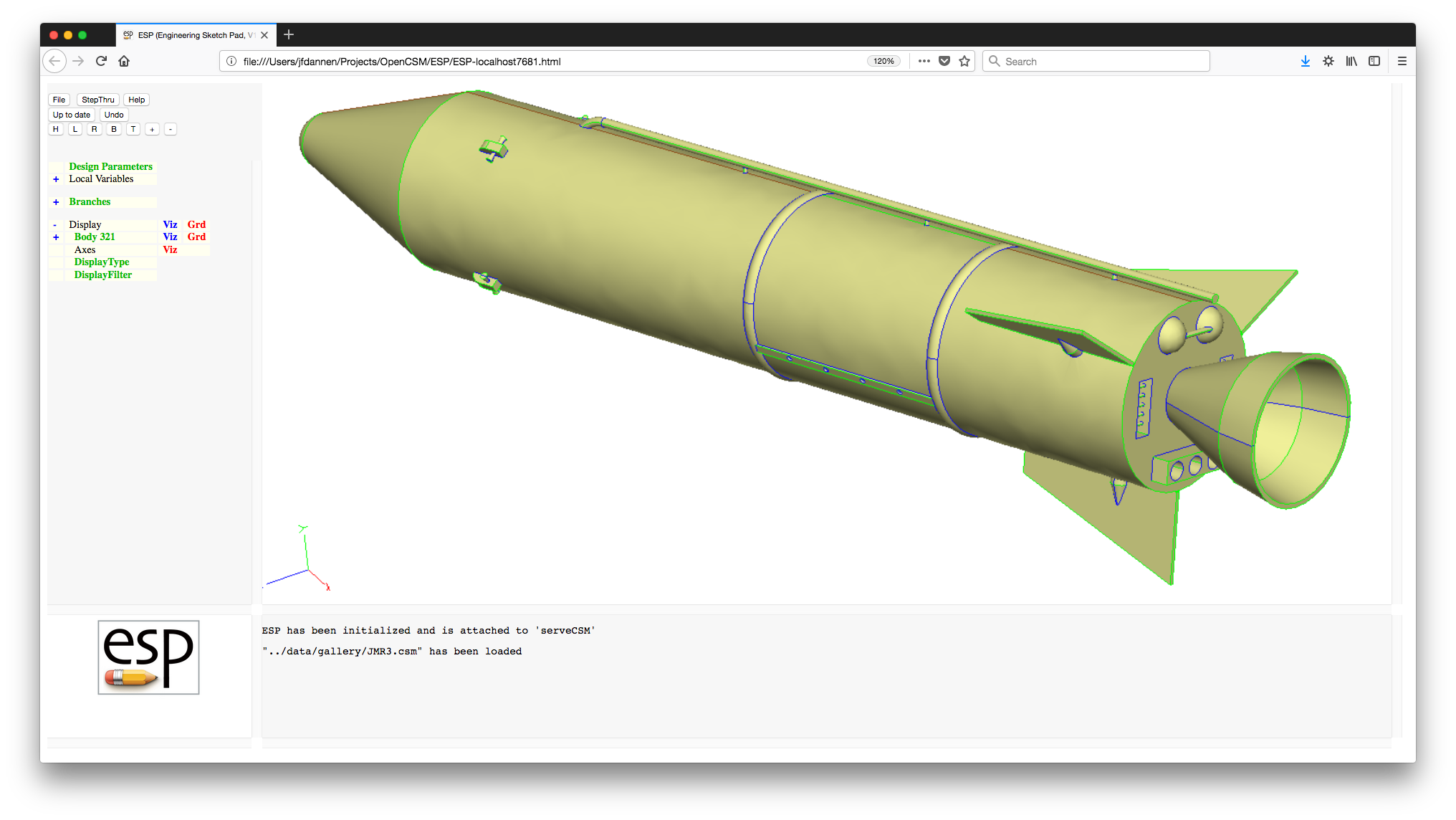

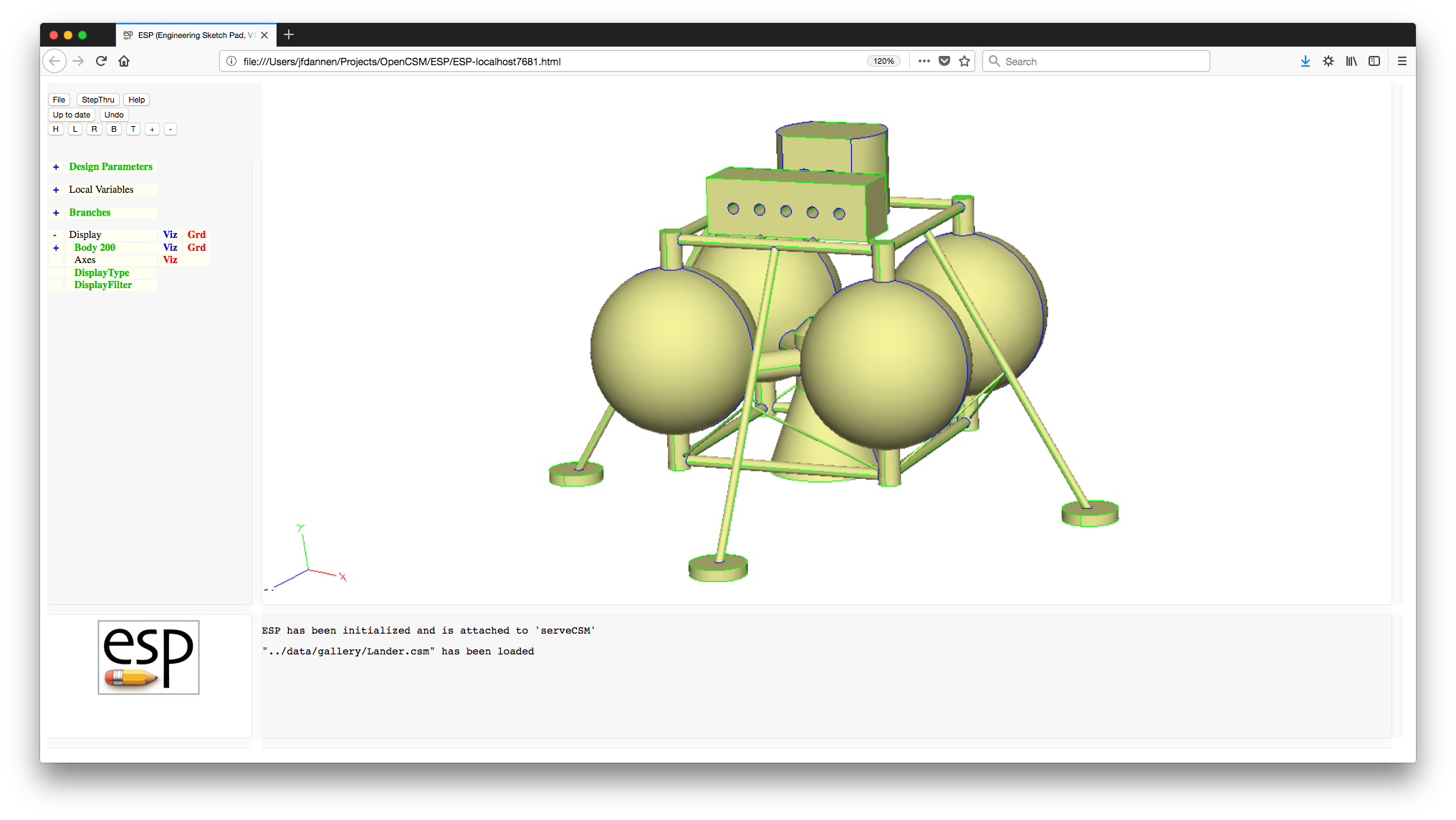

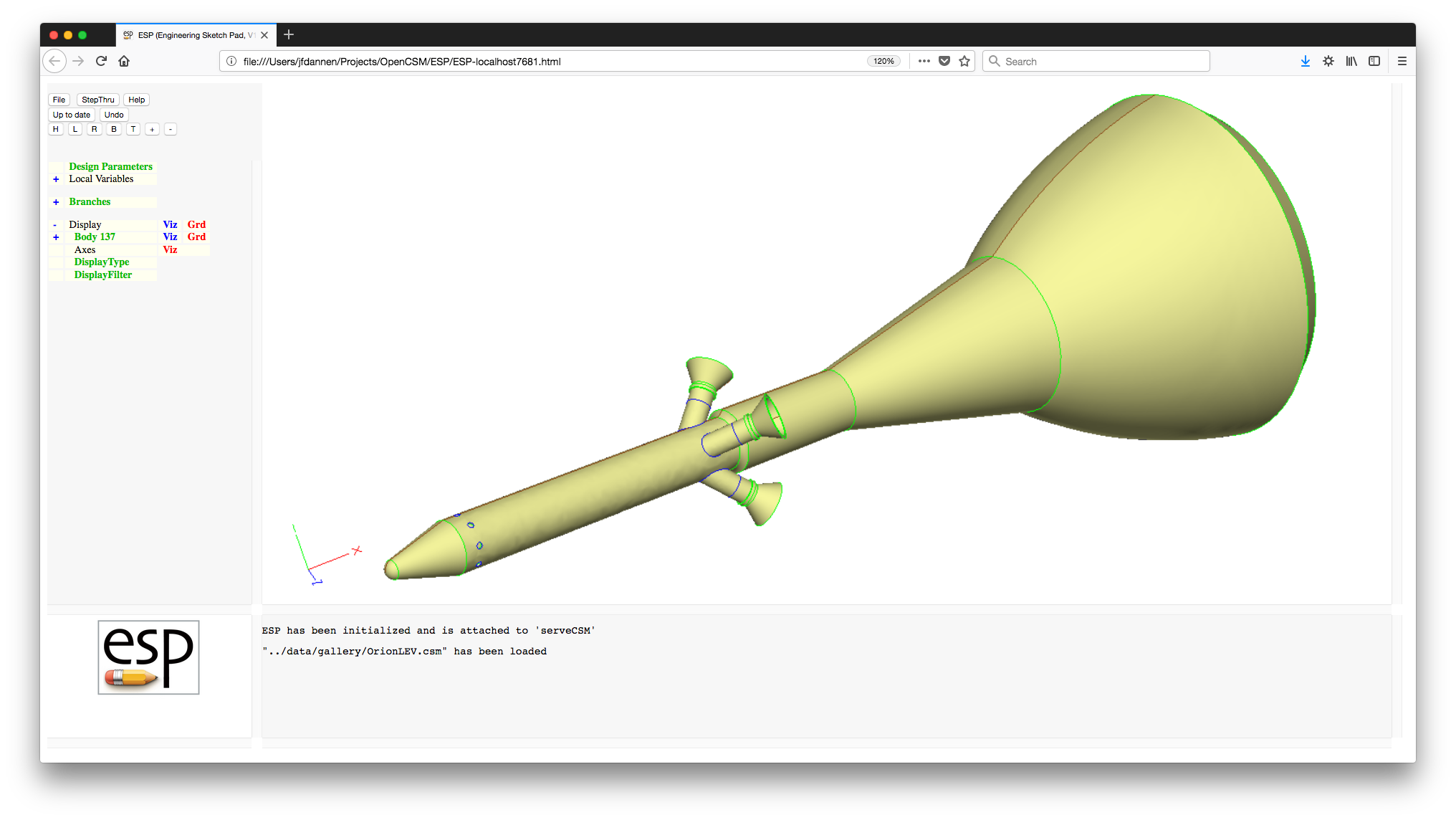

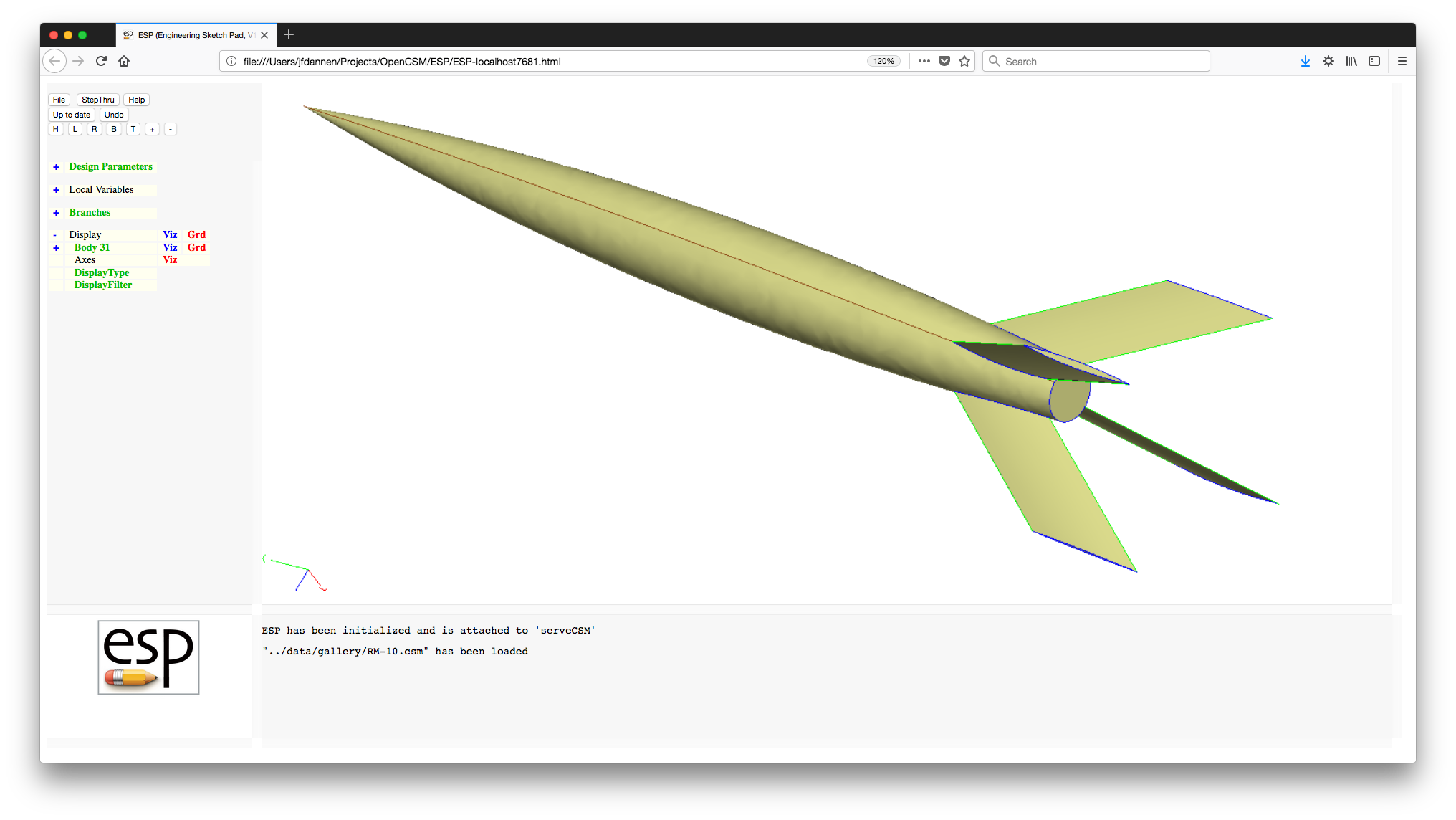

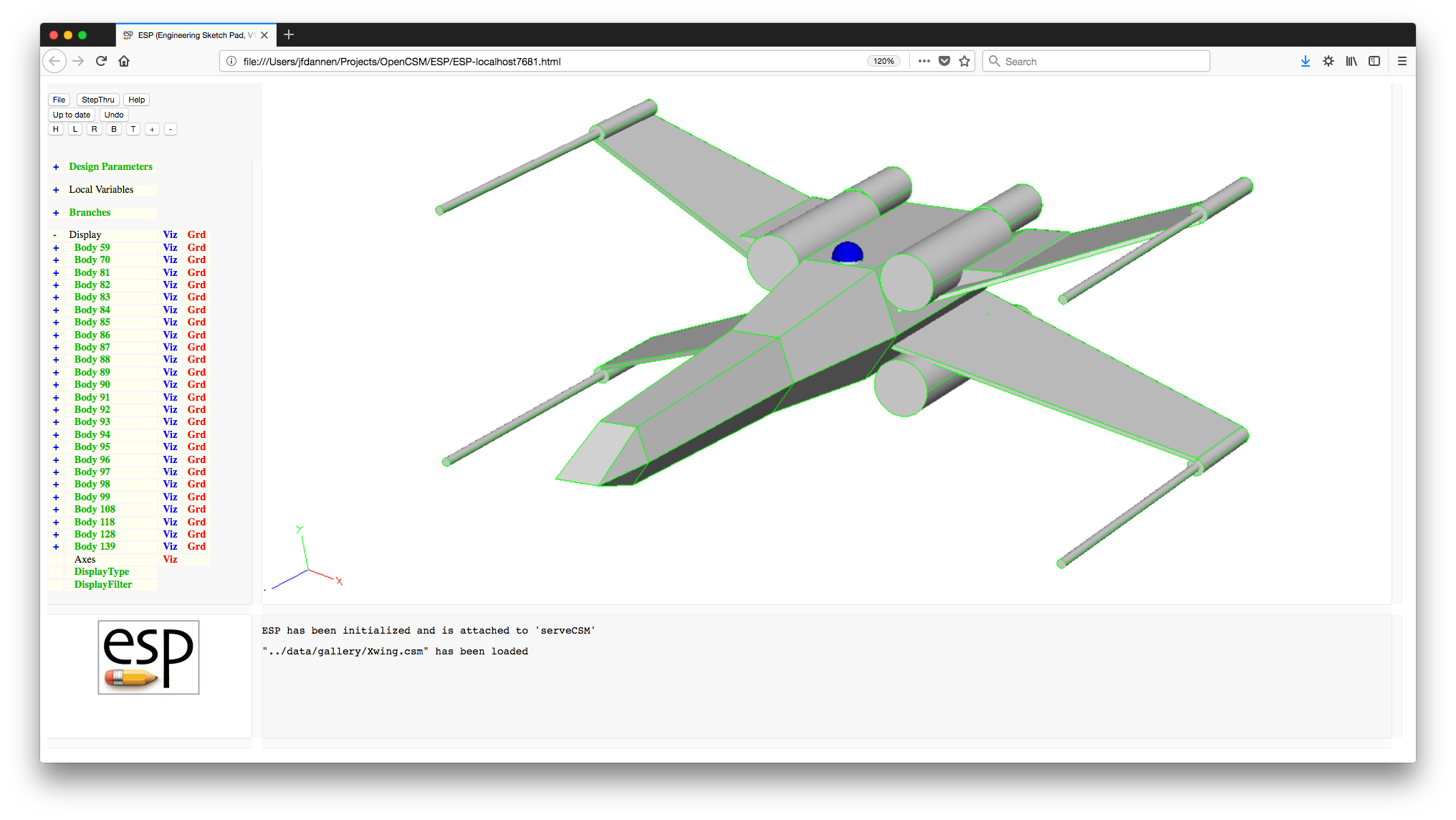

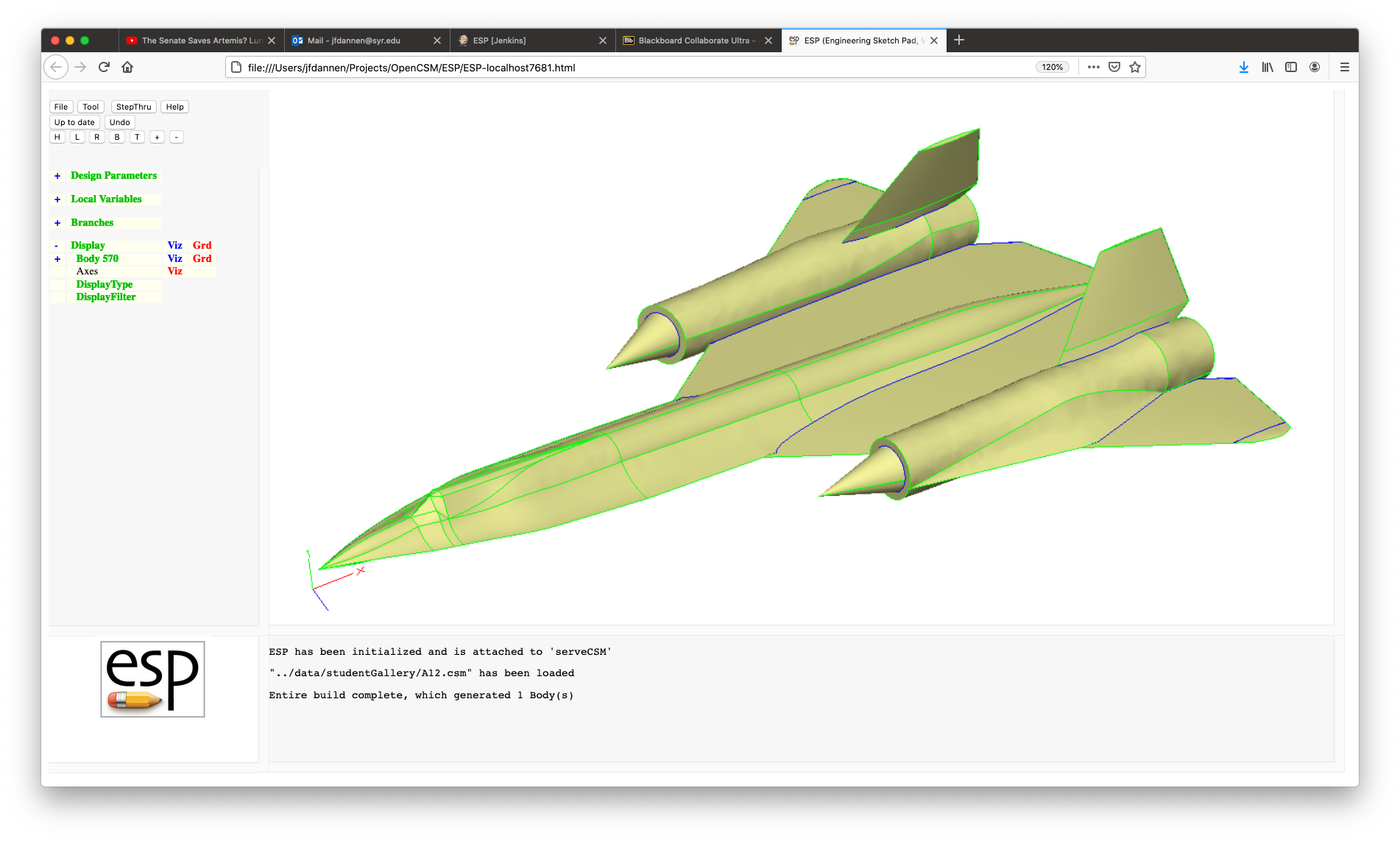

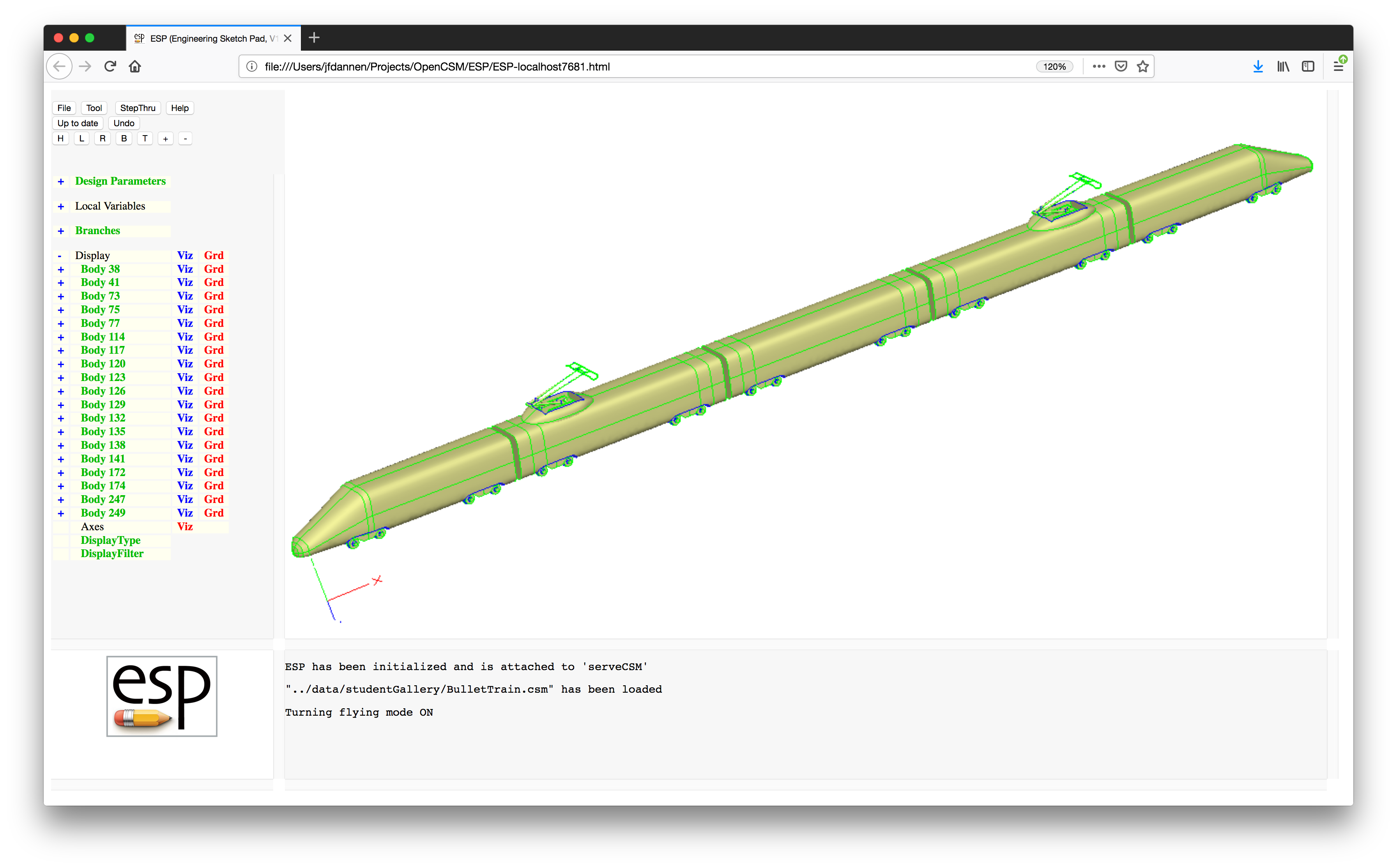

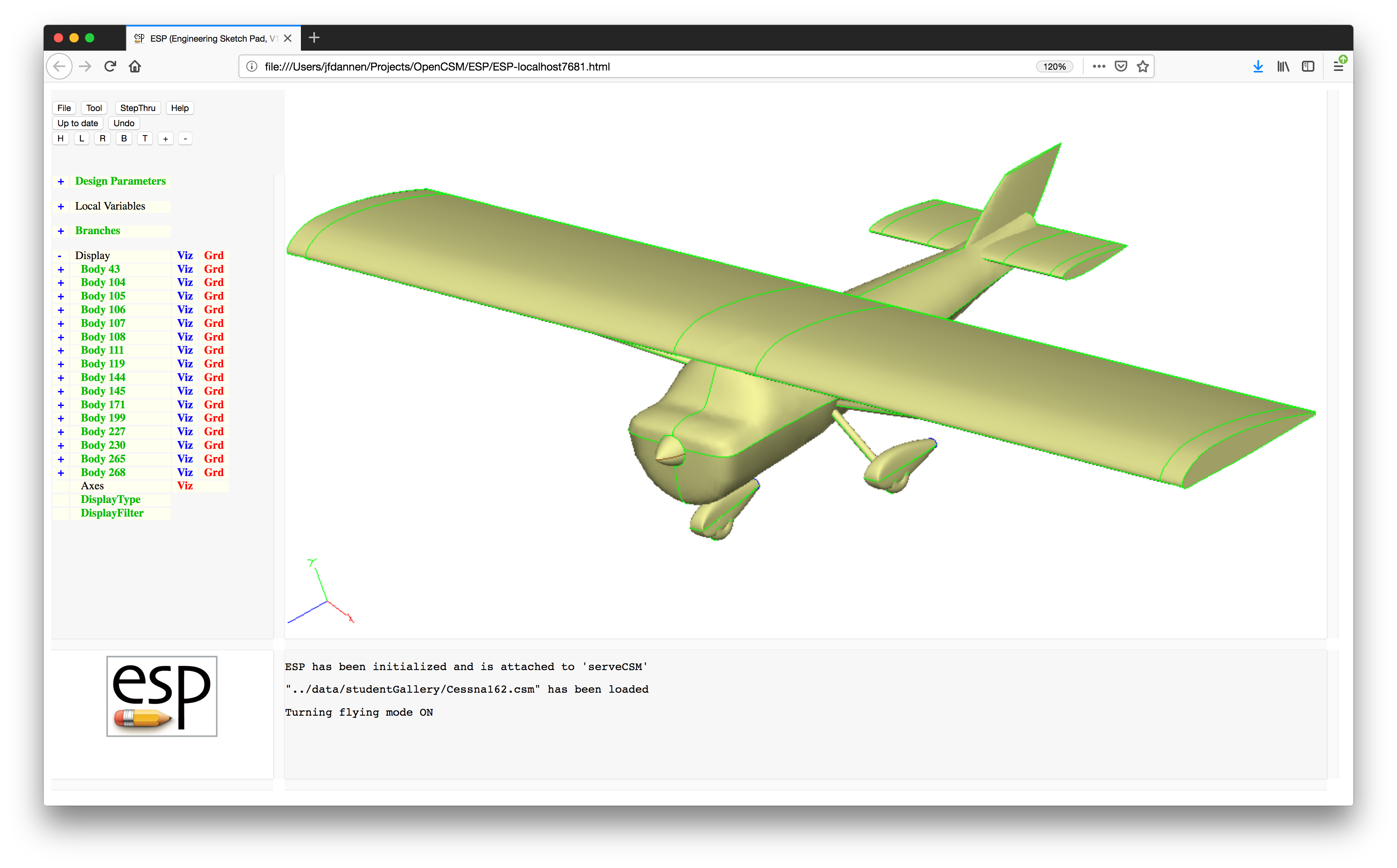

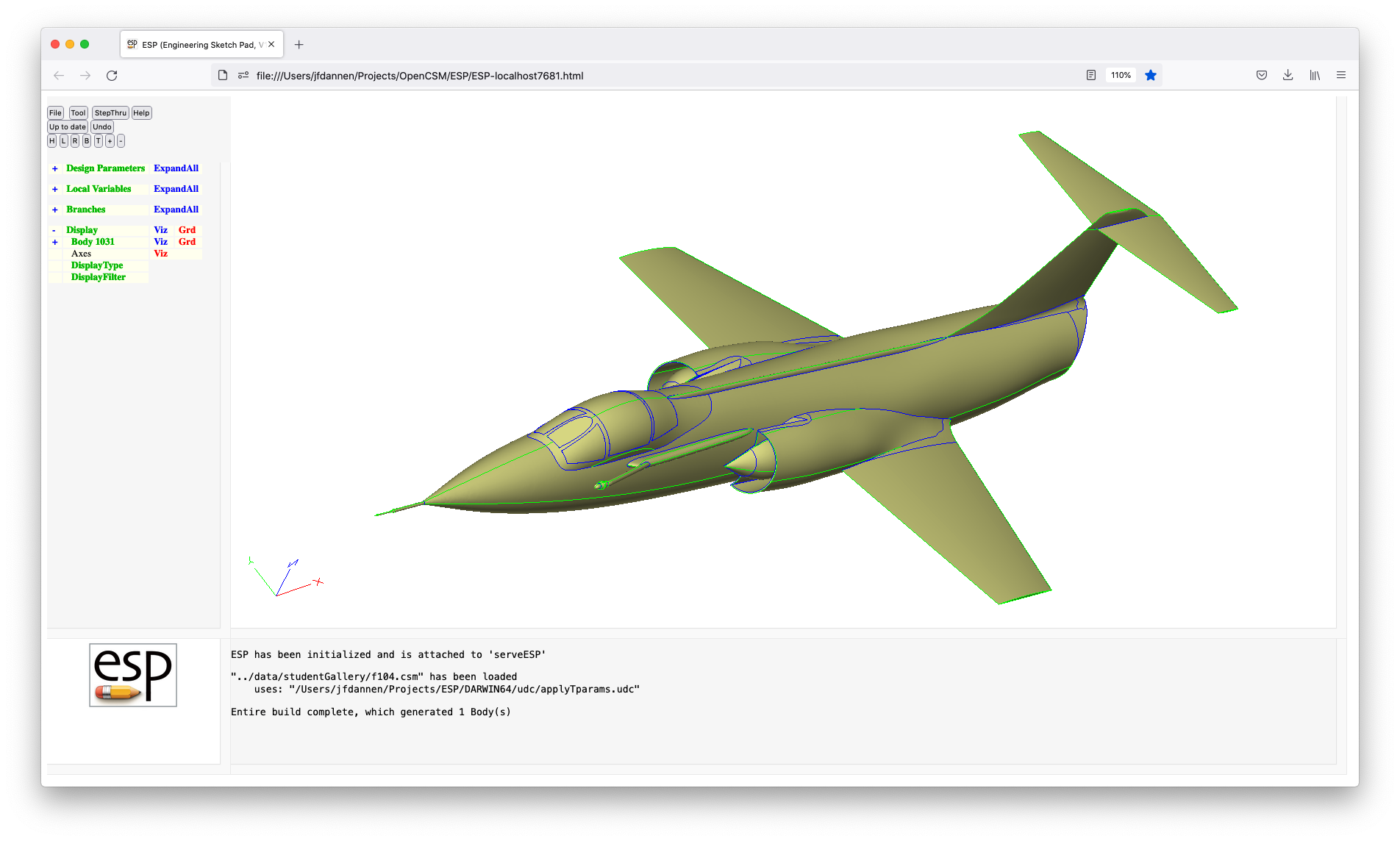

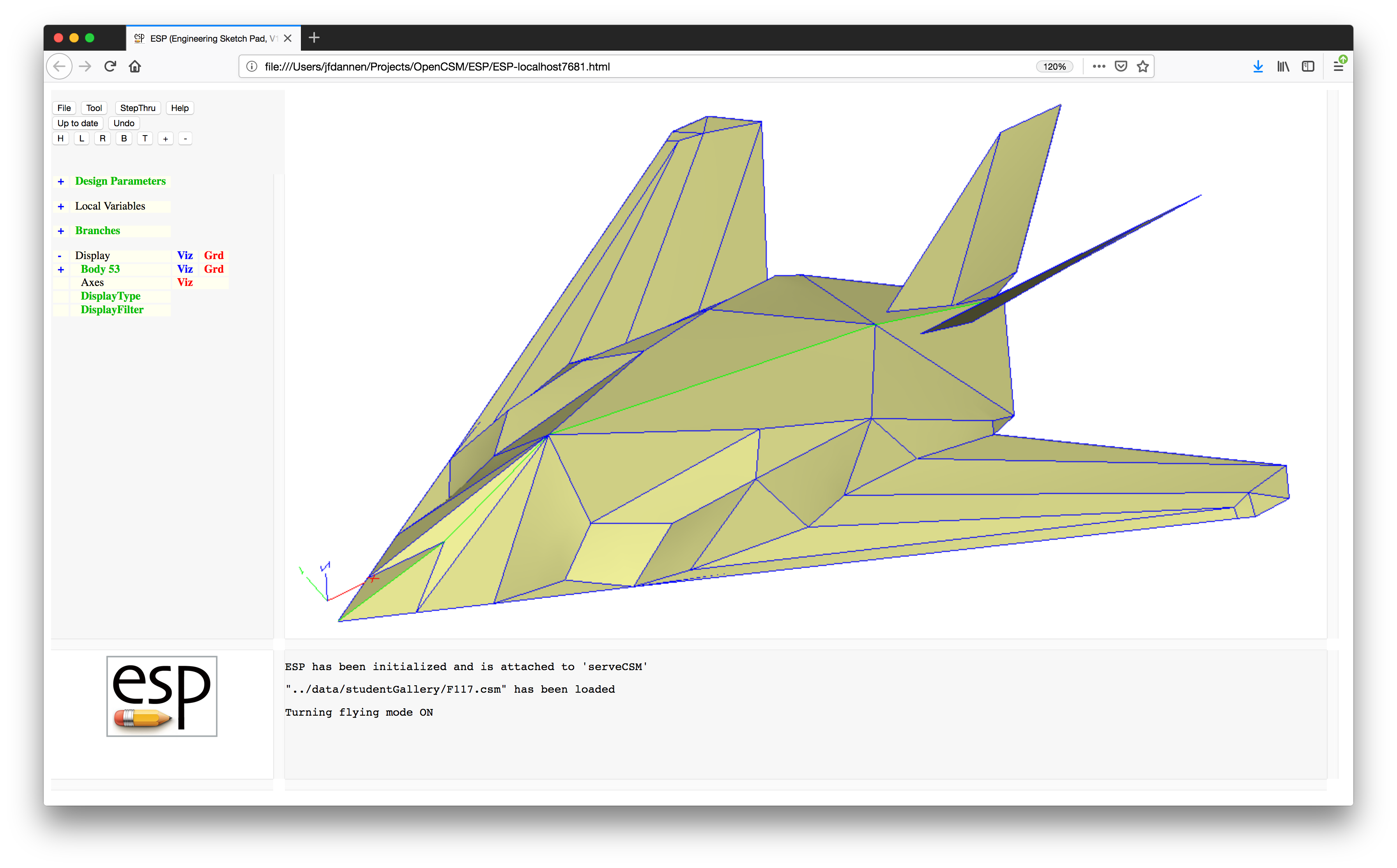

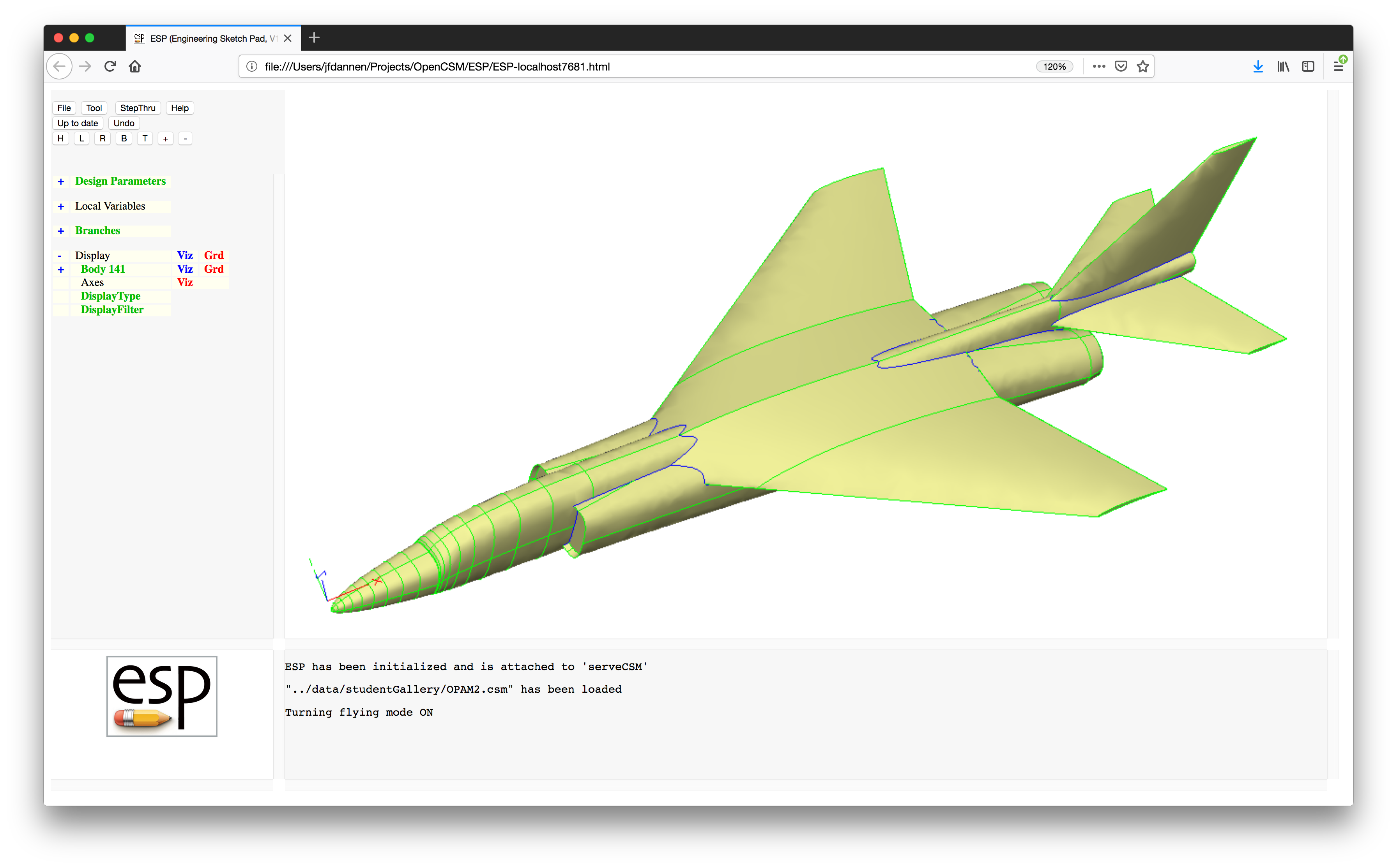

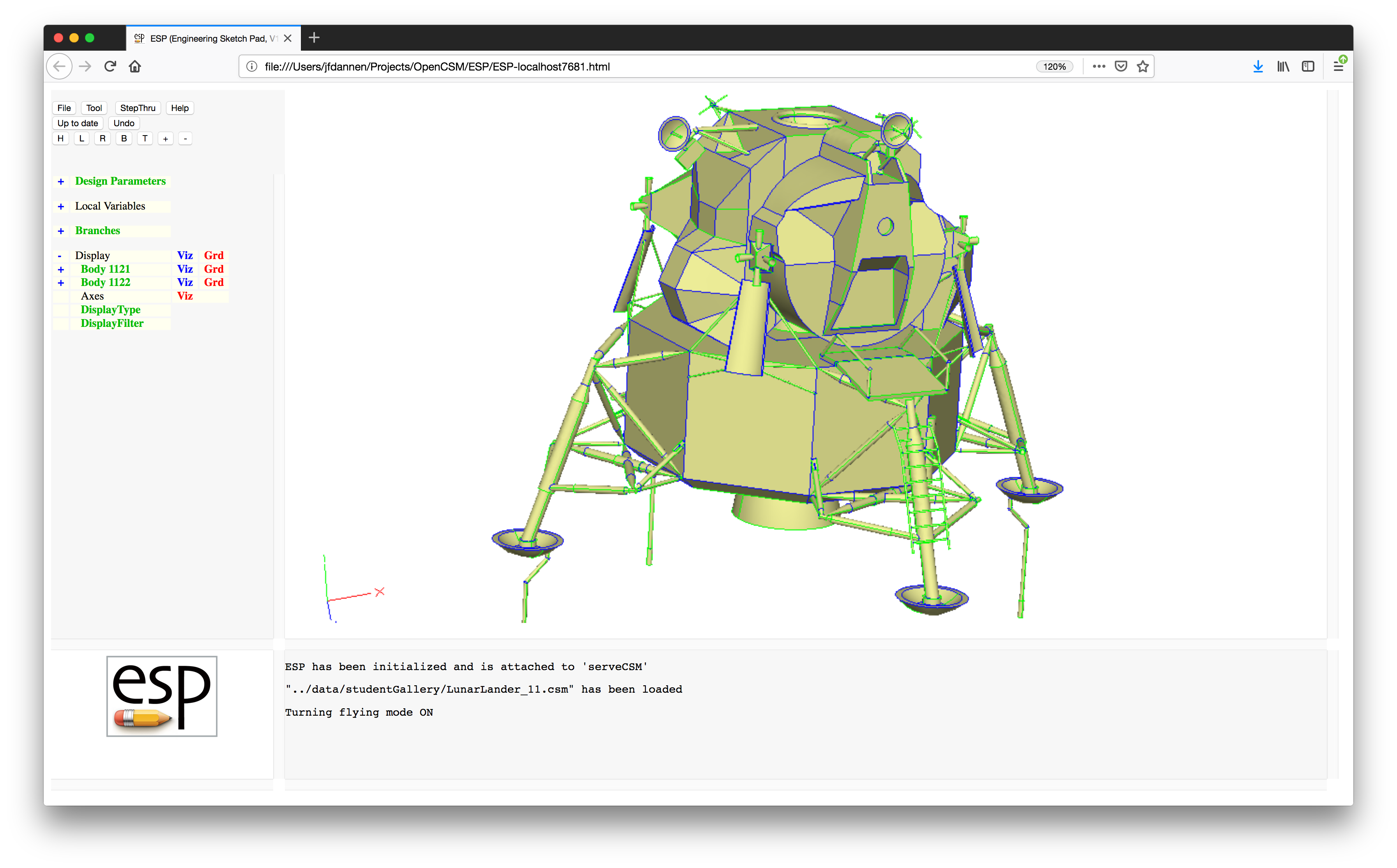

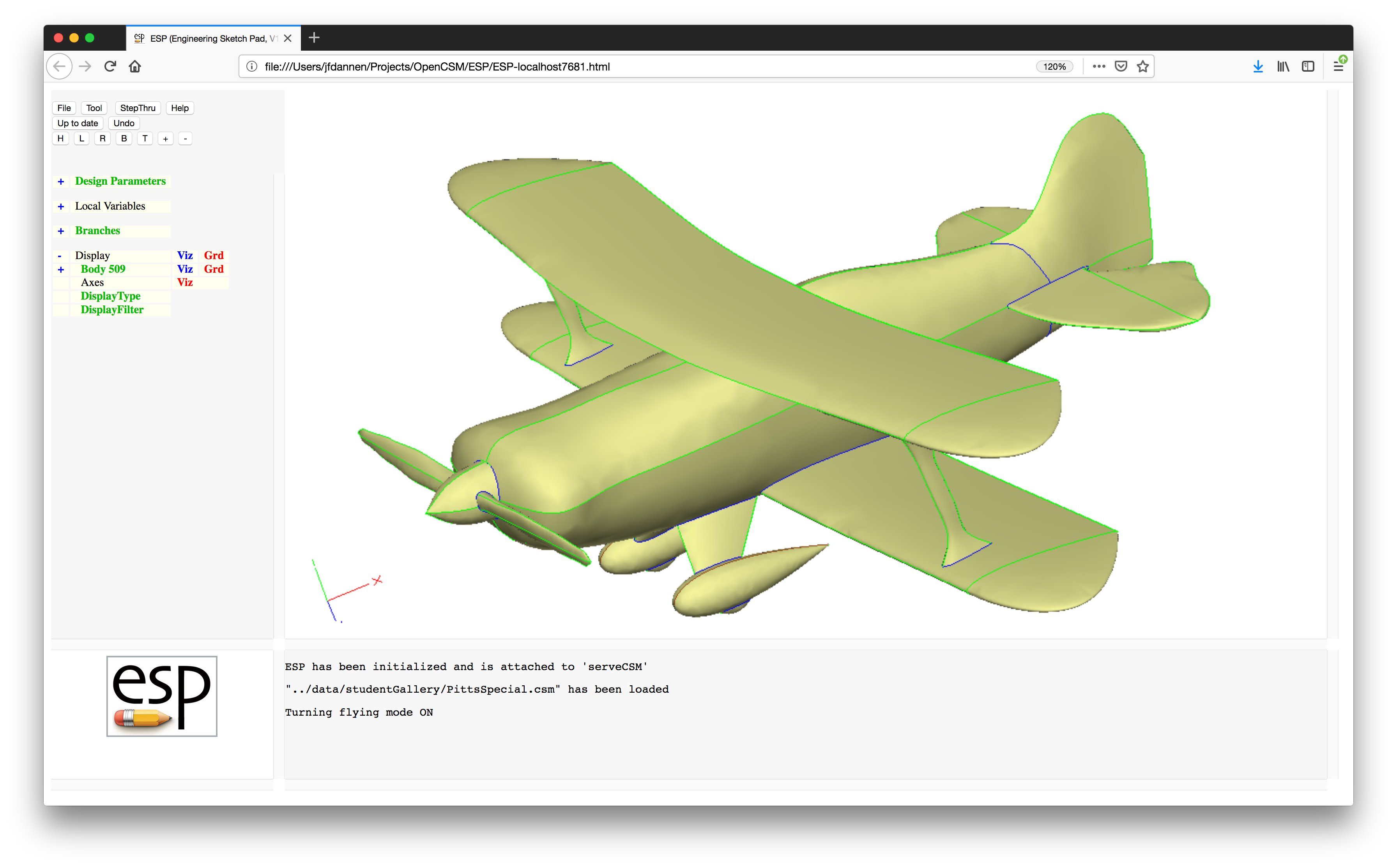

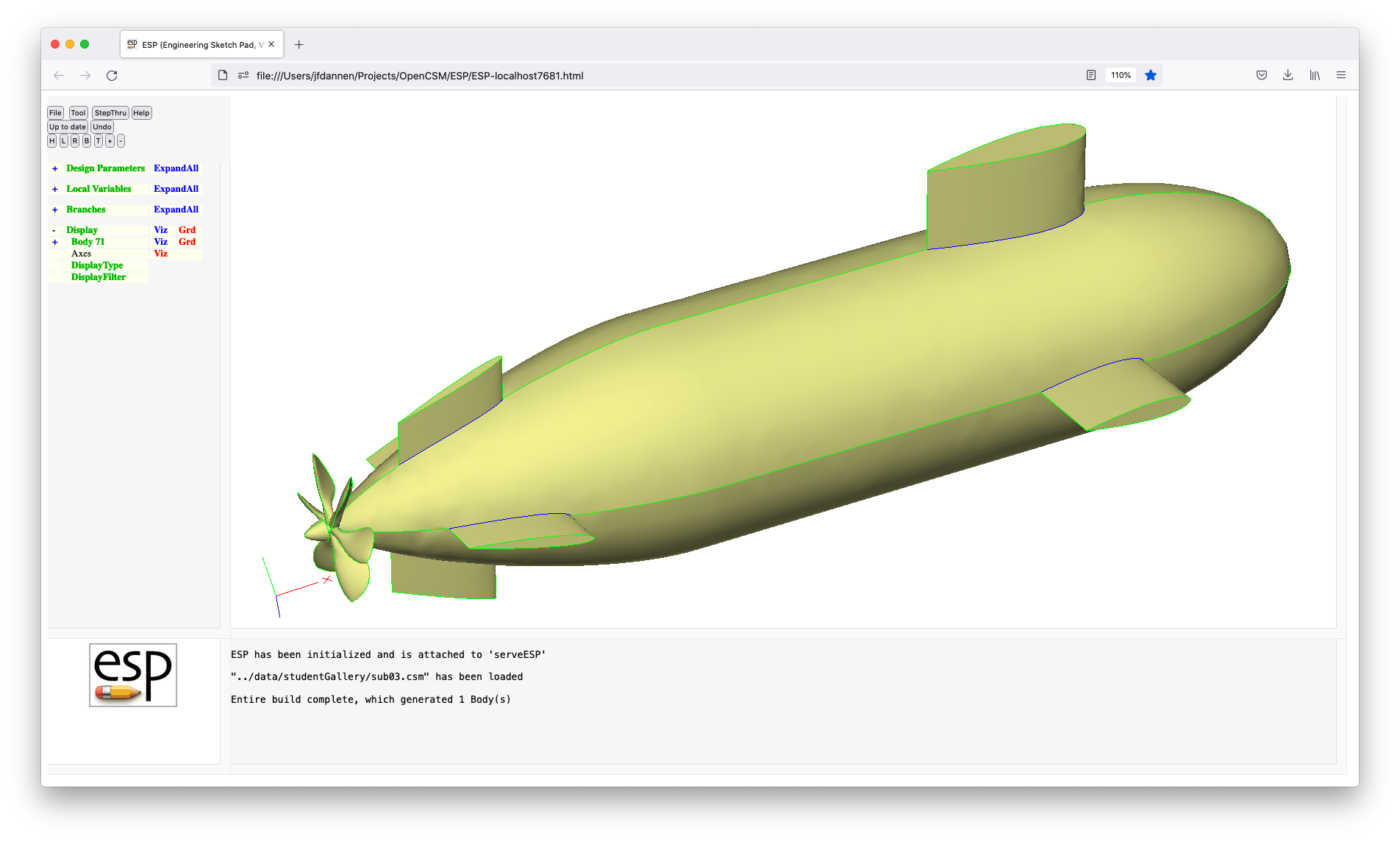

ESP ships with a assortment of

.csm files, as shown below. Feel free to open them

in your favorite text editor to see how they were constructed.

In addition, several students have created models of a variety

of configurations. The .csm files for these cases

are not included in the distribution since they have not been

cleaned up; nevertheless, the models are very impressive.

Back to Table of Contents

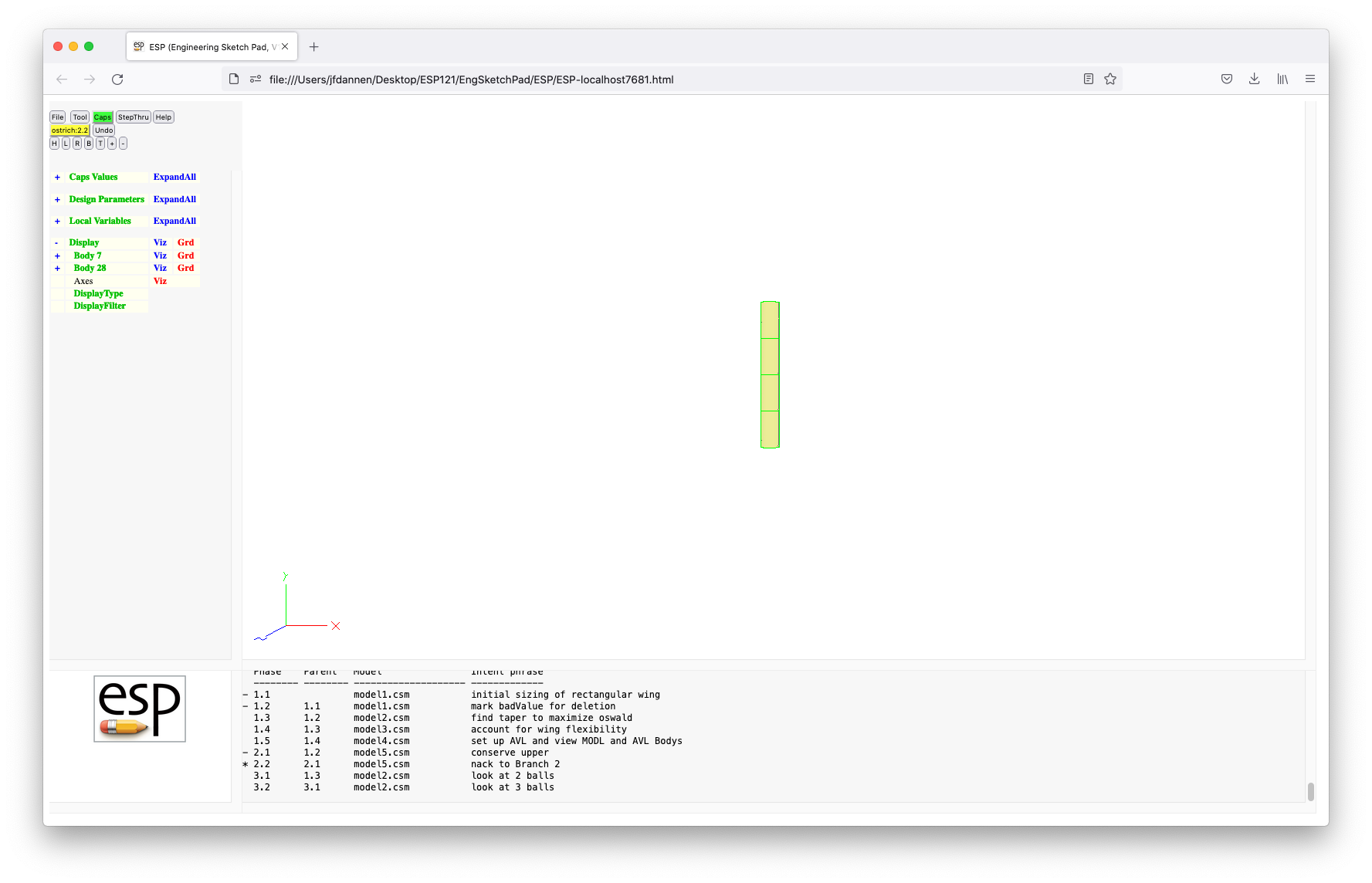

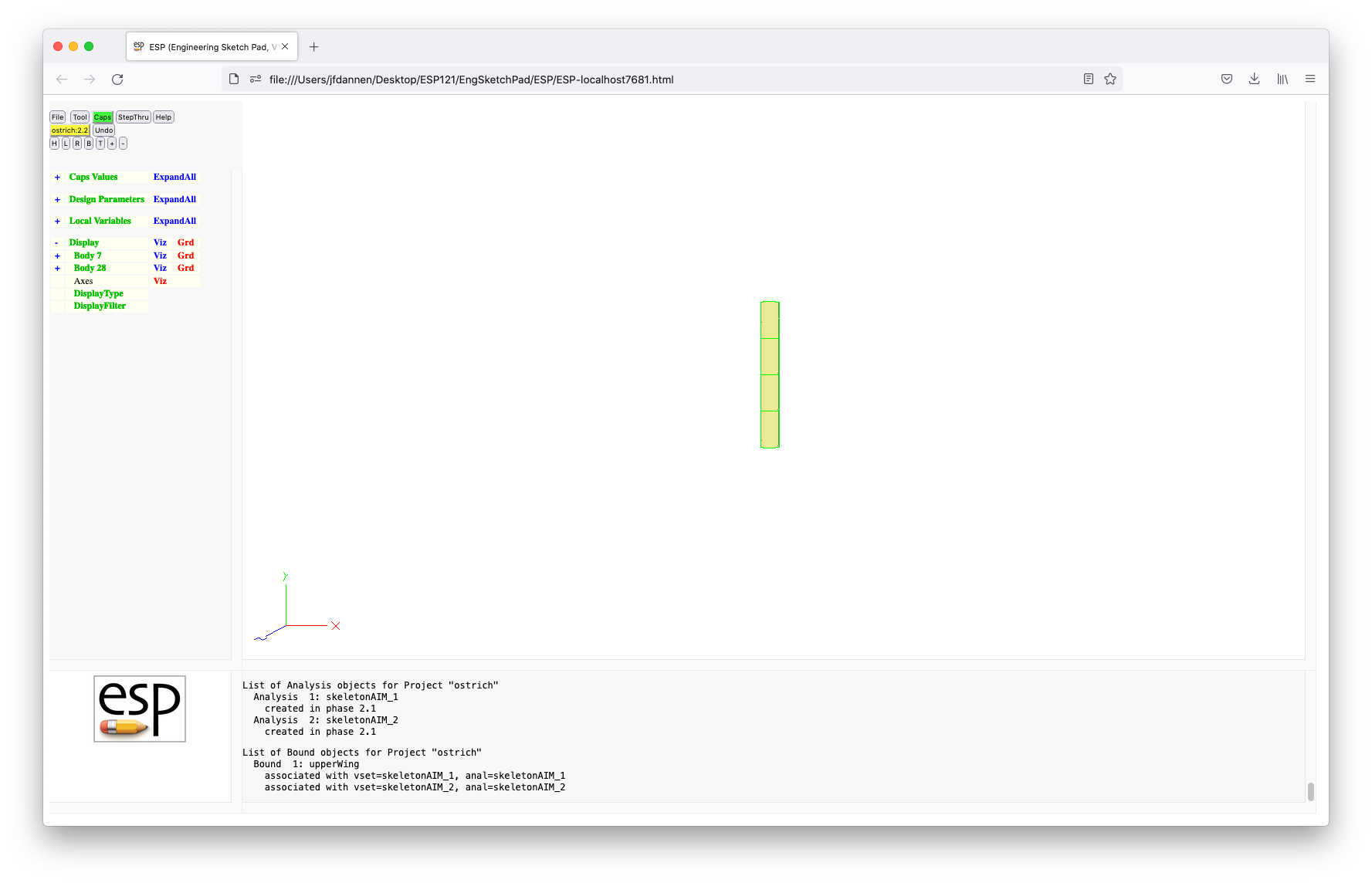

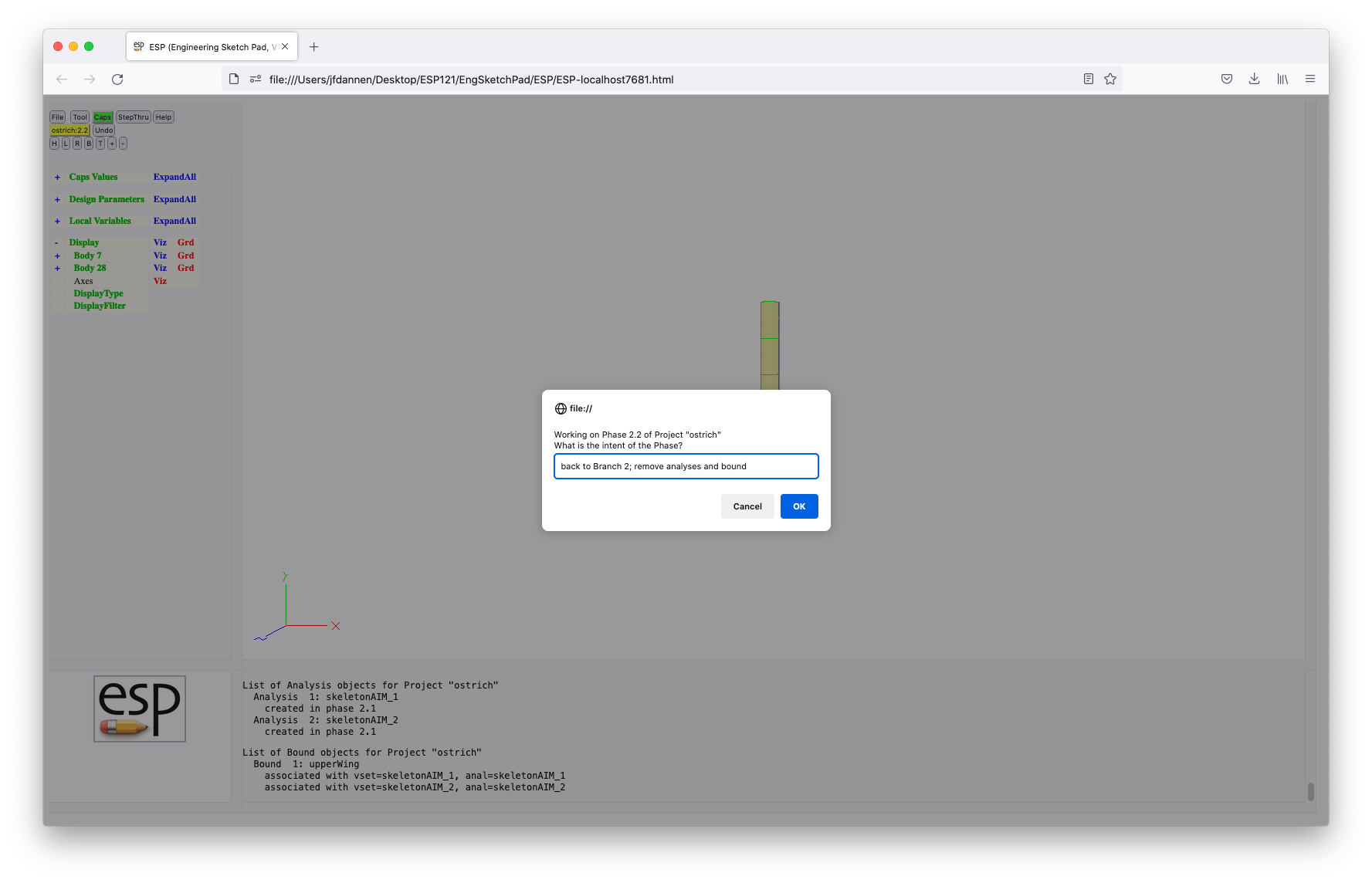

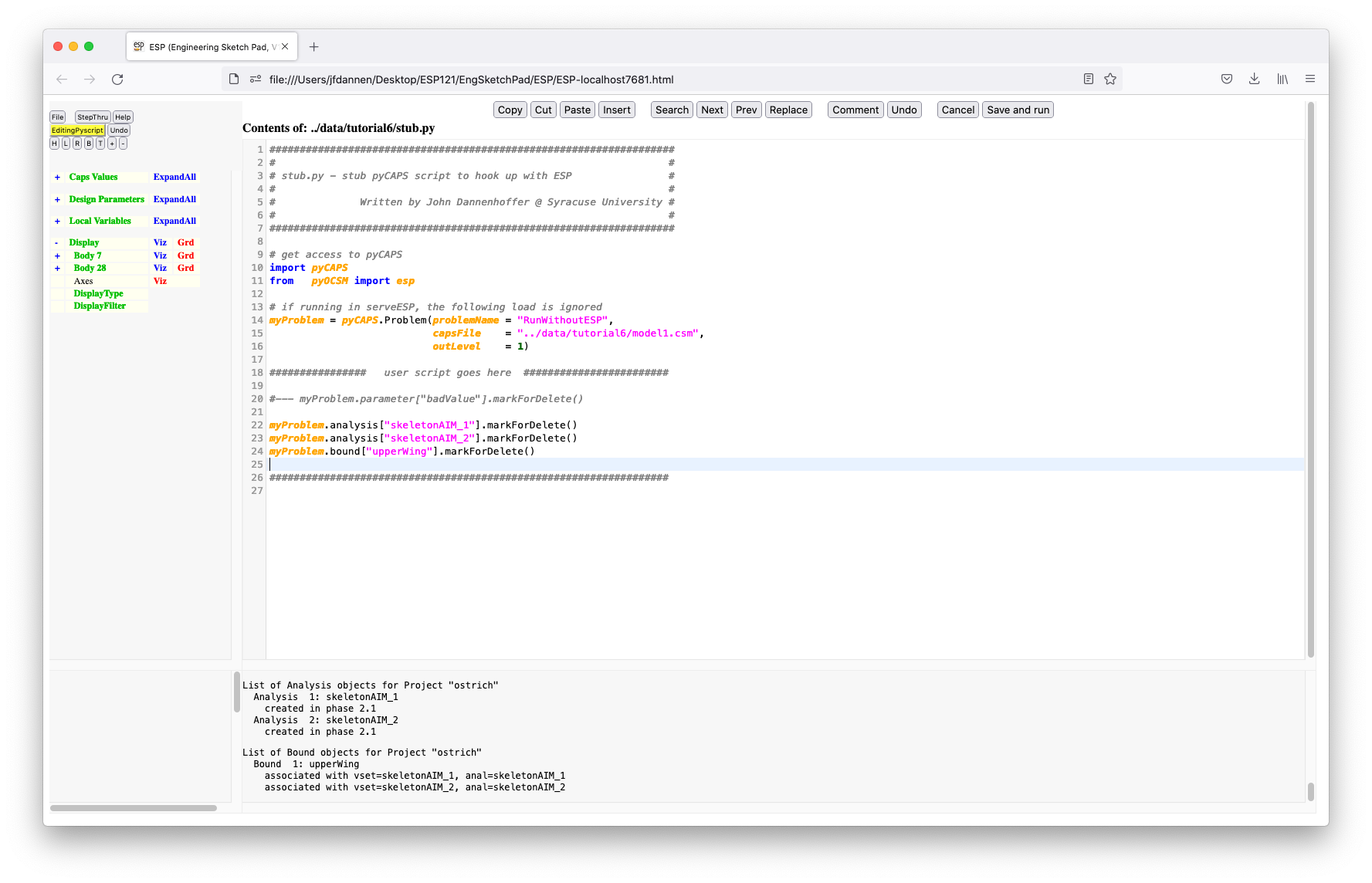

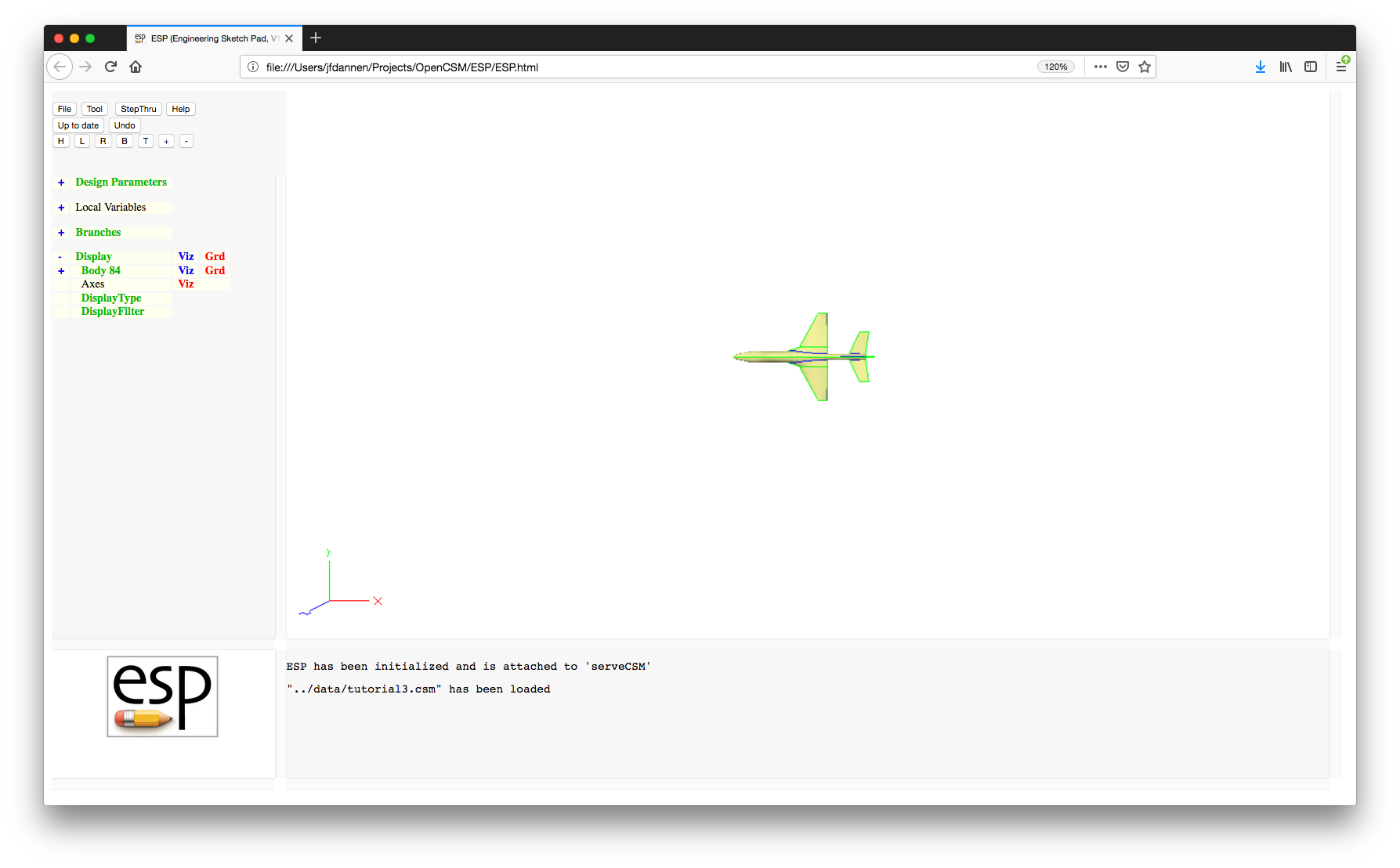

There are six (new) Tutorials that will help you get

acquainted with the Engineering Sketch Pad (ESP).

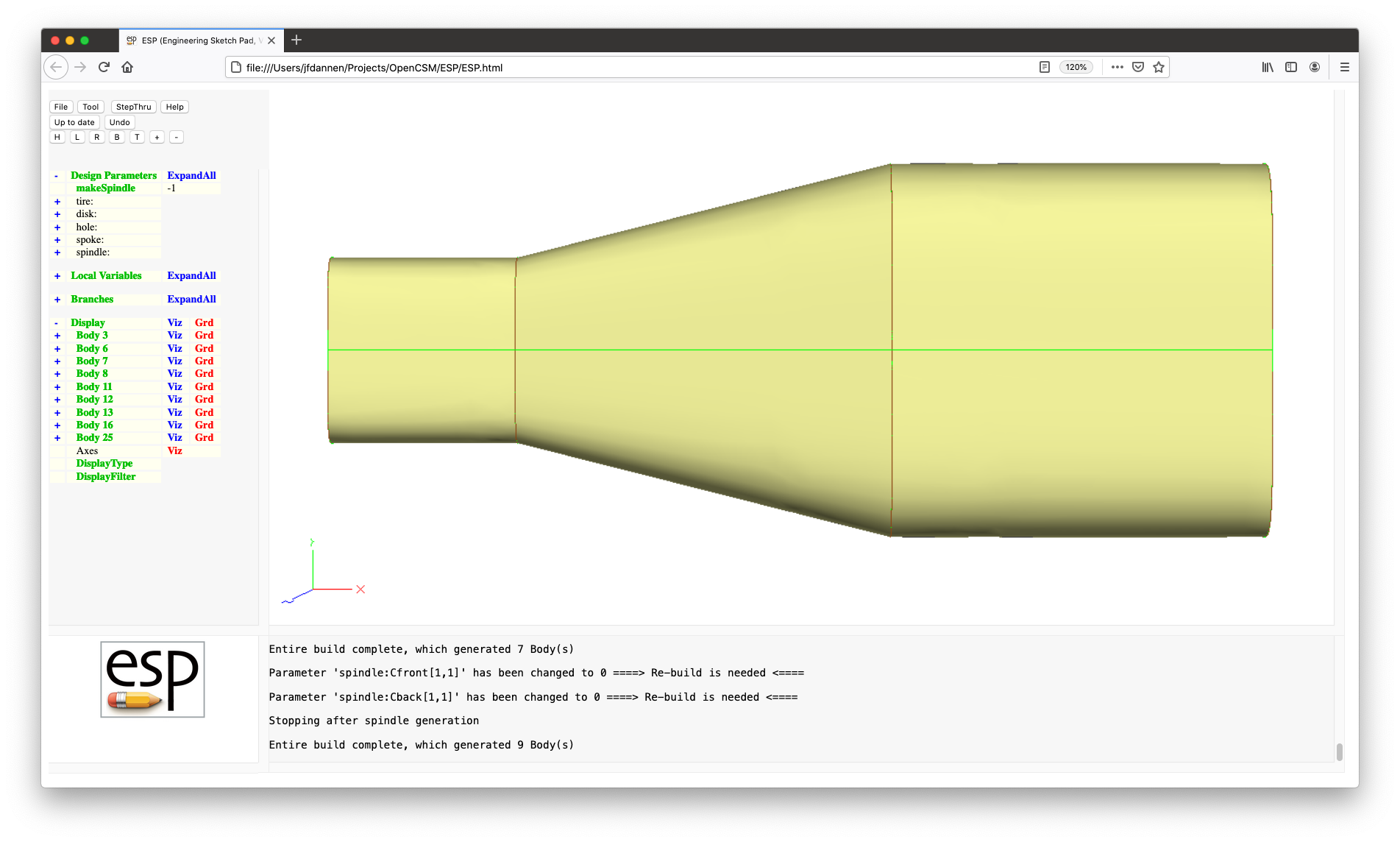

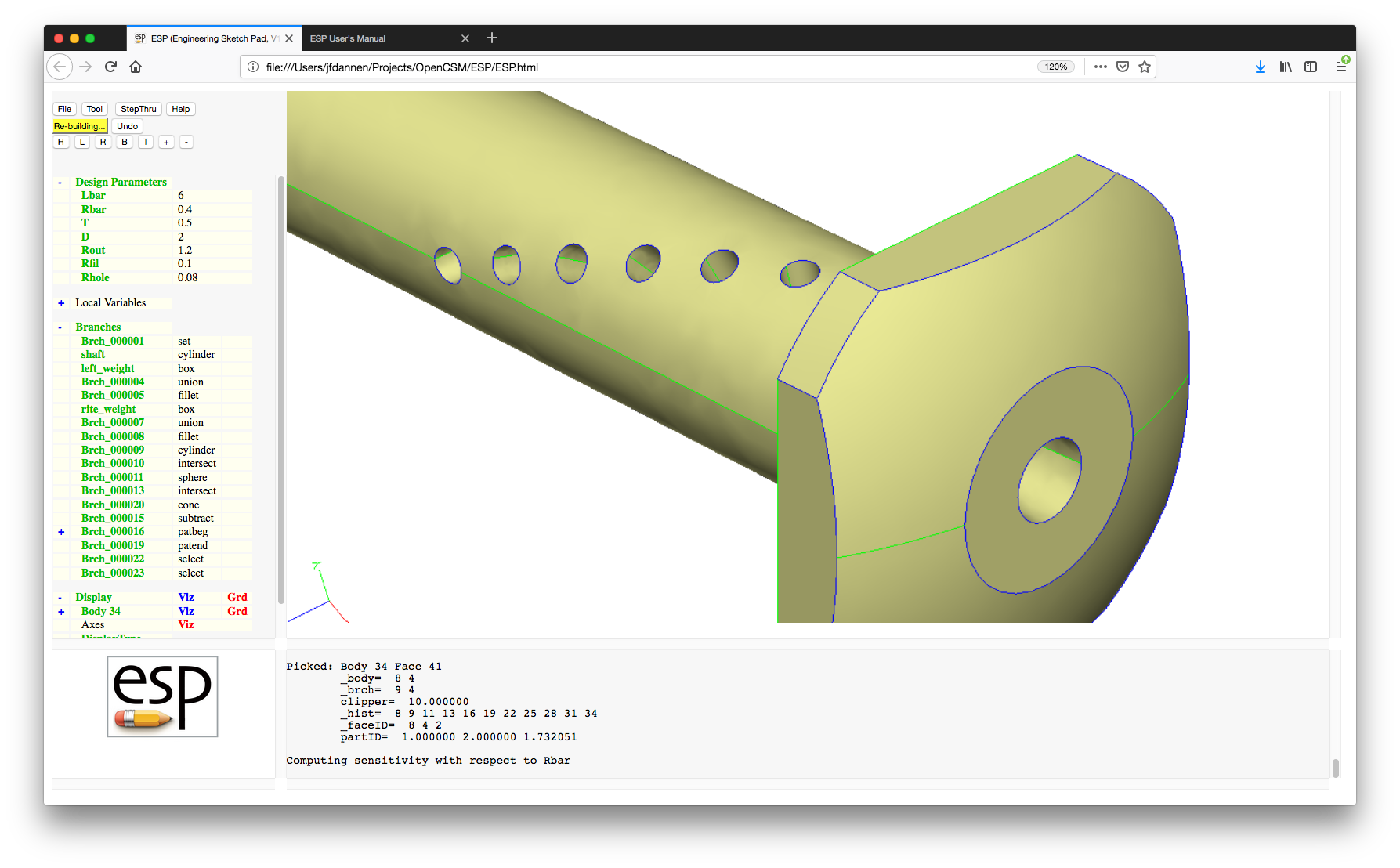

The first uses a fairly sophisticated multi-model to help you

get familiar with the ESP browser-based graphical

user interface (GUI). Then in Tutorials 2 through 5, the

configuration that was used in Tutorial 1 will be built up,

step by step.

These Tutorials cover many of ESP's features, but

not all of them. They follow current ESP best

practices, in which a configuration is built by using a

scripting language; most users find this mode of using

ESP to be more flexible and faster than the

GUI-based mode used by traditional CAD systems. But, if you

favor the traditional CAD system look-and-feel, check out the

legacy Tutorials (starting with First legacy

tutorial: Basic usage)

For a more extensive introduction to ESP, see

the ESP training slides (which are available

at acdl.mit.edu/ESP/ESPtraining2021.tgz). In

addition, detailed descriptions of all commands are included

later in this help document Valid CSM

statements.

Before we begin, a few notes:

ESP system; multi-word terms

are often given in camel-case, such as MessageWindow;ESP Commands are

shown UPPERCASE; andtypeface like this.ESP user interfaceThis first Tutorial is designed to help you get familiar with

the ESP browser-based user interface.

ESPThere are two main ways of starting ESP.

Technique 1. Click the ESP125 icon on your

desktop. This will open up a terminal window in which all the

environment variables needed to run ESP are

defined. After the window opens, you can issue a command such

as:

serveESP [options] [filename[.csm]]

where [options] is a list of one or more

command-line options, and filename (with or

without the .csm extension) is the (optional)

model file. The [options] gives you ability to do

things such as building the model in batch mode (i.e., no user

interface) with the -batch option, or changing the

port number used by the server with the -port

option. Try -help to get a full list of the

available [options].

To start the first Tutorial, simply enter:

serveESP ../data/tutorial1 (on MAC or LINUX)

or

serveESP ..\data\tutorial1 (on Windows)

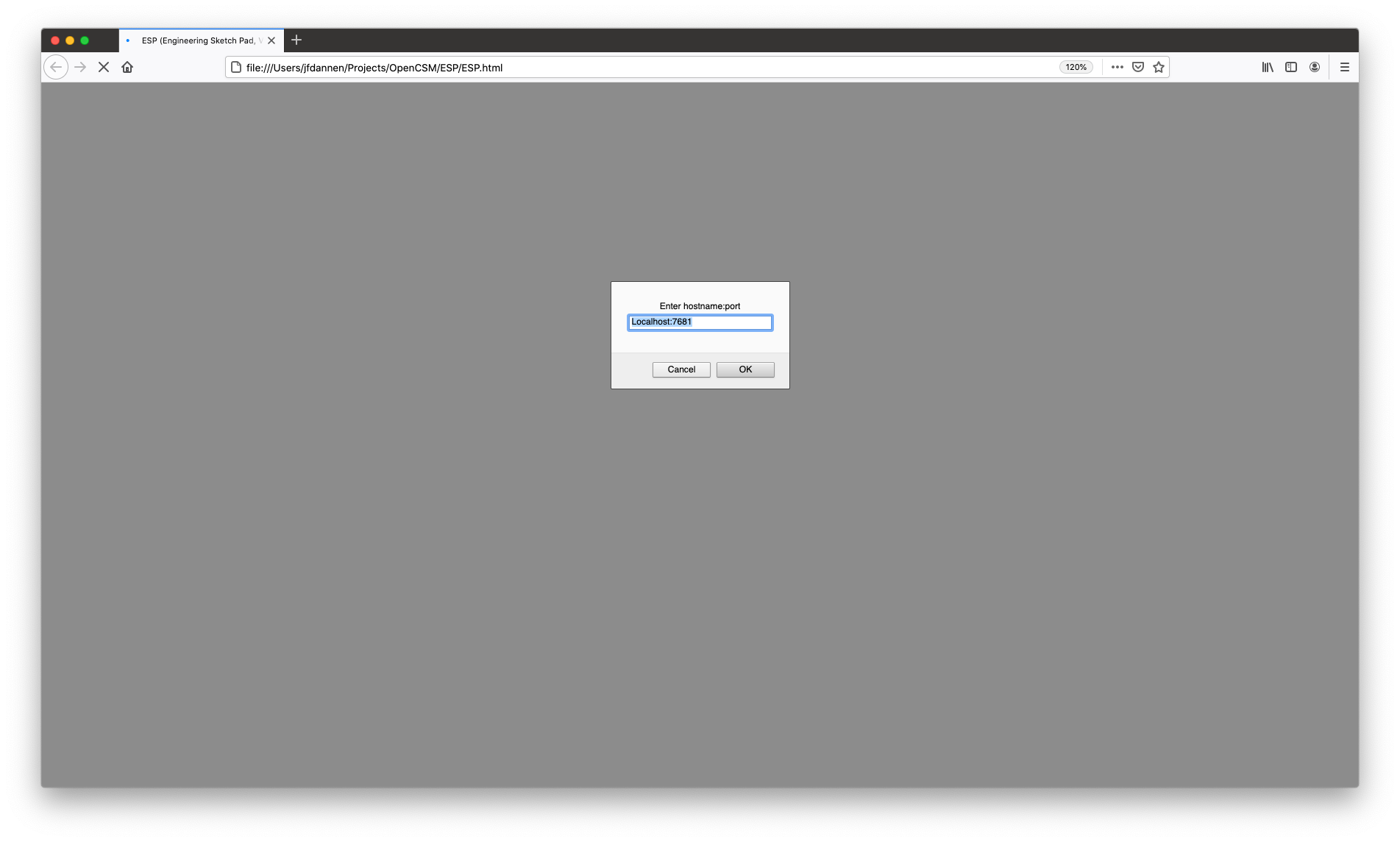

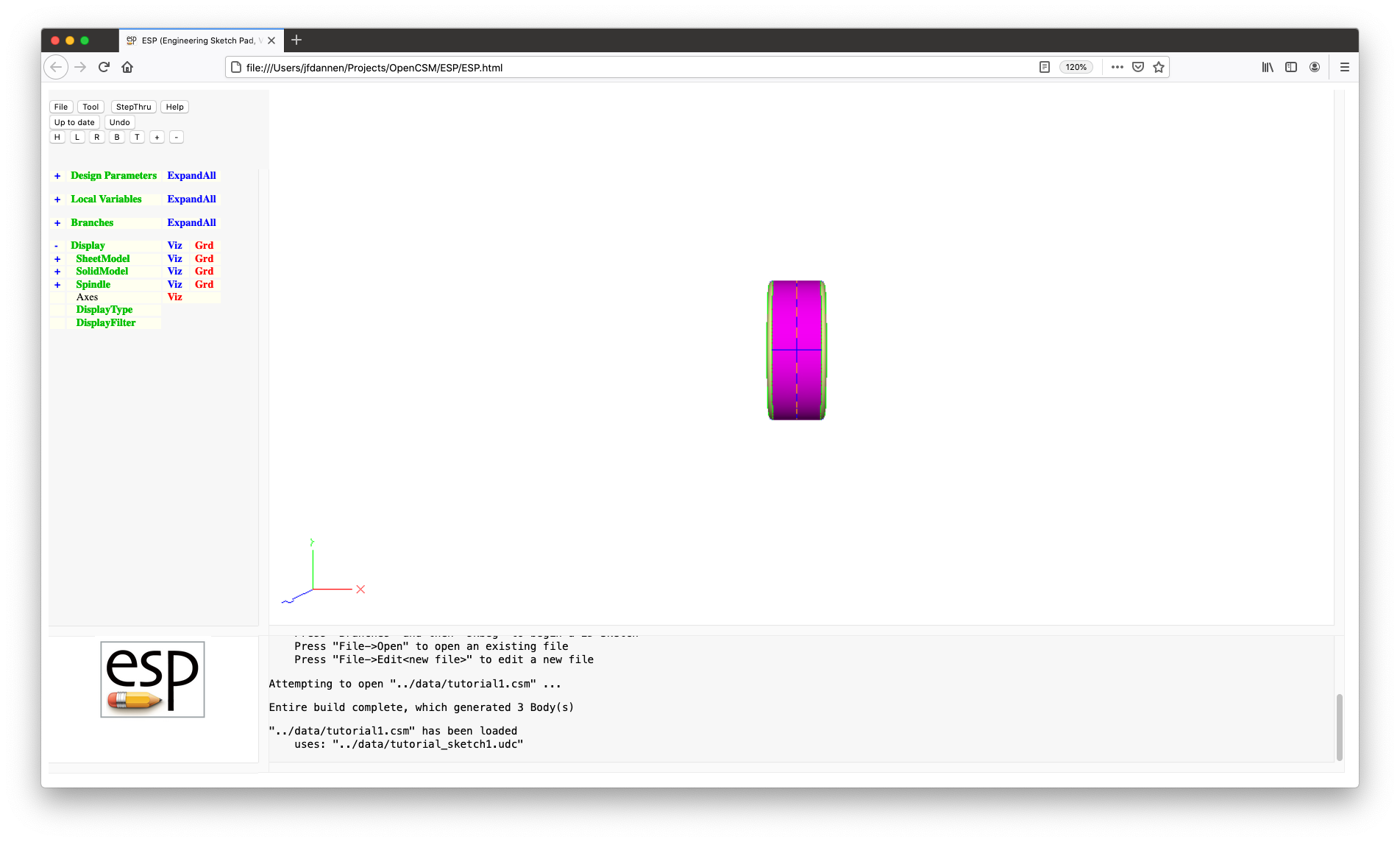

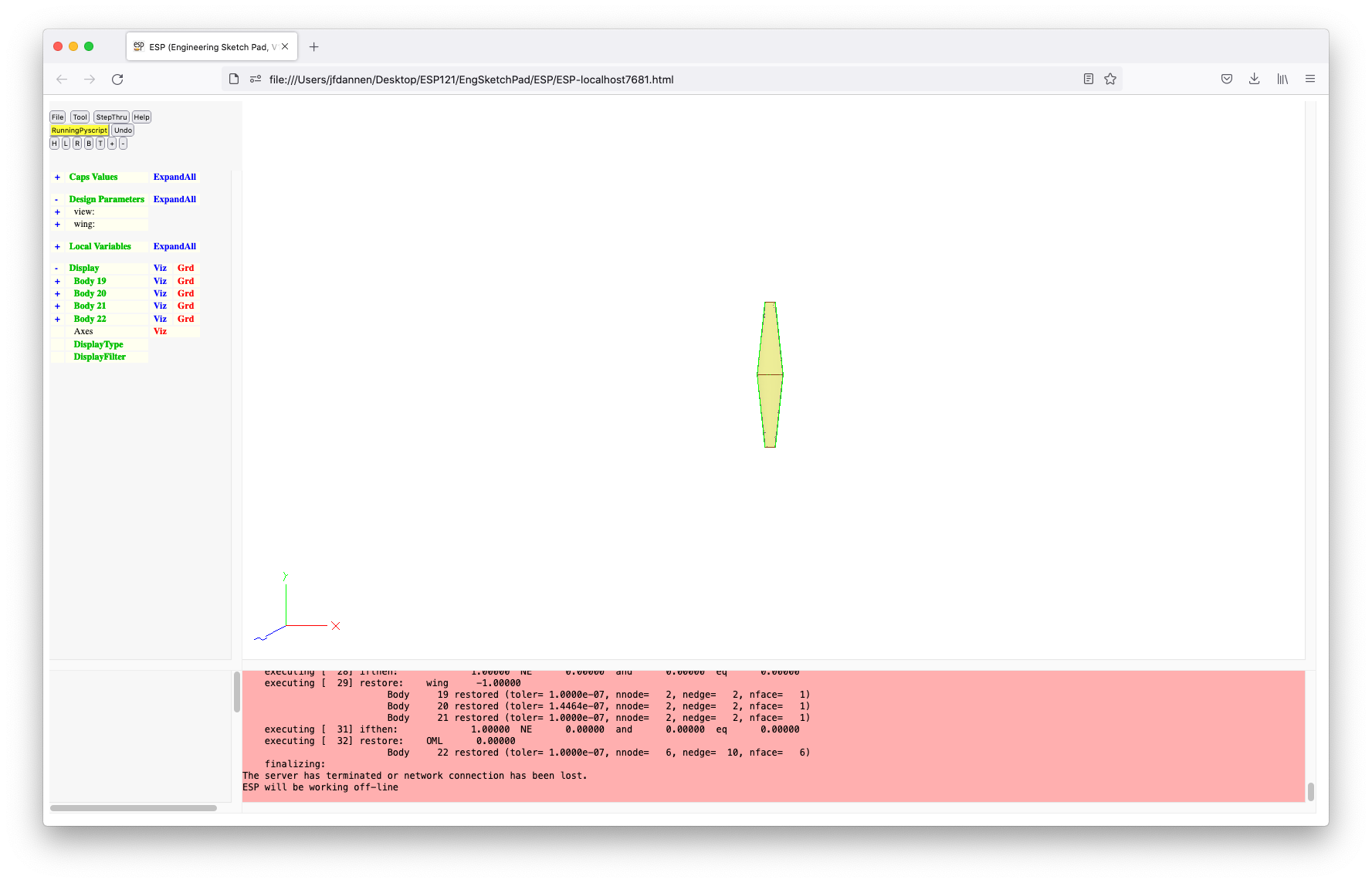

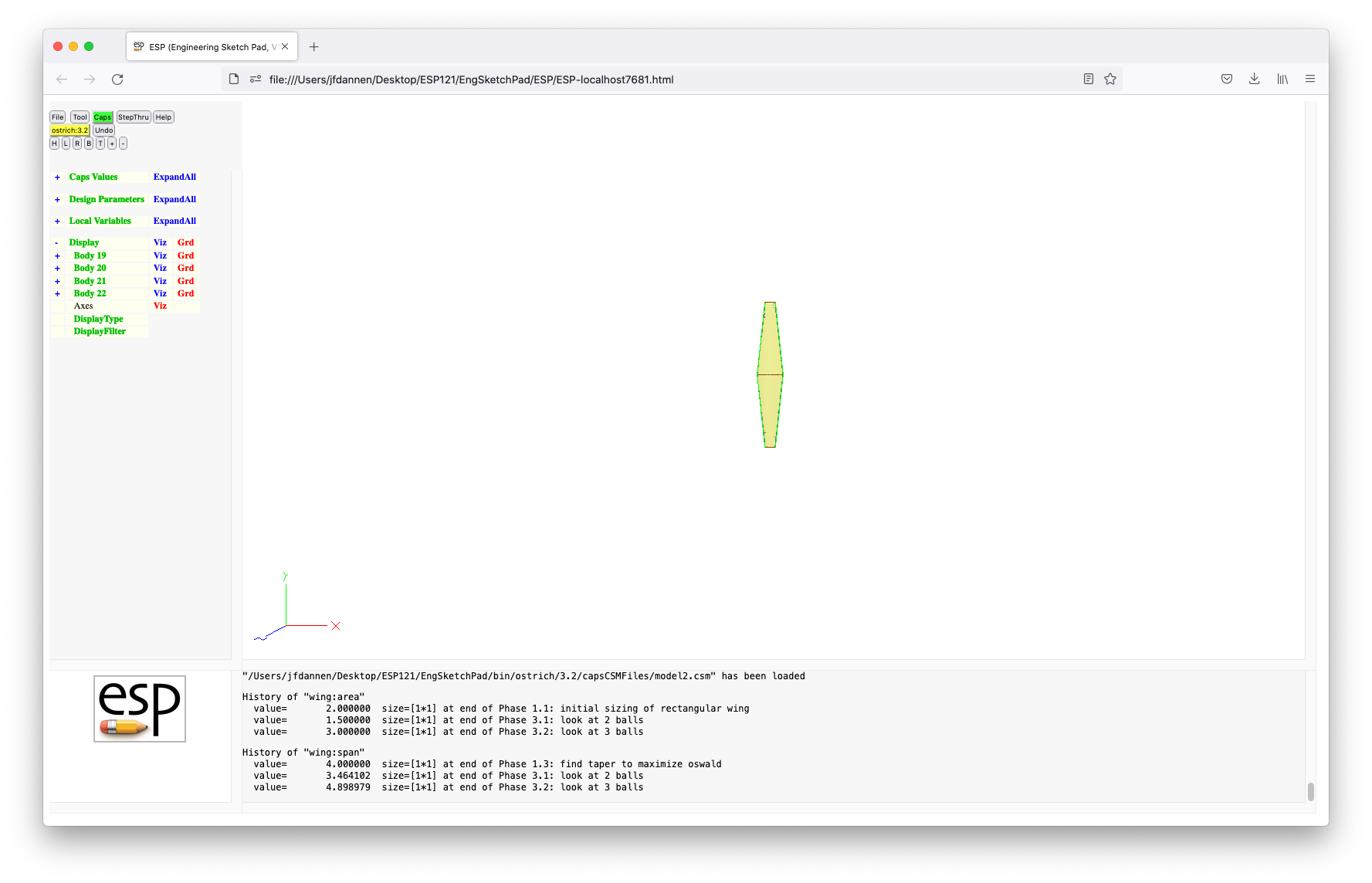

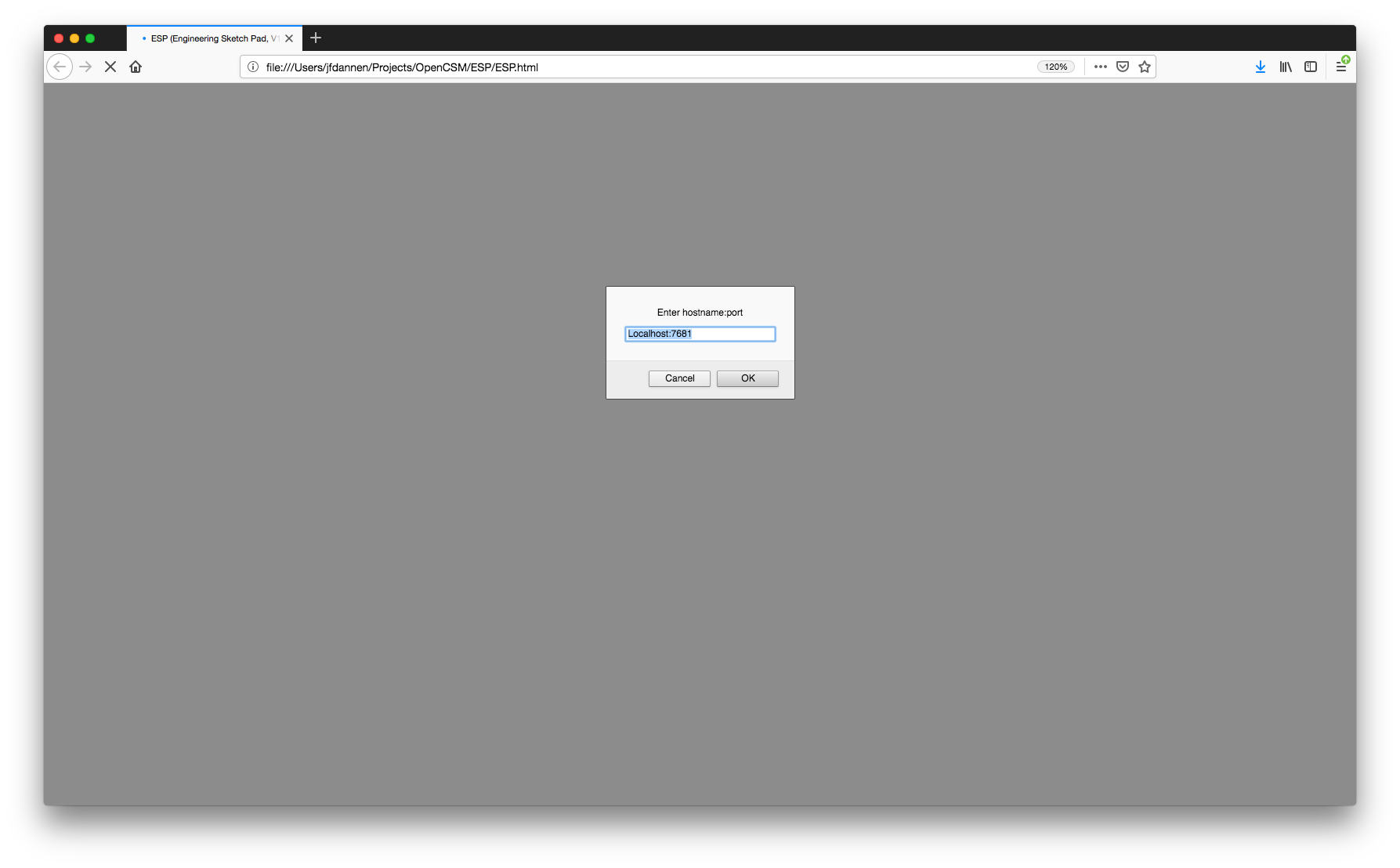

After serveESP builds the configuration, it will automatically

open up a browser containing the ESP user

interface. When ESP starts, it may first ask you

for the hostname and port associated with the server (which was

started when you typed serveESP).

Most often you will choose the default

Localhost:7681. Note that a new feature

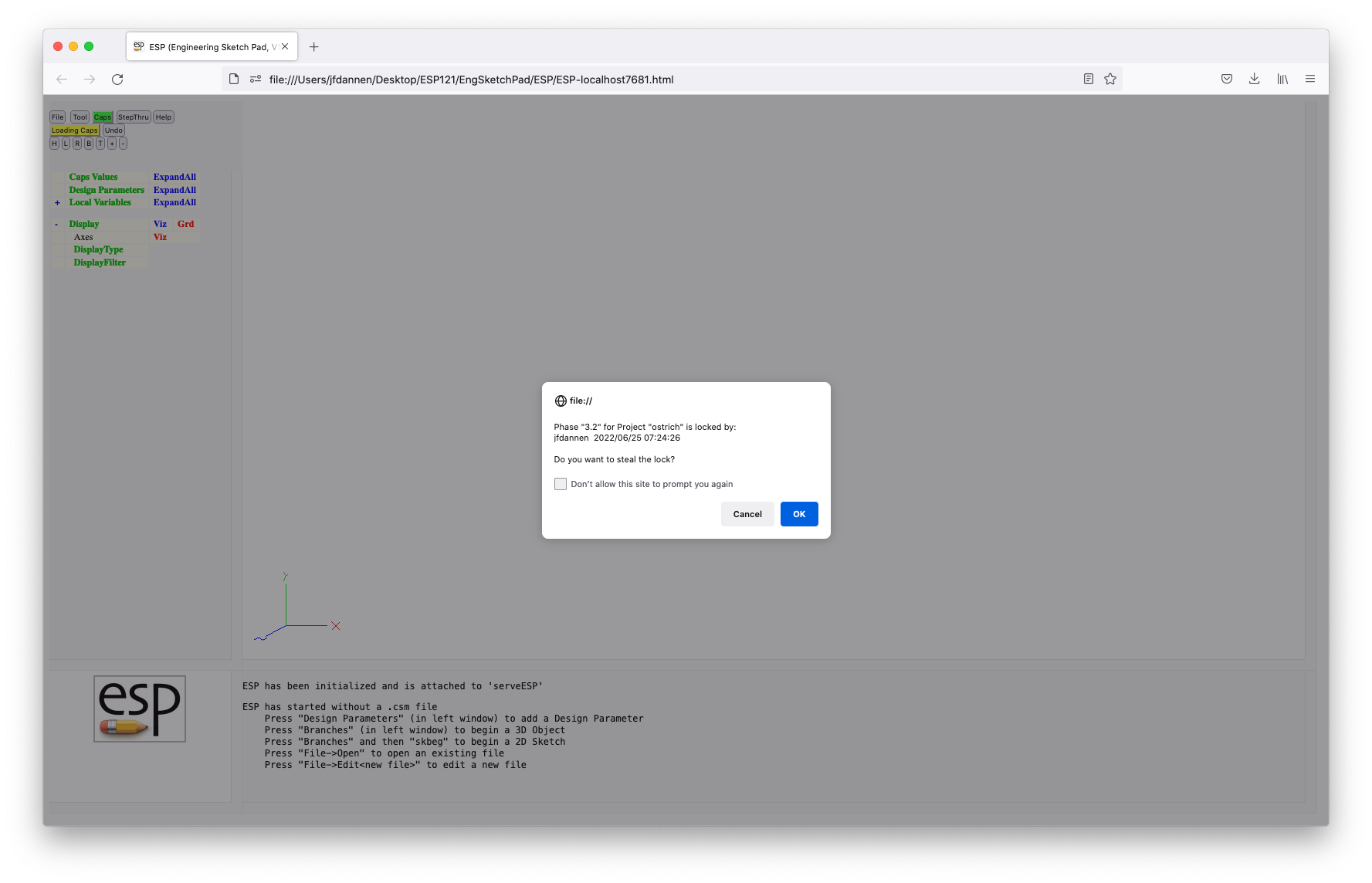

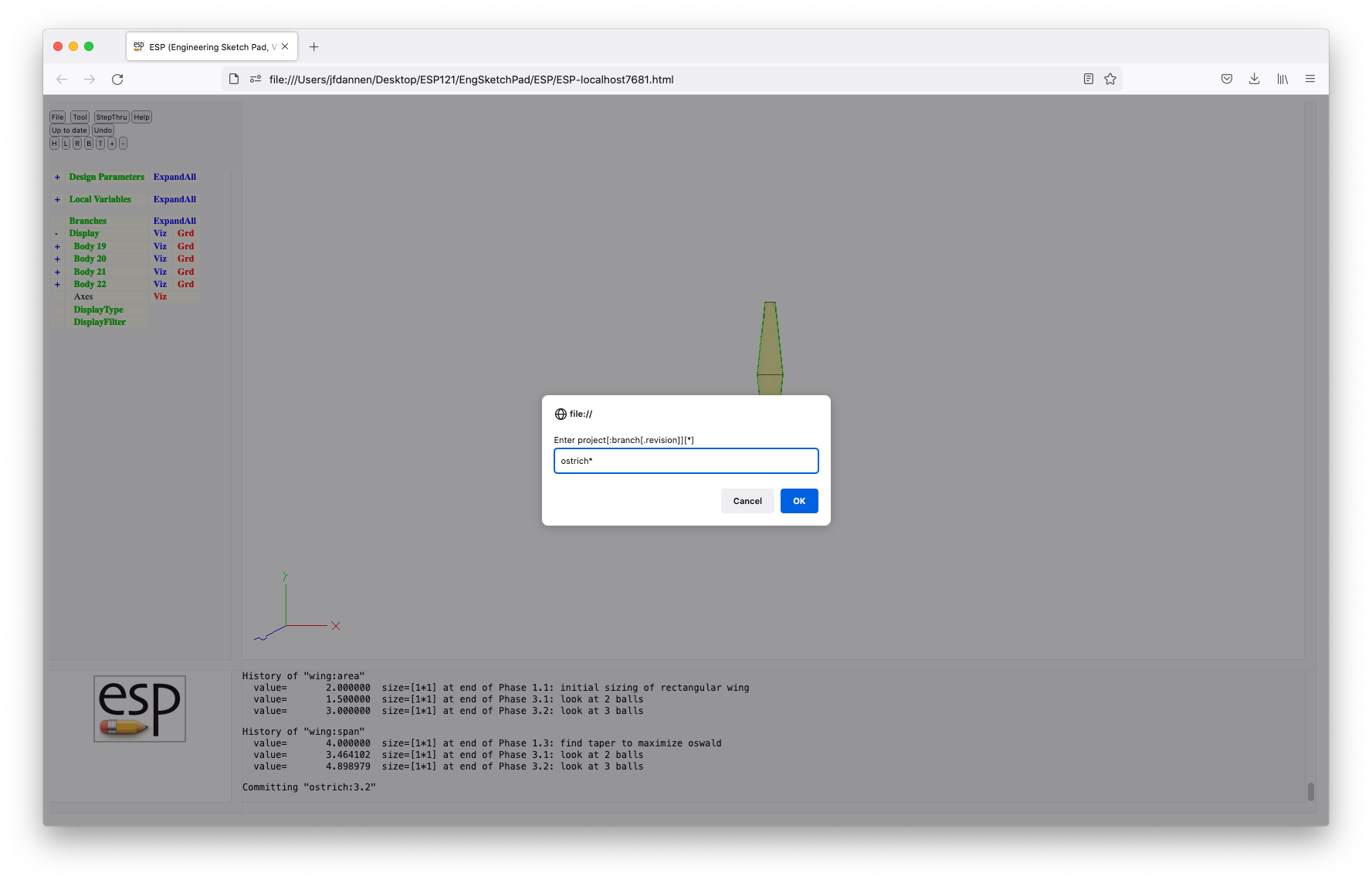

in ESP125 allows more than one user to attach to the

same session, allowing them to work collaboratively on the same

model at the same time. This new collaboration feature is not

explicitly covered in these Tutorials.

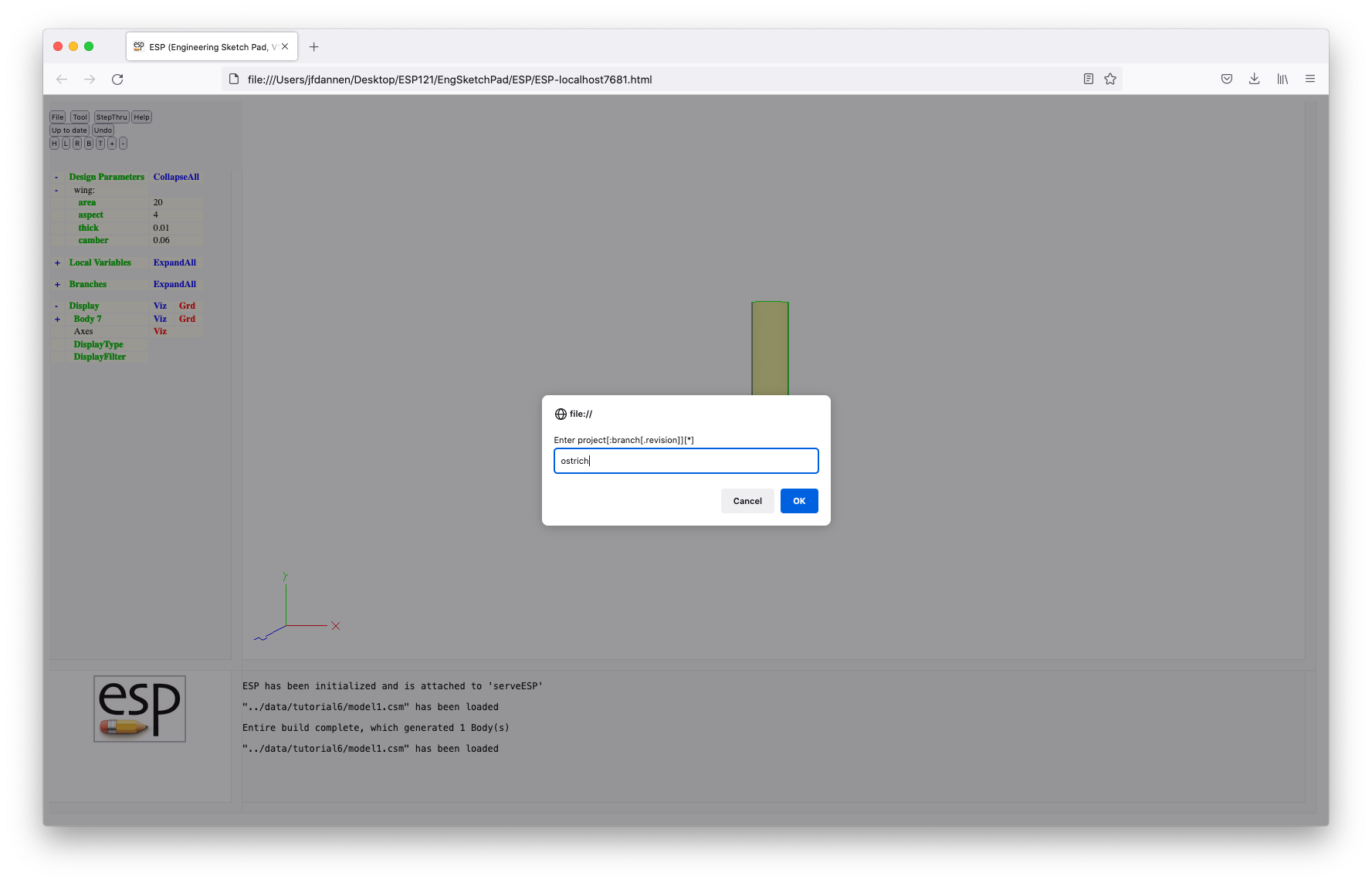

Technique 2. Click the runESP125 icon on your

desktop, which will open up (in the background) a terminal

window and then a browser containing the ESP user

interface. The first thing it may ask you for is the hostname

and port associated with the server (that is actually running

in the terminal window), as shown above. Most often you will

choose the default Localhost:7681. Note that a

new feature in ESP allows more than one user to

attach to the same session, allowing them to work

collaboratively on the same model at the same time. This new

collaboration feature is not explicitly covered in these

Tutorials.

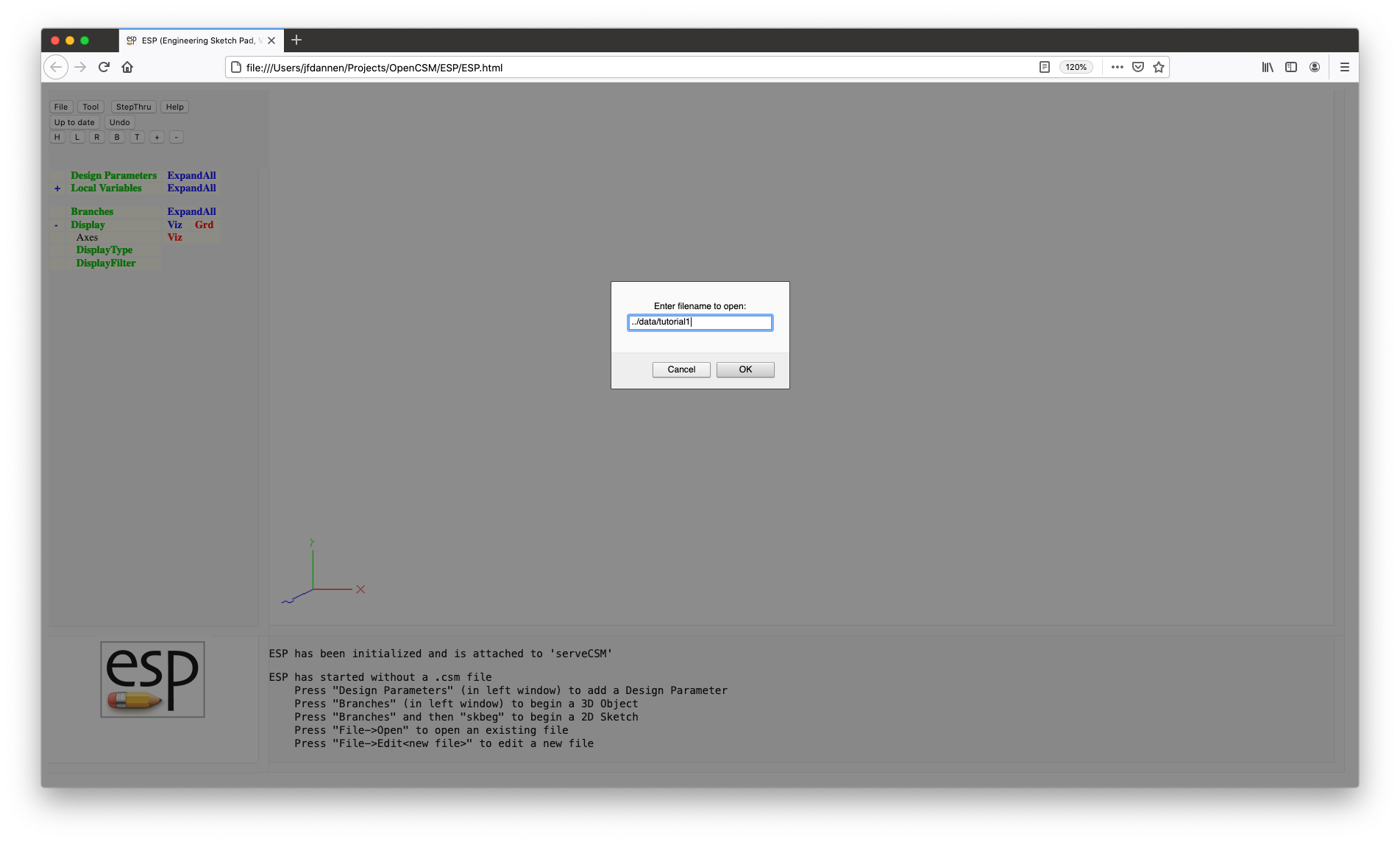

When ESP starts using technique 2, it will not

contain a model. You will have to manually load the model by

pressing the File button (near the top left) and then choosing

Open. You will be asked for the name of the file, at

which time you should answer:

../data/tutorial1 (on MAC or Linux)

or

..\data\tutorial1 (in Windows)

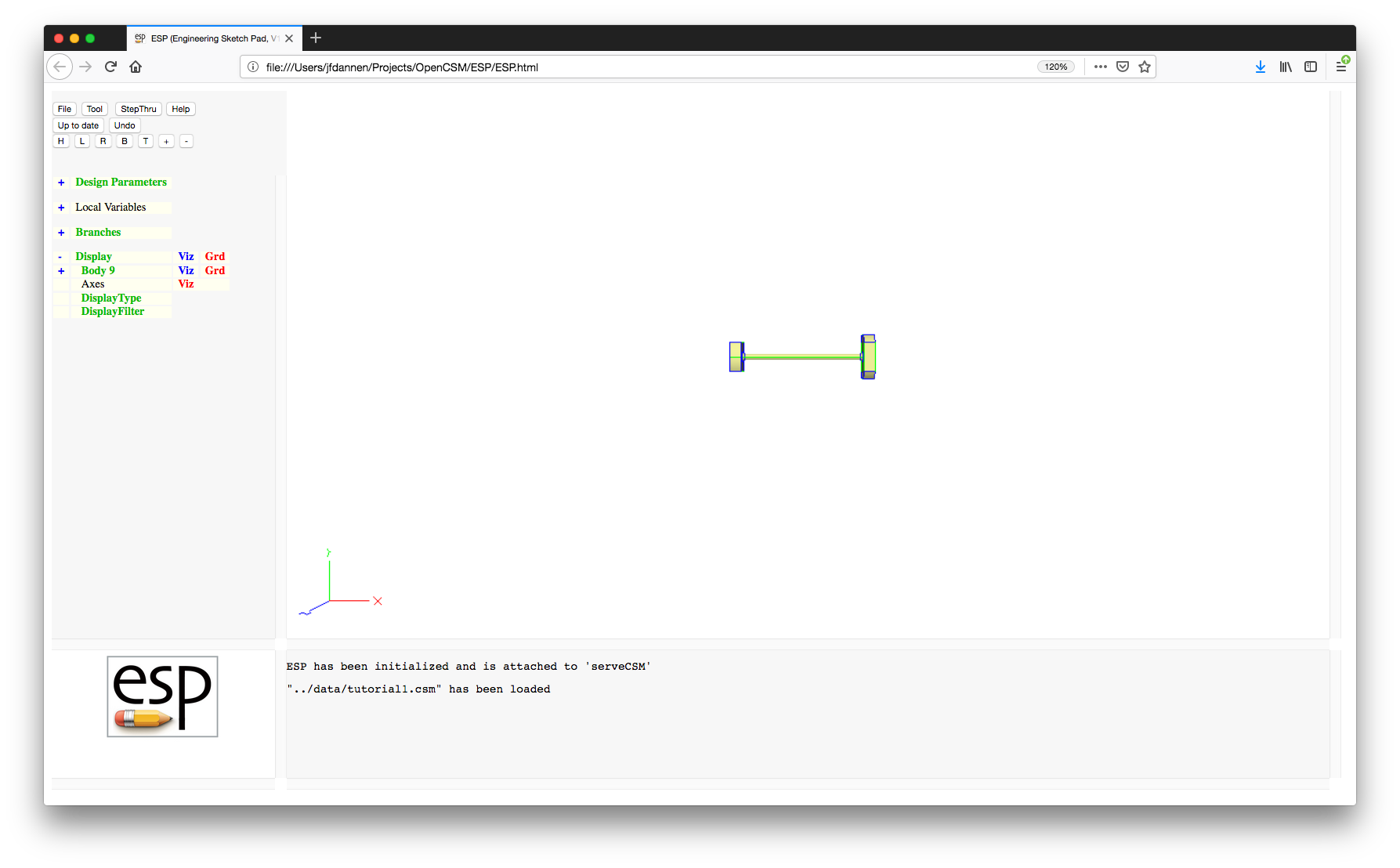

After you have chosen either technique 1 or 2, it is time to

explore the ESP user interface. You will see that

the window is broken into four frames:

ESP. It contains command buttons and a

tree-like structure that allows you to add/edit/examine

the DesignParameters, examine the LocalVariables,

add/edit/examine/delete the Branches in the FeatureTree,

and control the visibility of the Display. A full

description of the TreeWindow in contained below;ESP logo. Other uses

for the KeyWindow is for textual status (such as when you

are using the sketcher) or an annotated spectrum (when you

are showing sensitivities); andESP is doing. The background color of

the MessageWindow can be:

ESP authors so that the bug can be

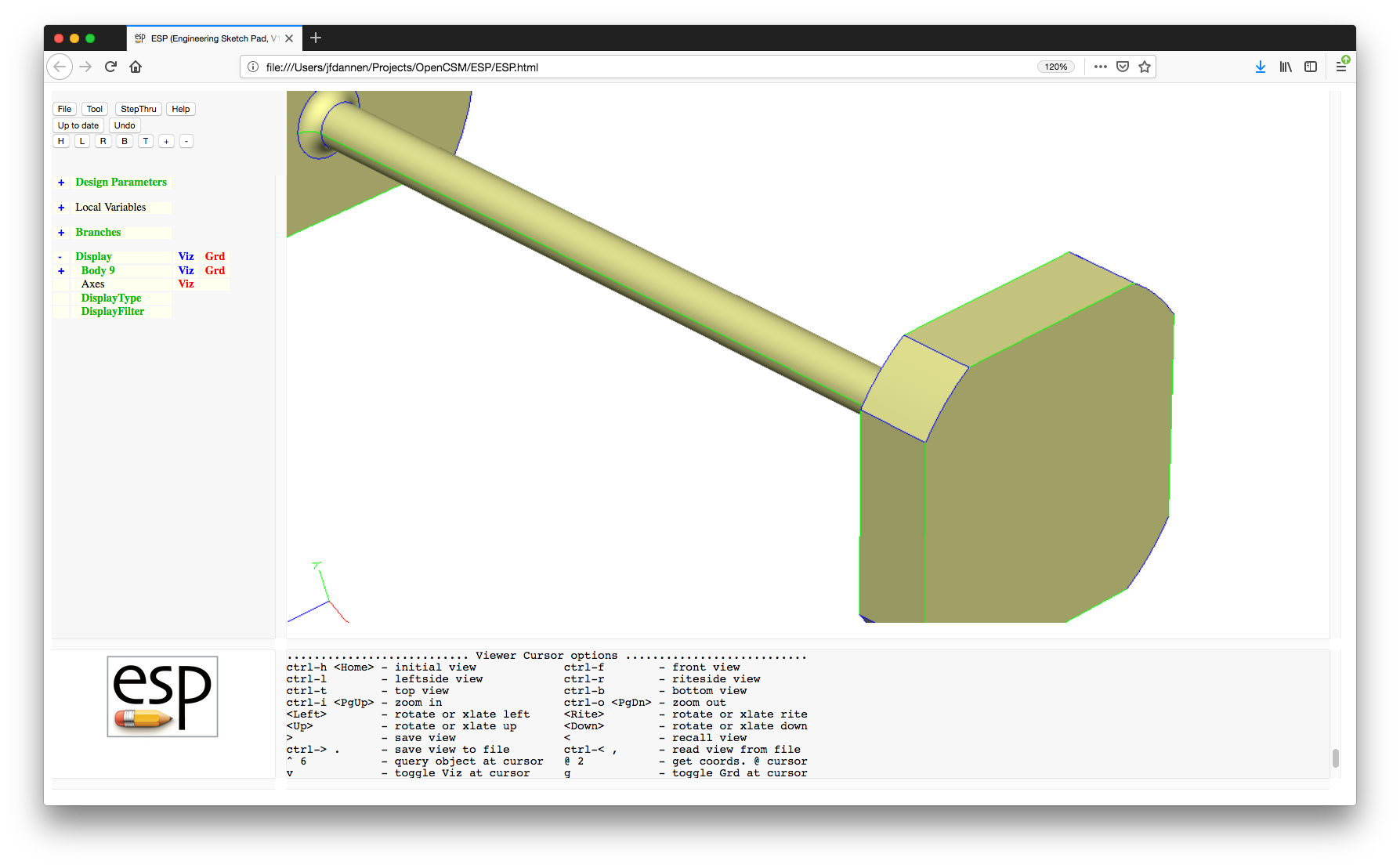

fixed.The first thing to do is to play with the image in the GraphicsWindow. This is done with the mouse in the following ways:

When using the mouse, it is possible to enter FlyingMode, in which the view continually changes until the mouse button is released. FlyingMode is particularly useful when one needs to translate a long distance. Toggling FlyingMode is done by pressing the ! key in the GraphicsWindow.

At any time, a user might want to save a view for later use in the browser session. This is done by pressing the > key in the GraphicsWindow; the saved view can be retrieved (multiple times) by pressing the < key.

You can also save a view into a file (for use in a

later ESP session) with the

<Ctrl->> or . keys, which will prompt

you for a filename. You can read a view file with

the <Ctrl-<> or , keys, which will

prompt you for the view filename. If the file does not exist,

nothing will happen.

The default (home) view can be obtained by pressing either the <Home> key or the H button near the top of the TreeWindow. (The home view is one in which the x-coordinate increases from left to right and the y-coordinate increases from bottom to top.) One can also get the top view by pressing the T button, the bottom view by pressing the B button, the left side view by pressing the L button, or the right side view by pressing the R button.

The function of the arrow keys on the keyboard depends on whether FlyingMode is active or not. For example, if FlyingMode is not active (the default), pressing the <Left> key causes the object to rotate to the left by 30 degrees; if FlyingMode is active (because the ! key was pressed), then pressing the <Left> key causes the object on the screen to translate to the left. If the Shift is held while the <Left> key is pressed, the increments are 5 degrees and the translations are also smaller.

The <PgUp> key or the + button can be used to zoom in and the <PgDn> key or the - button can be used to zoom out. (Recall that the mouse wheel can also be used.) The behavior of these keys/buttons does not depend on the current FlyingMode.

To re-center the image at a given point and simultaneously reset the point about which mouse rotations will occur, point to any object in the GraphicsWindow and press * or 8; the image will be re-centered and a message will be posted in the MessageWindow.

To determine the identity of any object in the GraphicsWindow, simply put your cursor on the object and press ^ or 6; a summary of the identified object is shown in the MessageWindow. (Note that if the cursor is not exactly over any object, the message will only be posted once the mouse passes over a graphic object.)

To determine the approximate coordinates of any location in the GraphicsWindow, simply put your cursor on the location and press @ or 2; a little red square is placed at the location and the approximate coordinates of the location are shown in the MessageWindow. Also posted is the distance from the previous query. Note that the little red square is cleared if the distance from the previous query is zero (i.e., the @ or 2 option was selected twice at the same screen location).

To add an Attribute to any Face or Edge, simply put your cursor on the object in the GraphicsWindow and press A (upper case A). You will then be asked for the name of the new Attribute as well of its value, which can either be a string (if is starts with a $) or a semi-colon separated list of expressions.

Lastly, to get help on the commands that are available in the GraphicsWindow, press ? and a short listing will be given in the MessageWindow.

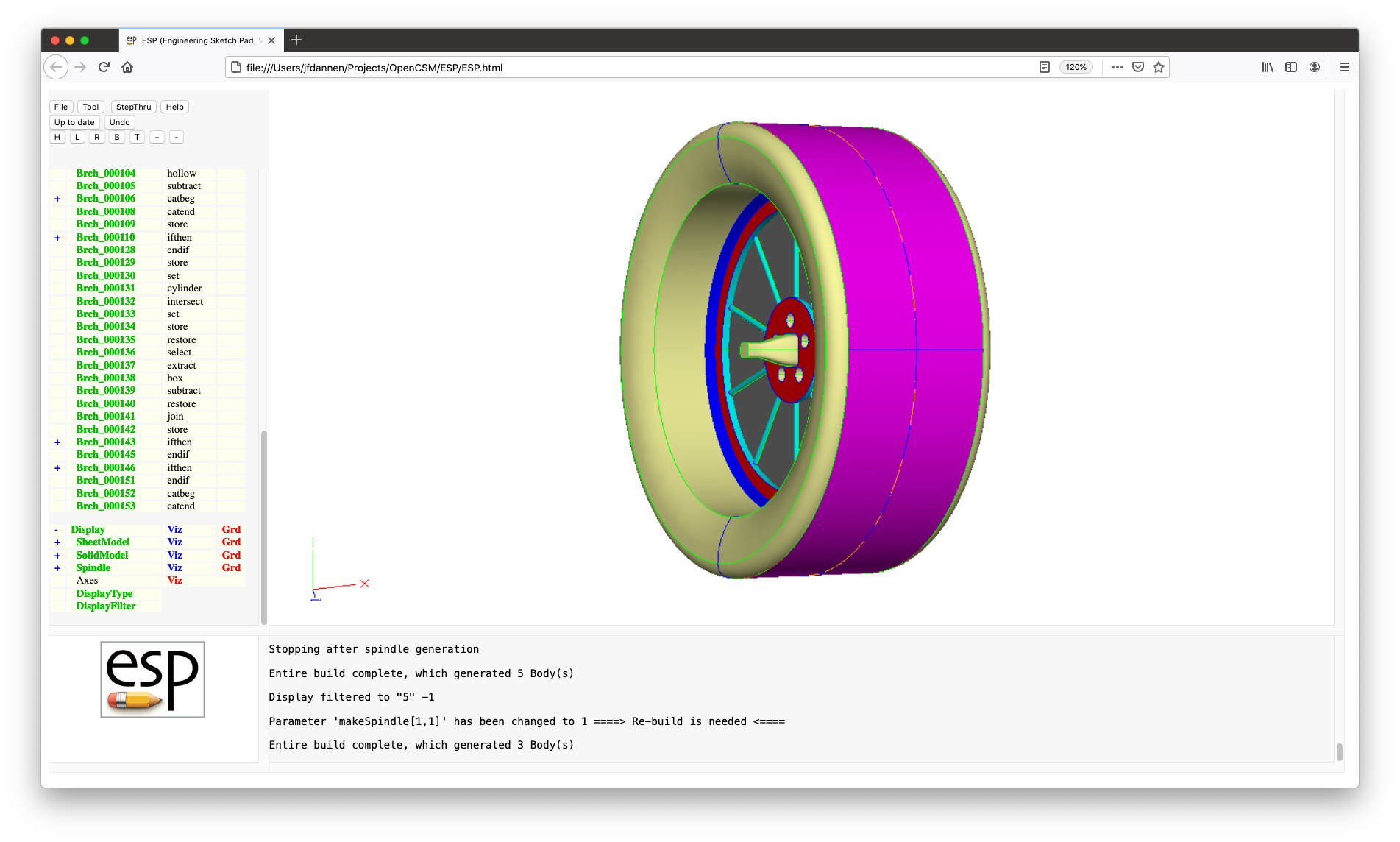

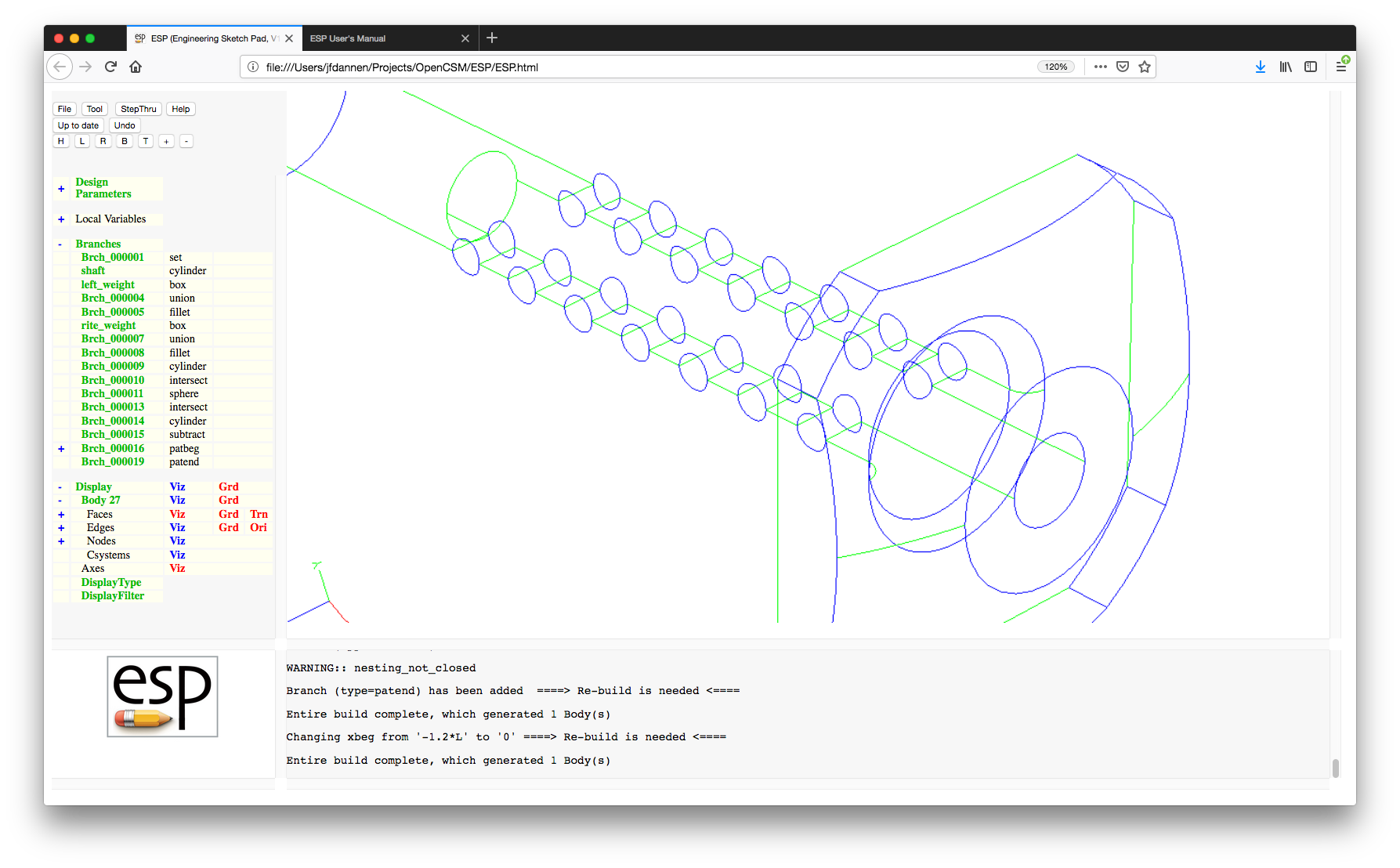

Now let's look at the Display part of the TreeWindow. By default, "Display" is expanded and you can see that you have Bodys named "SheetModel", "SolidModel", and "Spindle". Expand the listing for "SolidModel" by pressing the + to the left of "SolidModel" and you will see entries for Faces, Edges, and Nodes. To the right of "Faces" (below "SolidModel") you will see three items:

Notice also that there is a + to the left of "Faces", which indicates that you can interact with the object on a Face-by-Face basis. The basic rules here are:

Sometimes there are a series of entities for which you want to change a property (the visibility, grid, tranparency, or orientation). This can be done simply by changing the property of the first (or last) entity and pressing the Shift key while changing the property of the last (first) entity. As long as the first and last entities have the same parent, all the properties of all the intervening entities will be changed too.

When you have a configuration with lots of Bodys, it is sometimes useful to alter the visibility of all Faces, Edges, or Nodes (in all Bodys). This can be done by pressing on the word Display in the KeyWindow.

To see this working, press Viz to the right of

"Display", which will turn everything off. Pressing it again,

will now turn everything on, including little black squares at

every Node in all Bodys. Sometimes this is useful, but other

times it is annoying. So pressing on Display will bring

up a pop-up; if you now choose -1 (hide all Nodes)

and press Enter, the Nodes will be removed from the

graphical image.

Now it is time to look at the buttons at the top of the TreeWindow. The first one to look at is the File button, which posts a menu with the following options:

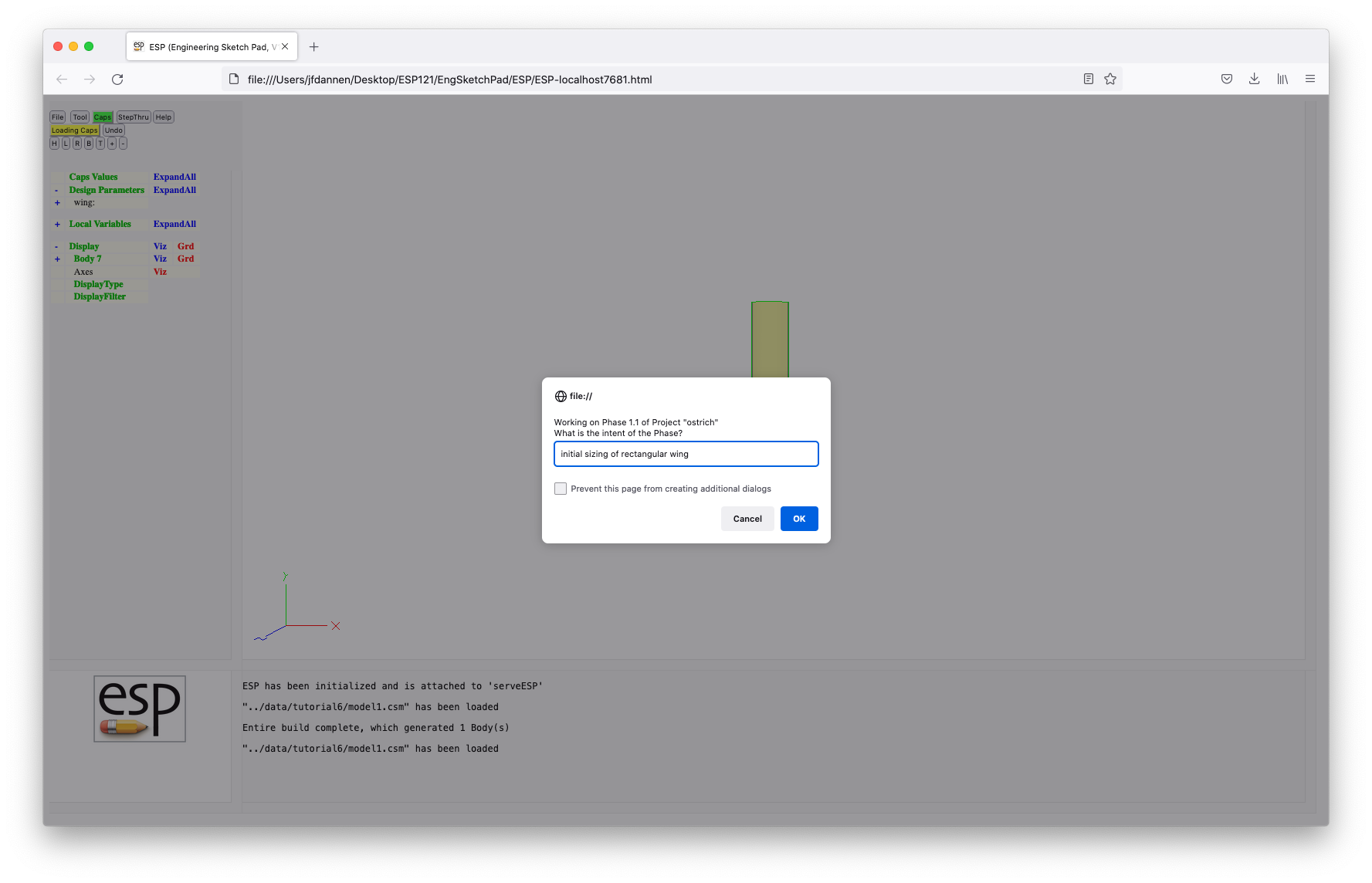

The second button on the top of the TreeWindow is

the Tool button, which gives you access to the various

tools within ESP. In version 1.25, there are only

six options here:

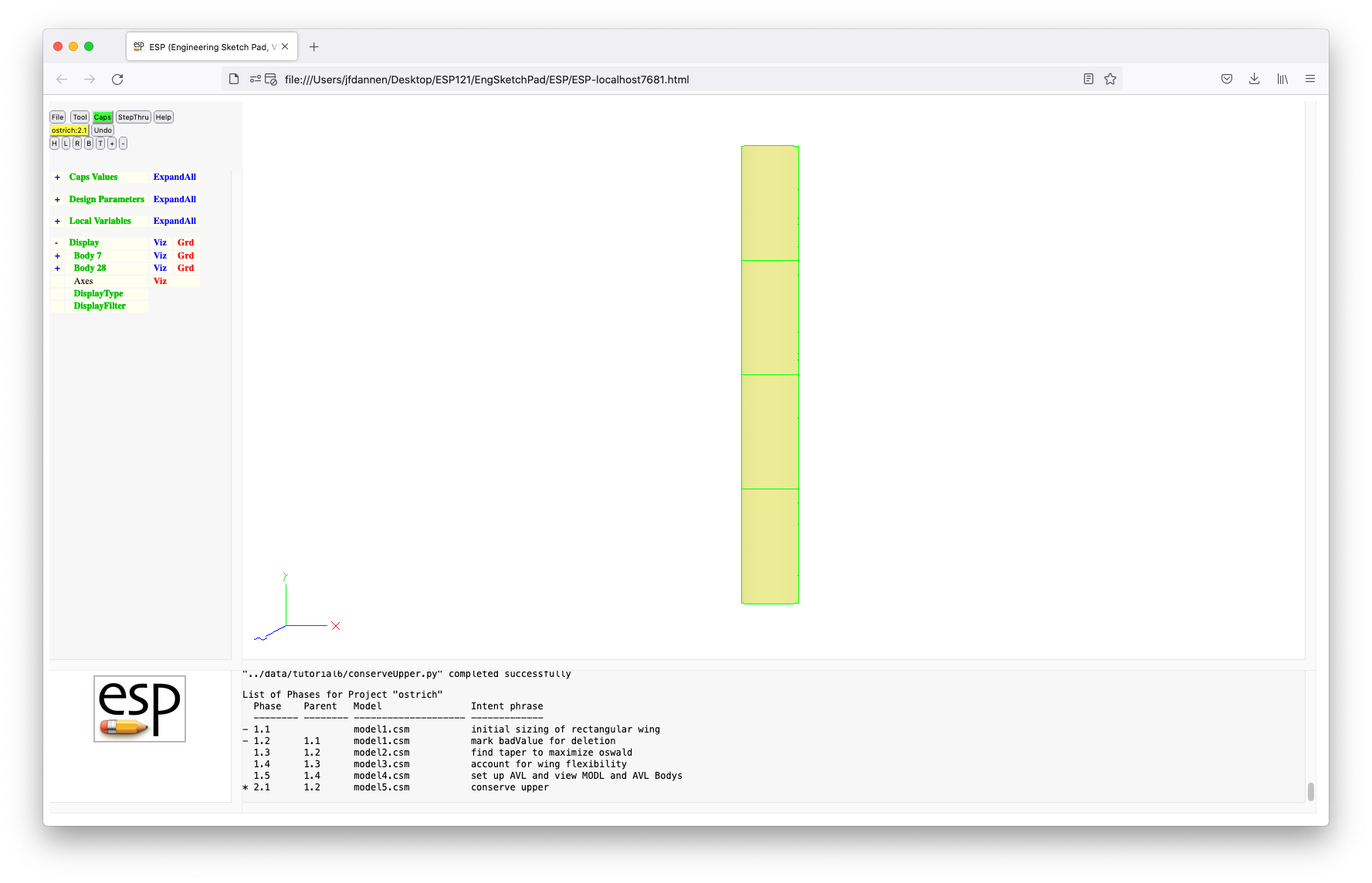

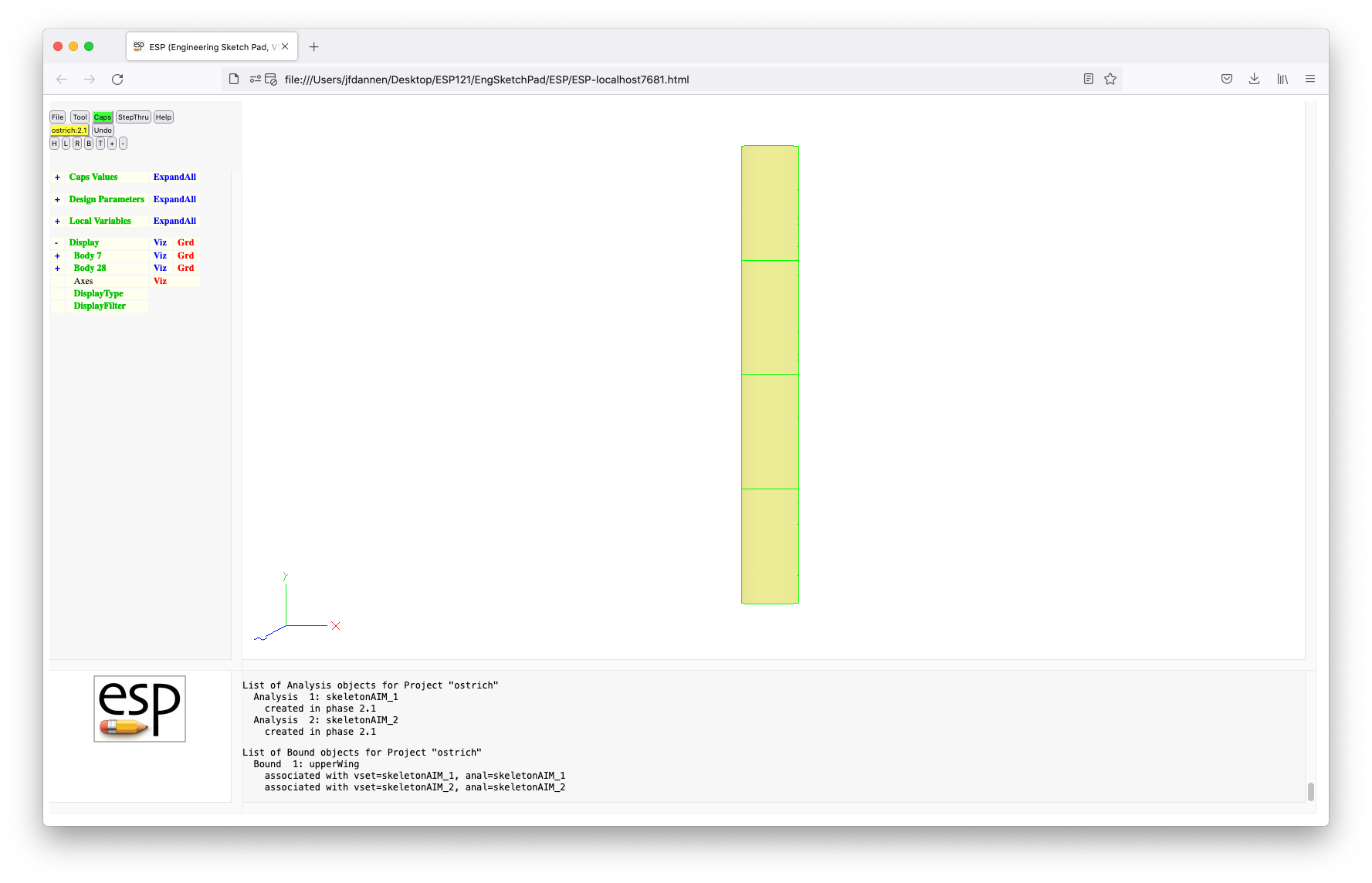

CAPS, which will be covered in Tutorial

6; ESP from an OpenVsp model.

This is not described further in these tutorials.ESP.

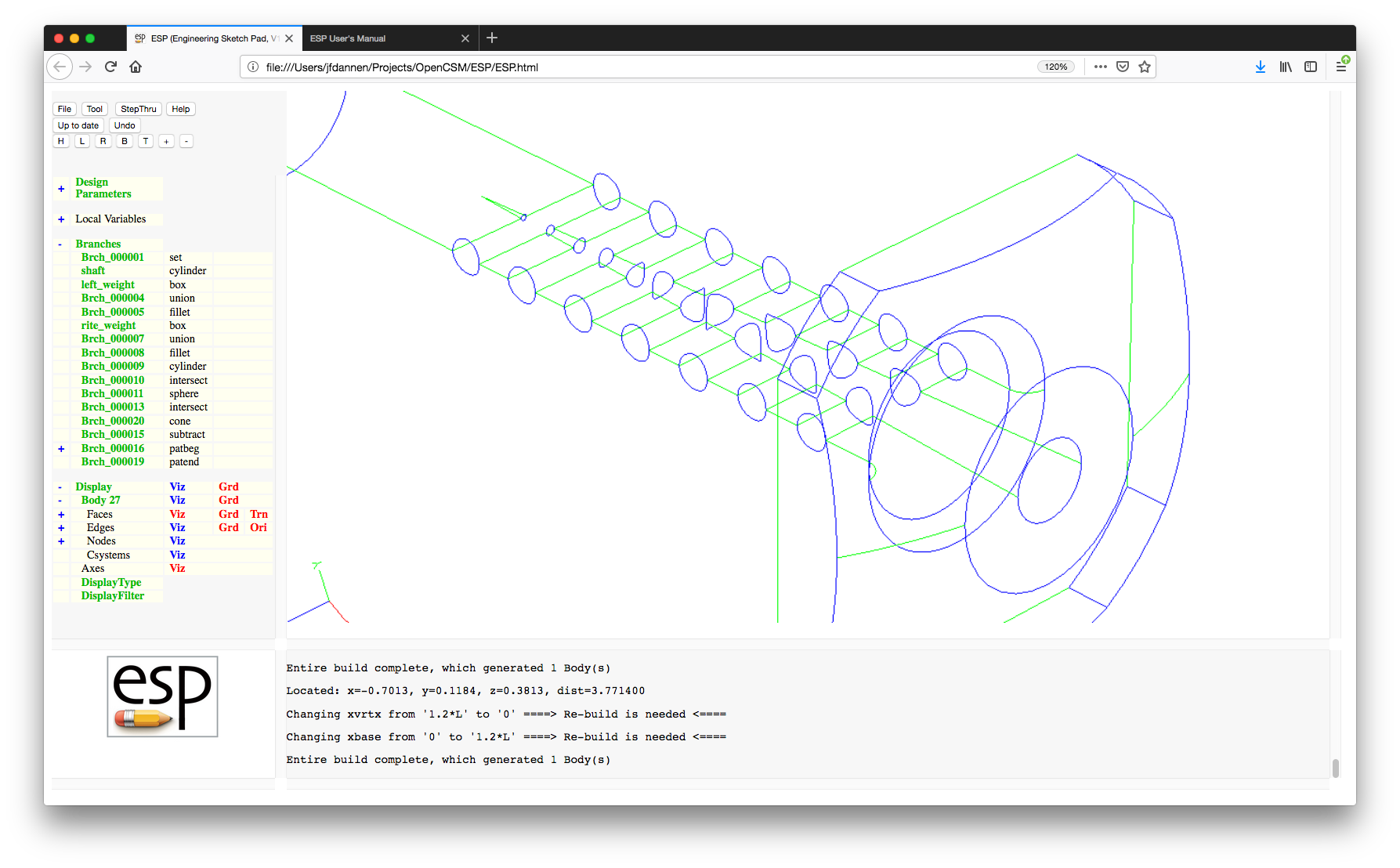

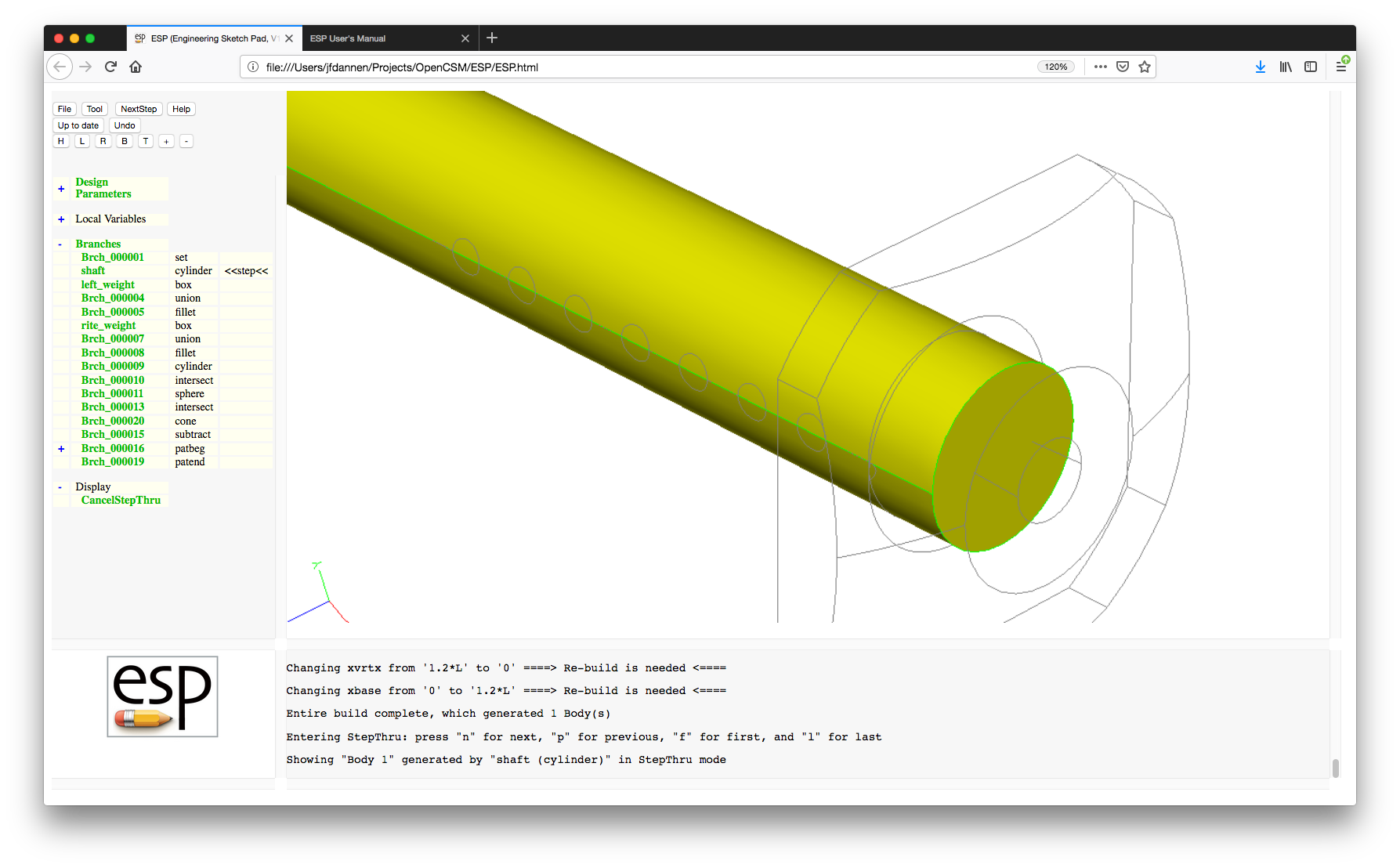

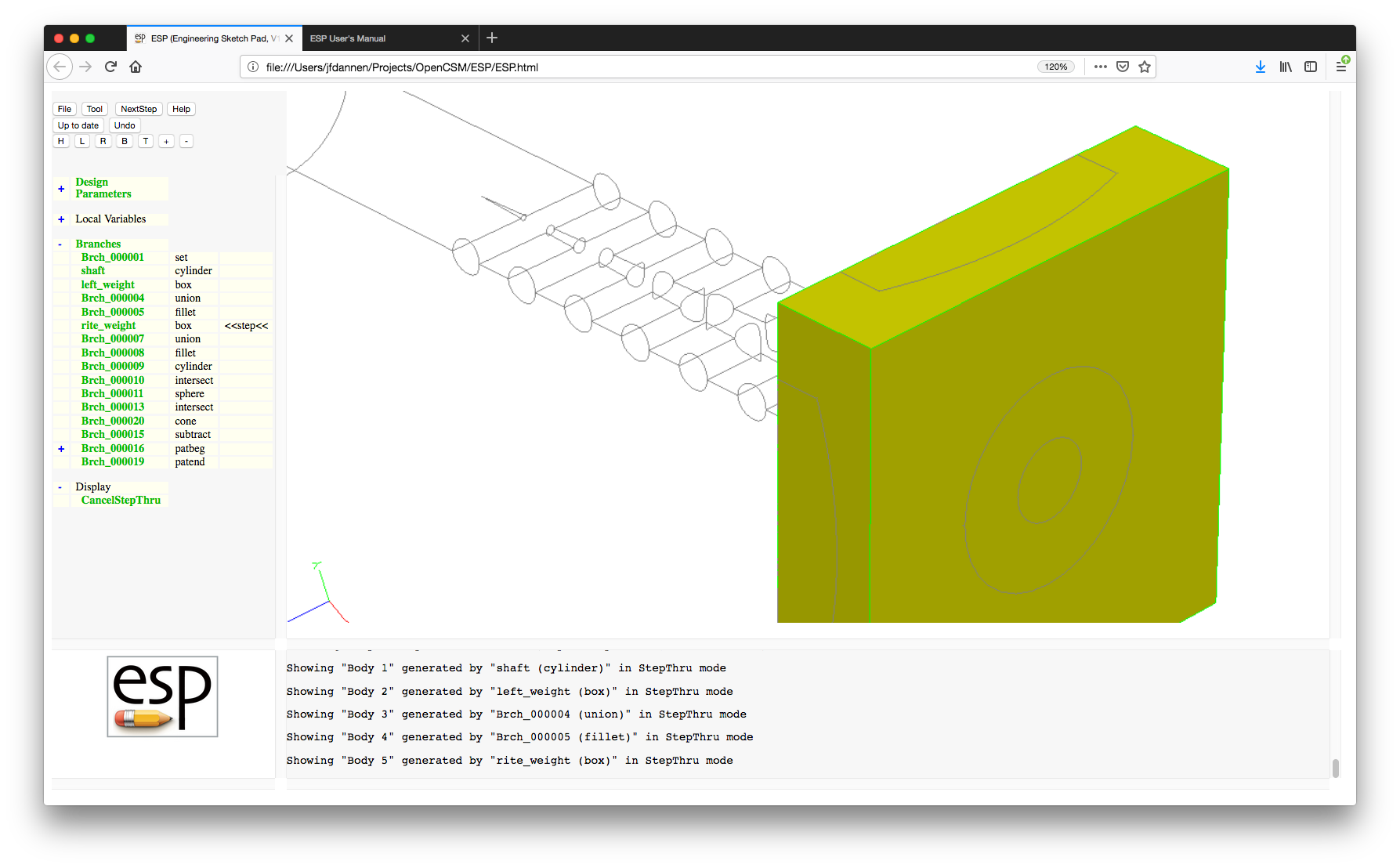

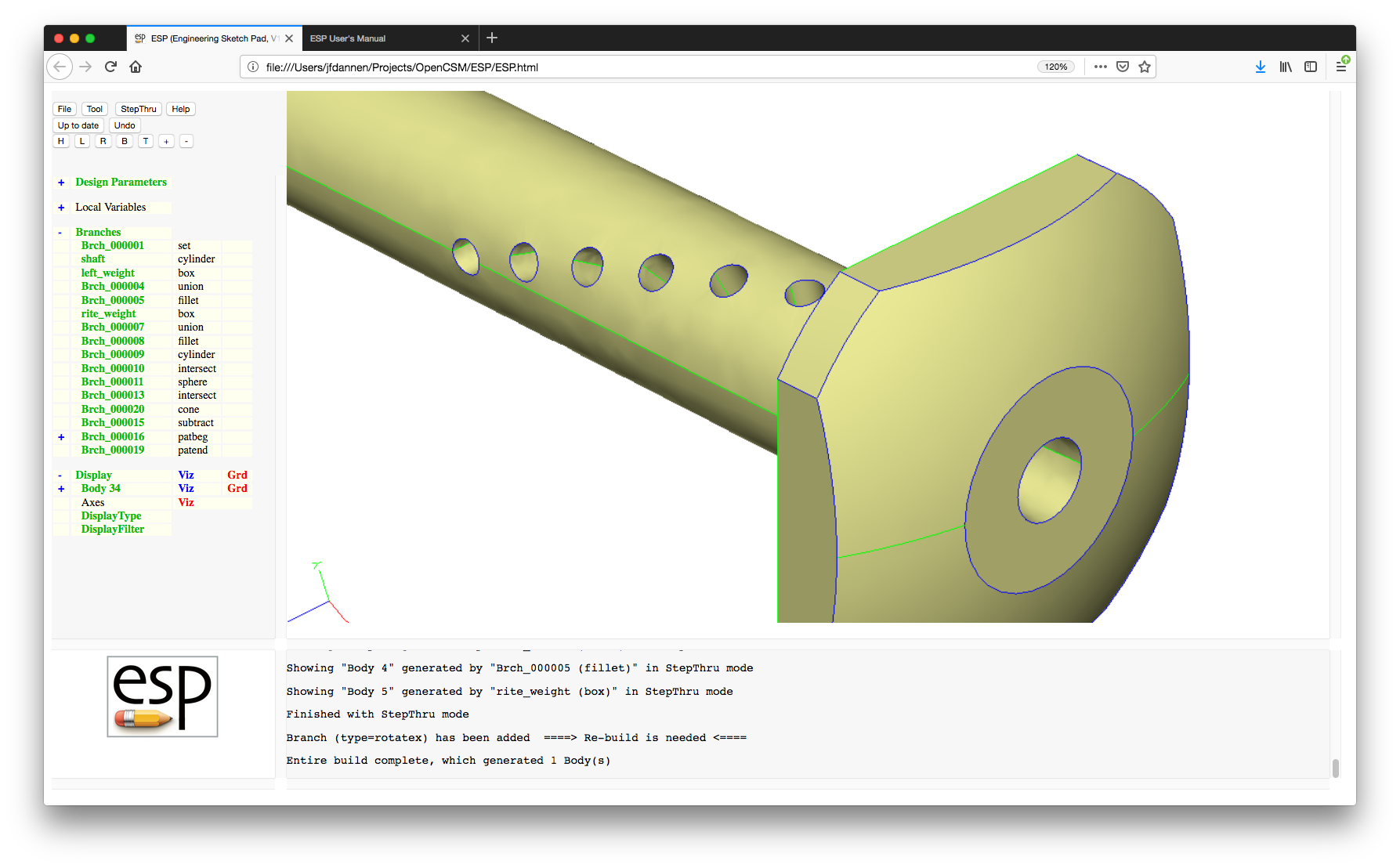

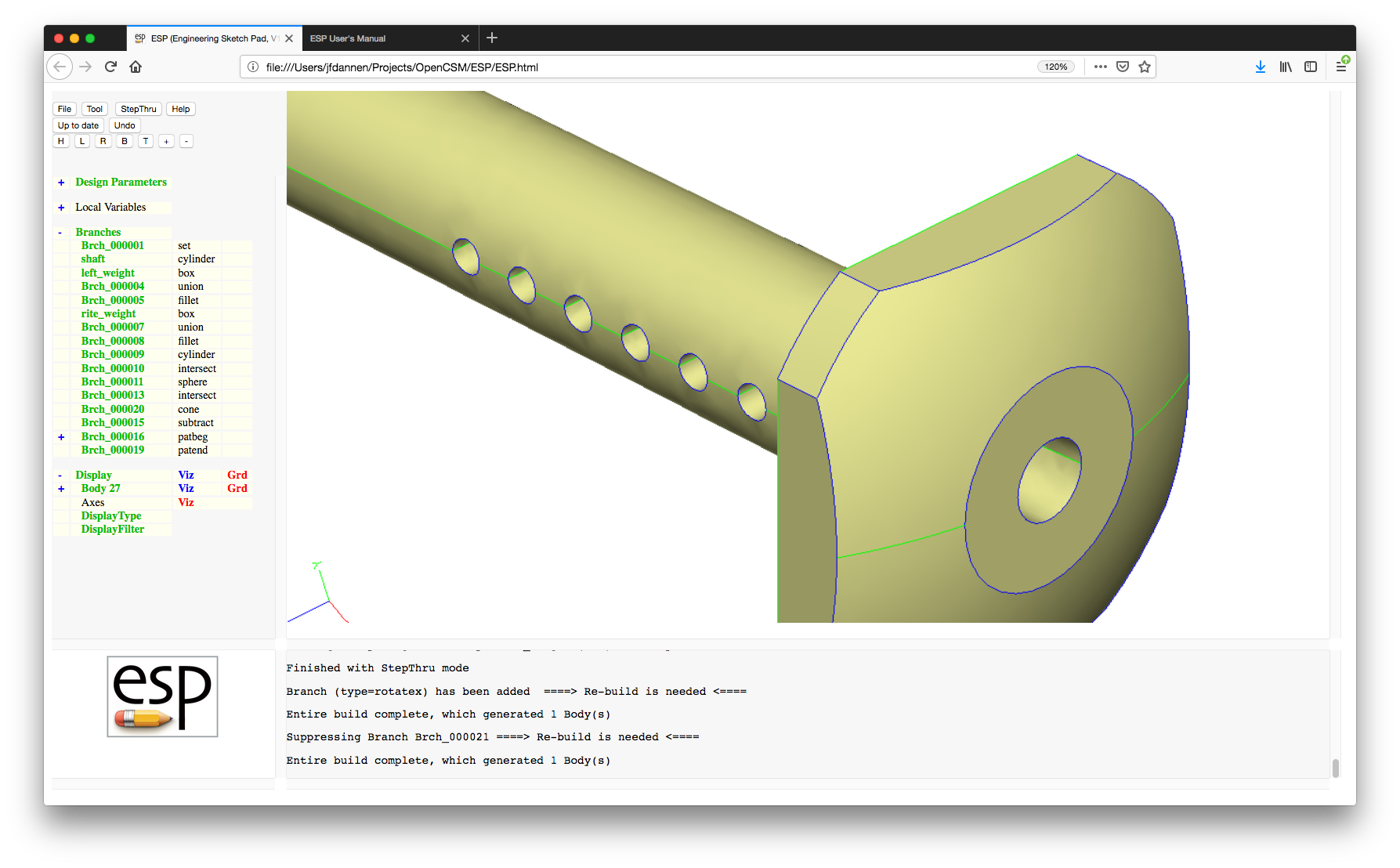

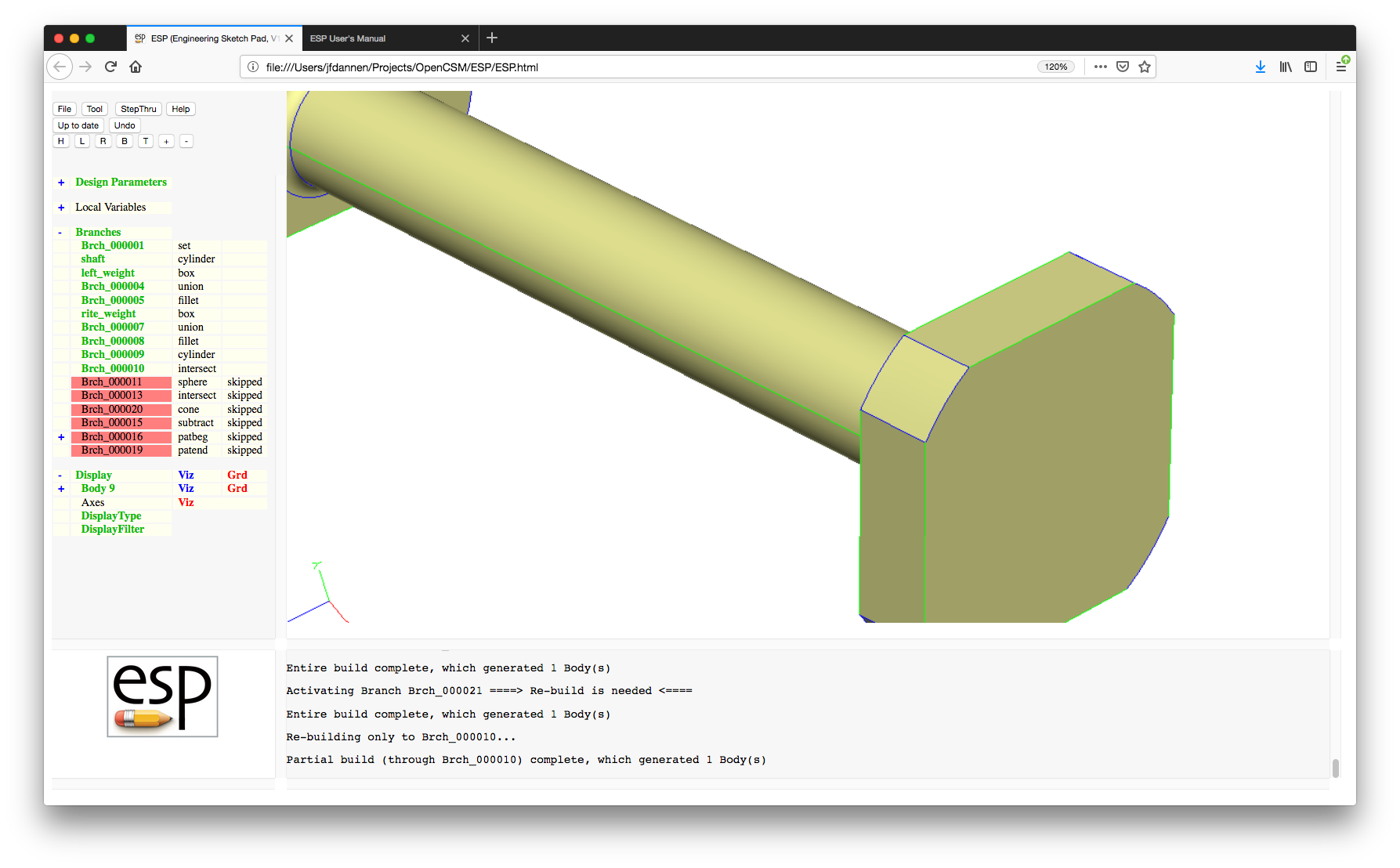

The StepThru button allows you to view the steps used to build a model. When you first press this button, the first Body created during the construction process is shown. The legend on the button changes to NextStep, which then gives you the option of seeing the next step in the build. This button can be pressed repeatedly to see the whole build process. If you want to leave StepThru mode, simply press CancelStepThru at the bottom of the TreeWindow. Also while in StepThru mode, you can use the following key-presses in the GraphicsWindow:

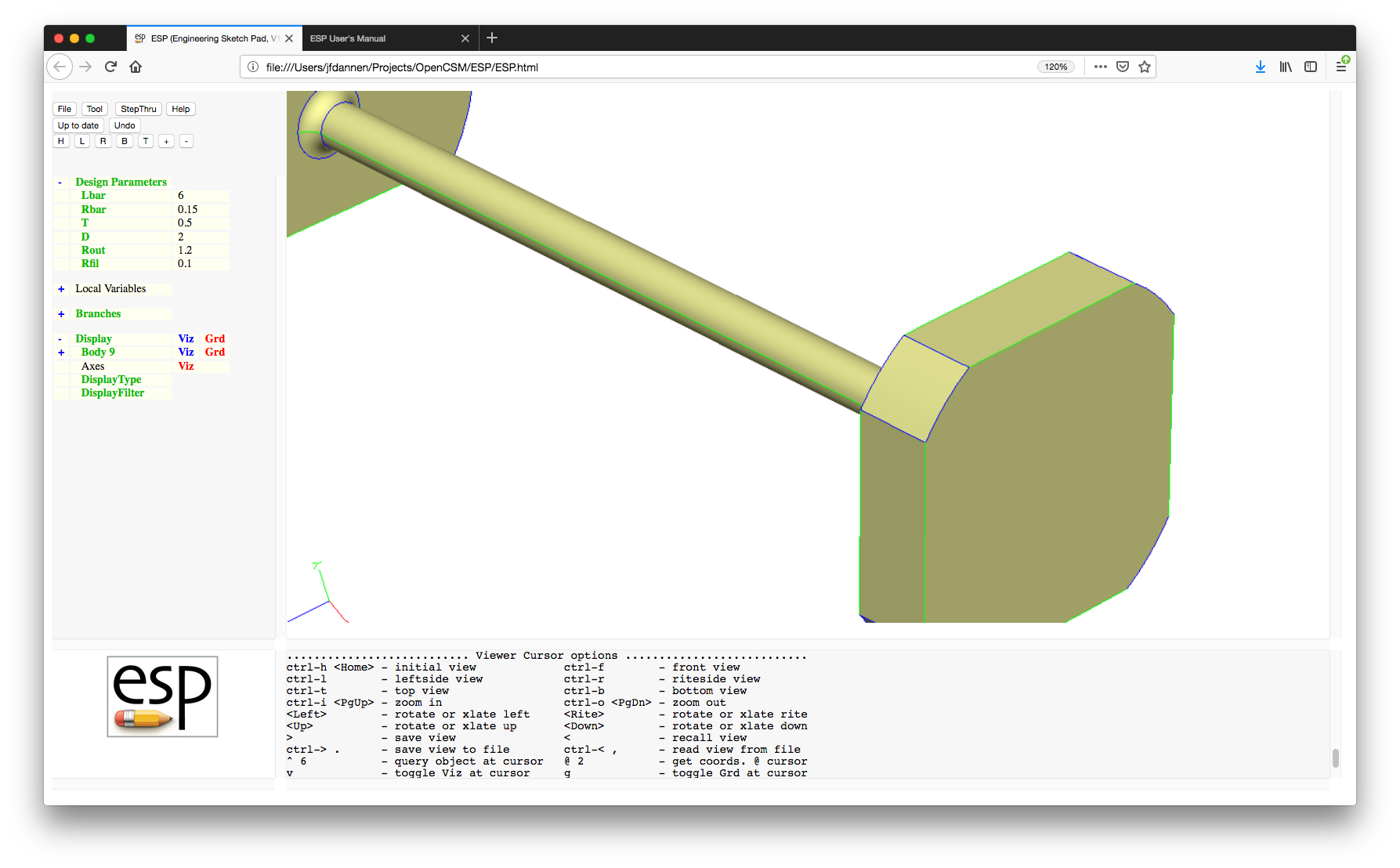

The Help button bring up the help document (which you are currently reading).

The second row of button contains two (or three) buttons.

The first button can have a variety of labels:

The second button in the second row, Undo, allows you to un-do the last change that you made using the GUI. Note that not all actions can be un-done.

The third button in the second row may, or may not, be visible. (In this Tutorial, it is not visible.) It is used when there is more than one user connected to the same hostname and port at the same time. In this case, the button will be visible with the legend Collab. The color of the button give you information about your collaboration status:

ESP feature.

The third row of buttons allows you to set the home, left, right, bottom, or top view and allow you to zoom in and out. These were described above.

Now it is time to start looking at the tree itself. At the top level of the tree are four groups:

If you click the + to the left of "Design Parameters", a list of the current DesignParameters is shown as well as the name of all DesignParameter groups (described later). The groups can have sub-groups, etc, so sometimes it is convenient to see everything at once. This can be done by pressing ExpandAll to the right of "Design Parameters". (When you have done this, the legend will change to CollapseAll which will have the opposite effect.

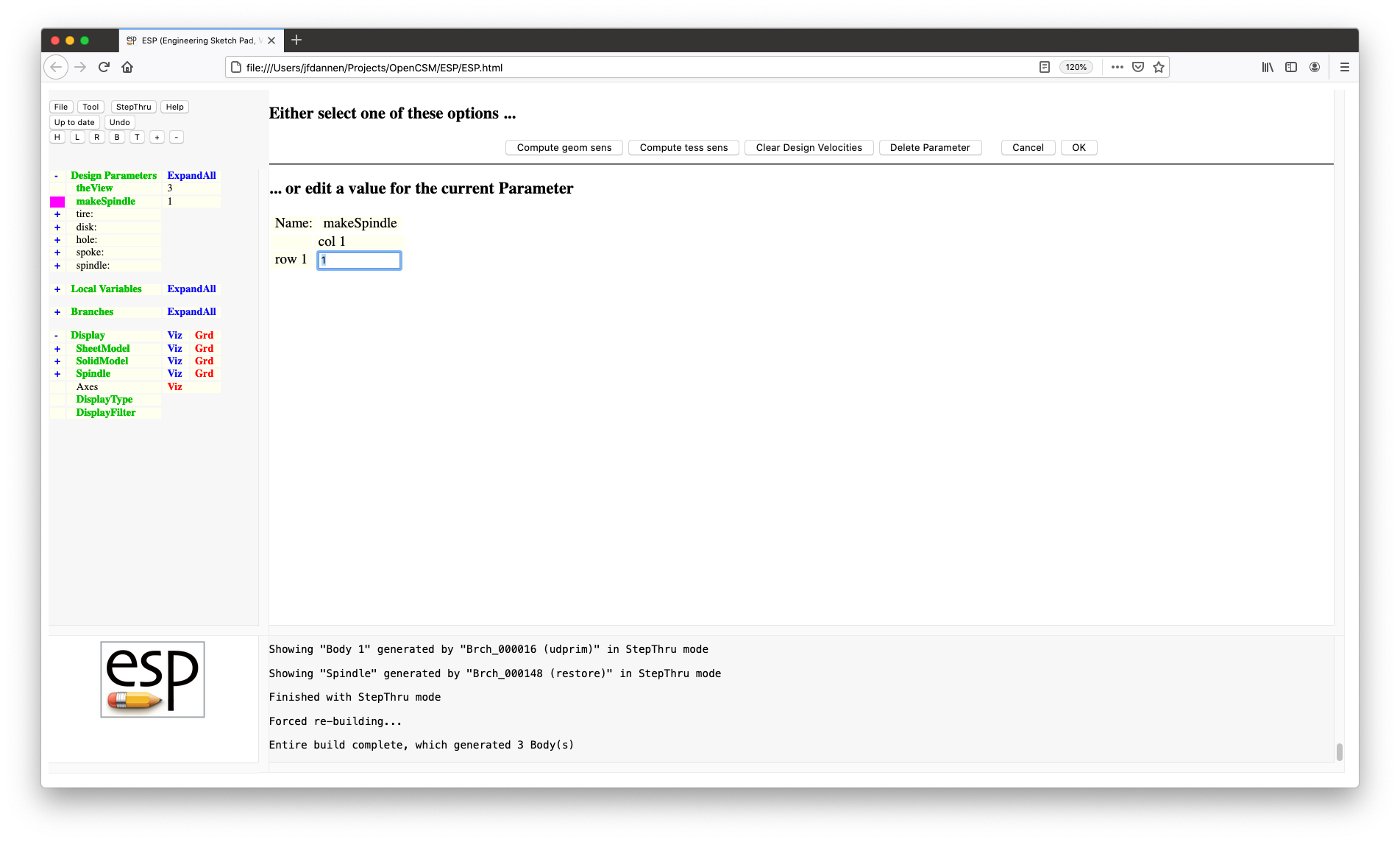

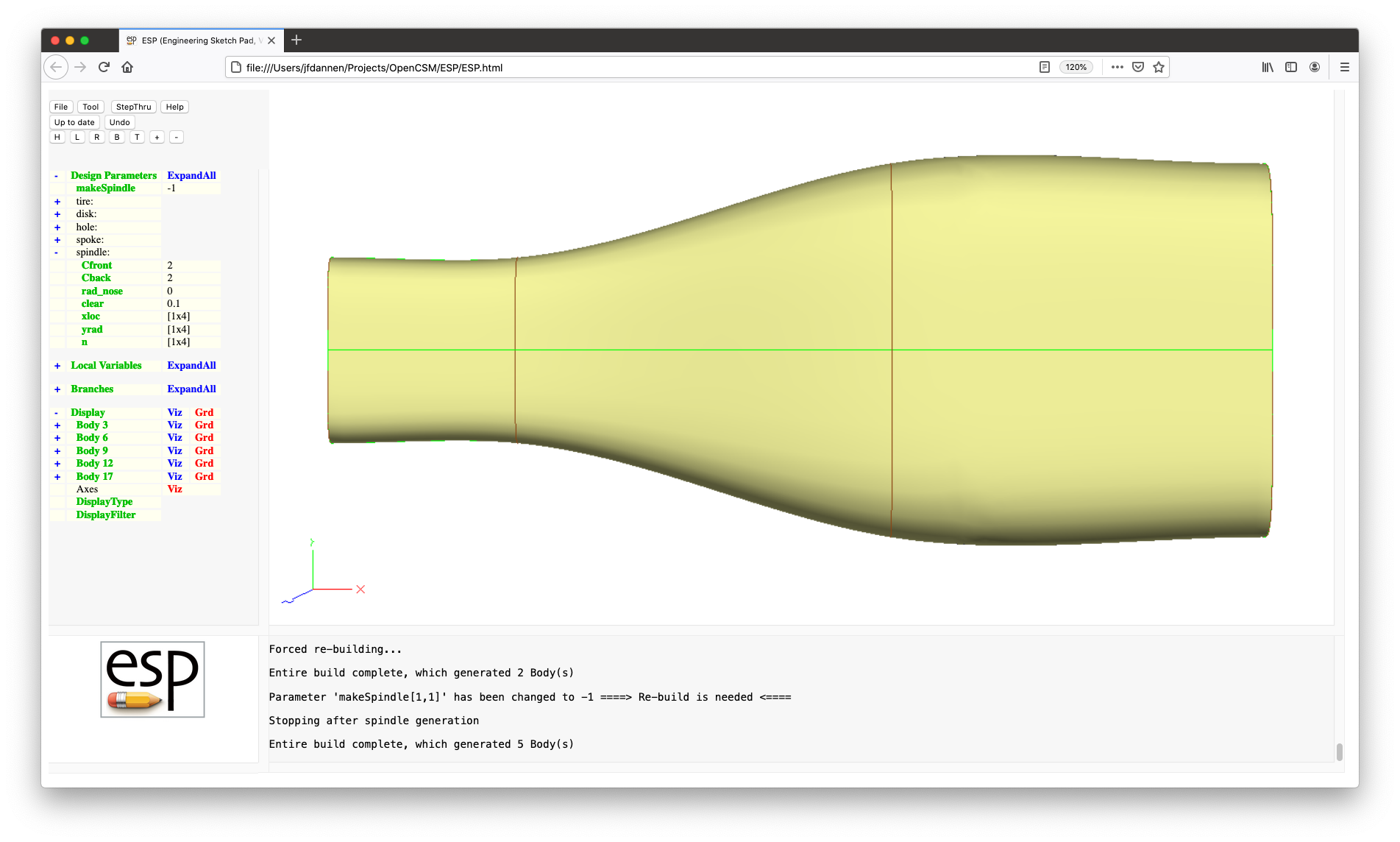

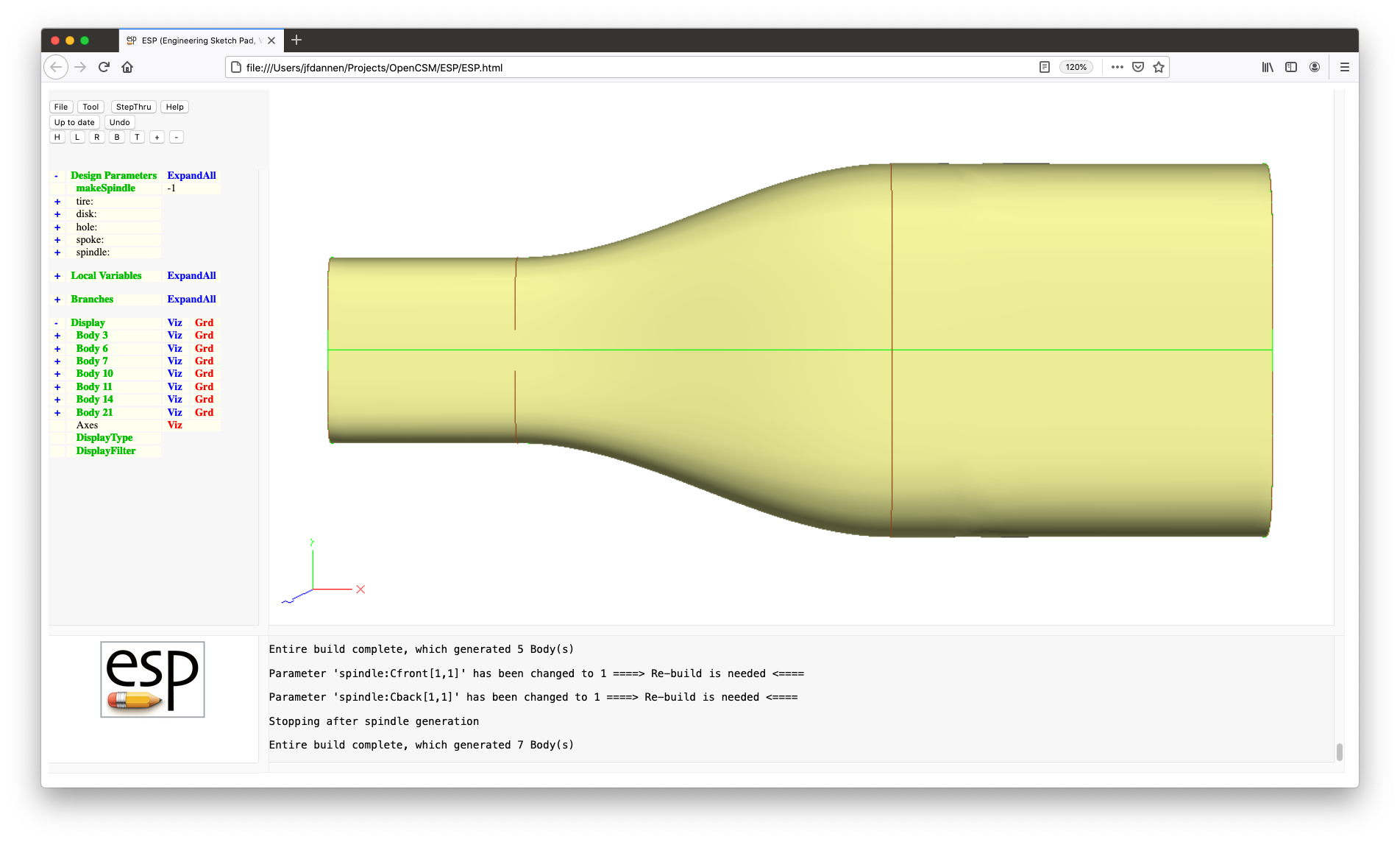

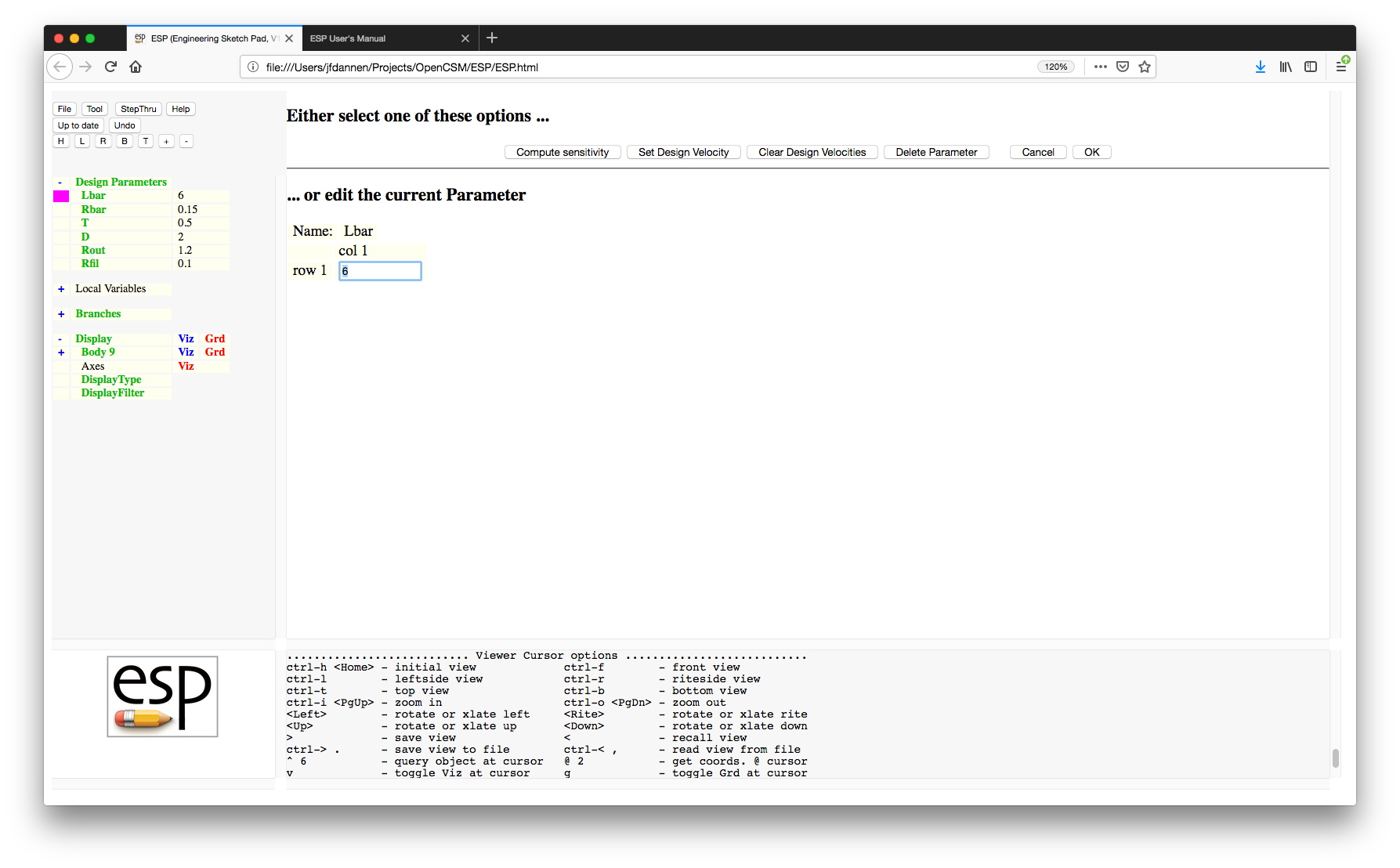

Now let us start looking at what happens when we change a DesignParameter. We are going to start by pressing makeSpindle (which, as you will see in Tutorial 4 allows us to make the spindle in various ways.) When you have done this, the GraphicsWindow will change to a form that gives you all the information associated with this DesignParameter.

Across the top of the form is a series of buttons:

Another thing you may notice is that the first column in the DesignParameter tree is changed to magenta for the DesignParameter that is being edited. Also, for any Branch that uses the DesignParameter, the first column in the Branches tree has a yellow background. You may have to press ExpandAll to the right of "Branches" to see the Branches ("Brch_000005" and "Brch_000039") that use "makeSpindle".

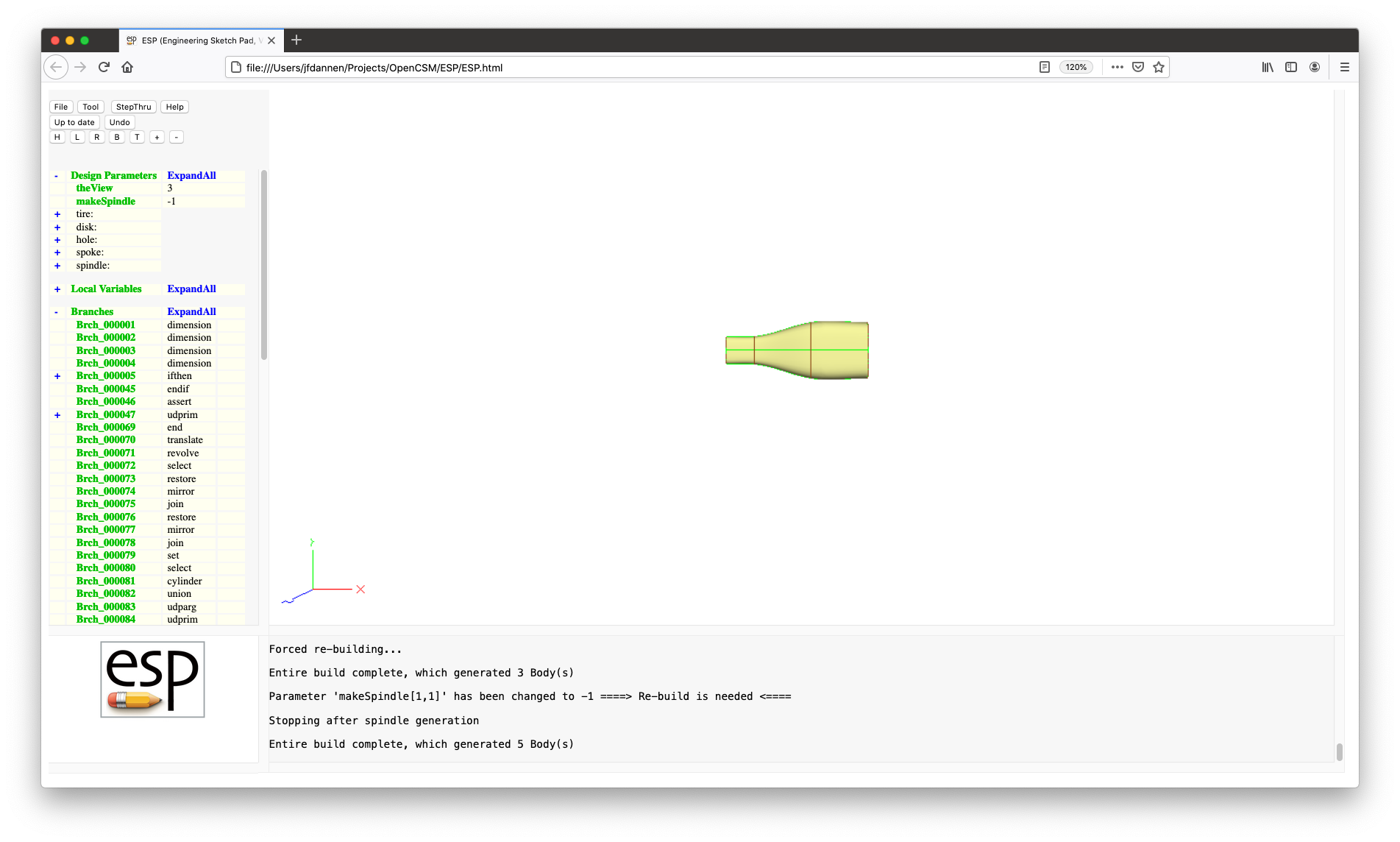

For now, change the value of makeSpindle

from 1 to -1", press

the <Enter> key or the OK button. Now

press Press to Re-build and you will see your new

configuration (which will only consist of the spindle).

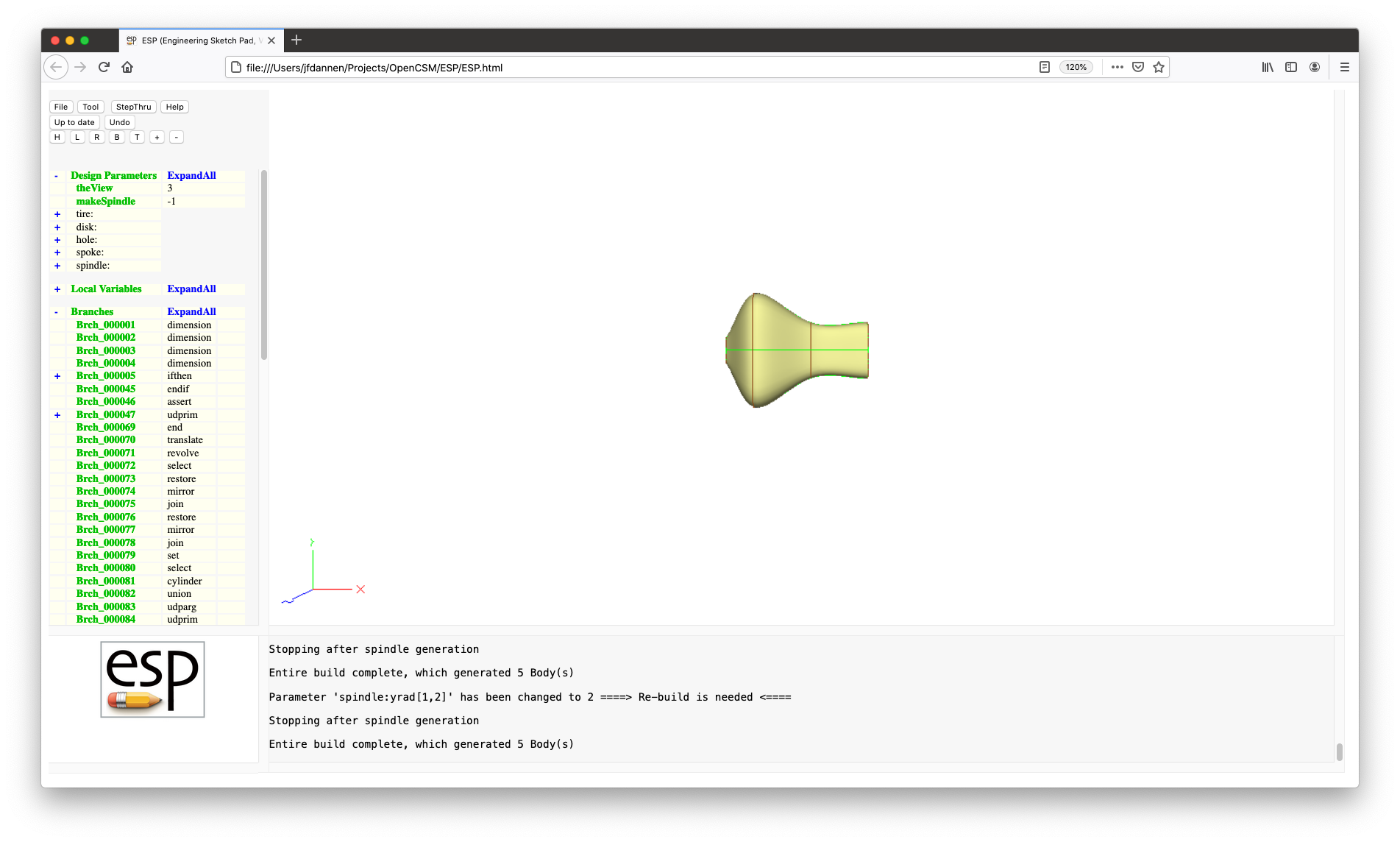

Now press the + under "Design Parameters" and to the

left of "spindle:" in the TreeWindow, and then

press yrad; this will open up a form that allows you

to edit the multi-valued DesignParameter. As you will see

later when we build the model, "yrad" has four values. For

now, change the value in "row 1" and "column 2"

to 2, hit Enter and Press to

Re-build. You should see that the configuration has now

changed (to make the second radius much larger).

Change the value back to 0.5 and re-build.

You can also press Delete Parameter to delete a DesignParameter from the model. Be aware that doing will break the model build process if the model refers to it in any of its Branches. So we will not delete any DesignParameters in this Tutorial.

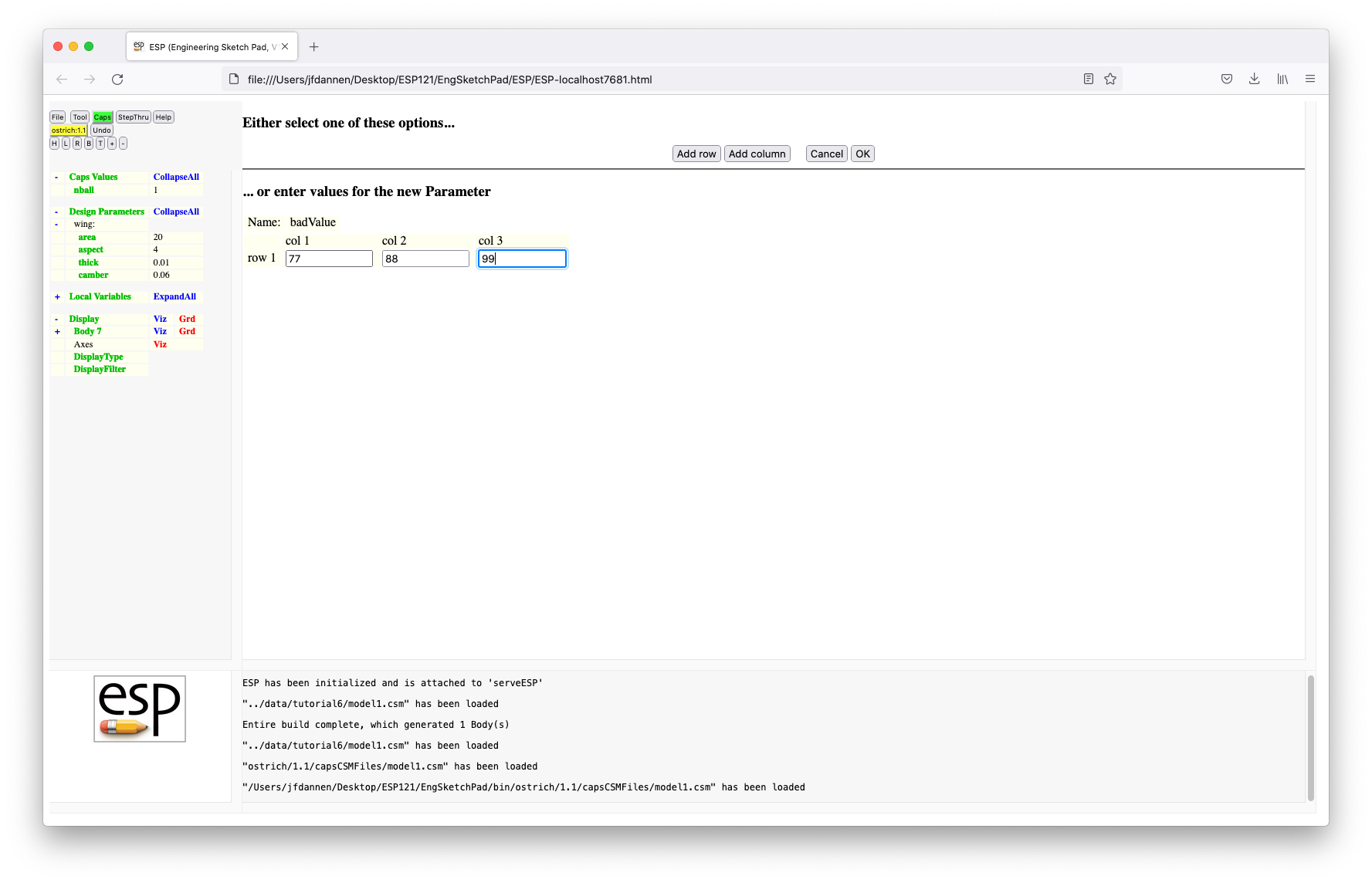

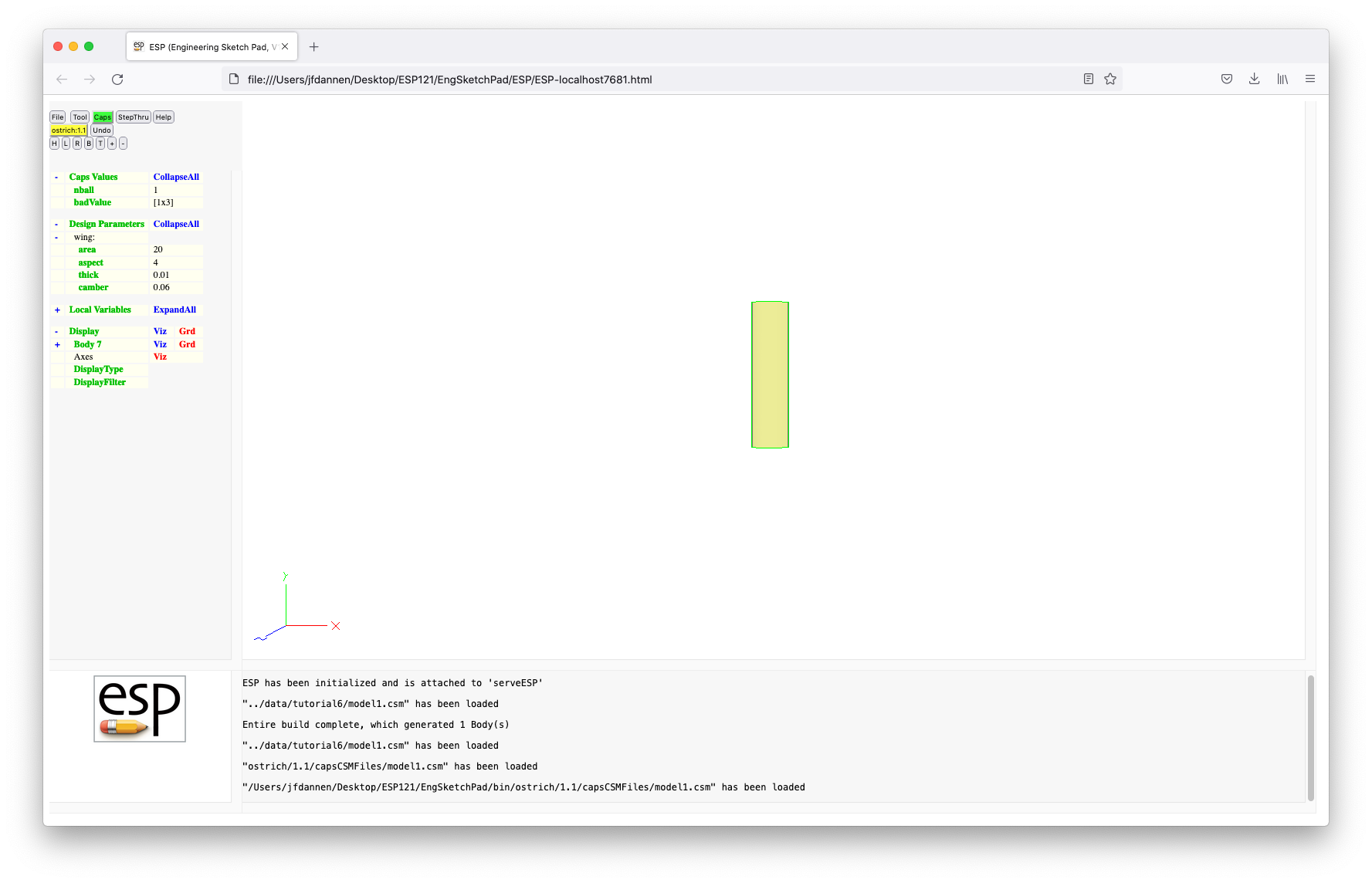

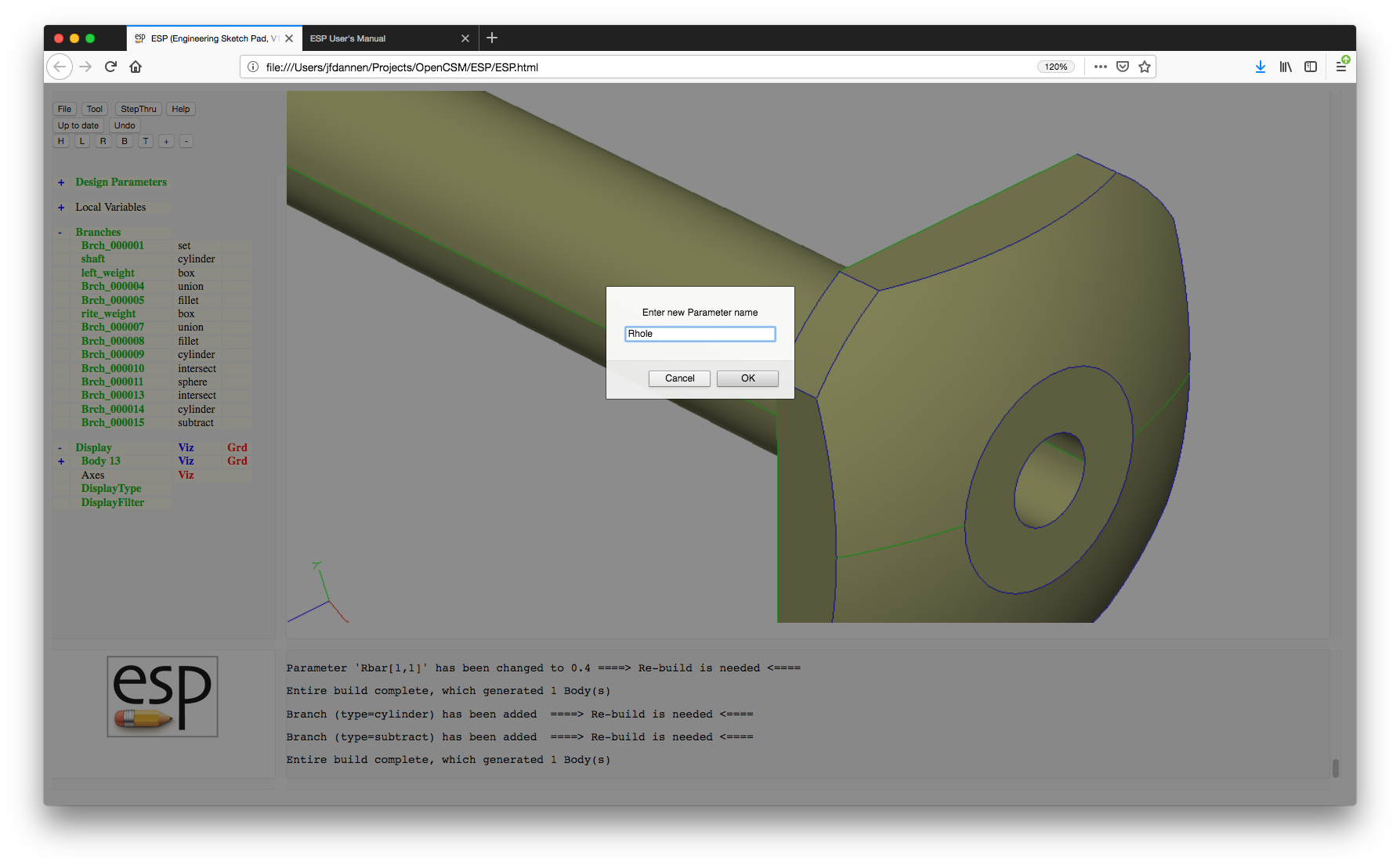

If you want to add a new DesignParameter, simply click on Design Parameters. You will be asked for the new parameter name (which must start with a letter, underscore, or colon, and be followed by up to 63 letters, digits, underscores, and colons). You will then get a form that looks like the one we have been using, except for the fact that it will contain two buttons near the top (in addition to OK and Cancel):

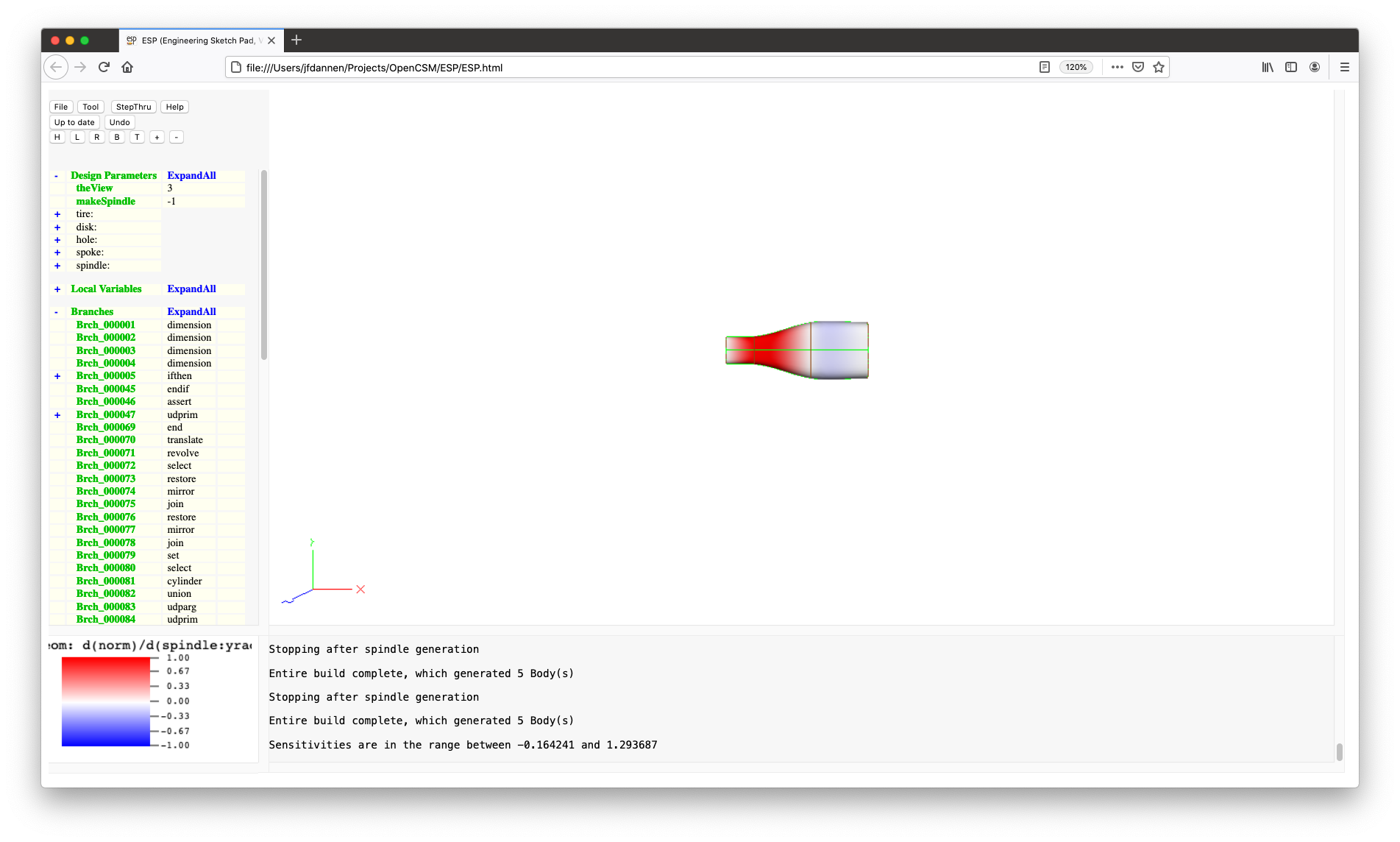

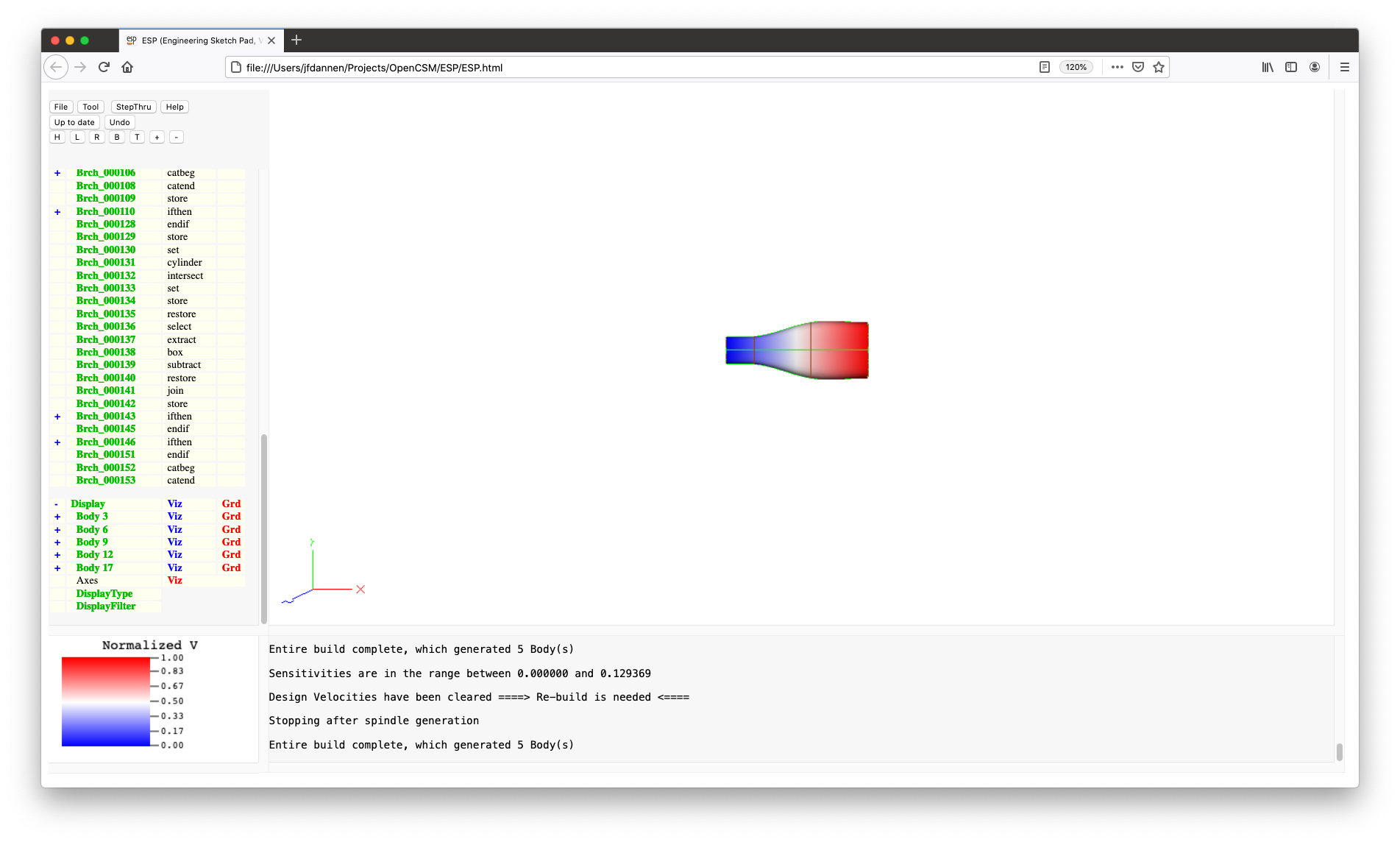

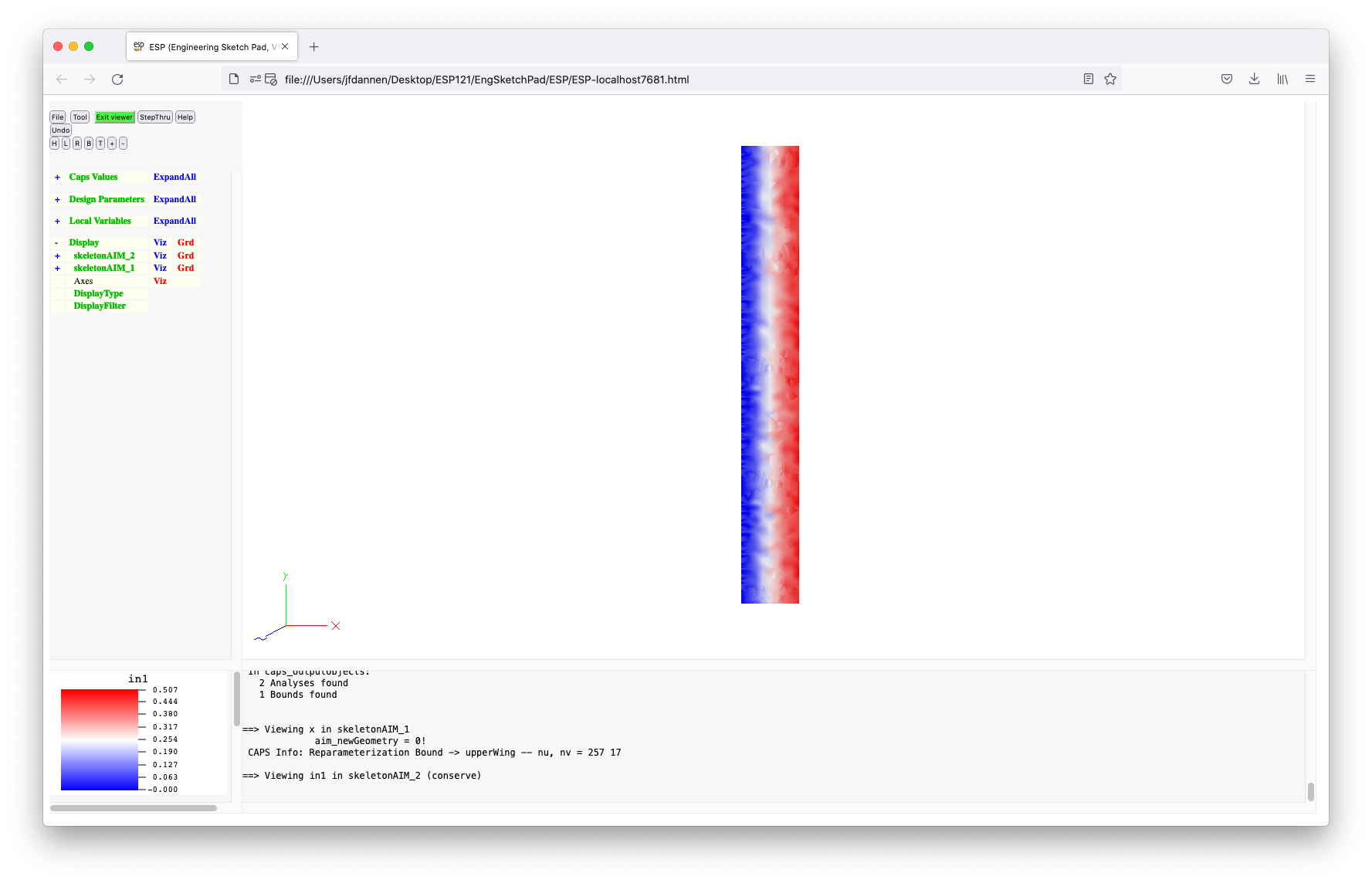

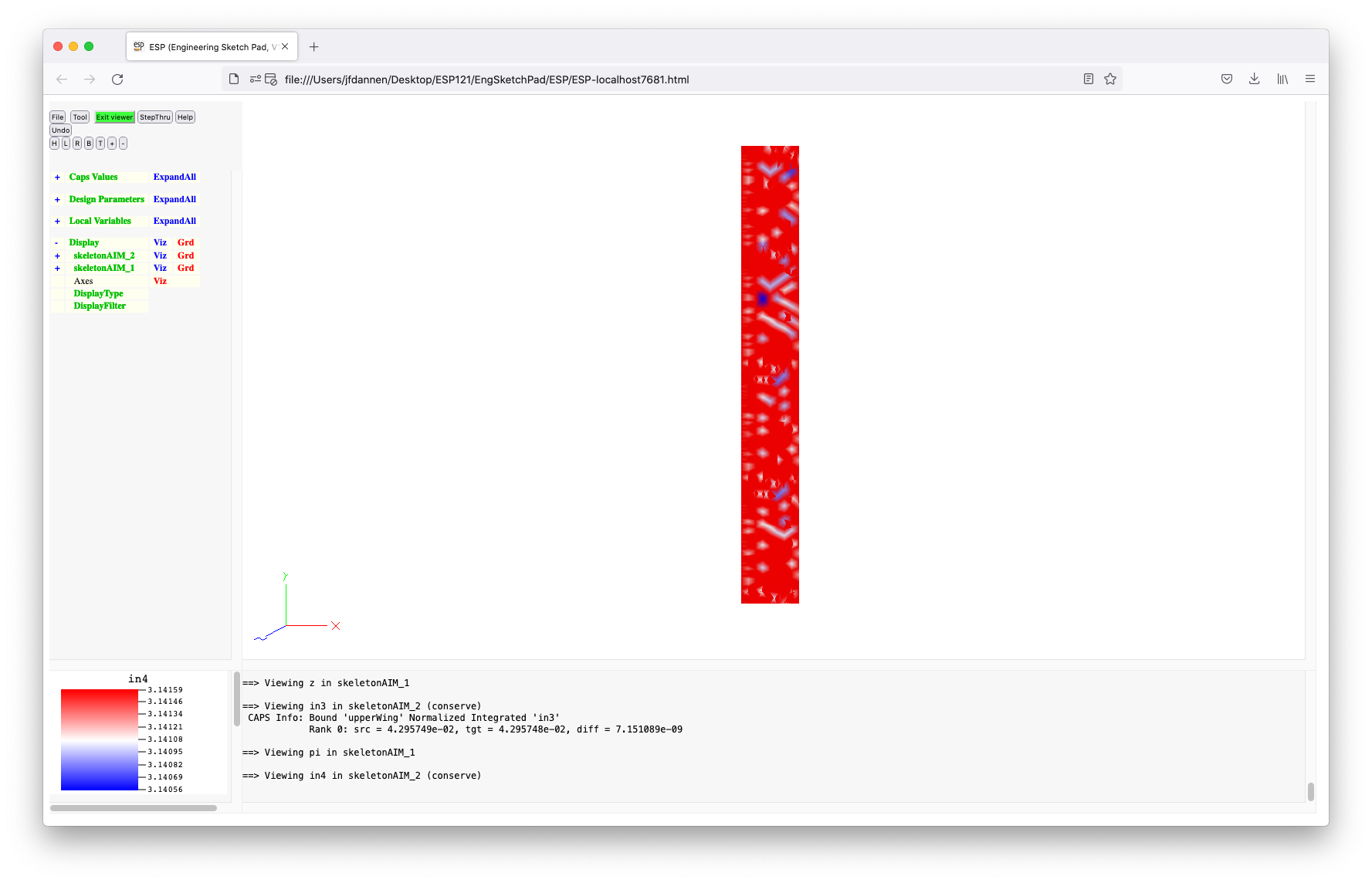

Now let us see how the sensitivities work. If you once again

edit the "spindle:yrad" DesignParameter, you will see that

since "spindle:yrad" is a multi-valued DesignParameter you

get a new row of entry boxes (near the bottom) in which to

enter the design velocities. So if you wanted to compute the

sensitivity of the geometry with respect to (WRT) the second

"spindle"yrad" value, enter a 1 in "row 1" and

"column 2" in the velocities table and press Compute geom

sens. The GraphicsWindow will switch back to a view of

the 3D configuration, which will be colored based upon the

sensitivity value at each point. You will also see that the

KeyWindow changed to show you a spectrum associated with the

colors in the GraphicsWindow. (red indicates that the

surface will move outward and blue indicates that the surface

will move inward). Since part of the configuration is red,

you can see that the geometry will grow outward. Note that

the geometric sensitivity tells you how the local surface

normal will change; this is generally computed exactly

in ESP by actually differentiating the build

process.

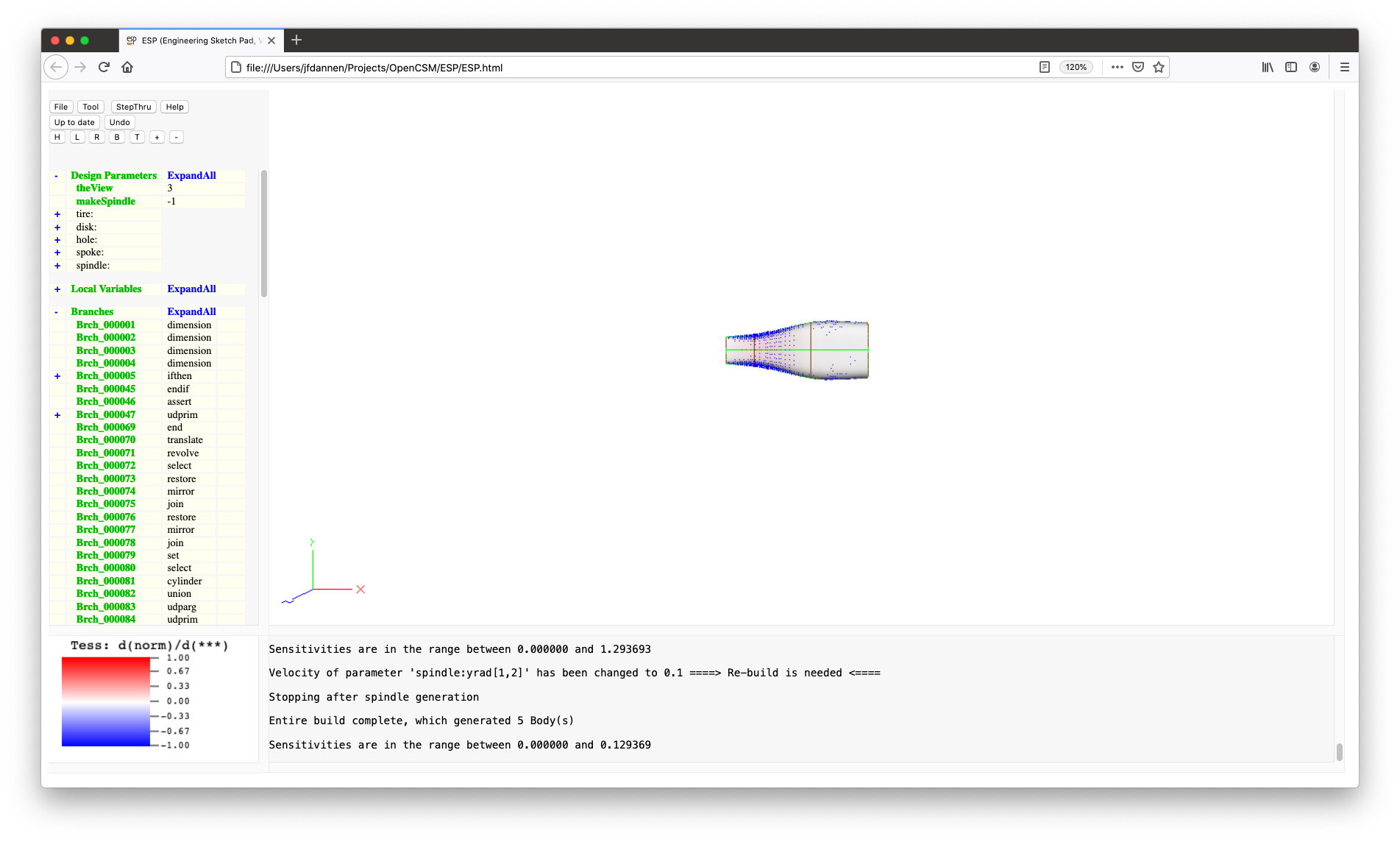

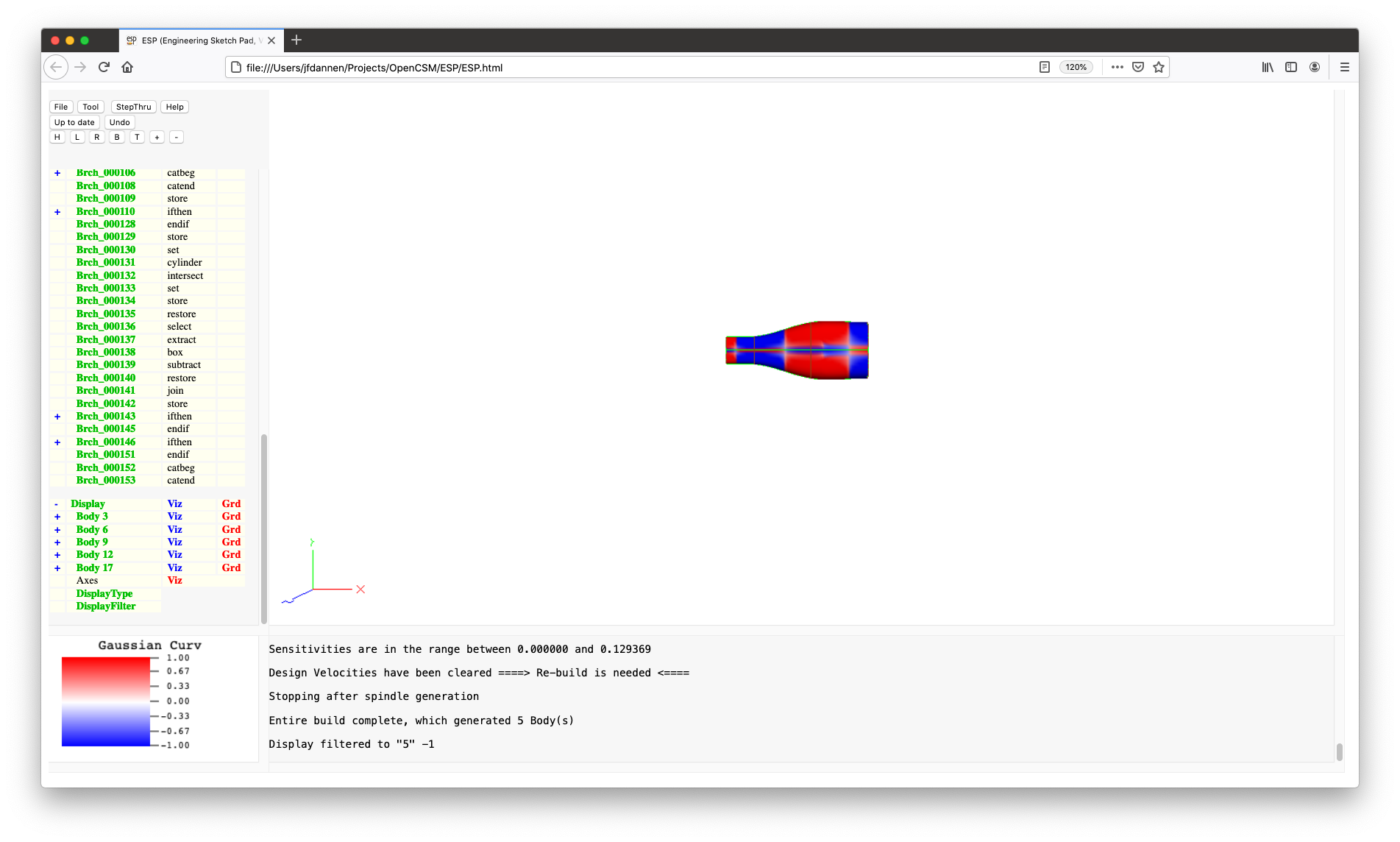

ESP has another sensitivity, namely the

tessellation sensitivity. This is an approximation of how

points will move if the DesignParameters changes. (It is only

an approximation, since we do not know how your particular

mesh generator will redistribute points on the surface when

the surface shape changes.) If you now re-edit "spindle:yrad"

and press Compute tess sens, you will get the surfaces

painted again and you will see little tufts showing the

sensitivity. If the tufts are too long, you could always

change the design velocity to a smaller value (such as 0.1)

and the spines will get shorter (which looks a lot better for

this case). By the way, blue spines are associated with

Faces, red spines are associated with Edges, and magenta

spines are associated with Nodes.

To return to a display without sensitivities, choose any DesignParameter, press Clear Design Velocities, then OK, and then Press to Re-build. Do this now.

A LocalVariable is a parameter that cannot be set before a

model is built (unlike DesignParameters, which get their

values before the model is built). Instead, it is created

and used during the build process. To understand the

difference, let us take an example. Suppose the you had a

DesignParameter called "diameter", but the operation that

creates a SPHERE takes the radius as one of its

arguments. There are a variety of ways of handling this

situation, but an obvious one is to create a LocalVariable

called "radius" and then using a SET statement

SET radius diameter/2

to set the radius to half the diameter. Clearly the "radius"

depends on the "diameter", so it cannot be directly set

outside the build process.

There are two special kinds of LocalVariables:

ESP (for example,

in CAPS). You can see the current value

(and velocity) of all OutputParameters by pressing the

word Local Variables in the TreeWindow; and@volume, which contains

the volume of the Body just built. To see all the

AtParameters, press the + to the left of

"@-parameters" for a full list; the meanings of these

are described in the Parameter

rules section in the latter

part of the help file.ExpandAll works exactly the same as it does for the DesignParameters.

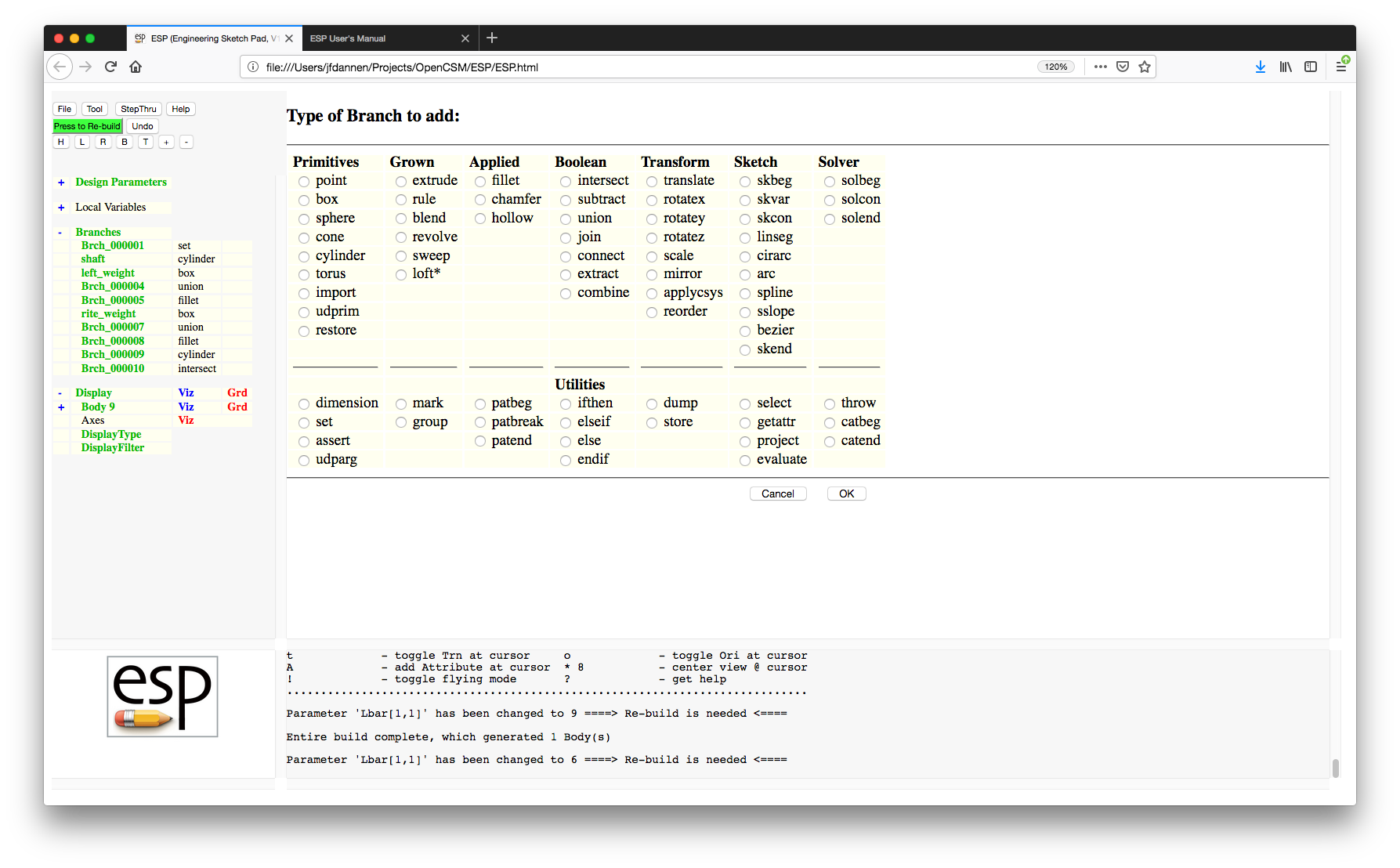

In ESP, a model is built by executing the

Branches in the FeatureTree. There are several kinds of

Branches in ESP:

BOX, CYLINDER,

SPHERE, CONE,

and TORUS) based upon its arguments;UNION, INTERSECT,

and SUBTRACT Boolean operators);TRANSLATE, SCALE,

ROTATE*, and MIRROR);IFTHEN/ELSEIF/ELSE/ENDIF logic blocks and

loops with PATBEG/PATEND); andSET

LocalVariables, etc..A new Branch can be created (at the end of the FeatureTree) by pressing the word Branches in the TreeWindow.

ExpandAll works exactly the same as it does for the DesignParameters and LocalVariables. Do that now.

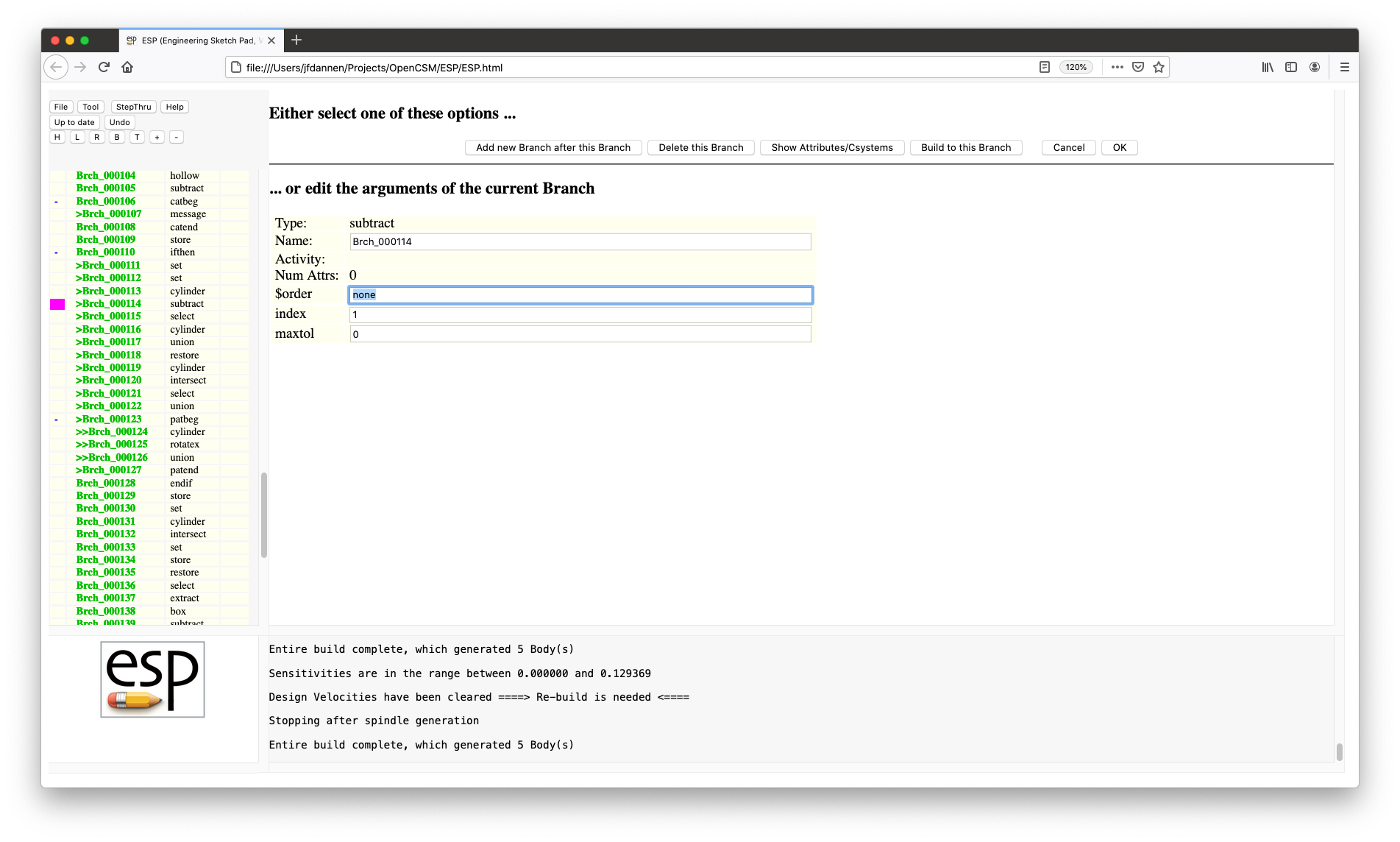

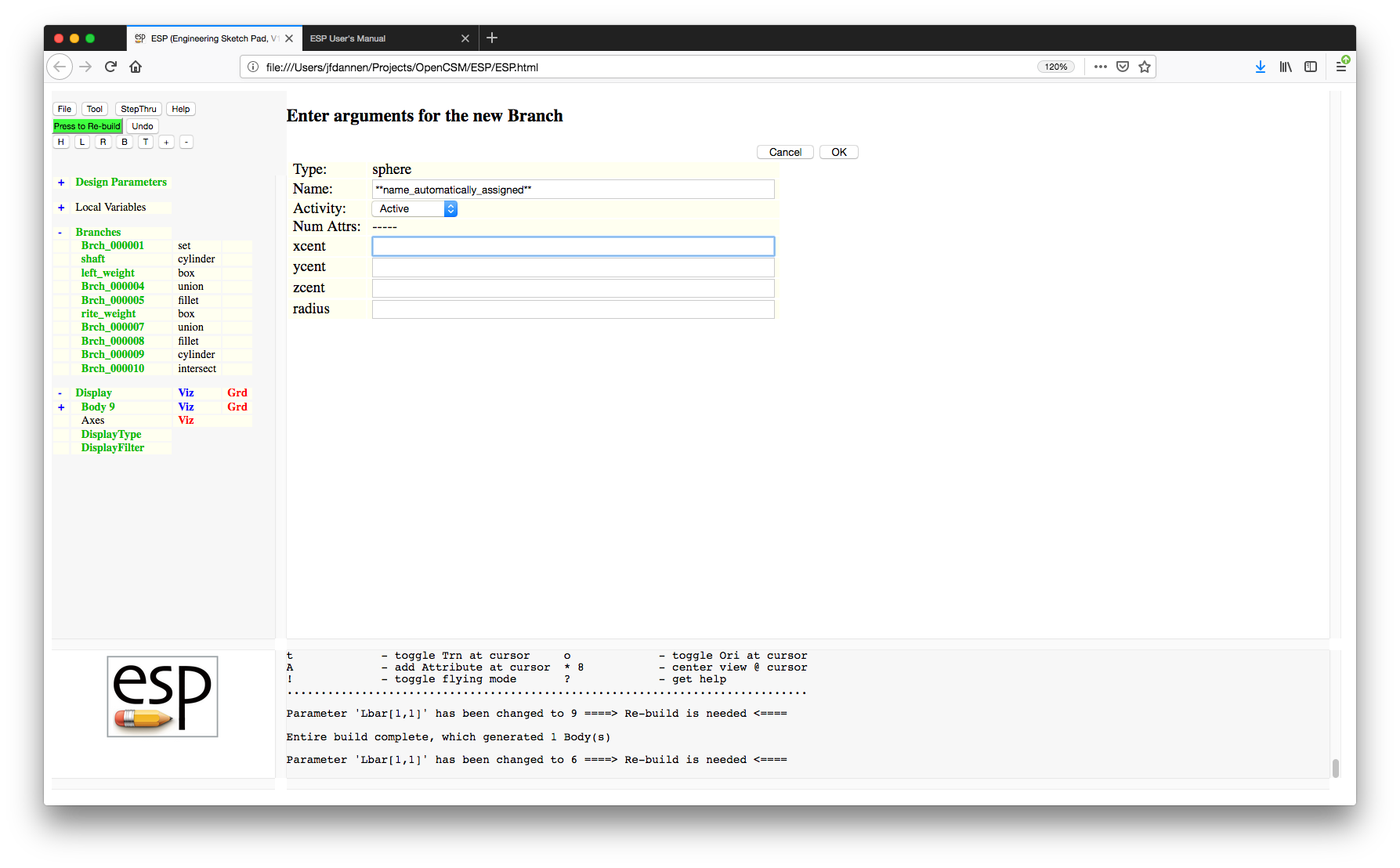

One can inspect, edit, or delete a Branch by pressing on the name of the Branch, which typically has a name such as "Brch_xxxxxx".

Now click on Brch_000114 and the Branch editor will appear.

At the top of the Branch editor you will see a series of buttons:

Below the button are the properties and arguments associated with the Branch. If you edit these, remember to press OK and then Press to Re-build to see the effect of the edits.

If you choose "Brch_000114", you will see that the first column is colored magenta. None of the other entries in the first column are colored, which either means that:

To get around this, change the DesignParameter "makeSpindle"

to o and Press to Re-build. Once you've

done this and re-edit "Brch_000114", the first column in the

Branches tree in the TreeWindow is colored as follows:

UNIONed (in this case "Brch_000101"

and "Brch_000113"); andUNION in "Brch_000117"),Current ESP best practice does not rely much on

editing the Branches using these features; these features are

typically used for "quick explorations" as you will see in

the Tutorials that follow.

For now, Cancel out of the Branch editor.

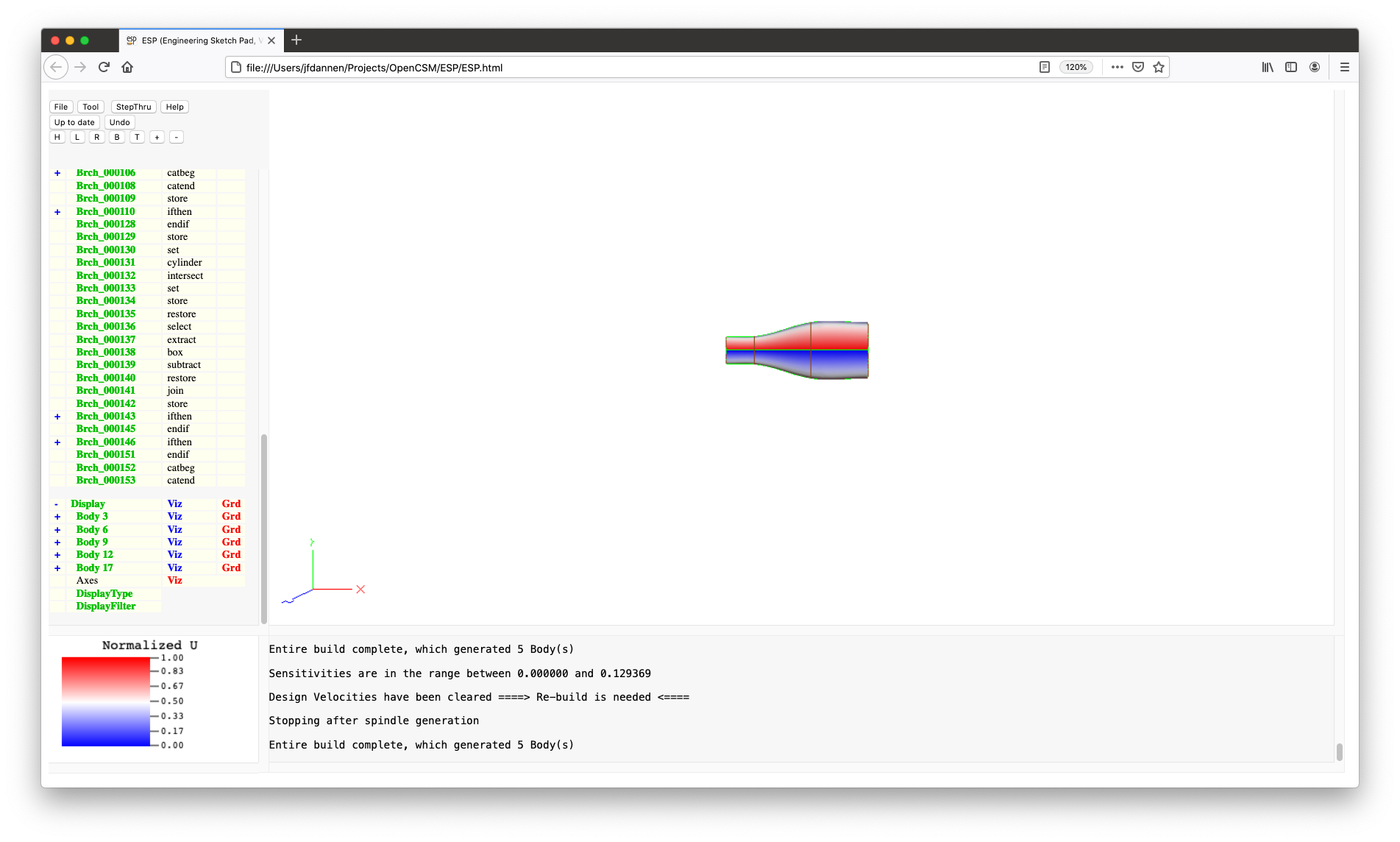

ESP can display the 3D configuration with

various coloring schemes. You can choose amongst them by

clicking on DisplayType:

0 to 1;0 to 1;0 and the

UpperLimit to 1 (or somthing smaller if the

tufts are too long); andWhen using any of the modes except monochrome or Erep, you will see that the KeyWindow shows you a title and a little spectrum to let you know what the various colors mean. If you click in the KeyWindow (when a spectrum is showing), you can change the values associated with the lower limit (blue) and the upper limit (red). When viewing normals, the lower KeyWindow limit will usually be zero and the upper limit can be used to adjust the lengths of the tufts. Trying these on the spindle gives you pictures like this.

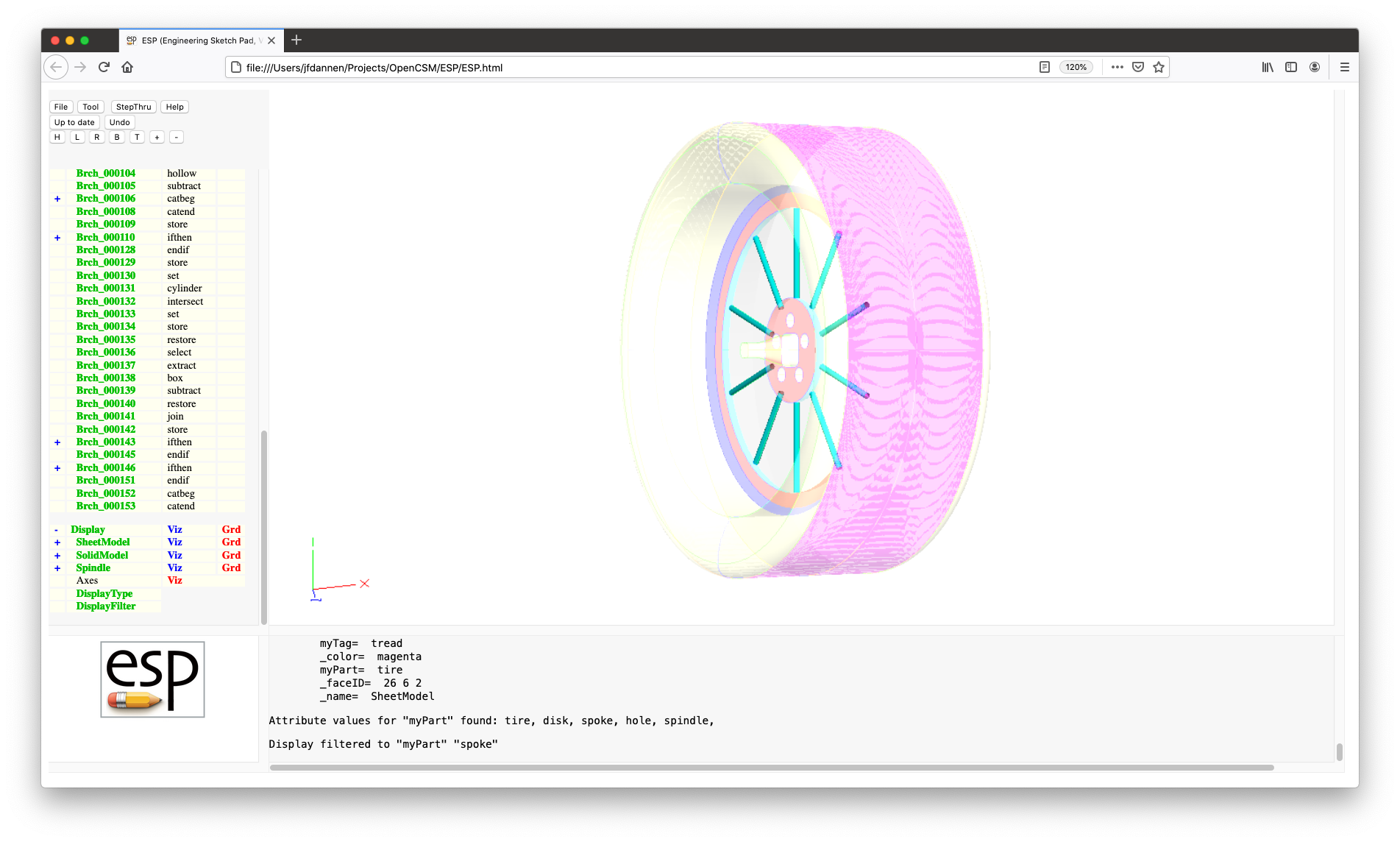

For the next part of the Tutorial it is probably best to focus on the SolidBody. So, do the following:

1;

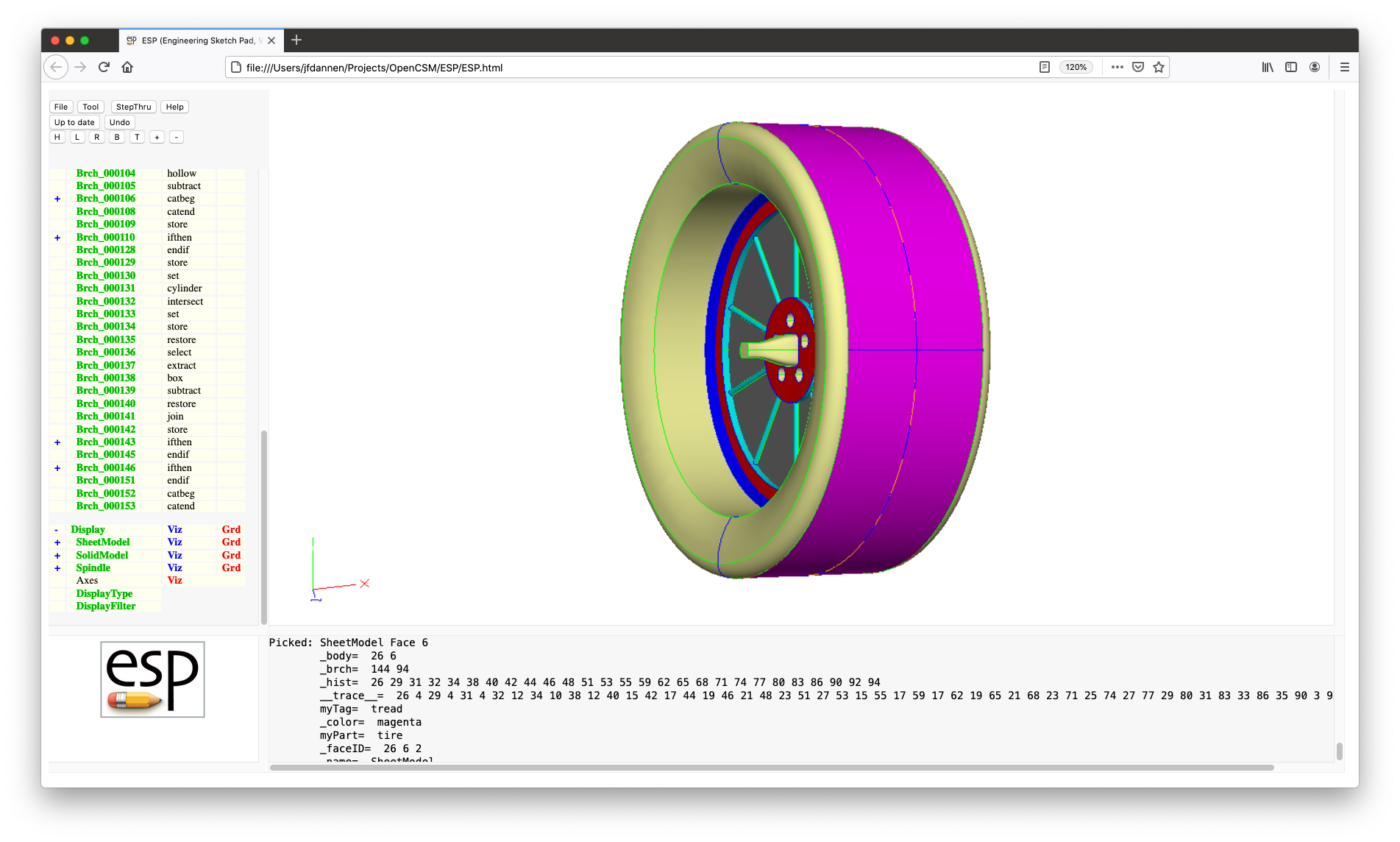

This model was constructed so that all of the Faces have an Attribute named "myPart" on it. To see this for yourself, put your cursor on any Face and press the ^ key; a description of the Face and all of its Attributes are displayed in the MessageWindow, such as:

Click on DisplayFilter and enter myPart

in the popup window. In order to see what the available

values for the "myPart" Attribute are for this model,

enter ? in the new popup; in a

popup, ESP tells you that the valid names are

"tire", "disk", "spoke", "hole", and "spindle".

Enter spoke and the Faces with that Attribute

are shown as usual, while all other Faces are shown

transparently, as in

Try changing the DisplayFilter

to myPart, hole to see the Faces

associated with the holes. You can turn the DisplayFilter

off by simply pressing Enter in one of the popups.

Starting either the Attribute name or value

with ~ (tilde) negates the specification. For

example:

myTag * shows all entities with

a myTag Attribute;~myTag * shows all entities without

a myTag Attribute;myTag tread shows all entities with

a myTag Attribute that is

tread; andmyTag ~tread shows all entities with

a myTag Attribute that is not

tread.As models get large, it is sometimes difficult to determine

what is going on. To aid in this, there are two buttons in

the .csm editor that can assist you. To

demonstrate these, choose File and then Edit:

../data/tutorial1.csm to open the editor. Ignore the

warning that there wil be some lost changes. Scroll down

to line 153 (which is a JOIN statement) and

press the Debug button. In the MessageWindow, you

will see:

Body 32 (join @ [[../data/tutorial1.csm:153]])

uses: Body 29 (join @ [[../data/tutorial1.csm:149]])

uses: Body 31 (mirror @ [[../data/tutorial1.csm:152]])

used by: Body 34 (union @ [[../data/tutorial1.csm:167]])

which says that the JOIN statement creates Body

32 by JOINing Bodys 29 and 31. The result of

the JOIN is subsequently used in

the UNION operation on line 167. If you

double-click on any of the double-bracketed text, the editor

will automatically jump to that line (in the proper file).

If you move to line 156 (the SET statement) and

press the Debug button, you will get a list of all the

Bodys that were created, and where they were created. (The

asterisk at the beginning of a line indicates that the Body is

on the stack.)

The other useful feature is the Trace button, which

shows you everywhere a top-level Parameter is defined and

used. Press the Trace button now, enter 1

to choose Parameters and

enter spindle:* to see all the top-level

Parameters that have the prefix spindle:. Again,

you can press on any of the double-bracketed text to jump to

the associated line in the associated file.

Closing your browser will close the interactive session

and wil also terminate the ESP server.

Now that you have finished your tour of the ESP

interface, proceed on to Tutorial 2 to start building up this

configuration from scratch.

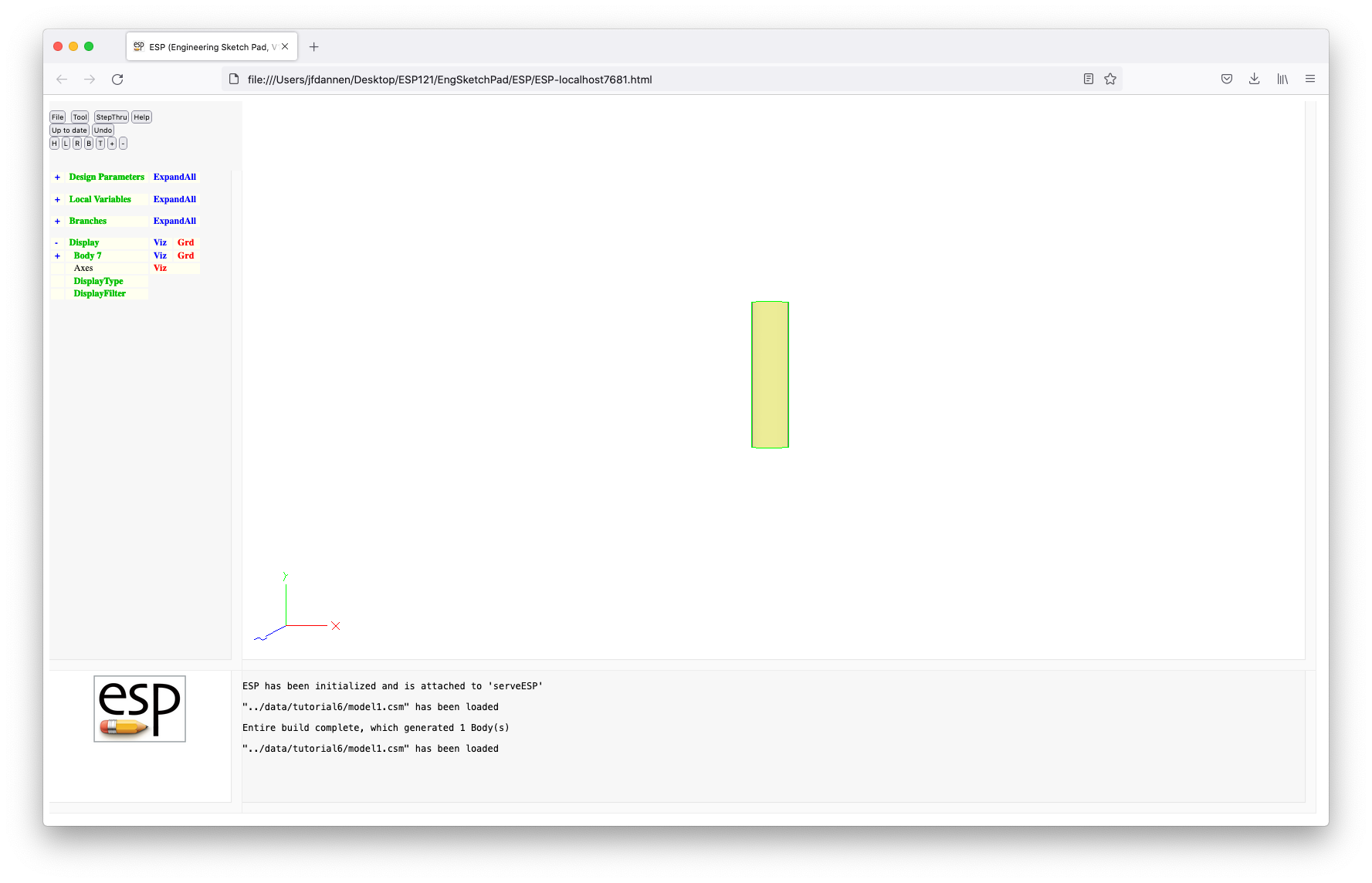

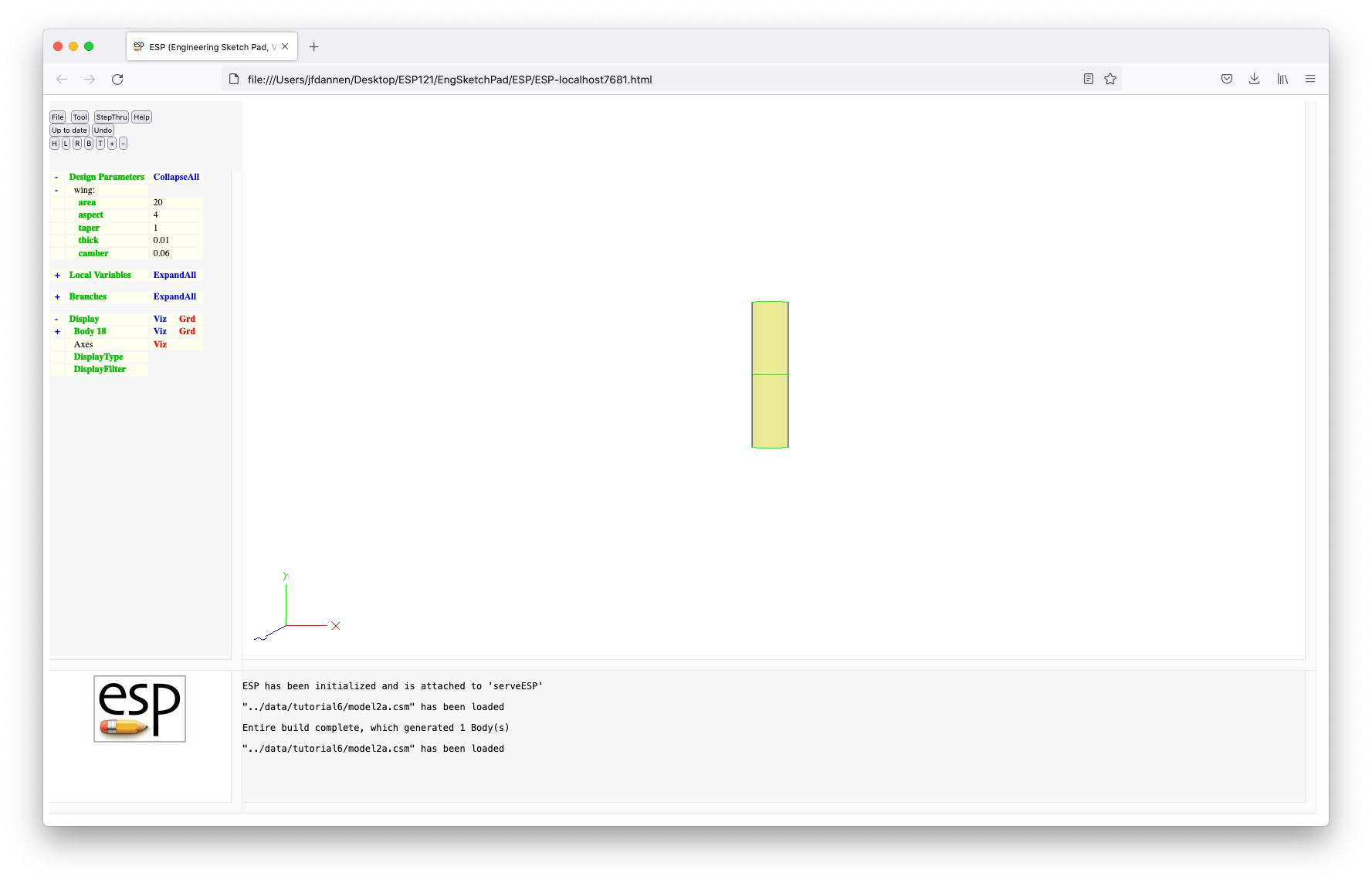

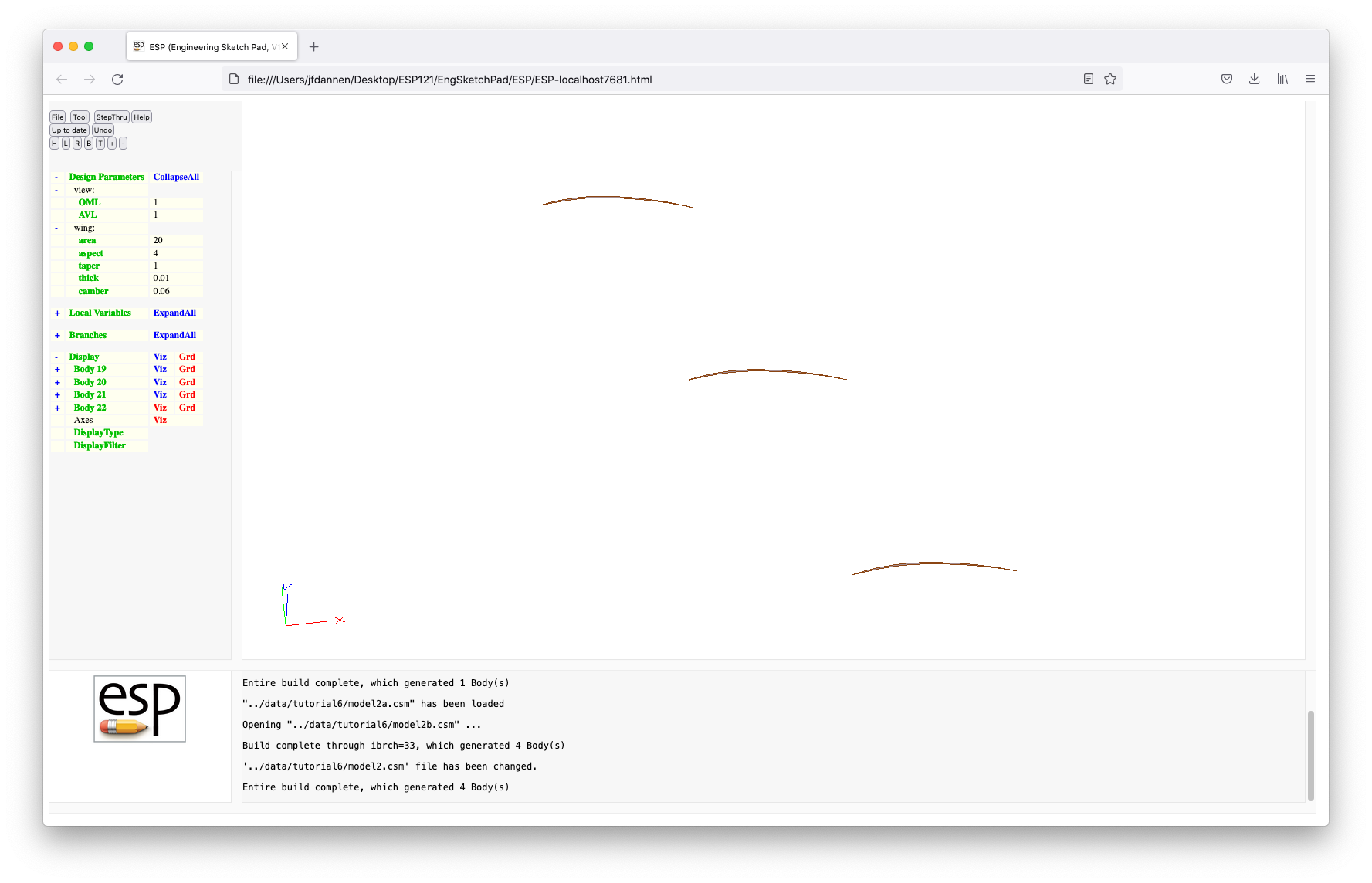

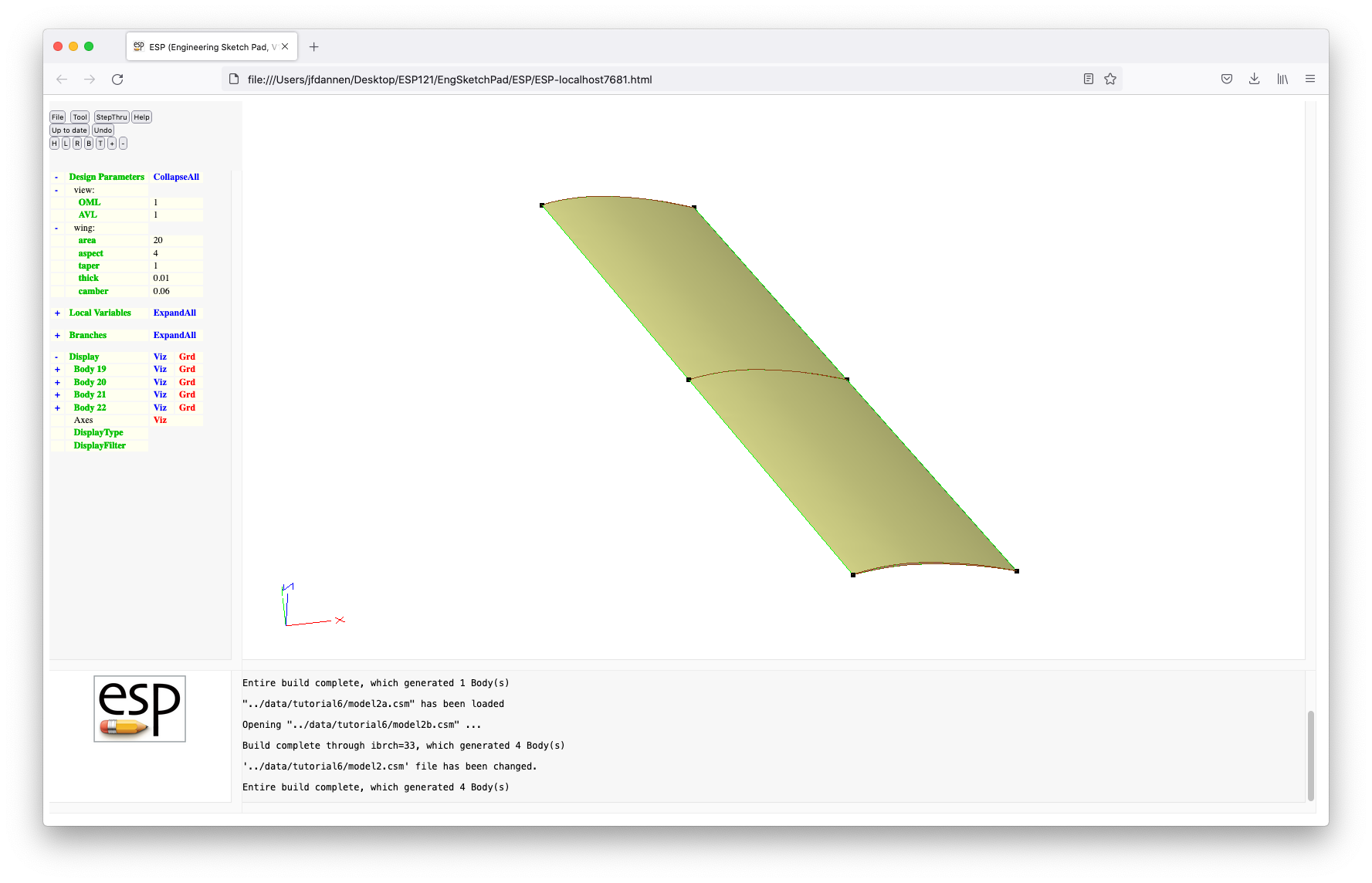

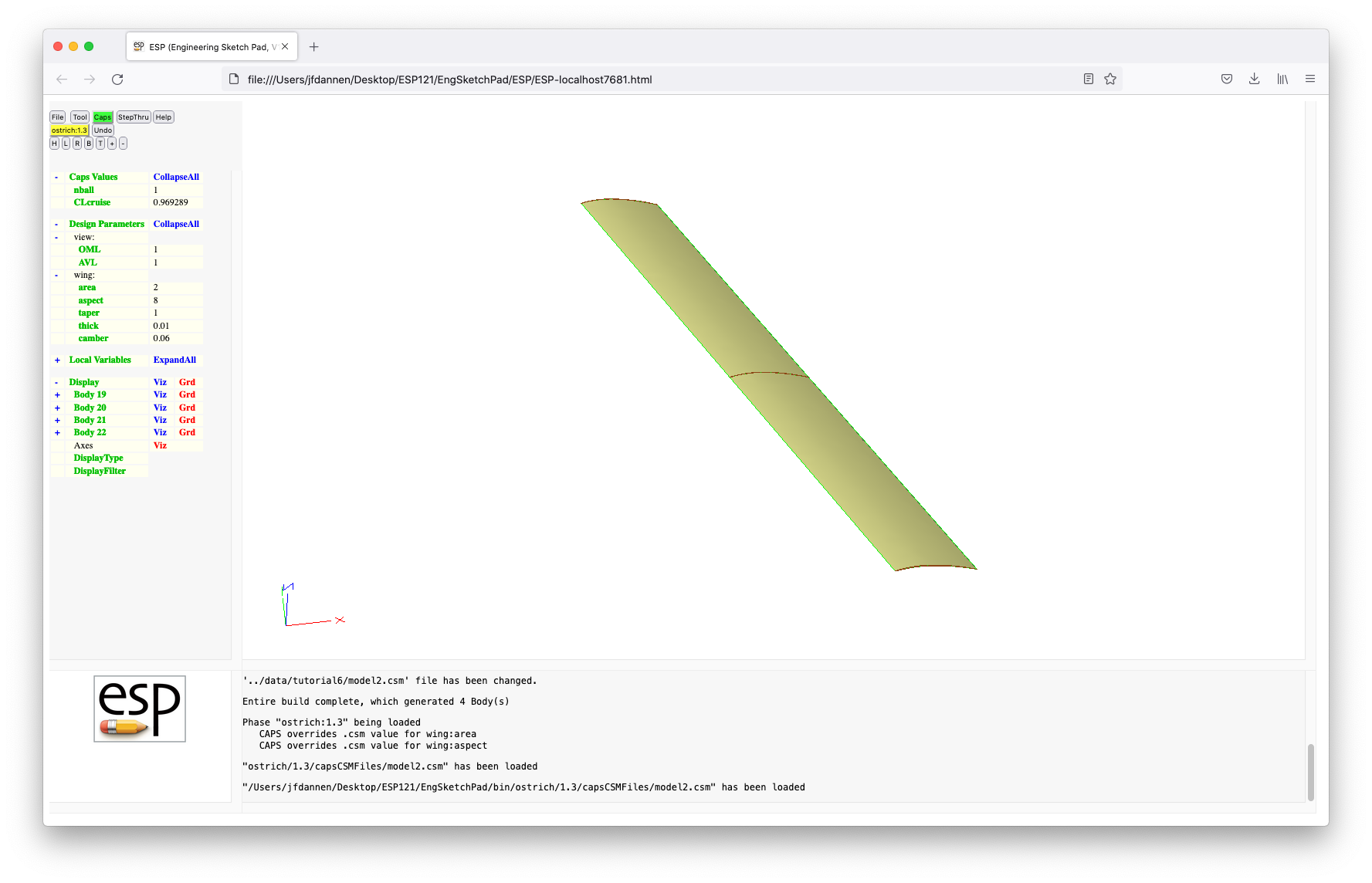

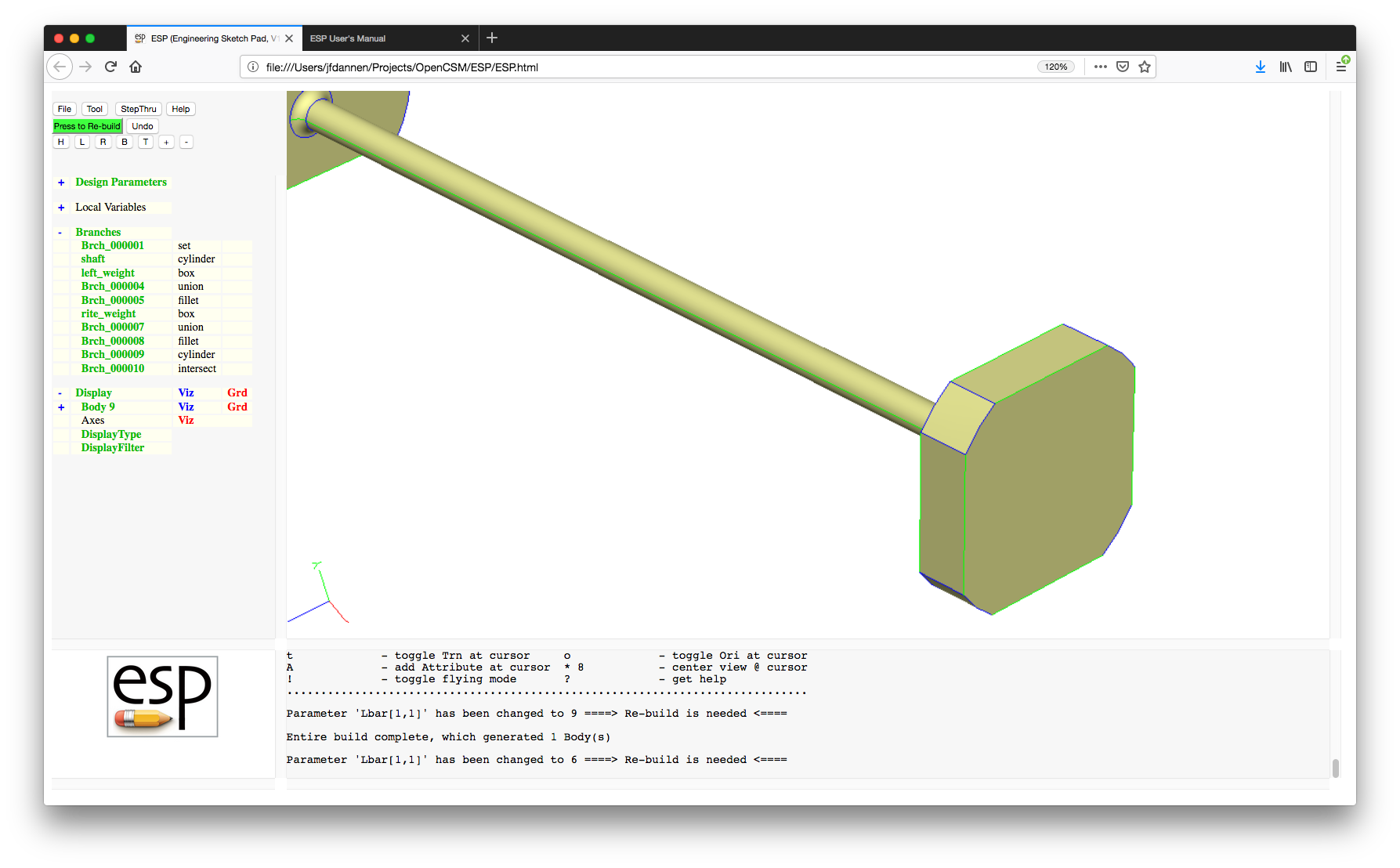

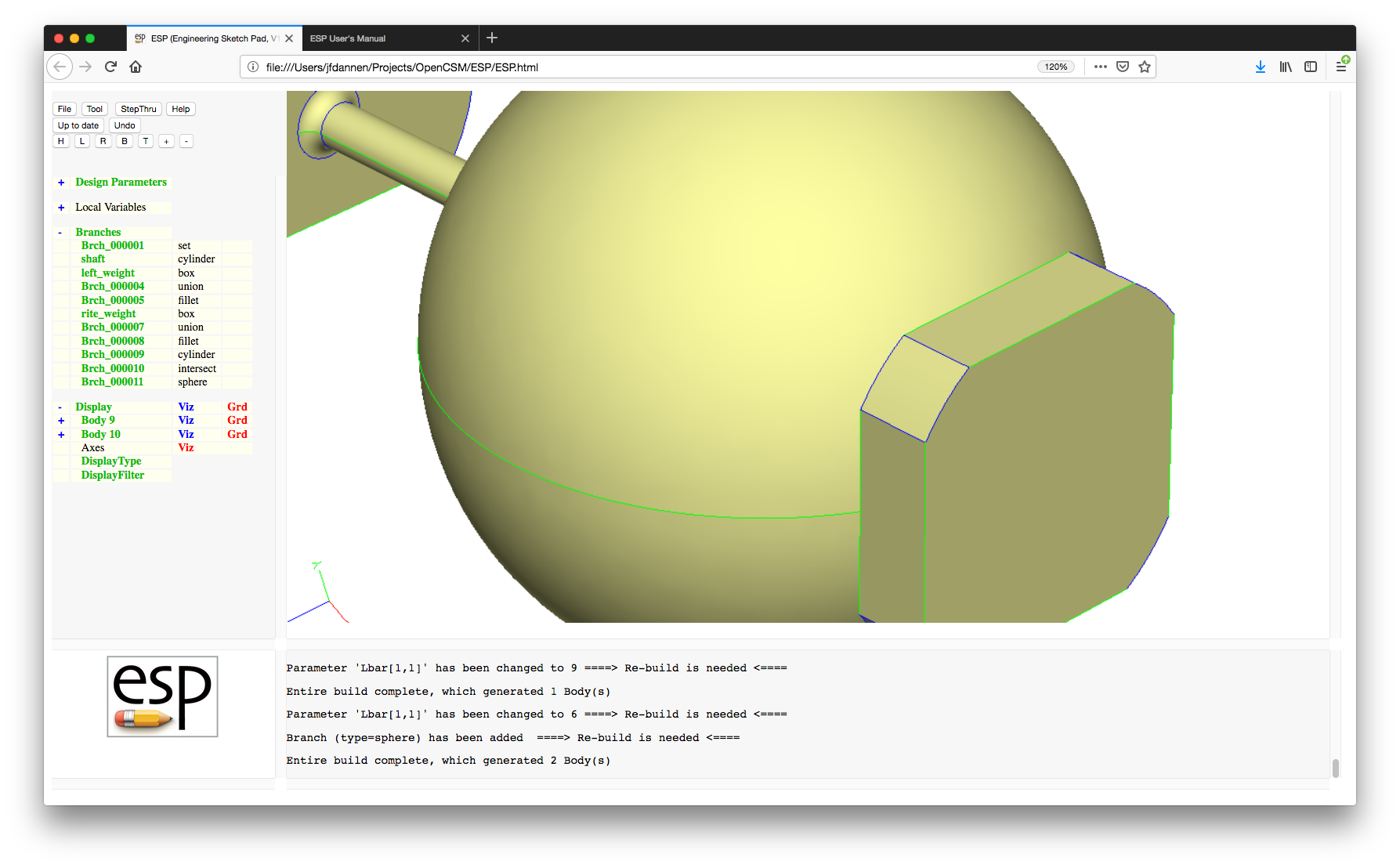

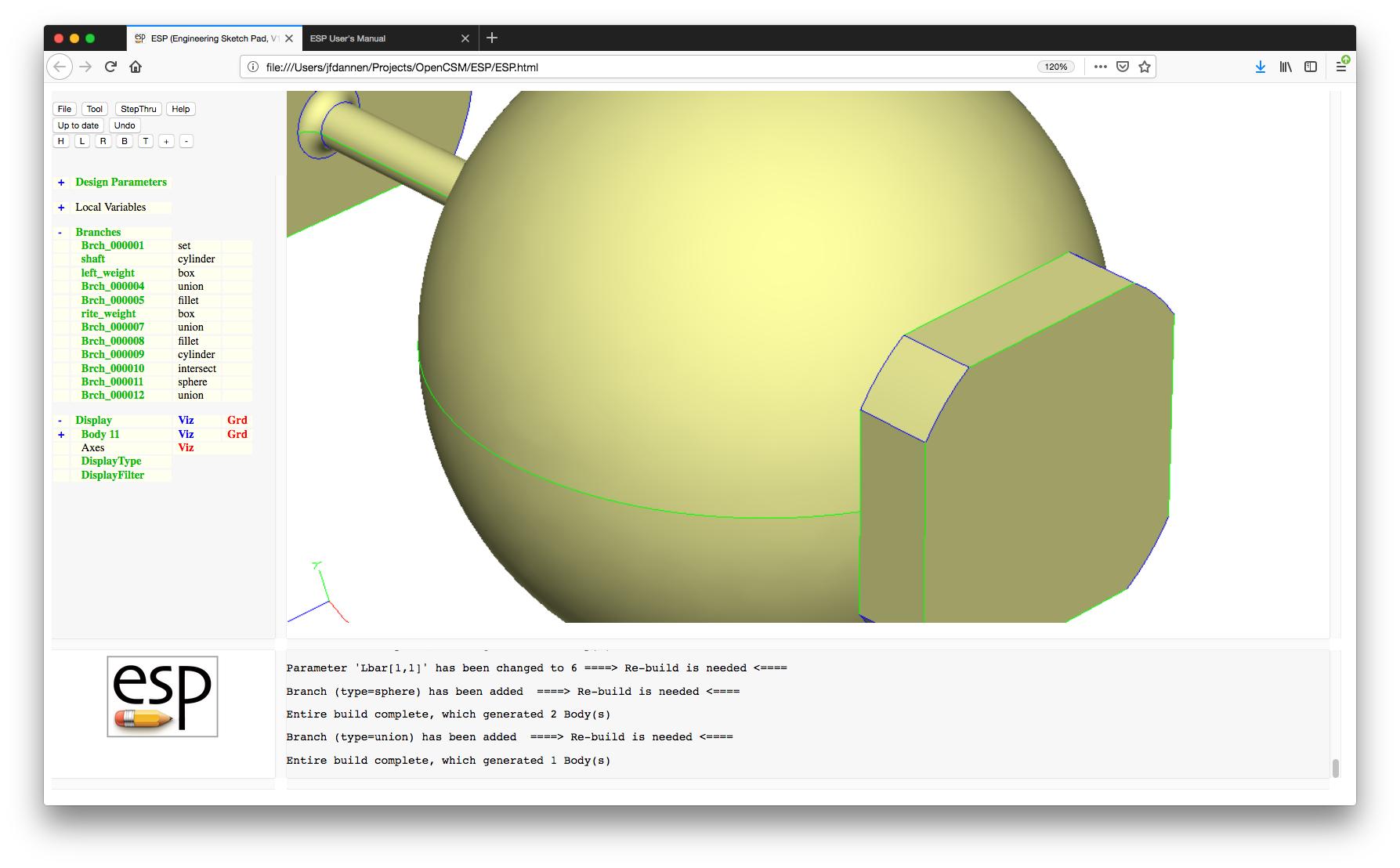

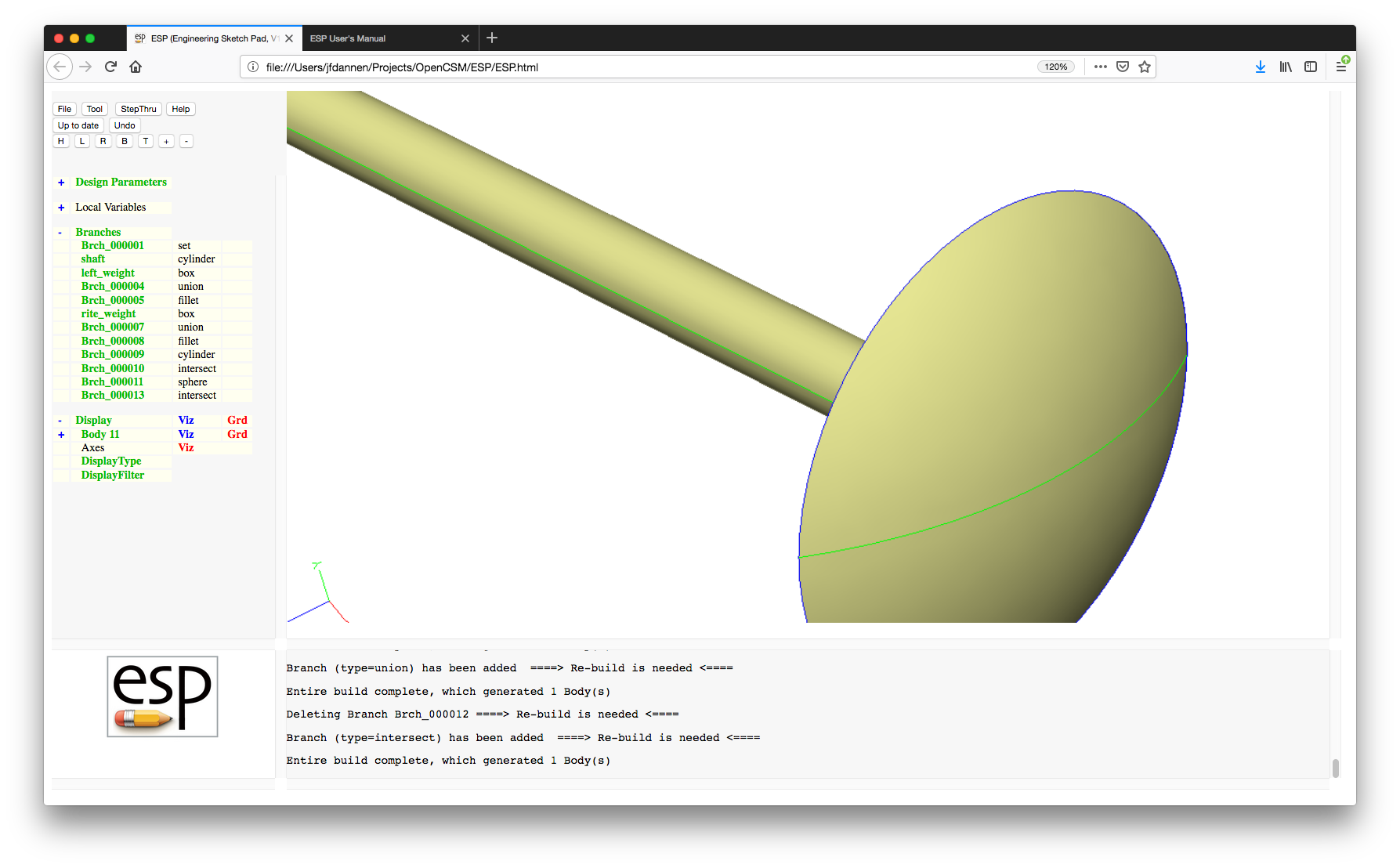

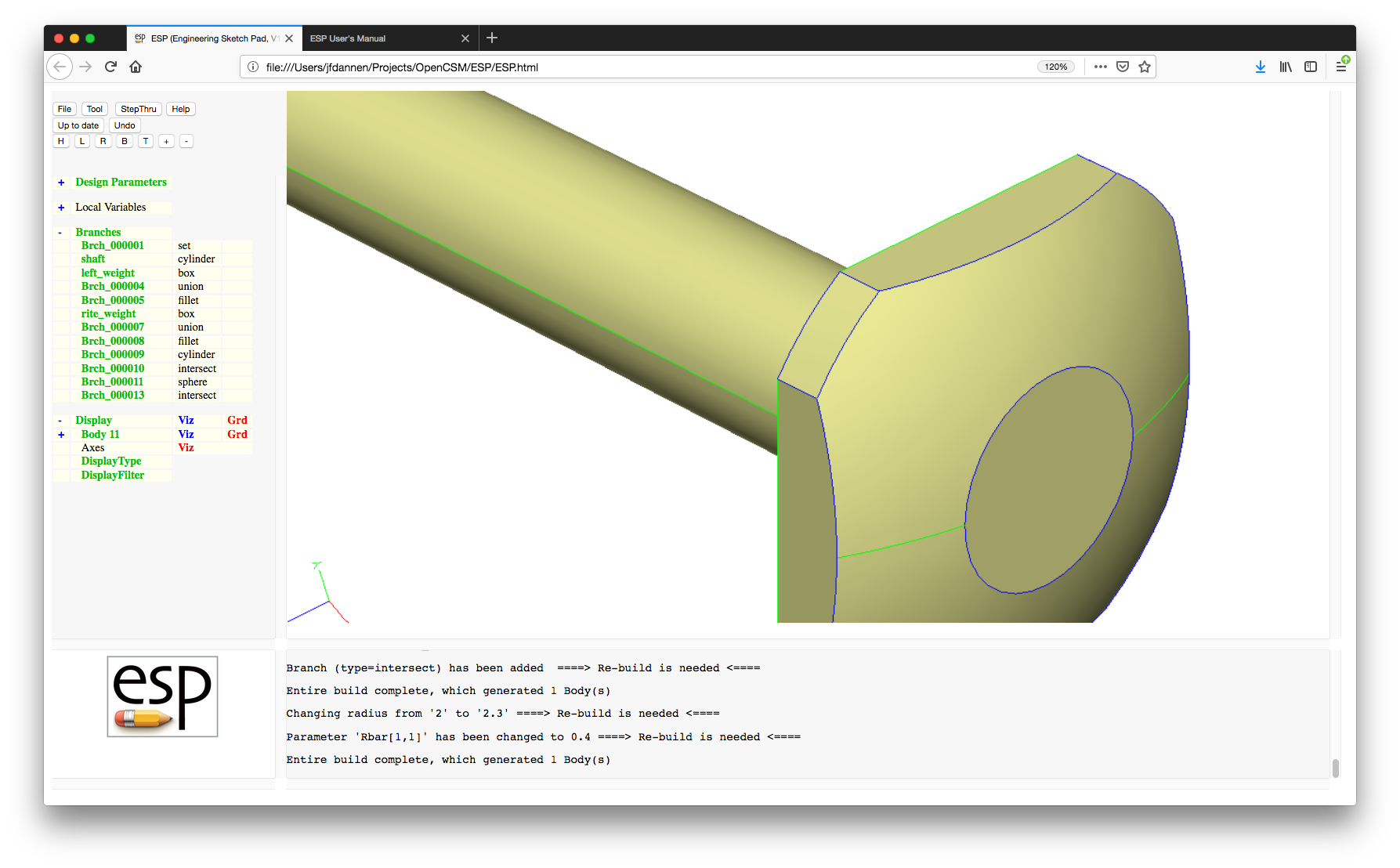

ESP modelIn the second tutorial, you will start building up a

configuration, step by step. It is assumed that you are

already familiar with the ESP browser-based

graphical user interface (GUI). If you are not, please

do Tutorial 1 first.

Begin by starting ESP by either pressing

the runESP125 icon on you desktop, or by pressing

the ESP125 icon and then typing serveESP

in the window that pops up.

In either case, if ESP asks for you hostname

and port, enter (the default) Localhost:7681.

This should bring up an empty ESP GUI.

We are going to start a new configuration, using

the ESP integrated code editor. To do that,

click on File and then choose Edit: <new

file>. The GraphicsWindow should now contain and

empty file.

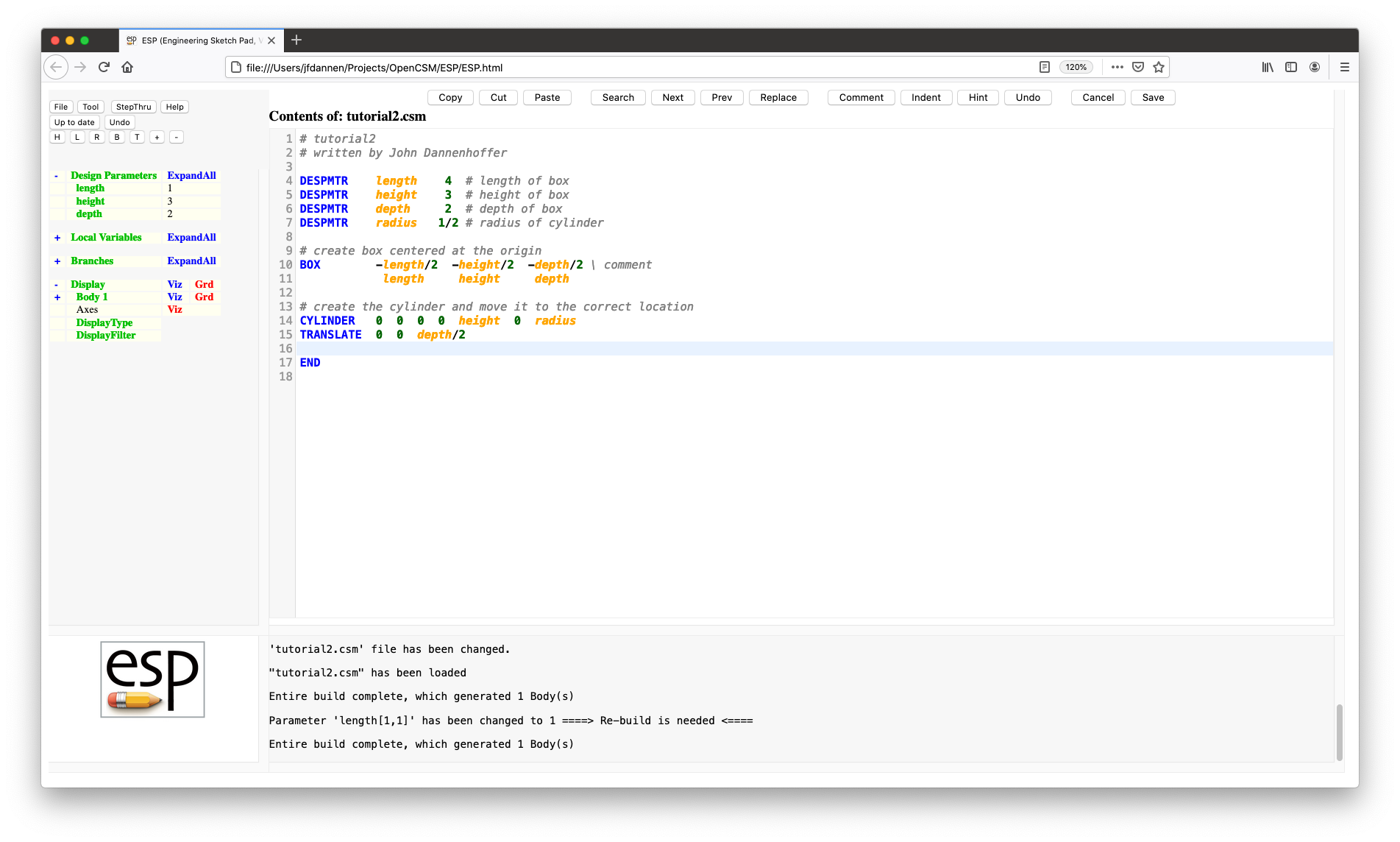

Start by typing the following into the code editor:

# tutorial2

# written by ...

DESPMTR length 4 # length of box

DESPMTR height 3 # height of box

DESPMTR depth 2 # depth of box

# create box centered at the origin

BOX -length/2 -height/2 -depth/2 \ comment

length height depth

END

When you have done this, you should see:

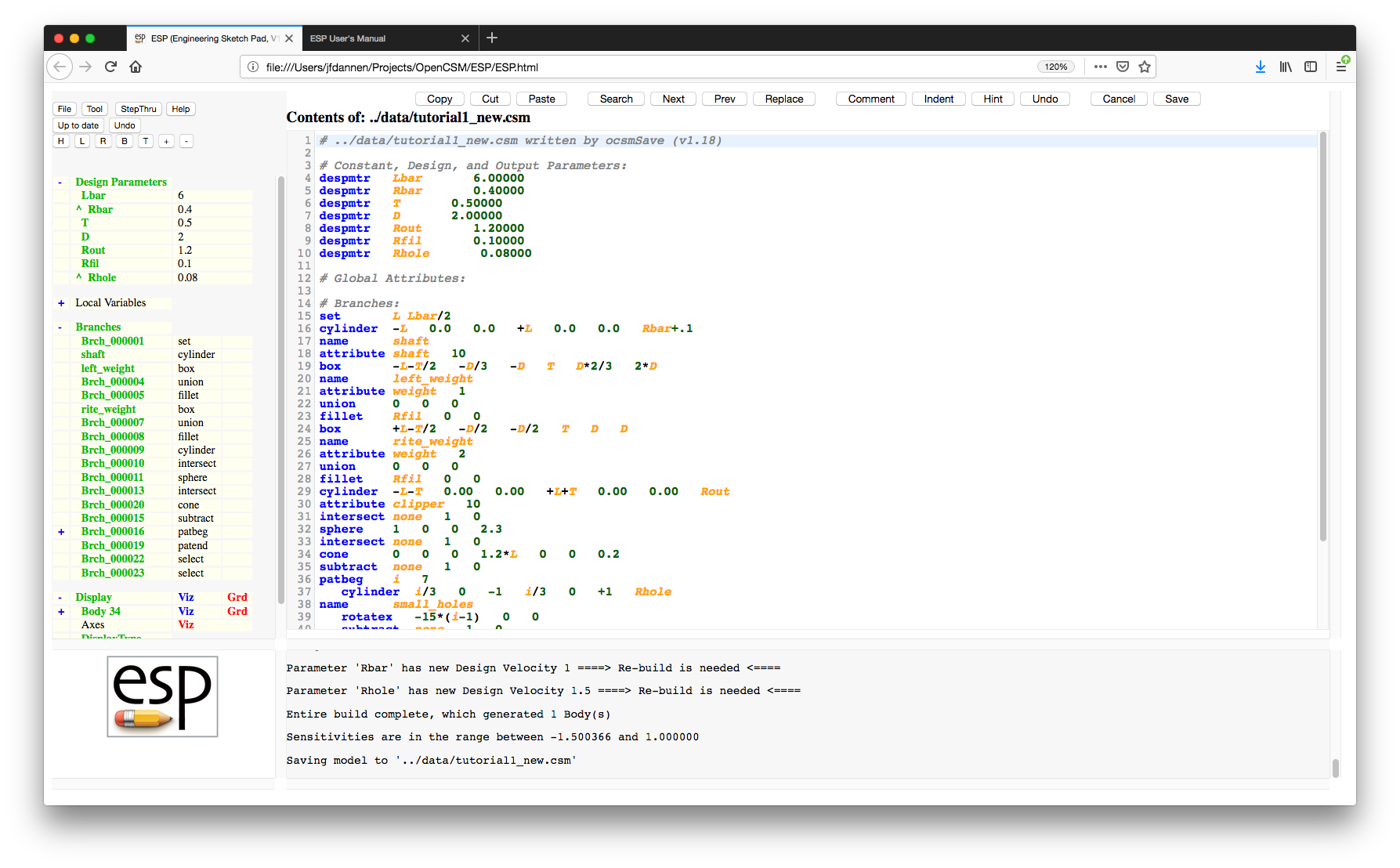

Before we go any further, some explanation about the code (or script) editor is in order. The integrated editor has a row of buttons at the top:

.csm file and there are

no current .udc files, then the

configuration is automatically rebuiltNote that the text in the file is colored:

Now it is time to explain the script that you typed.

Lines 1 and 2:

# tutorial2

# written by ...

are comments, designated by the comment symbol

(#). It is good practice to name and sign your scripts, since

you may return to them in the future, and any information that

you include will help you.

All ESP commands begin with a CommandName (which

you expect to see in blue), followed by zero or more arguments.

The CommandName can be either all UPPERCASE or lowercase, but

not MixedCase. The arguments are separated from the

CommandName and from each other by spaces. If you want to

include a space within an argument (to increase readability),

simply put quotation marks (" ") around the

argument. ESP ignores anything after it finds a

comment "#" symbol.

Lines 4 through 6:

DESPMTR length 4 # length of box

DESPMTR height 3 # height of box

DESPMTR depth 2 # depth of box

define DesignParameters. To get the most out

of an ESP model, you should define the

configuration in terms of DesignParameters so that you can:

DESPMTR statement is:

DESPMTR

or despmtr;Lines 9 and 10:

BOX -length/2 -height/2 -depth/2 \ comment

length height depth

actually generate a BOX, which is specified by its

beginning coordinates (xbase, ybase, zbase) and its size (dx,

dy, dz). If you put you cursor on line 9 and press

the Hint button near the top of the editor, the editor

will list (just below the buttons) the format of

the BOX command. Note that on line 9 there is a

backslash (\); this is the line continuation character, which

tells ESP to ignore the backslash and everything

following it, and concatenate the following line. So, lines 9

and 10 are equivalent to:

BOX -length/2 -height/2 -depth/2 length height depth

Note that the continuation character was used here to improve

readability.

Since we wanted the BOX centered at the origin,

and since the BOX command is defined in terms of a

"base" point, we needed to specify that the "base" was half

the length, height, and depth away from the origin.

In ESP, expressions follow the same syntax as most

modern computer languages. See Expression

rules for complete details.

Line 12:

END

identifies the END of the script. This

statement is technically not needed, but I always use

it. ESP does not read (or process) anything after

the END statement, so it is a convenient way of

testing an ESP script while you are writing and

debugging it.

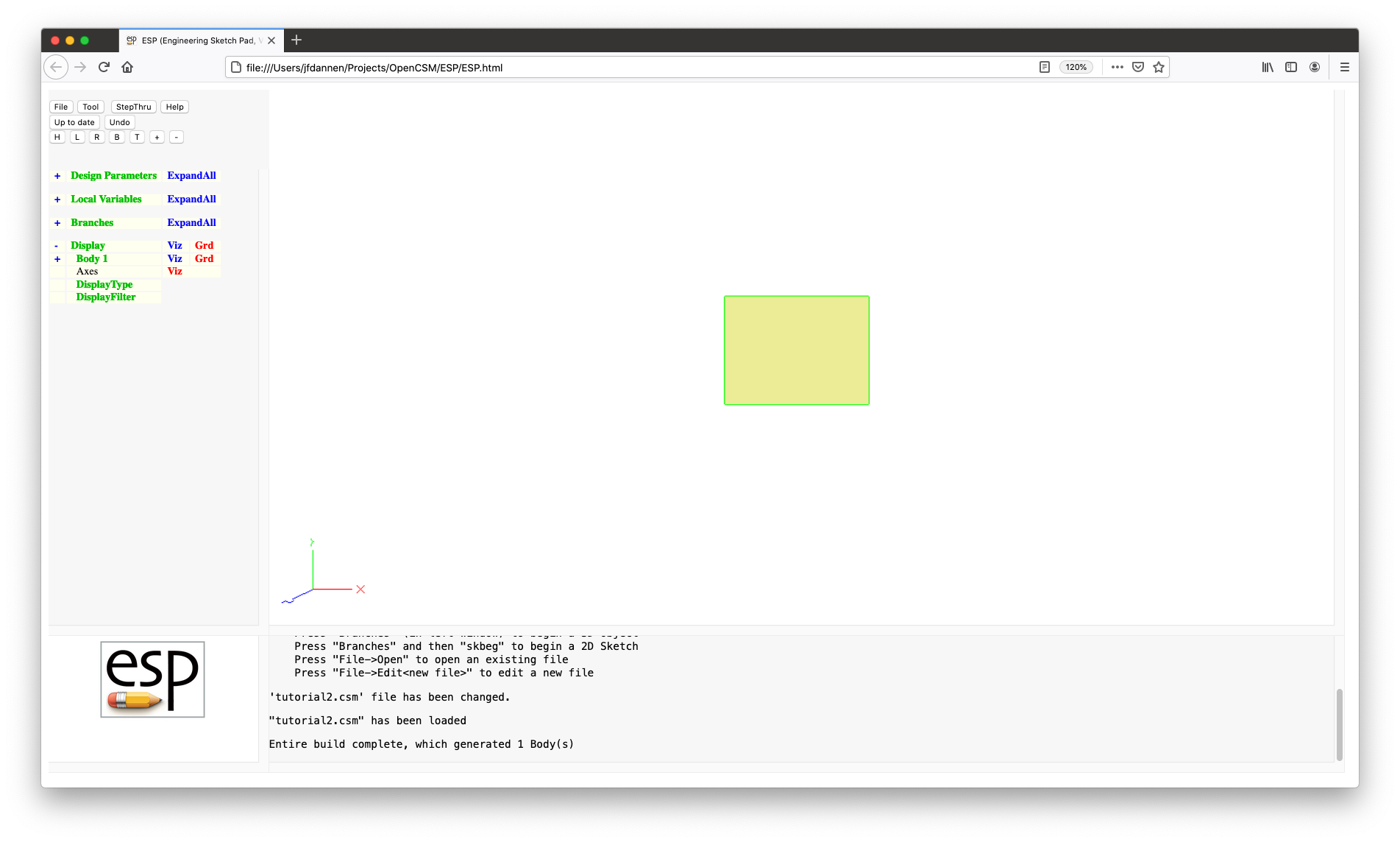

Now that the script is complete, it is time to run it. To do

this, press the Save button at the top of the editor.

Since this is a new file, ESP will ask for the

filename with which to save it. For this tutorial,

enter tutorial2 (or tutorial2.csm) at

the prompt. This will cause the file to be saved and the model

to be automatically executed. Your GraphicsWindow will then

change to a 3D view of your configuration.

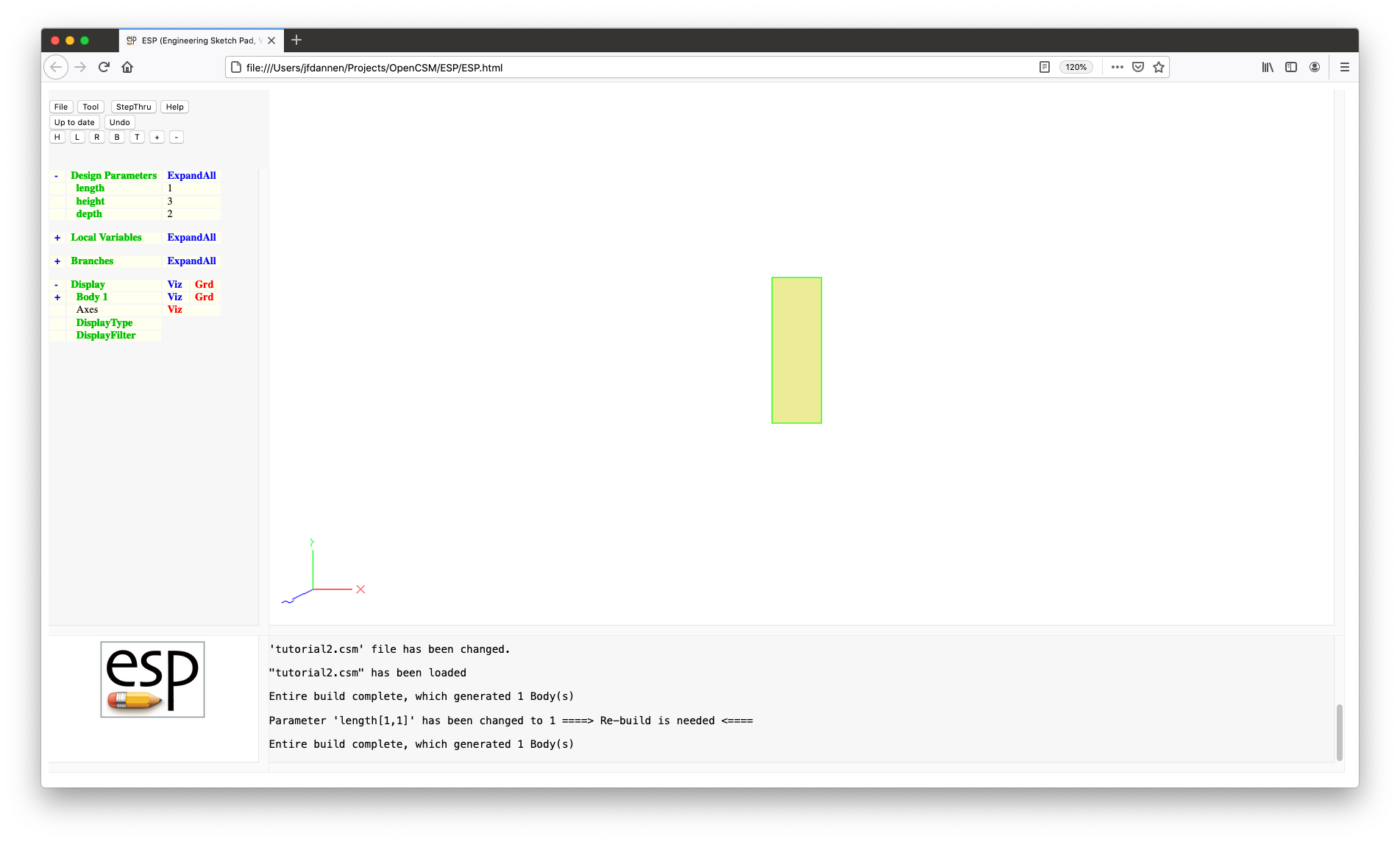

To see the effect of the DesignParameters in your model,

press length in the DesignParameters part of the

TreeWindow and change the value to 1,

hit OK and Press to Re-build. You should see a

shortened version of your box.

Now let us return to the code editor, by pressing File

(at the top of the TreeWindow), and then Edit:

tutorial2.csm. You will get a popup that says "1 change(s)

will be lost. Continue?". This is informing you that you

changed something via the TreeWindow (in this case, the length

of the BOX). Since we only did this to verify that

our DesignParameters were working okay, we can

discard this change and return to the code editor by

pressing OK.

Now we are going to add a cylinder that starts at the middle of the front Face and is vertical with a length of "height". This can be done by modifying your script to:

# tutorial2

# written by ...

DESPMTR length 4 # length of box

DESPMTR height 3 # height of box

DESPMTR depth 2 # depth of box

DESPMTR radius 1/2 # radius of cylinder

# create box centered at the origin

BOX -length/2 -height/2 -depth/2 \ comment

length height depth

# create the cylinder and move to correct location

CYLINDER 0 0 0 0 height 0 radius

TRANSLATE 0 0 depth/2

END

Your editor should look like this:

Note that we added a new line 7:

DESPMTR radius 1/2 # radius of cylinder

which is a new DesignParameter for the radius of

the CYLINDER.

Then in line 14:

CYLINDER 0 0 0 0 height 0 radius

we actually generate the CYLINDER

(see the Hint for help on the CYLINDER

statement). The CYLINDER is then

TRANSLATEd to its correct position in line 15:

TRANSLATE 0 0 depth/2

If you actually had looked at the Hint for

a CYLINDER you would have noticed that we could

have done the statements in lines 14 and 15 in the single

statement:

CYLINDER 0 0 depth/2 0 height depth/2 radius

The reason that this was done in two statements here was to

explain the concept of the Stack, which is used in the

construction process. ESP maintains of

last-in-first-out Stack of the Bodys that are created during

the build process. The Stack starts empty for every build.

Then the BOX statement in line 10

creates "Body 1", which is put onto the Stack. So the Stack

looks like:

Body 1 (the box)

Then the CYLINDER is generated in line 14

(creating "Body 2"), so the Stack looks like:

Body 2 (the cylinder)

Body 1 (the box)

Now the TRANSLATE statement in line 15 takes the

Body on the top of the Stack ("Body 2")

and TRANSLATEs it to its new location. In essence,

the Body on the top of the Stack has been replaced by the new

Body. So the Stack now looks like:

Body 3 (the translated cylinder)

Body 1 (the box)

By using the Stack, there was no need to

tell ESP which Body was to

be TRANLATEd.

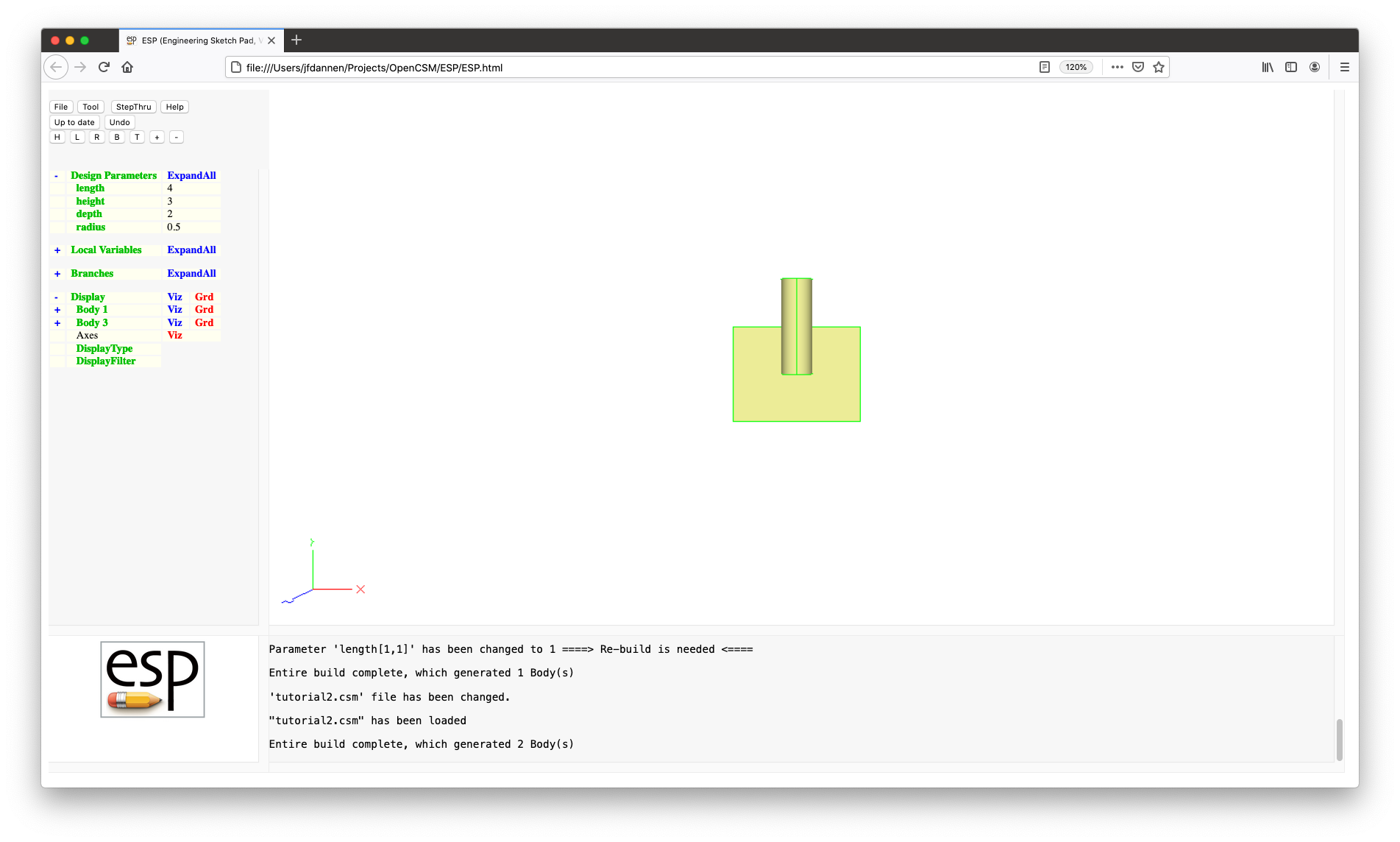

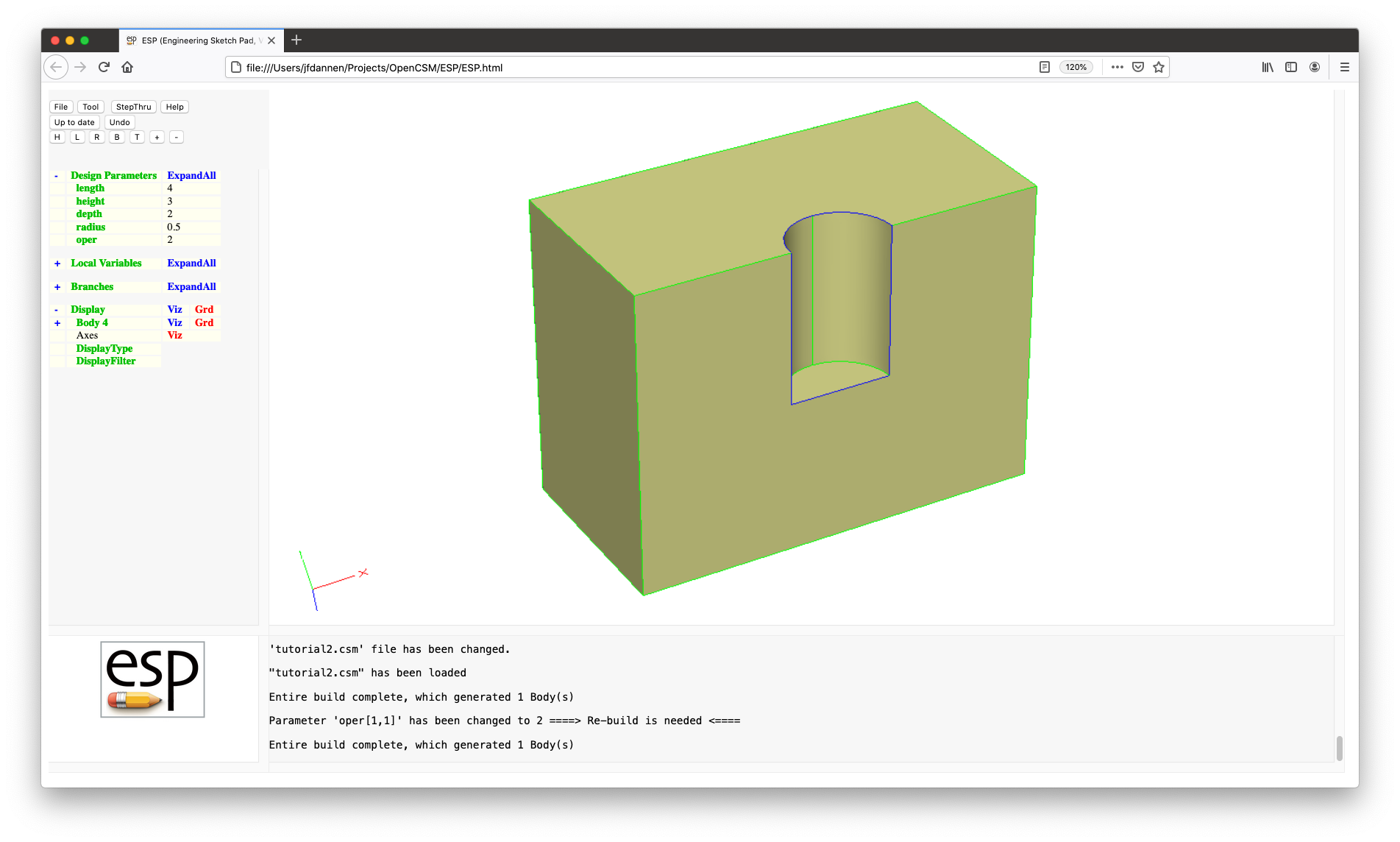

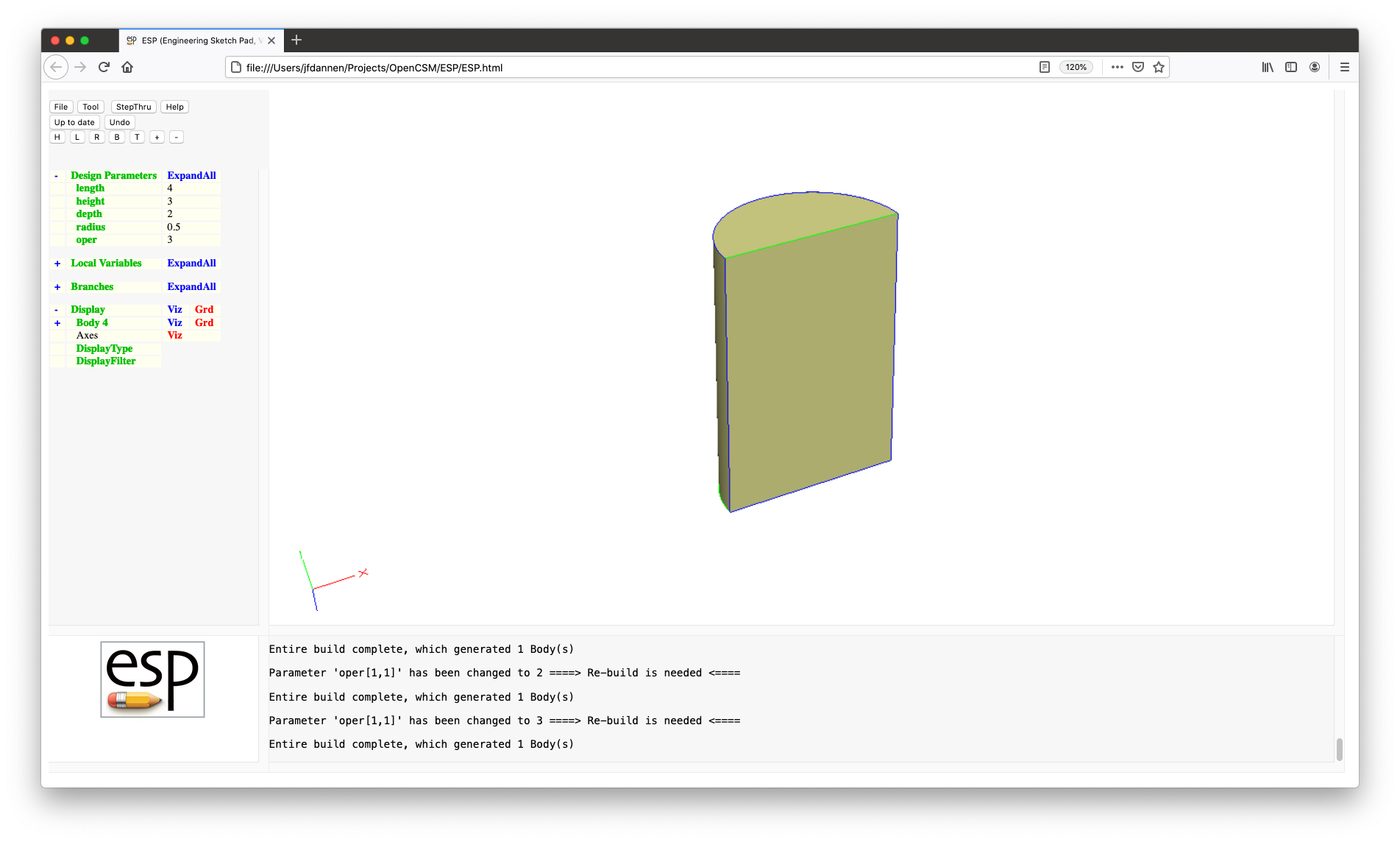

If we Save this modified script, we should get a configuration with two Bodys:

Finally we want to combine the two Bodys on the top of the Stack (which currently only contains two Bodys) using a Boolean operation:

UNION fuses the two Bodys together;SUBTRACT removes from "Body 1" any part of

"Body 3" that is within it; andINTERSECT returns the common part of its two

input Bodys.UNION, so add a new line

to you script, to produce:

# tutorial2

# written by ...

DESPMTR length 4 # length of box

DESPMTR height 3 # height of box

DESPMTR depth 2 # depth of box

DESPMTR radius 1/2 # radius of cylinder

# create box centered at the origin

BOX -length/2 -height/2 -depth/2 \ comment

length height depth

# create the cylinder and move to correct location

CYLINDER 0 0 0 0 height 0 radius

TRANSLATE 0 0 depth/2

UNION

END

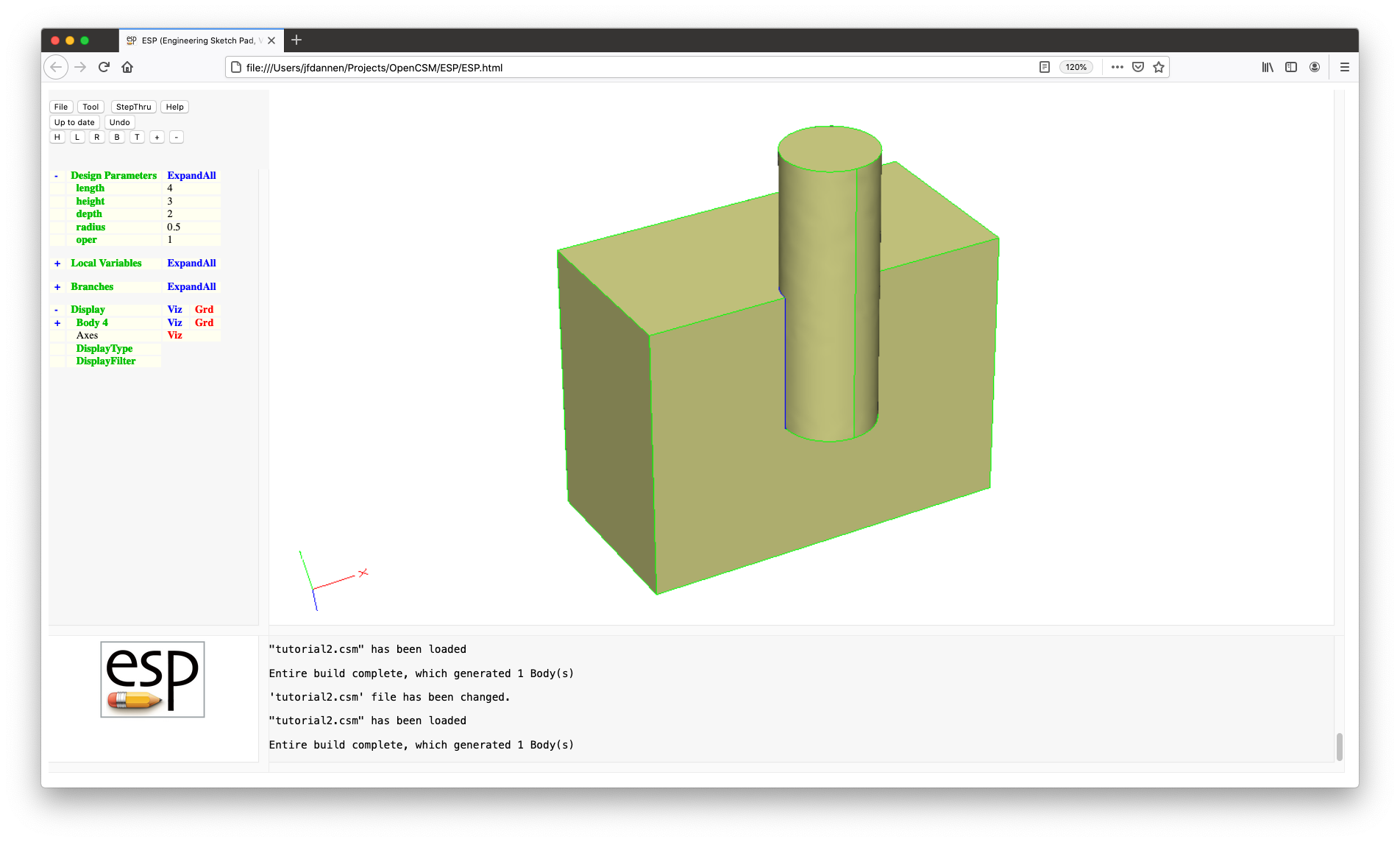

If you Save your new script, you will see one Body

("Body 4"). Also, the Stack now just contains the result of

the UNION

Body 4 (the result of the union)

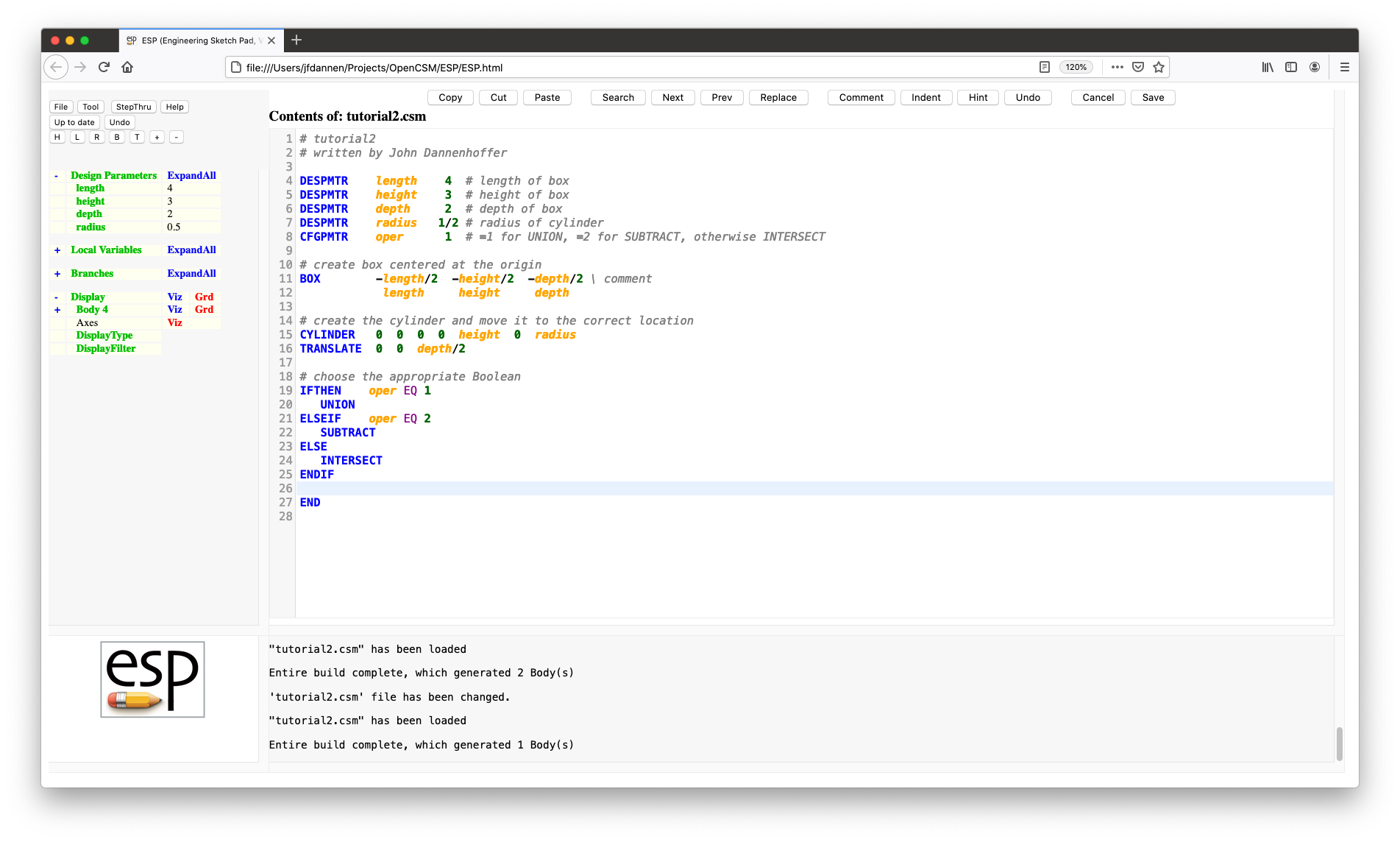

Imagine that you wanted to set up your script so the particular Boolean operation that was to be used could be selected during the build process. This could be done by modifying your script to be:

# tutorial2

# written by ...

DESPMTR length 4 # length of box

DESPMTR height 3 # height of box

DESPMTR depth 2 # depth of box

DESPMTR radius 1/2 # radius of cylinder

CFGPMTR oper 1 # =1 for UNION, =2 for SUBTRACT, otherwise INTERSECT

# create box centered at the origin

BOX -length/2 -height/2 -depth/2 \ comment

length height depth

# create the cylinder and move to correct location

CYLINDER 0 0 0 0 height 0 radius

TRANSLATE 0 0 depth/2

# choose the appropriate Boolean

IFTHEN oper EQ 1

UNION

ELSEIF oper EQ 2

SUBTRACT

ELSE

INTERSECT

ENDIF

END

which would look like this:

The first this we should note is line 8:

CFGPMTR oper 1 # =1 for UNION, =2 for SUBTRACT, otherwise INTERSECT

which contains a ConfigurationParameter. A

ConfigurationParameter is like a DesignParameter in every

respect, except that you cannot take the sensitivity with

respect to it. That makes it ideal for cases (such as this),

where you want to be able to influence the build before it

happens, but not in a way that could be differentiated.

Here we have introduced a new concept (line lines 19 through 25):

IFTHEN oper EQ 1

UNION

ELSEIF oper EQ 2

SUBTRACT

ELSE

INTERSECT

ENDIF

that is fairly unique to ESP: the logic block.

This is introduced by the IFTHEN statement,

followed by zero or more statements, followed by zero or

more ELSEIF statements (each of which can be

followed by zero or more statements), followed by an

optional ELSE statement (with its own included

statements), followed by the ENDIF statement.

This logic construct can be found in every computer language;

oddly is seems to be lacking in most CAD system.

The relations operations allowed in the IFTHEN

and ELSEIF statments are:

EQ for is equal;NE for is not equal;LT for is less than;LE for is less than or equal;GT for is greater than; andGE for is greater than or equal.AND

or OR.

Save your modified script. Try modifying "oper" in

the ESP TreeWindow to get each of the following:

Rather than typing a lot of code, we are going to use the

Tutorial files in the ESP distribution. To do

that, press File, then Open, and then

enter ../data/tutorial2 on MAC or LINUX or

..\data\tutorial2 on Windows.

If we open the script editor, we see DESPMTR

statements such as those in lines 5 through 7:

DESPMTR tire:width 12.0 # width of tire

DESPMTR tire:diam_outer 30.0 # outer diam of tire

DESPMTR tire:diam_inner 22.0 # inner diam of tire

before. The only difference here is that the names contain a

colon (:). This is done because we expect the model to get

fairly complicated and it would be good to group

DesignParameters so that they are easier to find in

the ESP GUI.

The strategy that we are going to use to build a tire-like object is to define a cross-section and then use it to make a body of revolution. In Tutorial 3 we will use the sketcher to make a complex cross-section, but for this Tutorial we will just be using a rectangle.

We will start with a BOX command (in line 19), but

this time we will make its "dz" zero, to create a SheetBody (a

Body without volume) instead of the traditional SolidBody.

Notice that the SheetBody is defined in the xy-plane

(because zbase is 0) and that is goes

between 0 and tire:width/2 in

the x direction and tire:diam_inner/2

and tire:diam_outer/2 in the y direction.

(By the way, after this statement there is only one Body on the

Stack.)

We want to now REVOLVE this Body around

the x-axis to make a ring. In ESP, it is

NOT the best practice to actually REVOLVE

something 360 degrees since some of the (subsequent) geometric

operations are not robust for this case. Therefore the best

practice is to REVOLVE it 180 degrees and

then MIRROR it and JOIN the two

halves together.

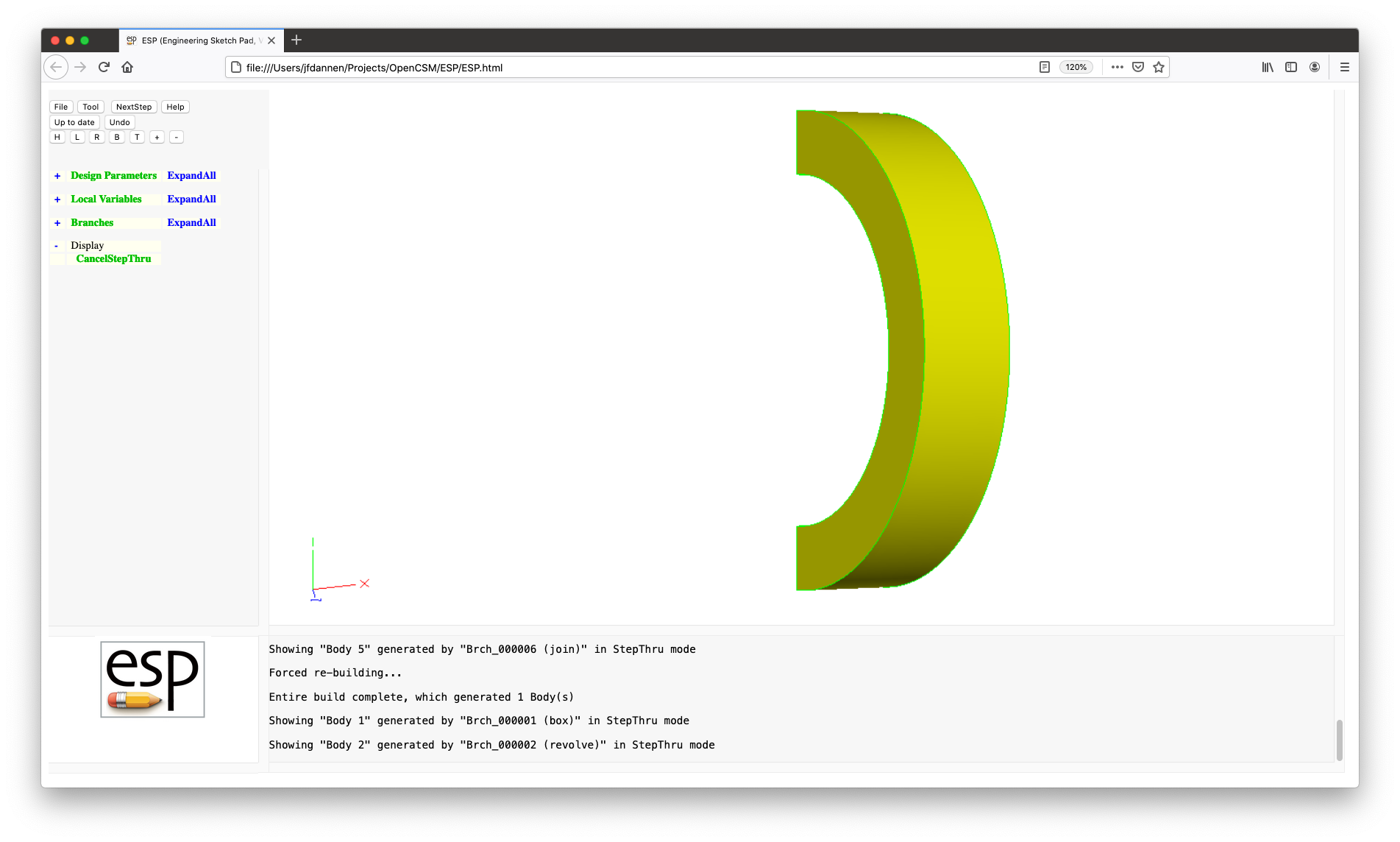

In line 22:

REVOLVE 0 0 0 1 0 0 180

you can see that we REVOLVE the Body

on the Stack (that is, the Body that was created by

the BOX command) around an axis that passes

through (0,0,0), which is in the (1,0,0) (that is x) direction,

and REVOLVE it 180 degrees. (See the Hint

on the REVOLVE command if you need it by putting

the cursor on line 22 and pressing the Hint button.)

If we use StepThru mode, we can see the REVOLVEd Body.

After doing this, the Stack will contain:

Body 2 (the revolved Body)

Next we will be transforming this Body (that is, we will

be MIRRORing it). The various transformations

in ESP are:

TRANSLATE to move a Body;SCALE to make a Body bigger or smaller;ROTATEX to rotate around an axis that is

parallel to the x-axis;ROTATEY to rotate around an axis that is

parallel to the y-axis;ROTATEZ to rotate around an axis that is

parallel to the z-axis; andMIRROR to make the mirror image of a

Body.We now want to MIRROR across the xy plane

(signified as the (0,0,1) plane). But, the MIRROR

operates the same as all the other transformations; that is it

takes the Body off the top of the Stack, performs the

transformation, and then pushes the result back onto the Stack.

Since we want to keep the original Body and then make a mirror

image, we need do a little manipulation of the Stack. This is

done by line 30:

RESTORE .

which tells ESP to make another copy of the Body

on the top of the Stack. After doing this, the Stack will

contain:

Body 3 (a copy of Body 2)

Body 2 (the original revolved Body)

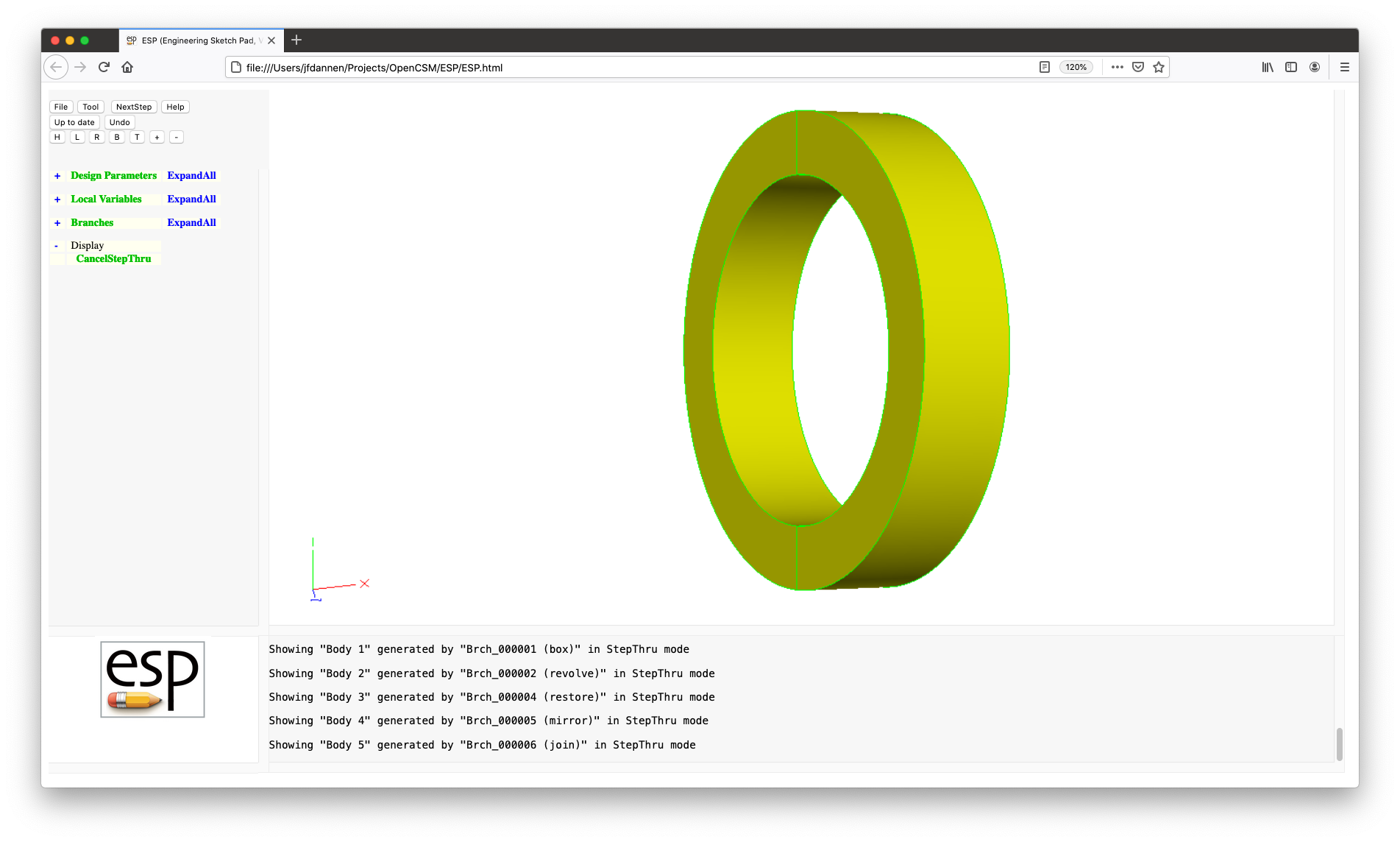

We can now MIRROR the Body on the top of the

Stack (Body 3), producing:

Body 4 (a mirrored version of Body 3)

Body 2 (the original revolved Body)

Finally we can JOIN the two halves together. The

difference between UNION and JOIN is

subtle, but important. JOIN should be used when

you expect to have Faces (or Edges) that are coincident in the

input Bodys; UNION is more general, but has the

possibility of creating lots of little sliver Faces if the

Faces that are being combined are not exactly the same. Best

practices say to use JOIN whenever appropriate

and UNION only when needed.

Again, if we use StepThru mode, we can see the JOINed original and MIRRORed Bodys.

Lines 34 through 36:

RESTORE .

MIRROR 1 0 0

JOIN

do exactly the same as above, but makes and

combines a mirror image about the x (1,0,0) plane.

The next thing that we will do is add in the disk and provide Attributes on the model.

We are going to go through the new statements a little at a time.

First look at lines 10 and 11:

DESPMTR disk:width 1.0 # width of disk

DESPMTR disk:chamfer 0.5 # chamfer radius btwn disk and tire

in which we define new DesignParameters for putting a disk

inside the tire. The disk itself is generated in line 46 (and

continued in line 47):

CYLINDER -disk:width/2 0 0 \

+disk:width/2 0 0 (tire:diam_inner+tire:diam_outer)/4

and then UNIONed with the tire in line 50:

UNION

ESP models get much of their value through the use

of Attributes. An Attribute is a name/value pair that can be

attached to any Body, any Face, any Edge, or any Node. The

value can be:

See lines 48 and 49:

ATTRIBUTE myPart $disk

ATTRIBUTE _color $red

These ATTRIBUTE statements tell ESP

to put the indicated Attribute on the CYLINDER

Body (that was created by the immediately-preceding Branch) as

well as any Faces created when the CYLIDER was

being created. Hence all the Faces will be marked as being

part of the "disk" (via the "myPart" Attribute) and will be

colored "red". See the section on Attribute

rules below for details about special Attributes, such as

"_color".

Identifying the "tread" part of the configuration is a bit

trickier. This is because the tread Faces were generated by

the REVOLVE operation. But we do not want all the

Faces that were created to get the "tread" Attribute. To get

around this, we will use the SELECT statement.

This statement has lots of options, and in fact is the longest

entry in the sections that describes the various commands.

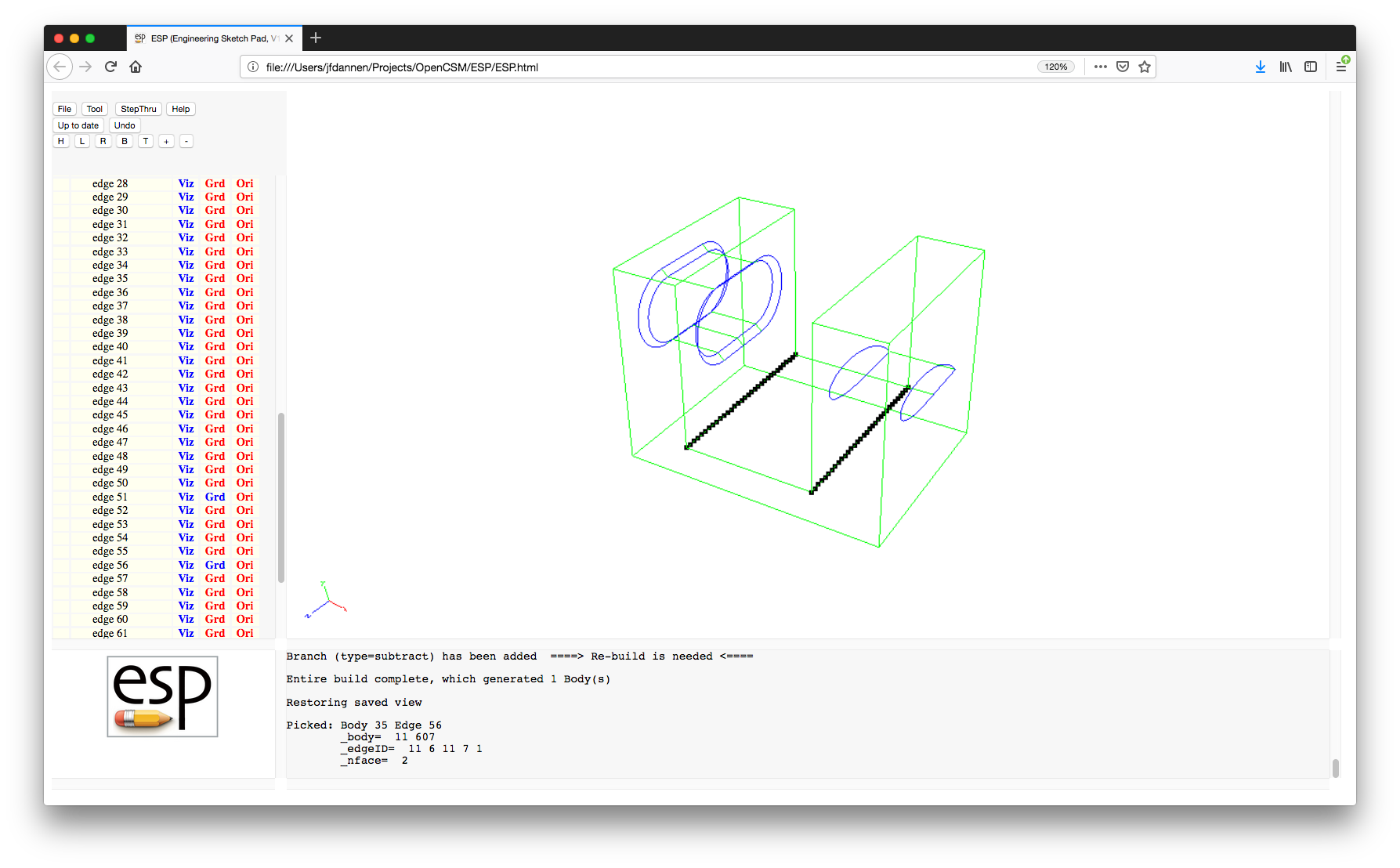

To figure out which Face we want to Attribute:

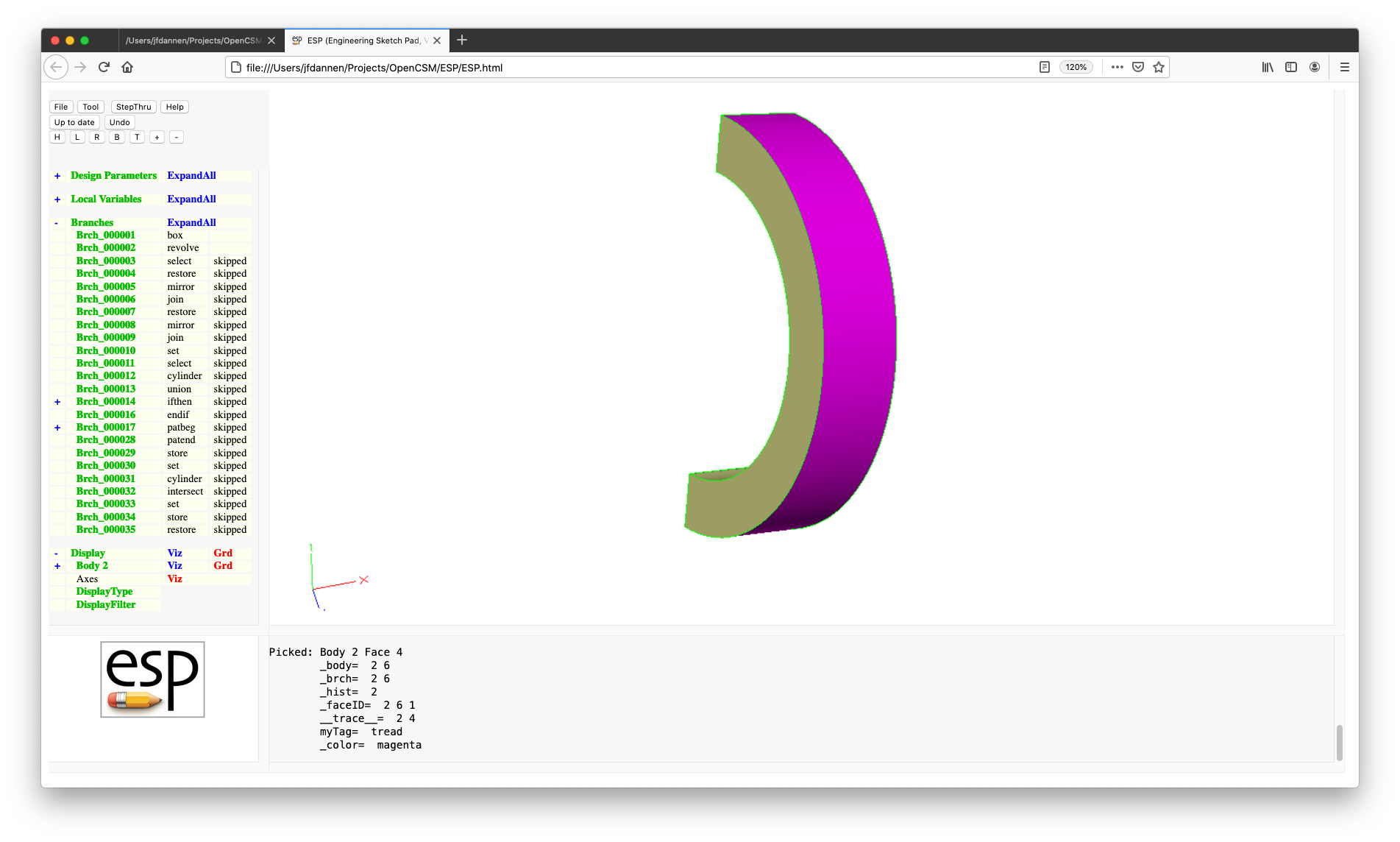

REVOLVE Branch; andPut your cursor over the magenta Face and press the ^ (or 6) key in the GraphicsWindow, and you should see this:

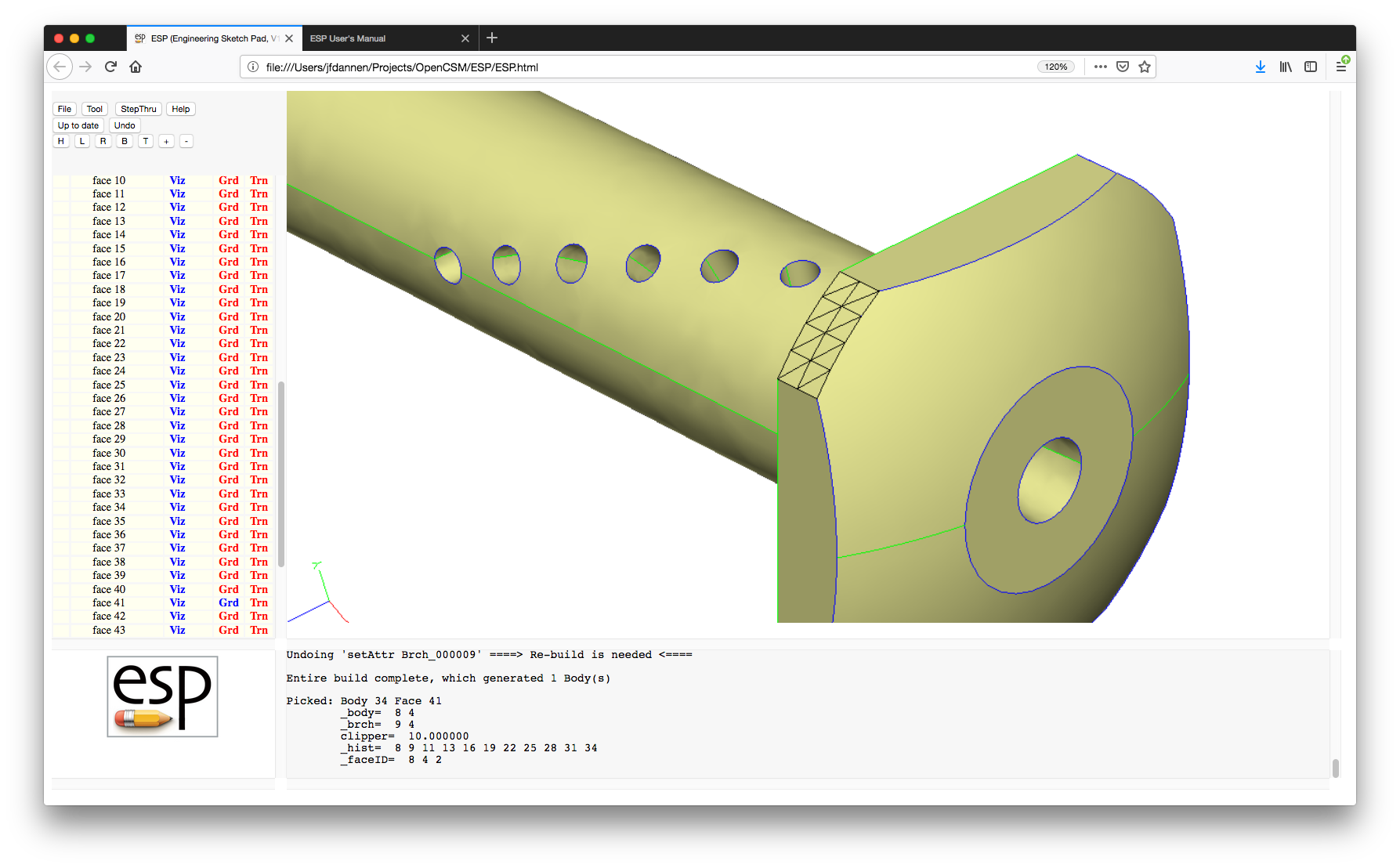

In the MessageWindow, you can see that the Face has many Attributes, but the one we are interested in is the one called "_faceID". The "_faceID" is a unique triple of numbers that tell you:

REVOLVE);REVOLVE command; and1 unless the

original Face was cut up as part of a prior

operation.So we could use a statement such as:

SELECT FACE 2 6 1

to get this Face. But, if we were to edit the script and add

something else before the REVOLVE, then the first

entry would change. A safer way of doing this is to use the

"last" Body; this can be done conveniently using

the @nbody AtParameter. Hence, we used the line:

SELECT FACE @nbody 6

where the trailing 1 is assumed.

We can ATTRIBUTE this SELECT

statement (in lines 26 and 27):

ATTRIBUTE myTag $tread

ATTRIBUTE _color $magenta

to get the desired result.

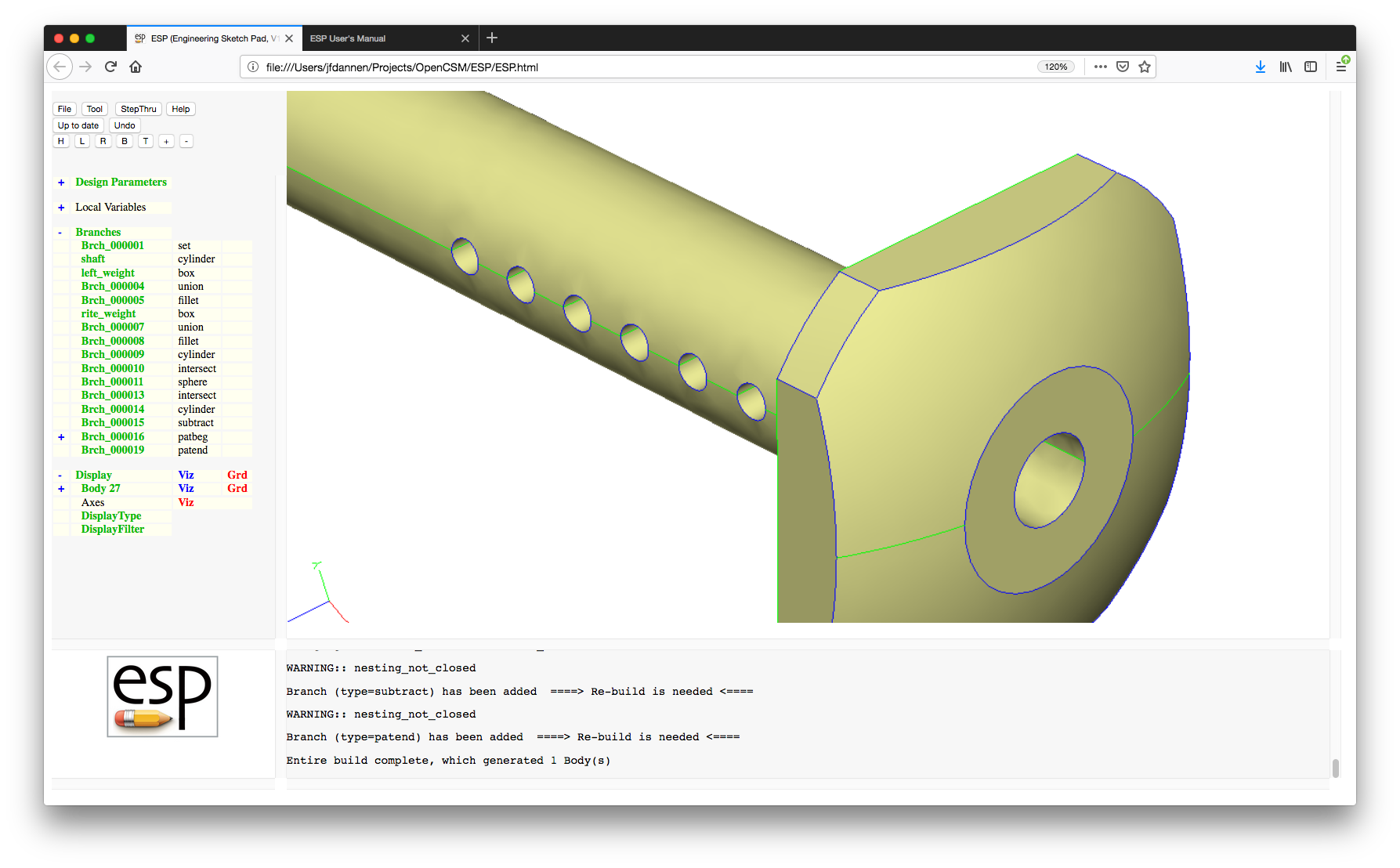

The next thing is to add in a series (called a pattern) of holes, through the disk and around the x-axis. To do this, we are going to have to start by defining the DesignParameters associated with the holes (in lines 14 through 16):

CFGPMTR hole:num 5 # number of holes

DESPMTR hole:diam_circ 4.0 # diam of circle of holes

DESPMTR hole:rad 0.5 # radius of each hole

Note that it does not make sense to compute the sensitivity

with respect to the number of holes, so "hole:num" is actually

a ConfigurationParameter.

The actual drilling of the holes is performed by the pattern in lines 59 through 75: To start off, look at lines 59 and 75:

PATBEG ihole hole:num

PATEND

These define a pattern (in C a "for" loop and in FORTRAN a "do"

loop), where the LocalVariable ihole gets the value

"1" the during first trip through the loop, the value "2" the second

time, ... and the value hole:num the last time.

Note that if hole:num is not greater than zero, the

pattern will be skipped.

The actual drilling of the holes is done by

the SUBTRACTion of a CYLINDER from

the disk; this is done in lines 71 through 74:

CYLINDER -disk:width y z \

+disk:width y z hole:rad

ATTRIBUTE myPart $hole

SUBTRACT

Note a few things:

CYLINDER are will beyond

the thickness of the disk. Making sure that you have a

"clean Boolean" is a best practice; andmyPart=$holeOne other thing to note here is how the center of the hole (in y and z) is computed. In cases where there is only one hole, it is placed on the x-axis with the lines:

SET y 0

SET z 0

In cases with more than one hole, they are equally spaced

around the x-axis by lines 66 through 68. Note a few things in

line 67:

SET y "hole:diam_circ/2 * cosd(theta)"

hole:diam_circ/2*cosd(theta));

andESP has many built-in function (described in the

Expression rules part of this

document). In particular, cosd() takes the

cosine of its argument in degrees.The next step is to add a CHAMFER between the tire

and the disk. To see how to do this, see the help

on CHAMFER:

CHAMFER radius edgeList=0

use: apply a chamfer to a Body

pops: Body

pushes: Body

notes: Sketch may not be open

Solver may not be open

if listStyle==0

if previous operation is boolean, apply to all new Edges

edgeList=0 is the same as edgeList=[0;0]

edgeList is a multi-value Parameter or a semicolon-separated

list

pairs of edgeList entries are processed in order

pairs of edgeList entries are interpreted as follows:

col1 col2 meaning

=0 =0 add all Edges

>0 >0 add Edges between iford=+icol1

and iford=+icol2

<0 <0 remove Edges between iford=-icol1

and iford=-icol2

>0 =0 add Edges adjacent to iford=+icol1

<0 =0 remove Edges adjacent to iford=-icol1

else

edgeList contains Edge number(s)

sensitivity computed w.r.t. radius

sets up @-parameters

new Faces all receive the Branchs Attributes

face-order is based upon order that is returned from EGADS

signals that may be thrown/caught:

$illegal_argument

$illegal_value

$insufficient_bodys_on_stack

$wrong_types_on_stack

Note a few things:

edgeList=0 has a

default value of 0;For our case, we simply want to put the CHAMFER

between the tire and the disk, for which edgeList

can be left blank if we place the CHAMFER command

just after the UNION of the tire and the disk.

This is done in lines 54 and 55:

CHAMFER disk:chamfer

ATTRIBUTE _color $blue

(Note that the Faces created by the CHAMFER are

colored blue in line 55).

But what if the user does not want a CHAMFER? We

can add the statements in lines 53 and 56 to skip this if the

use specifies a non-positive value

for disk:chamfer.

ESP has the ability to make some of its

LocalVariables available outside ESP (such as

in CAPS). This is done with

the OUTPMTR statements in lines 8 and 12:

OUTPMTR tire:volume # volume of tire

OUTPMTR disk:volume # volume of disk

The first one is fairly easy to compute since there is an

AtParameter that contains the volume of the last Body created

(or SELECTed). Line 39:

SET tire:volume @volume

stores that value in the OUTPMTR tire:volume.

Getting the volume of the disk is a bit harder, since we must

account for the holes and/or CHAMFER. The easiest

way of doing this is to make a CYLINDER that just

fits within the tire, INTERSECTing it with the

current configuration, and then looking up

its @volume. But the problem with that is that we

still want to keep the whole configuration (and

the INTERSECT operation will consume it).

The answer to this is STORE

and RESTORE. Earlier, we saw a special version

of RESTORE (that is, RESTORE .) to duplicate

the Body on the top of the Stack.

The STORE command in line 78:

STORE SolidModel 0 1

says to remember the Body on the top of the Stack

as SolidModel 0 (name and index) and furthermore

to leave the copy of the Body on the stack (because the third

argument keep had a non-zero value). So after line

78 the Stack is unchanged but the Body on the top of the Stack

was STOREd away for future use.

Lines 82 through 86:

SET xmax 2*tire:width

CYLINDER -xmax 0 0 +xmax 0 0 tire:diam_inner/2

INTERSECT

SET disk:volume @volume

STORE . # pop Body off stack

create the temporary CYLINDER,

INTERSECT it with the configuration that had been

on the top of the Stack, and then saves its volume

in disk:volume. The last line, STORE

. removes the Body that was left on the Stack after

the INTERSECT operation from the Stack.

Finally, we want to display the final configurations, so

we RESTORE it in line 89:

RESTORE SolidModel

and then name it (in the ESP GUI) so that it is

easier for the user.

One final note. Although it might seem daunting to build a

script like tutorial2.csm, if you build it up,

step-by-step, it is not quite so difficult.

As with the second Tutorial, this third Tutorial will start with the basics on a sample problem and then we will apply what we learned to the real Tutorial problem.

For the third tutorial, we will start without

a .csm file. This can either be done by starting

over or by pressing File and then New.

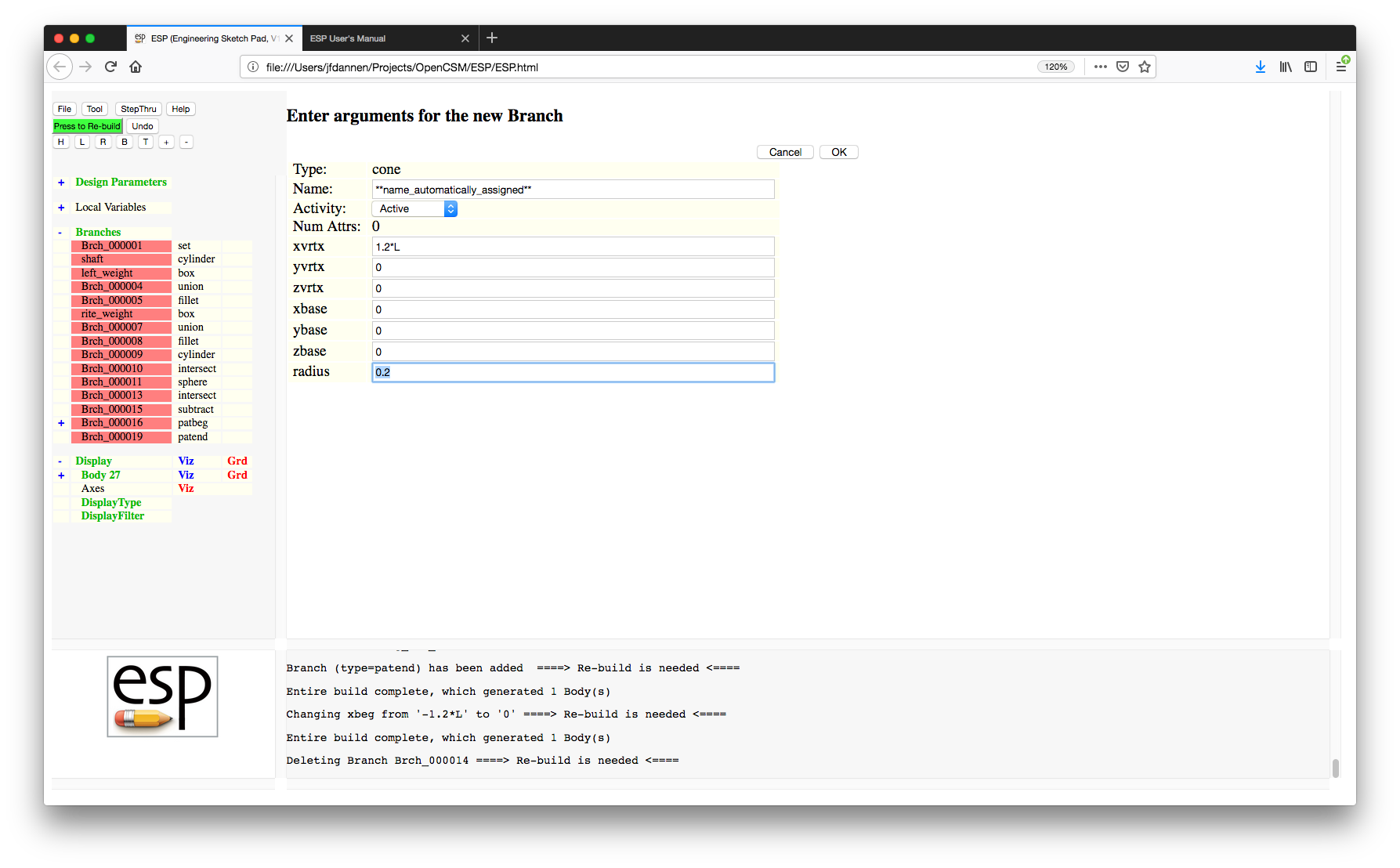

We are going to start with an empty sketch. To do this we will

first add a SKBEG Branch by pressing

Branches, selecting a SKBEG, and making

the x, y, and z all

zero. The final argument, relative, is set

to 1 to indicate that all coordinates in the

sketch are relative to the coordinates that were contained in

the SKBEG statement.

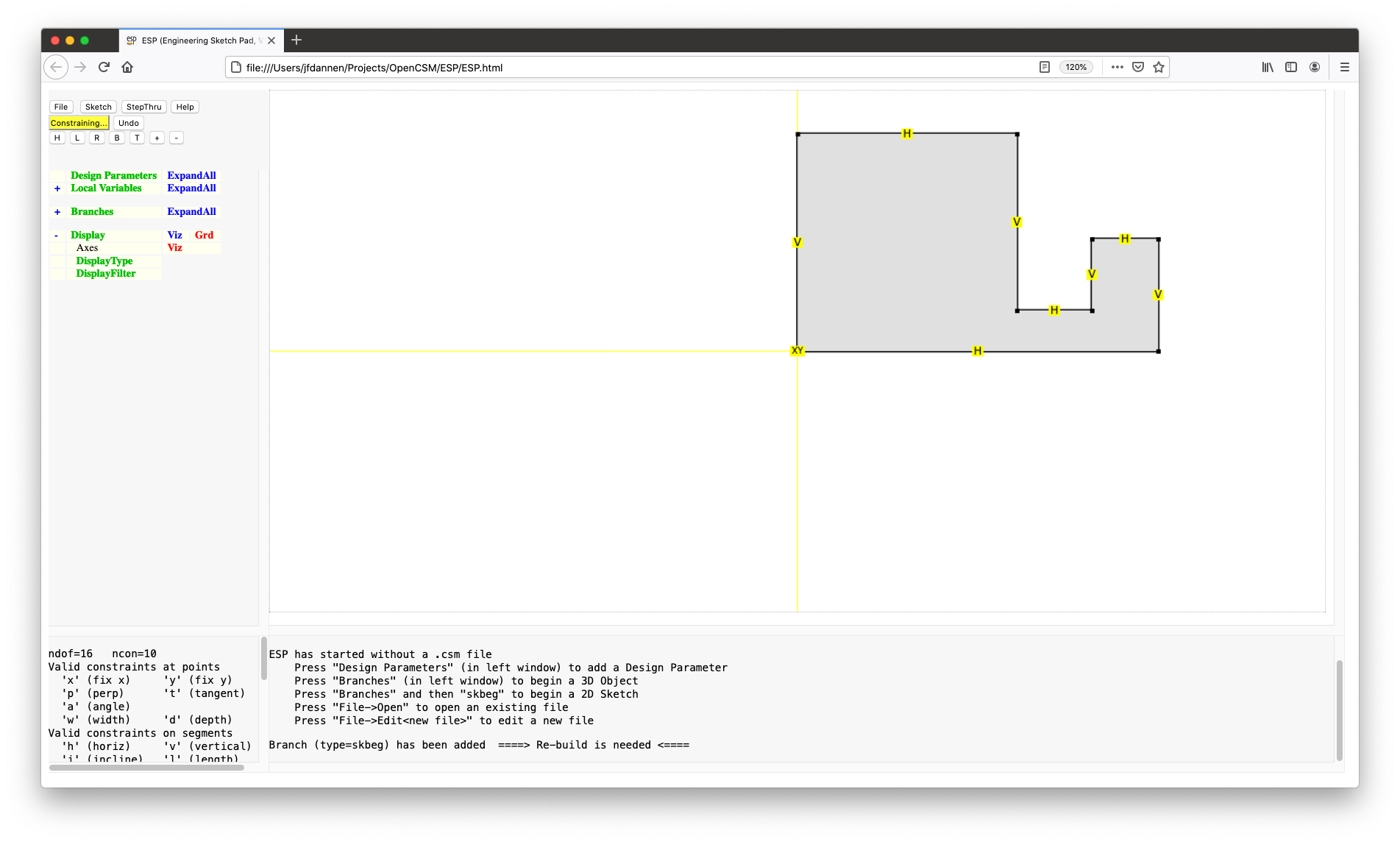

When a SKBEG Branch is added, ESP now

automatically adds the matching SKEND Branch and

automatically enters the Sketcher.

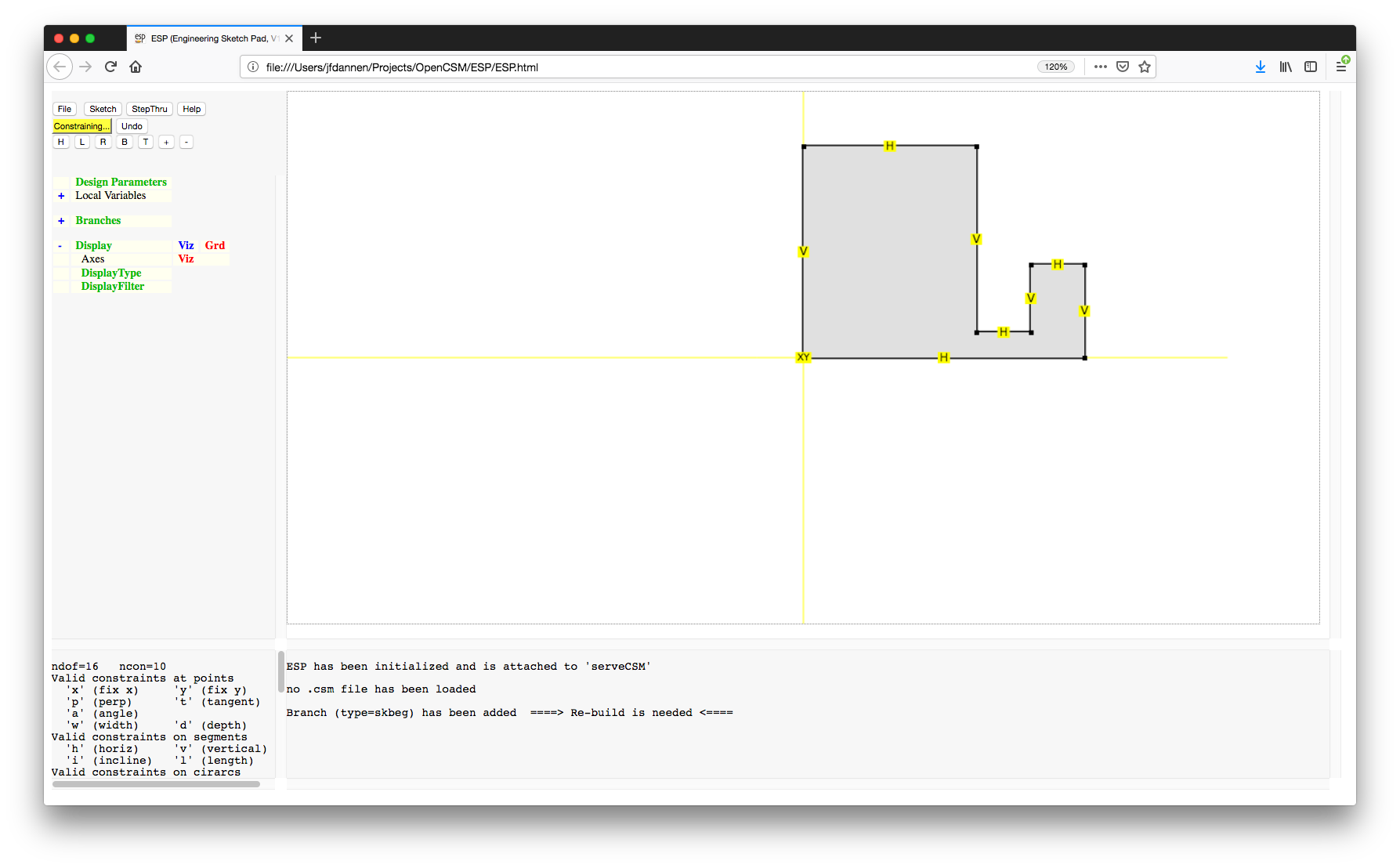

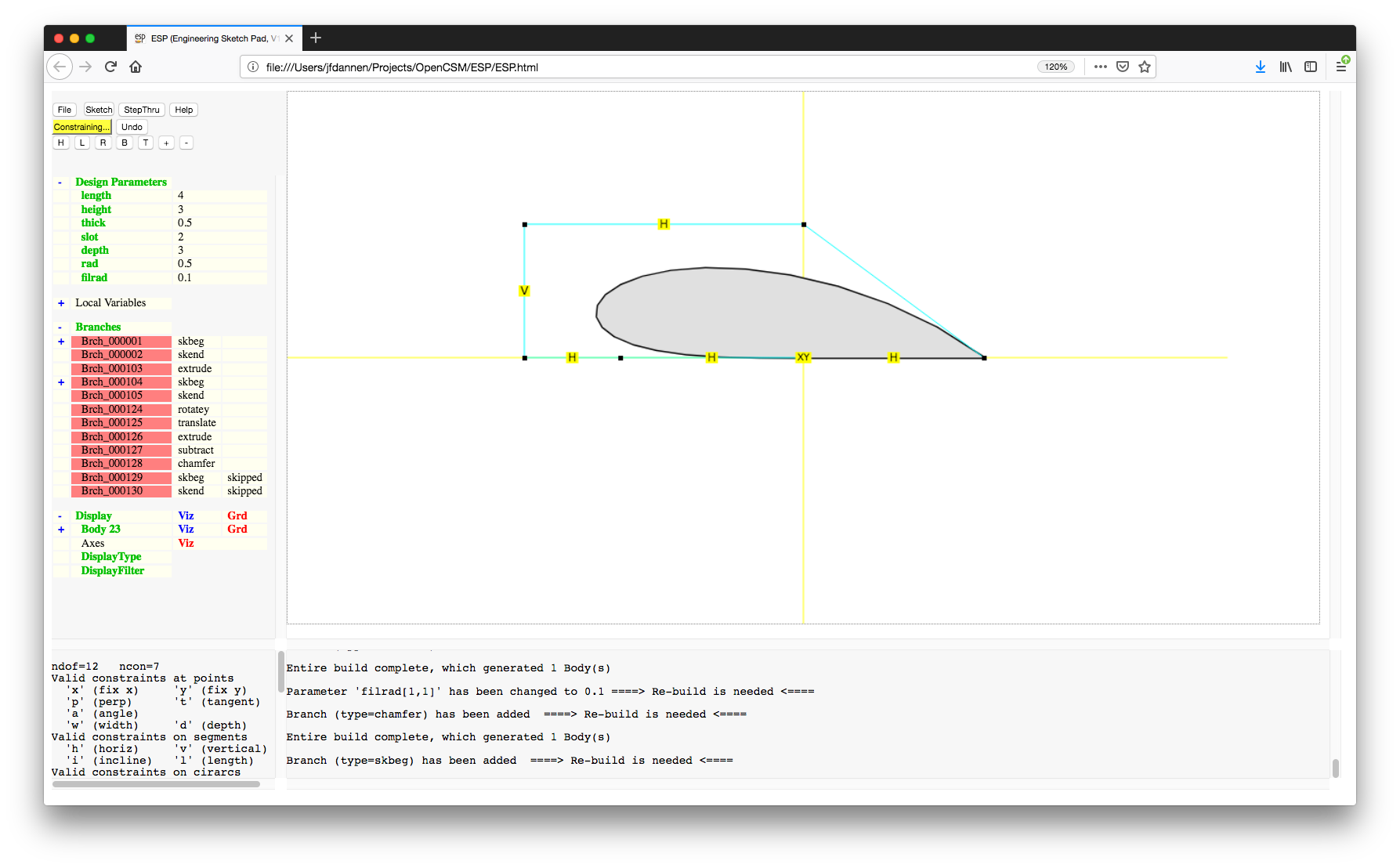

There are several changes between normal 3D mode and the Sketcher. The first difference is the buttons on the top of the TreeWindow. A second button has now appeared that is labeled Sketch, which will pop up a menu with the entries:

The legend on another button has now changed to Drawing..., which describes the status of the Sketcher.

Also, the KeyWindow now lists the status of the Sketcher

status, in terms of the number of degrees of freedom

(ndof) and the number of constraints

(ncon). This is followed by a listing of the

available commands in the Sketcher.

Within the Sketcher (which is displayed in the GraphicsWindow), there is a point at the center that has the legend "XY" and a blue line between that point and the current cursor location. As you move the cursor around in the Sketcher, you will notice that the blue line follows the cursor. You will also notice that if the line is approximately horizontal or vertical, it will change from blue to orange; this is an indication that if the current cursor location is chosen (see below), an implicit "horizontal" or "vertical" constraint will be created.

As you can see in the KeyWindow, you have 6 choices:

LINSEG) in the sketch;ARC) in the

sketch;SPLINE) to the

sketch;BEZIER) to the sketch;If you just press the mouse button, the l (lower case L) option will be chosen for you. So now, draw the sketch shown in:

in a counter-clockwise direction, starting at the point with the label "XY". Make sure that when you have completed the closed sketch, the last point should be the same as the first point. You can ensure this by noting that a circle is placed around the first point if the last point is "close enough".

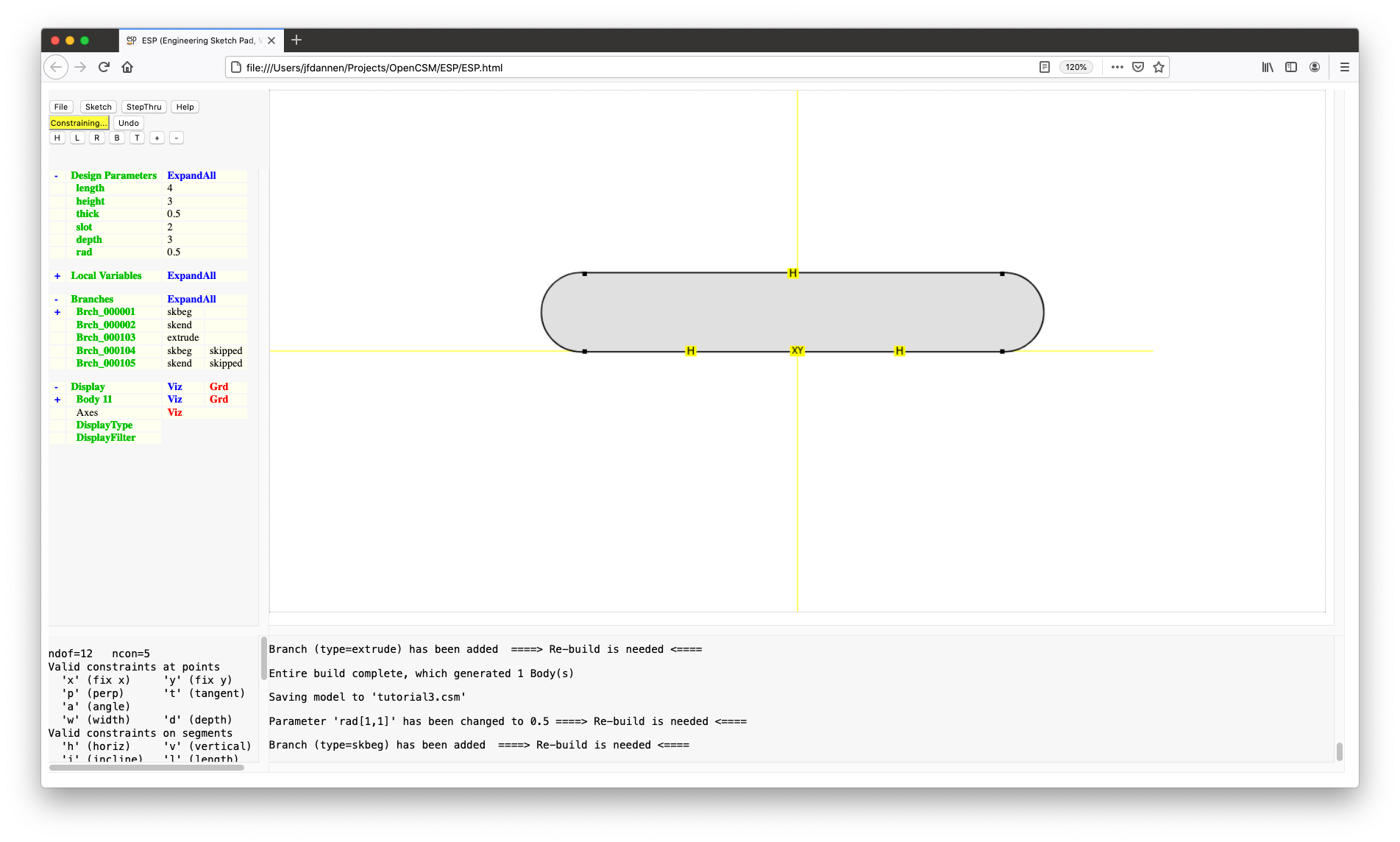

Notice that several of the line segments have either the letter "H" or "V" associated with them. These "horizontal" or "vertical" constraints were automatically added for you since you pressed l or the mouse button when the line was orange. Also notice that since you "closed" the sketch, it got filled in with grey. (If you had left it open by pressing the o key, there would be no filling.)

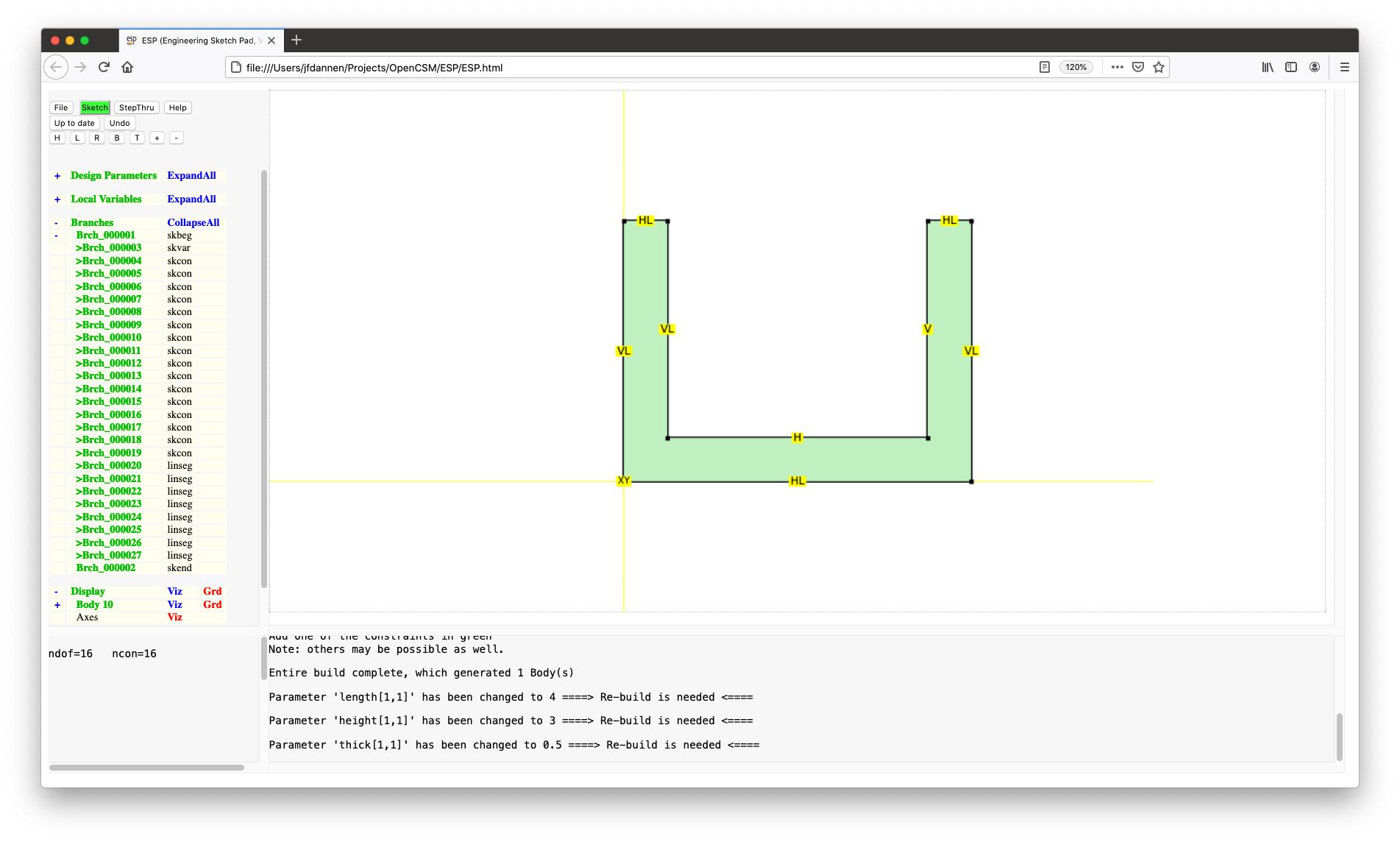

Your completed sketch should now have 16 degrees of freedom (since there are 8 points and no arcs) and 10 constraints. To see what the meaning of the various constraint letters are, notice that the KeyWindow has now changed to explain the meaning of the constraints. In summary, at the first point, both the "X" and "Y" coordinates are fixed. The other constraints are that certain line segments are either constrained to be horizontal ("H") or vertical("V").

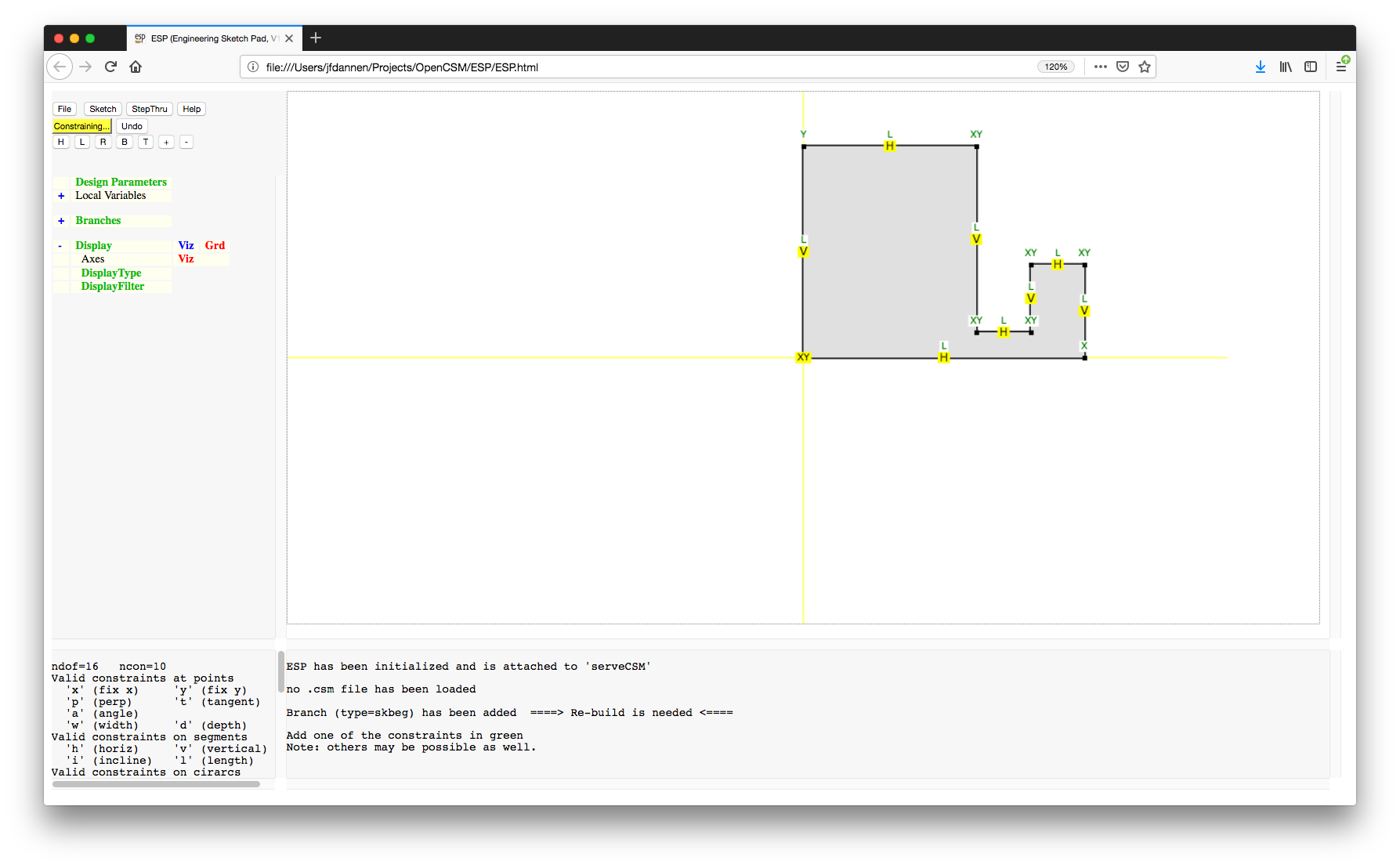

Since the number of constraints is fewer than the number of degrees of freedom, we will have to add more constraints.

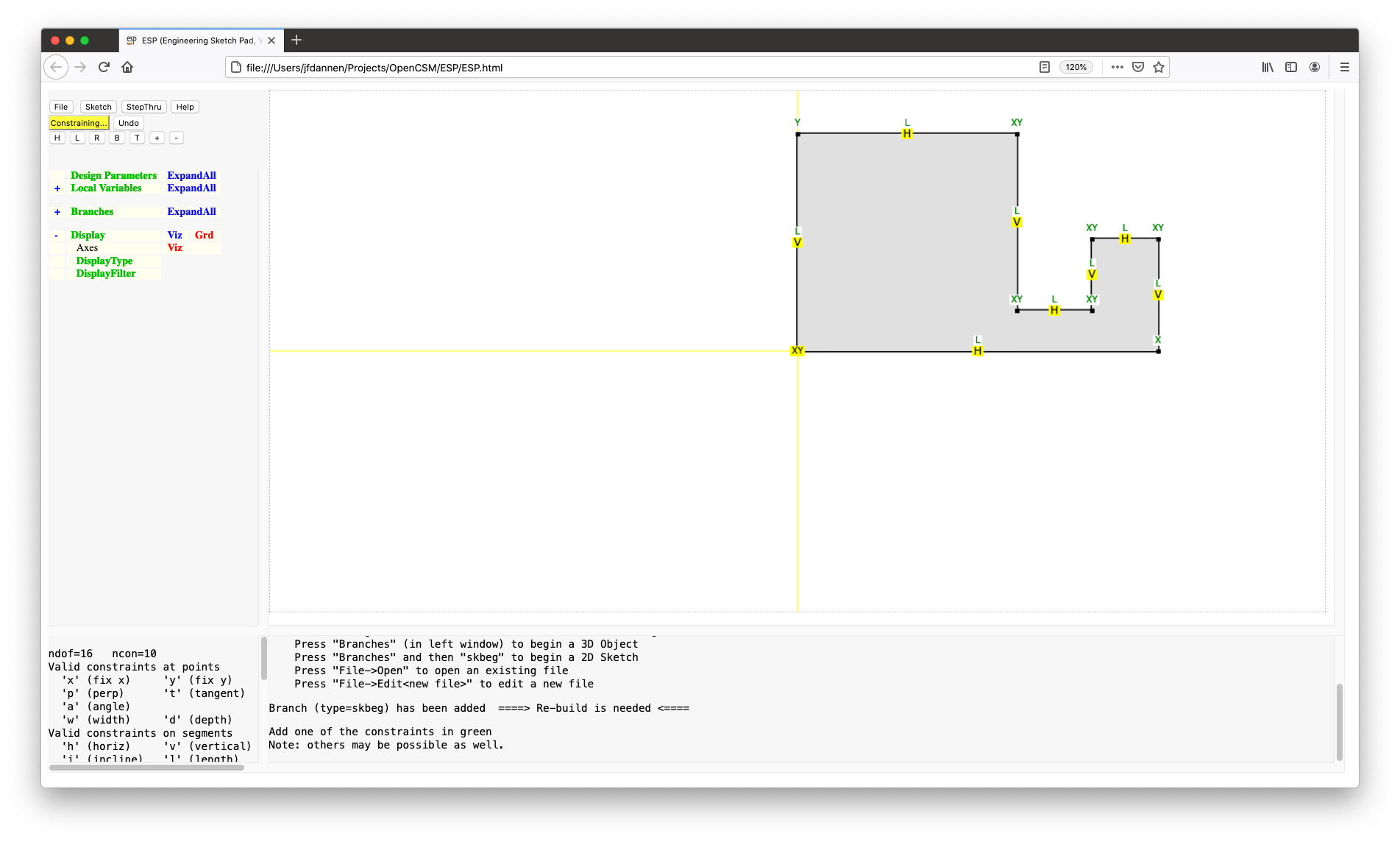

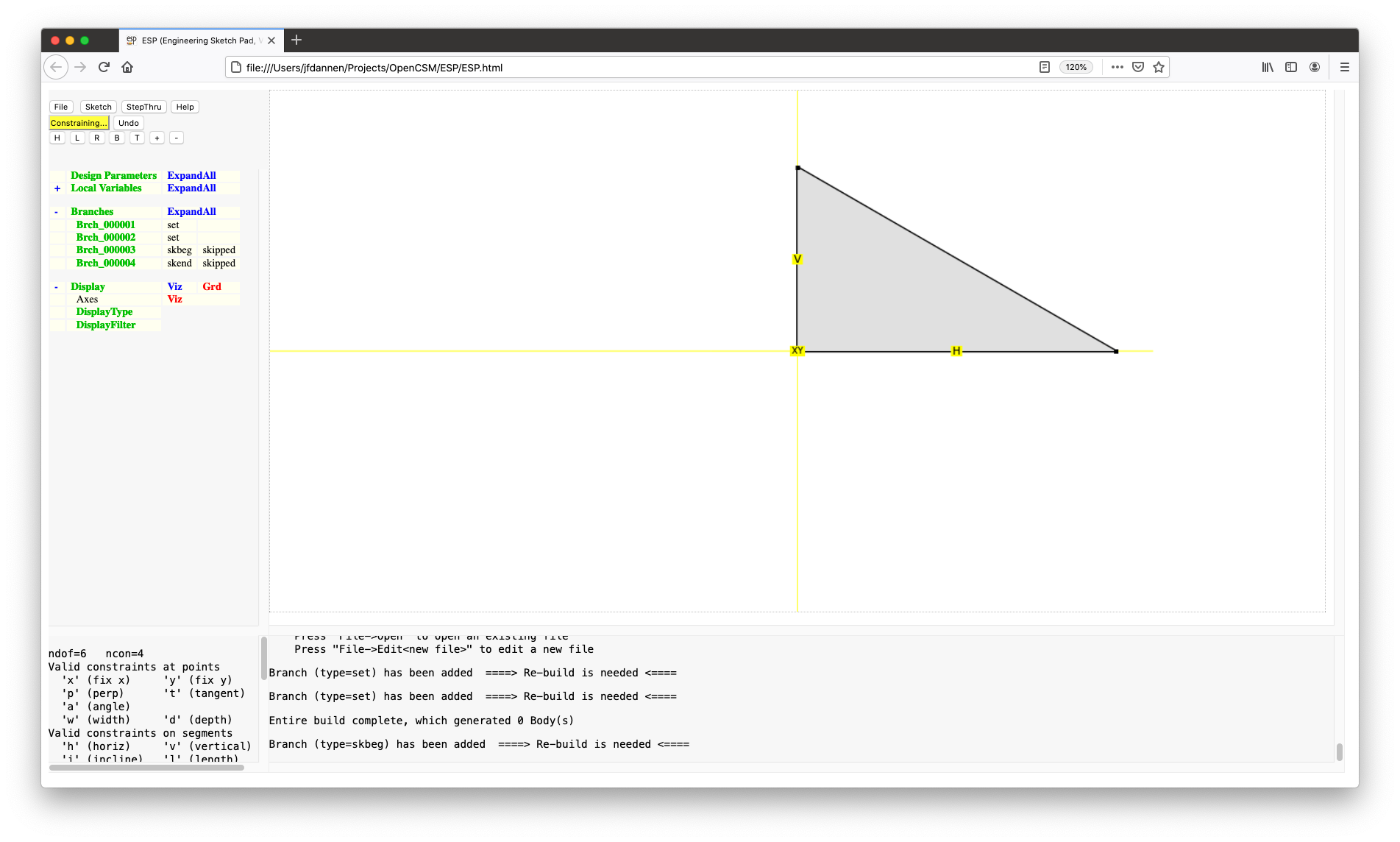

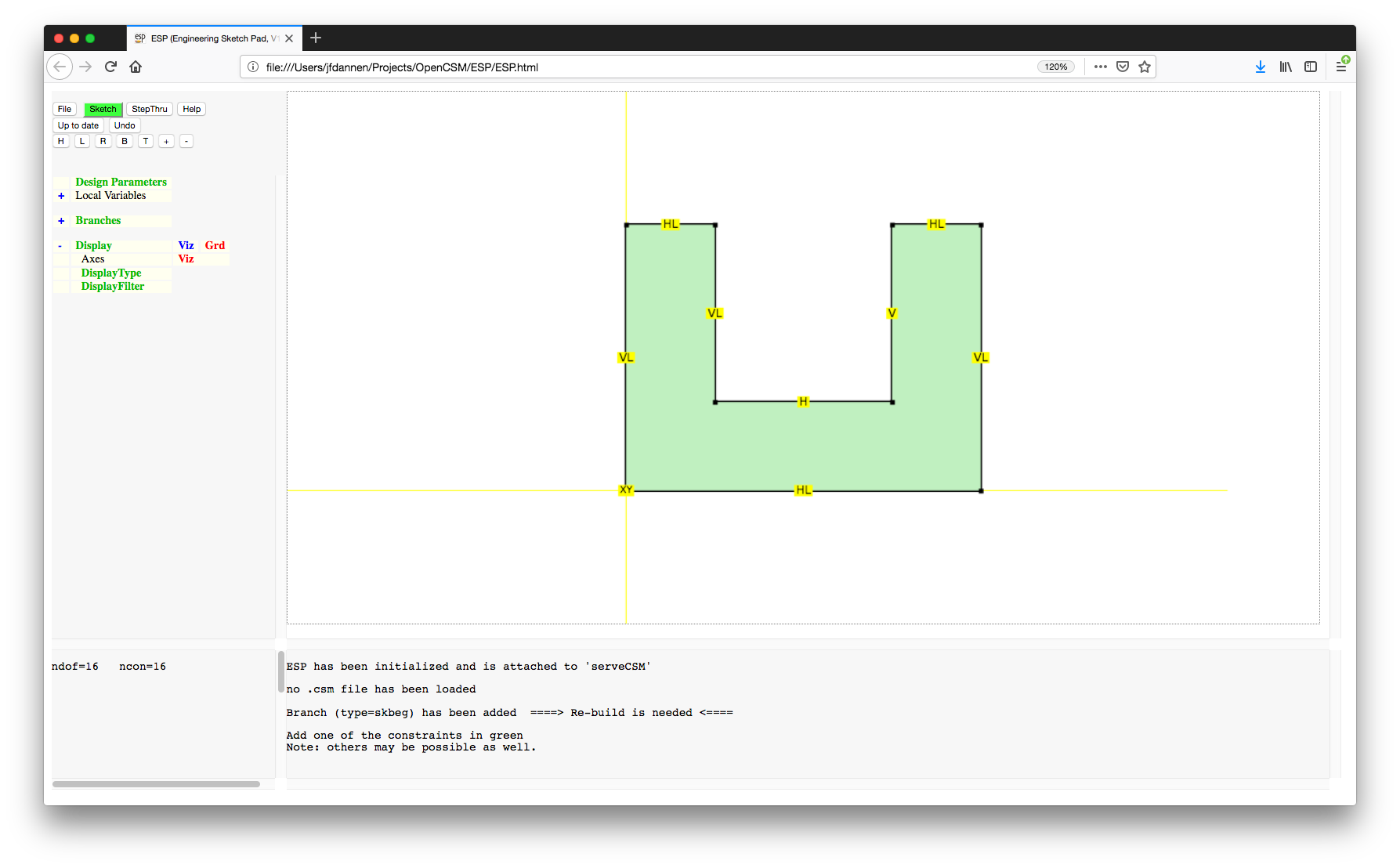

If you do not know what constraint(s) to add, press the Constraining... button and several choices will be presented to you (in green), as in:

We will choose the following:

4 in the pop-up;3;3;1;1;

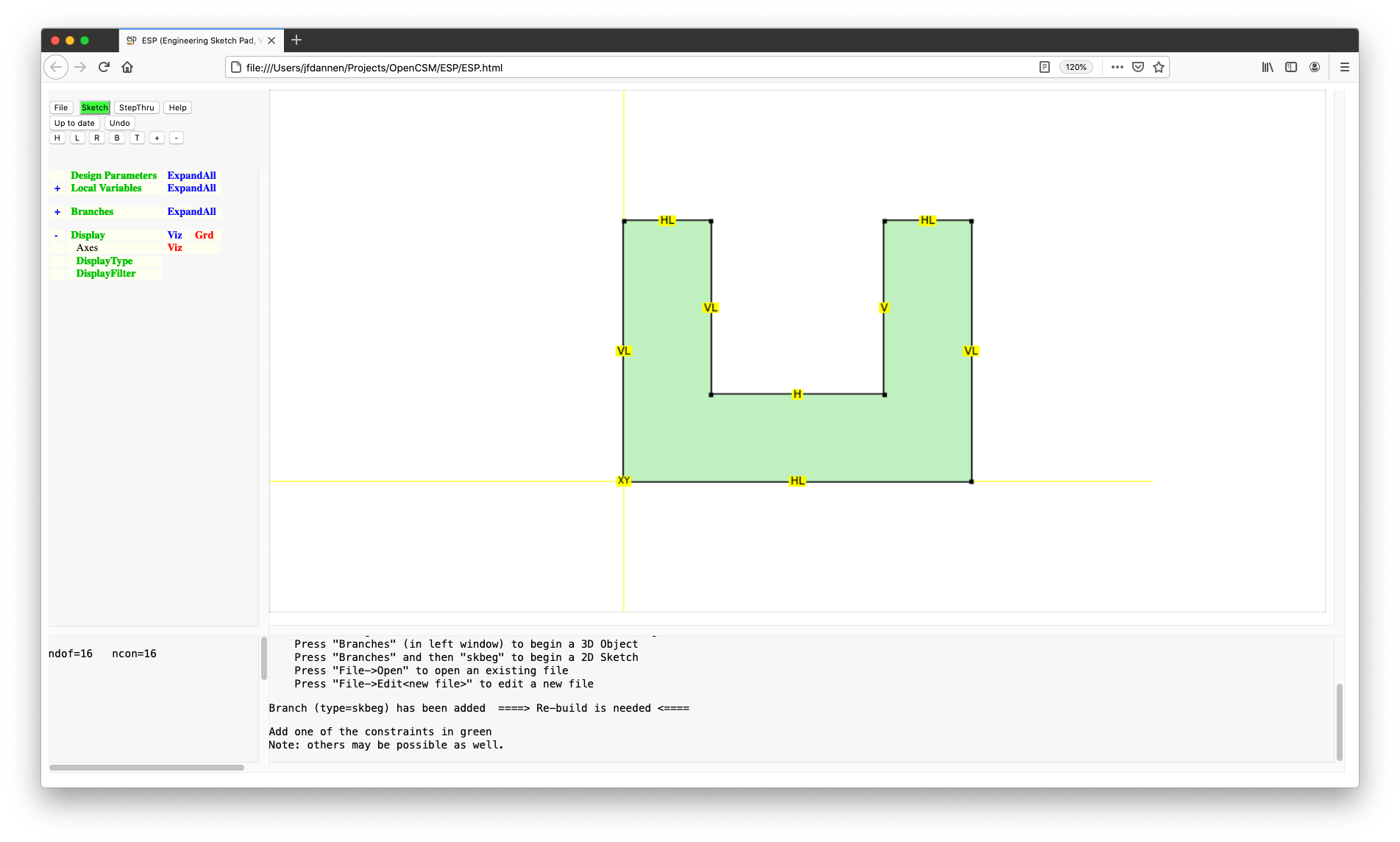

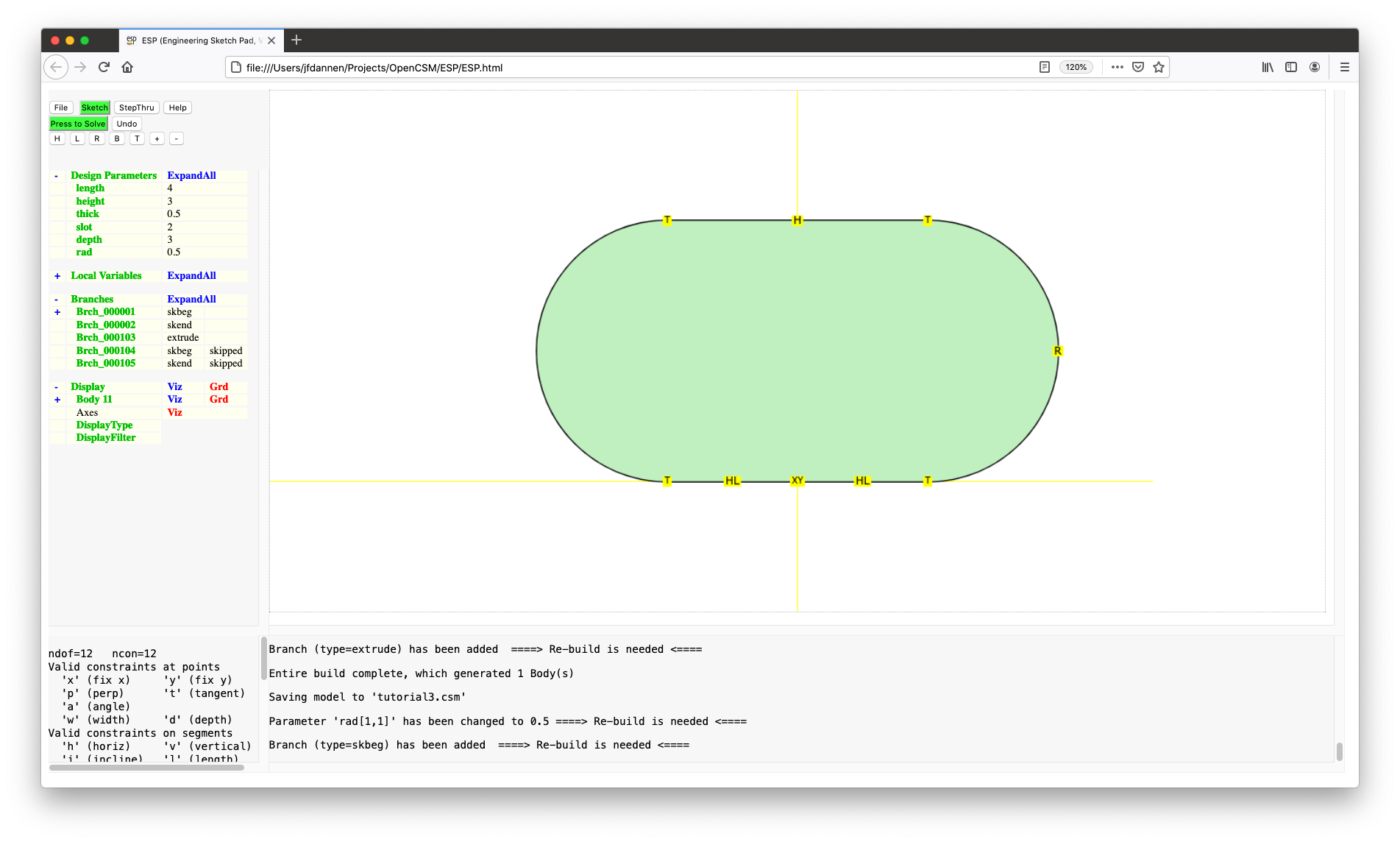

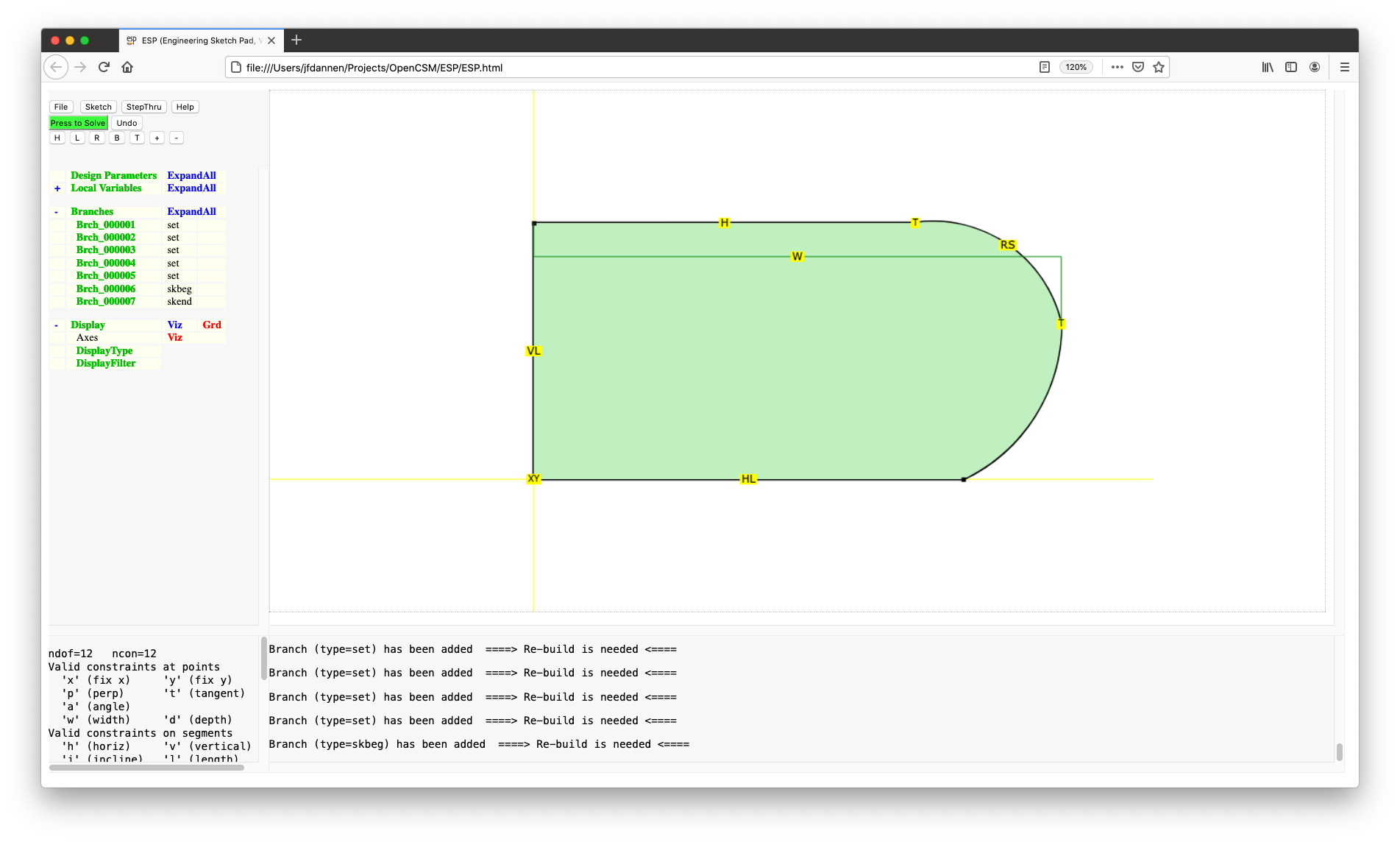

and2Since the number of constraints now matches the number of degrees of freedom, the grey fill has changed to a light green fill and the first button has turned green with the legend Press to Solve. Press that button and (hopefully) your sketch will solve. (If it does not, you can always remove constraints by moving the cursor over the constraint and pressing <, which deletes selected constraints at that point or on that segment.) To center the image, press the H button. You screen should look like:

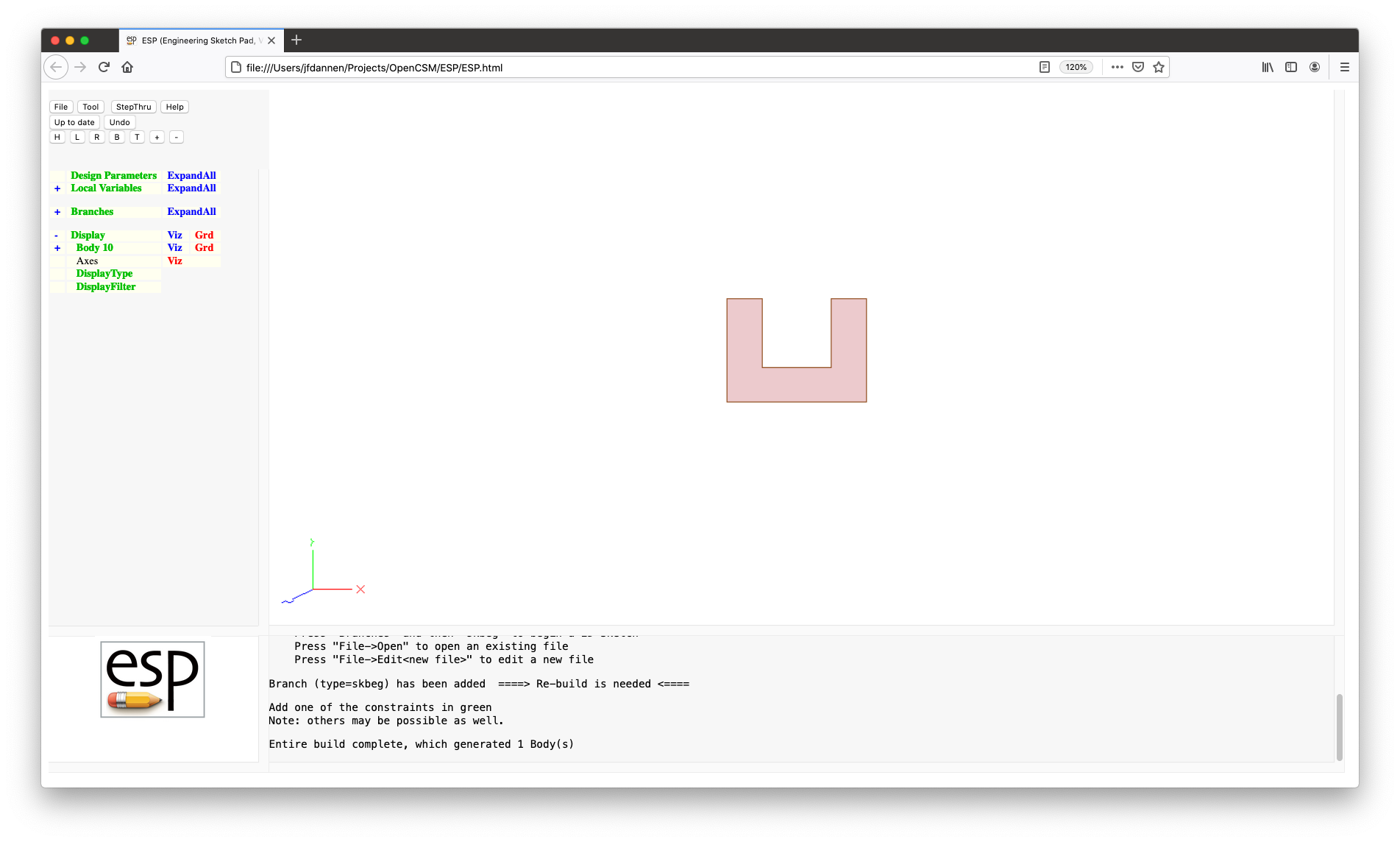

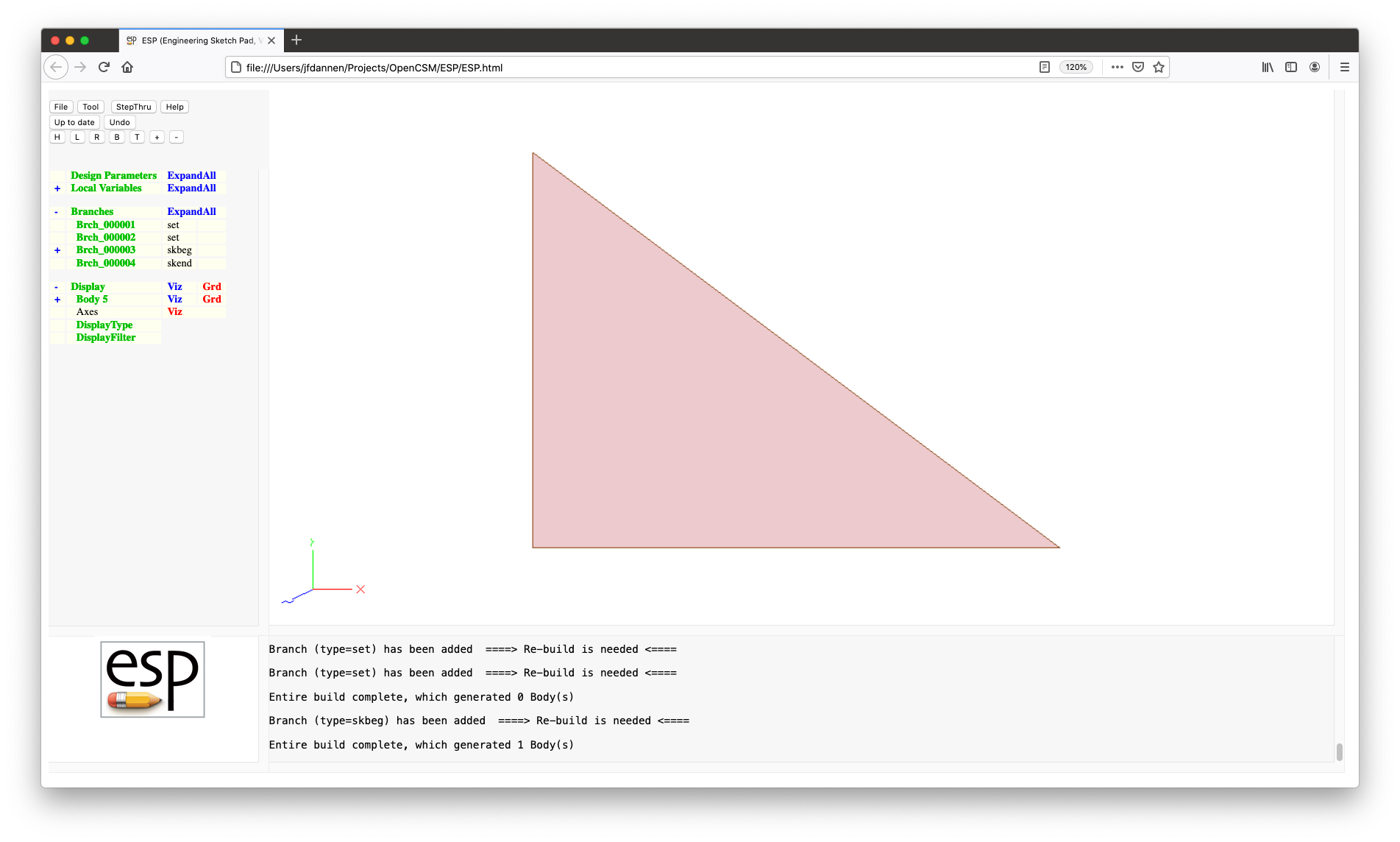

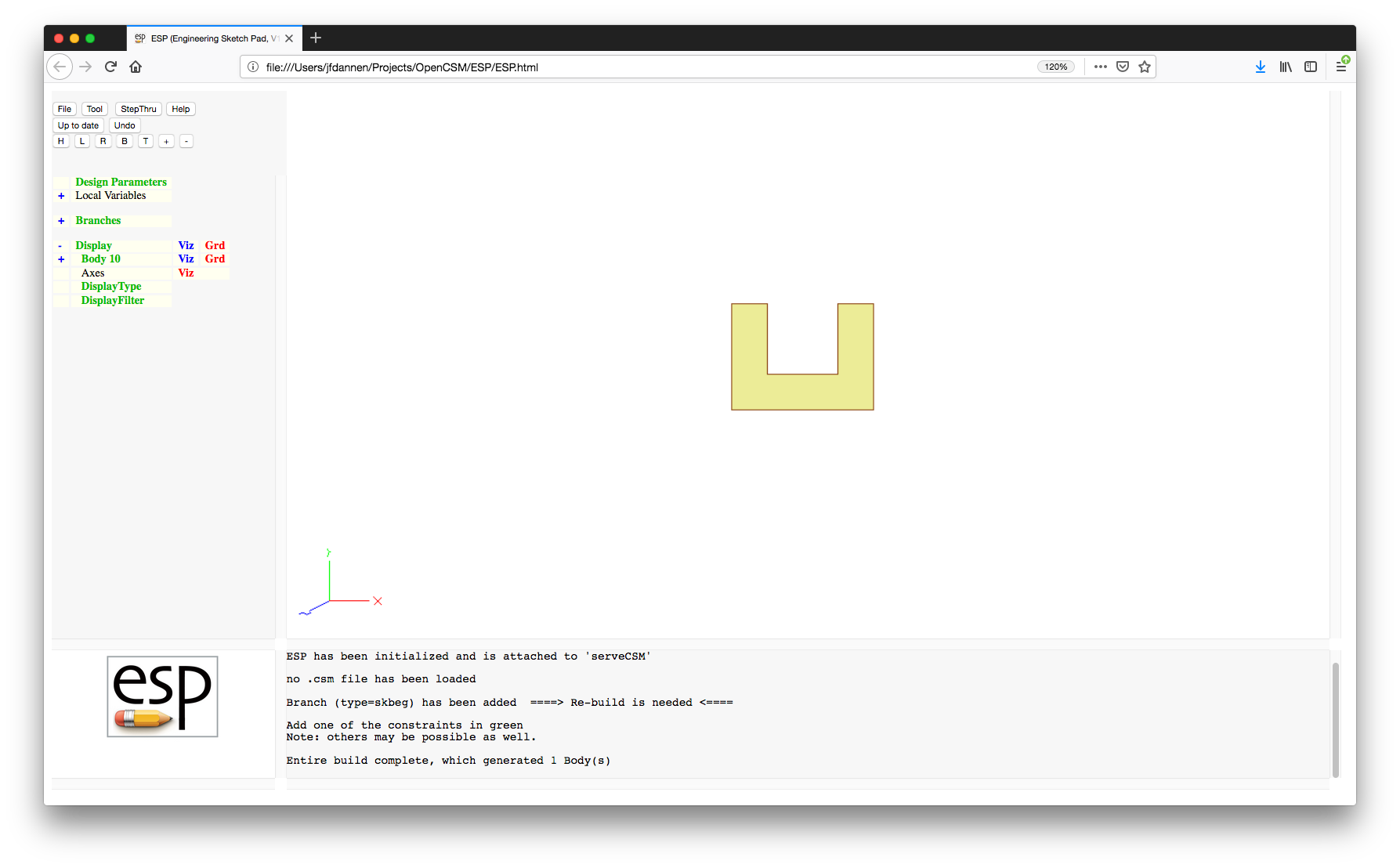

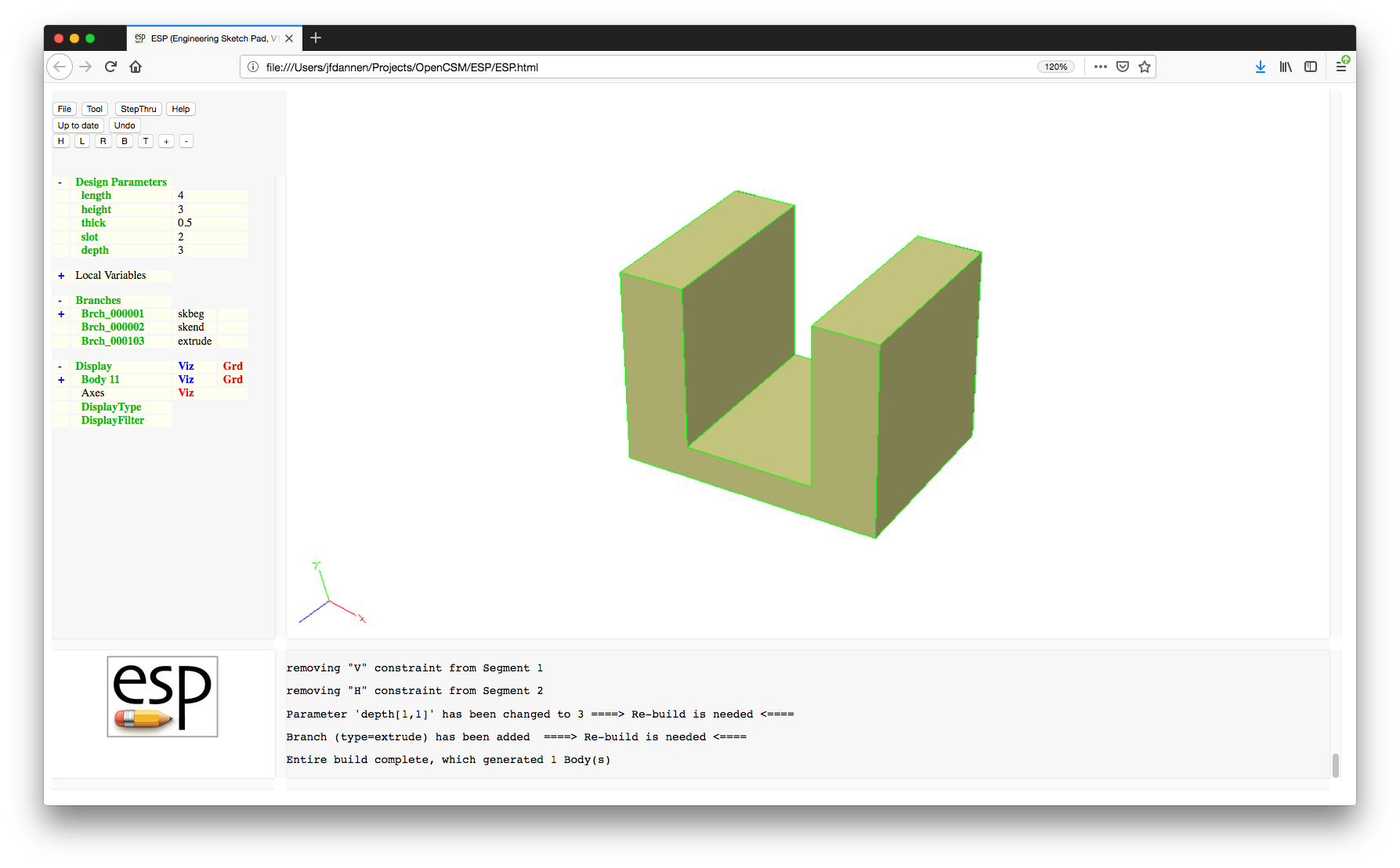

We are now finished with the Sketcher (for now), so press Sketch and then Save to return to the normal 3D view. You can now press Press to Re-build to rebuild the 3D object, giving a screen that looks like:

You will notice that we hard-coded dimensions into our sketch.

To make the sketch more useful, it would be convenient to drive

it with DesignParameters. To do this, we first have to create

them. This is done in the code editor or by pressing

Design Parameters in the TreeWindow,

entering length as the Parameter name and setting

its value to 4.

In a similar way, create a height DesignParameter

whose value is 3 and a thick

DesignParameter whose value is 0.5.

Now, let us use these DesignParameters in the sketch. To do

this, choose one of the statements between the SKBEG and

SKEND. I suggest choosing Brch_000003,

which is the SKVAR statement (which shows the

default locations of each of the sketch points).

Select Enter Sketcher.

We are now going to change the various "L" constraints, by moving the mouse over the "L", pressing L and entering the new value. Specifically, you should change the "L" constrains as follows:

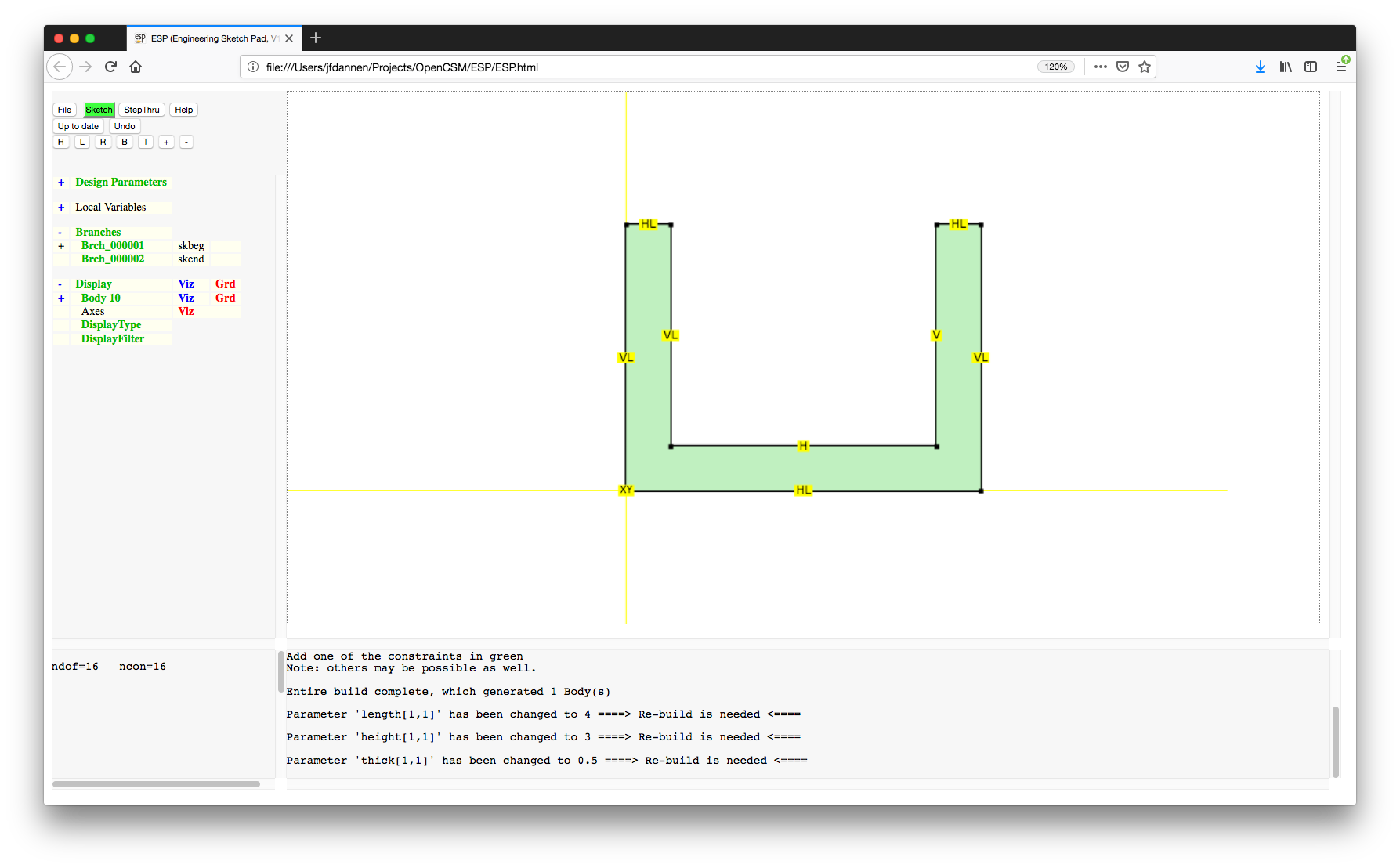

length;height;height;thick;thick; andheight-thickPress to Solve, giving:

Press Sketch and Save (to exit the Sketcher) and Press to Re-build to use the latest changes.

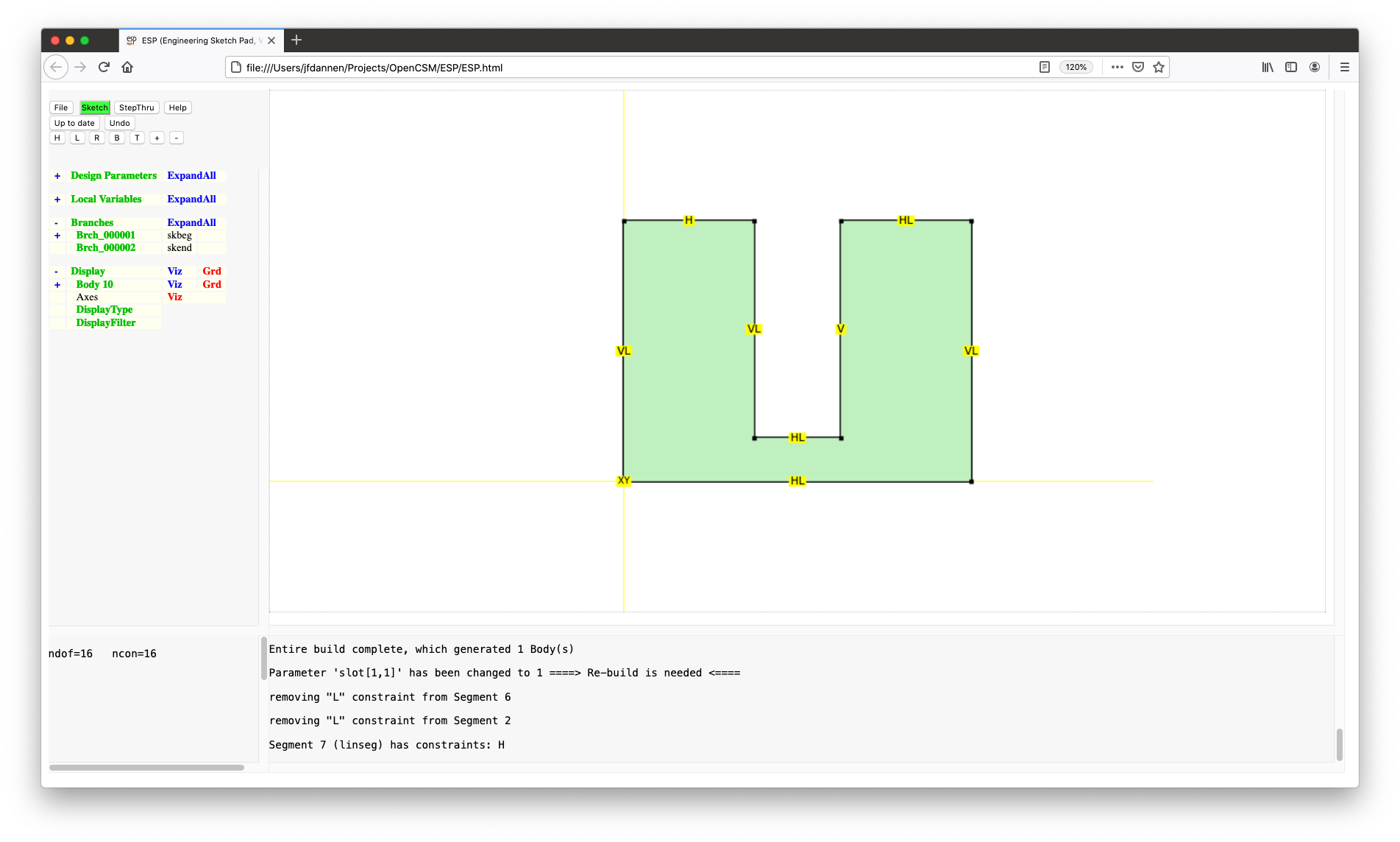

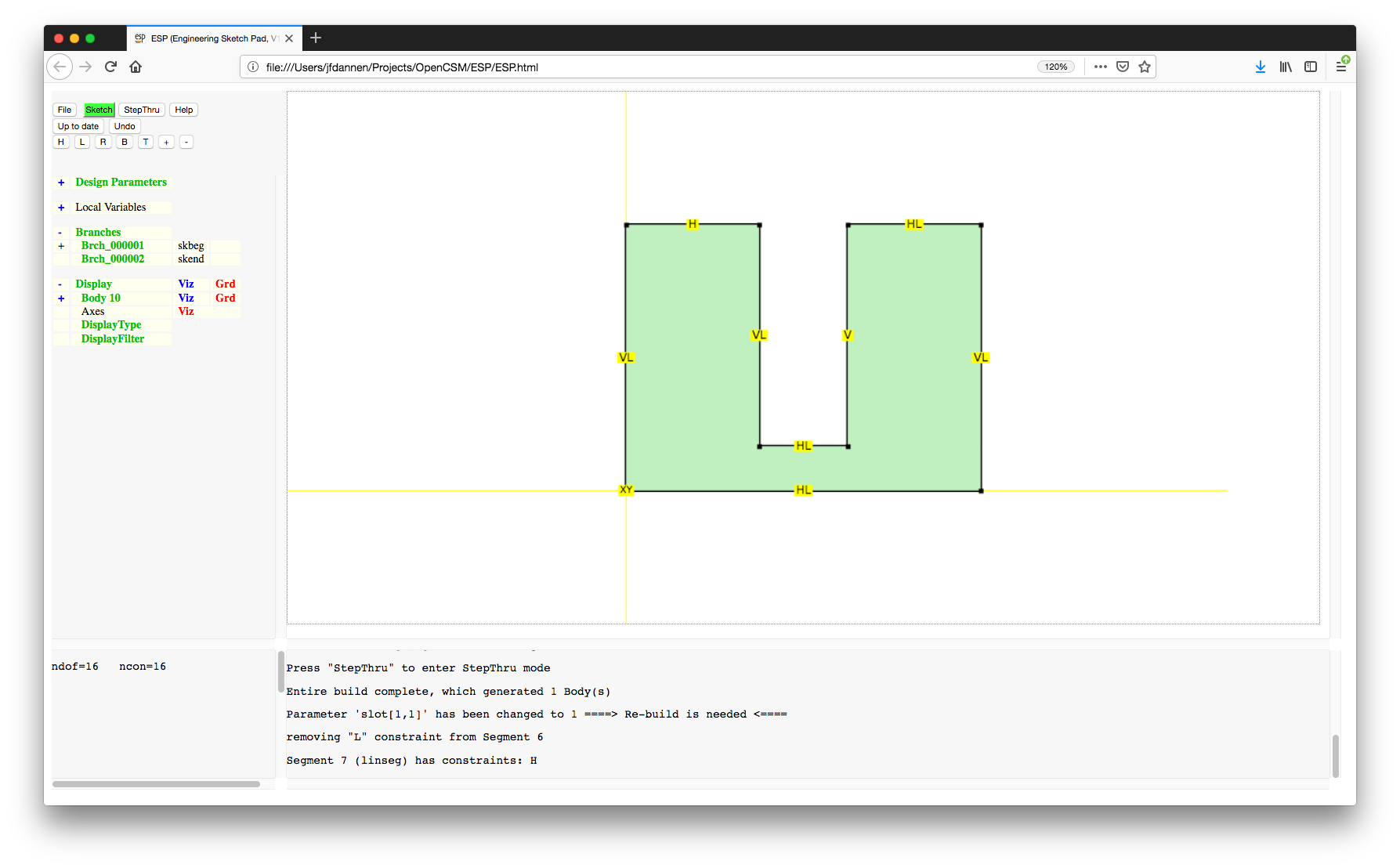

Think about what we have done. We have made a U-shaped channel whose overall length and height were given, and whose channel walls were all set to "thick". Suppose instead that the "design intent" of the channel was to create a channel of a given slot width. In this case, we would want to constrain the sketch differently.

Start by creating a DesignParameter named slot

whose single value was 1. Now

select Brch_000002 and Enter Sketcher. We are

going to have to remove the "L" constraints from the top two

horizontal segments, so go to each and press <.

Since there are two constraints here, you are asked which

constraint to remove. Simply enter L at the

prompt and the length constraint will be removed but the

horizontal constraint will remain. If you want to remove all

constraints, press < multiple times.

Now move the mouse over the horizontal segment at the bottom of

the slot and press L and set the length to

slot. You will notice that the sketch is

under-constrained (is grey). We need to add a constraint that

the slot is centered. To do this, we are going to make the

lengths of the two small horizontal segments near the top on

each side of the U equal to each other. The first step here is

to identify one of the segments. This is done with

the ? command. So, move the cursor over the top-left

horizontal segment and press ?. You will notice in the

MessageWindow that this is segment 7. Now move over the

top-right horizontal segment and enter the length ::L[7],

which tells it to use the same length as segment 7. Press

to Solve to give:

Press Sketch and Save and Press to Re-build.

Now open the list of DesignParameters (using the "+" to

the left of "Design Parameters") and change the value

of slot to 2. Press to Re-build to

see the effect of this change.

We will now experiment with some of the other constraints. Specifically we will be removing some of our "H" and "V" constraints and instead add constraints at some of the points. Re-enter the Sketcher and move the cursor over the right-hand segment, press < to remove the vertical constraint. Similarly remove the horizontal constraint from the top-right horizontal segment.

The sketch is under-constrained (is grey). We are going to add

a perpendicularity constraint at the point at the lower-right

corner by moving the mouse over the point and pressing

P. Just to be different, at the top-right

point we are going to add an "angle" constraint by pressing

A and adding a value of 90. Note that an

angle less than 180 turns to the left whereas one greater than

180 turns to the right.

Press to Solve and Sketch and Save.

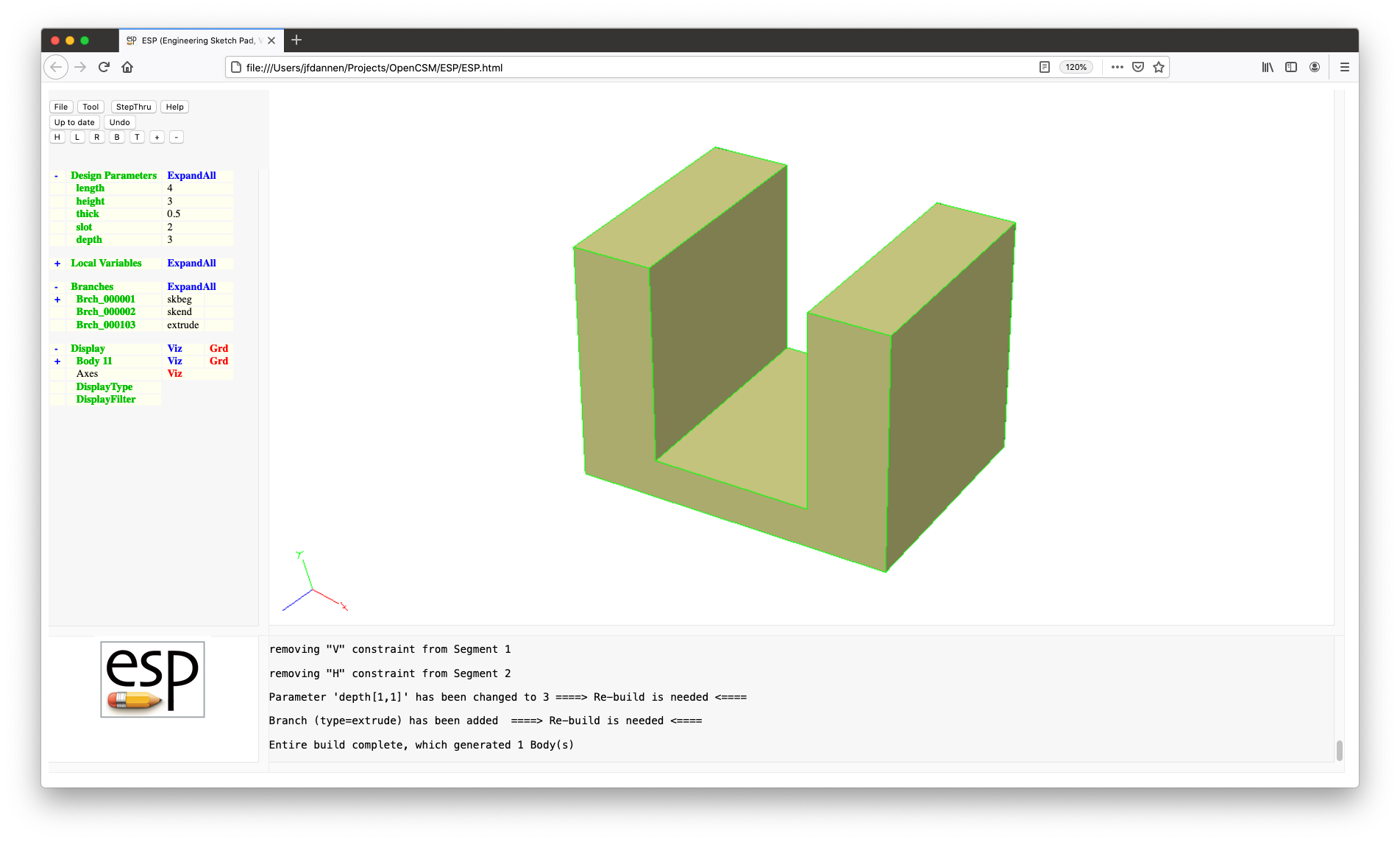

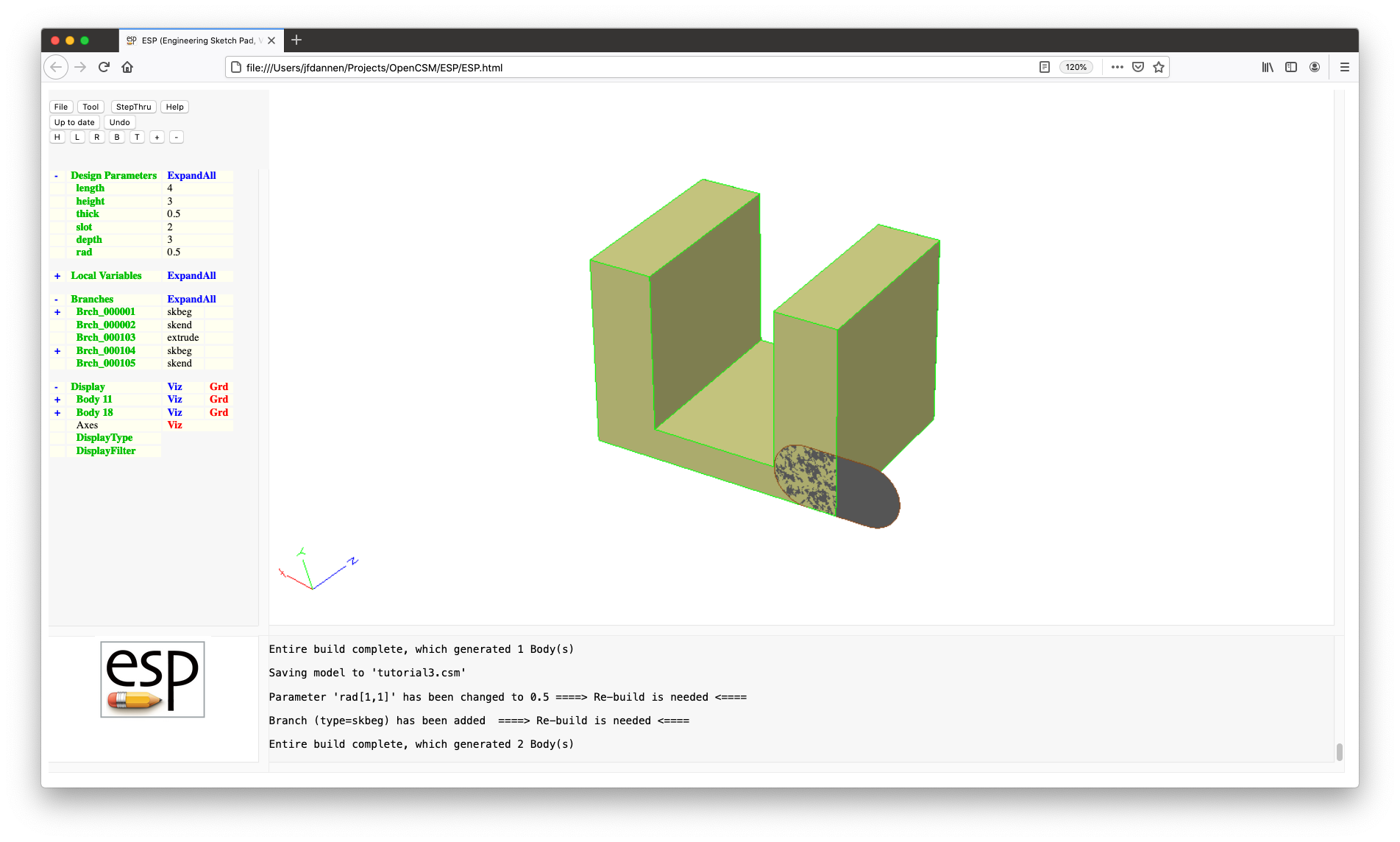

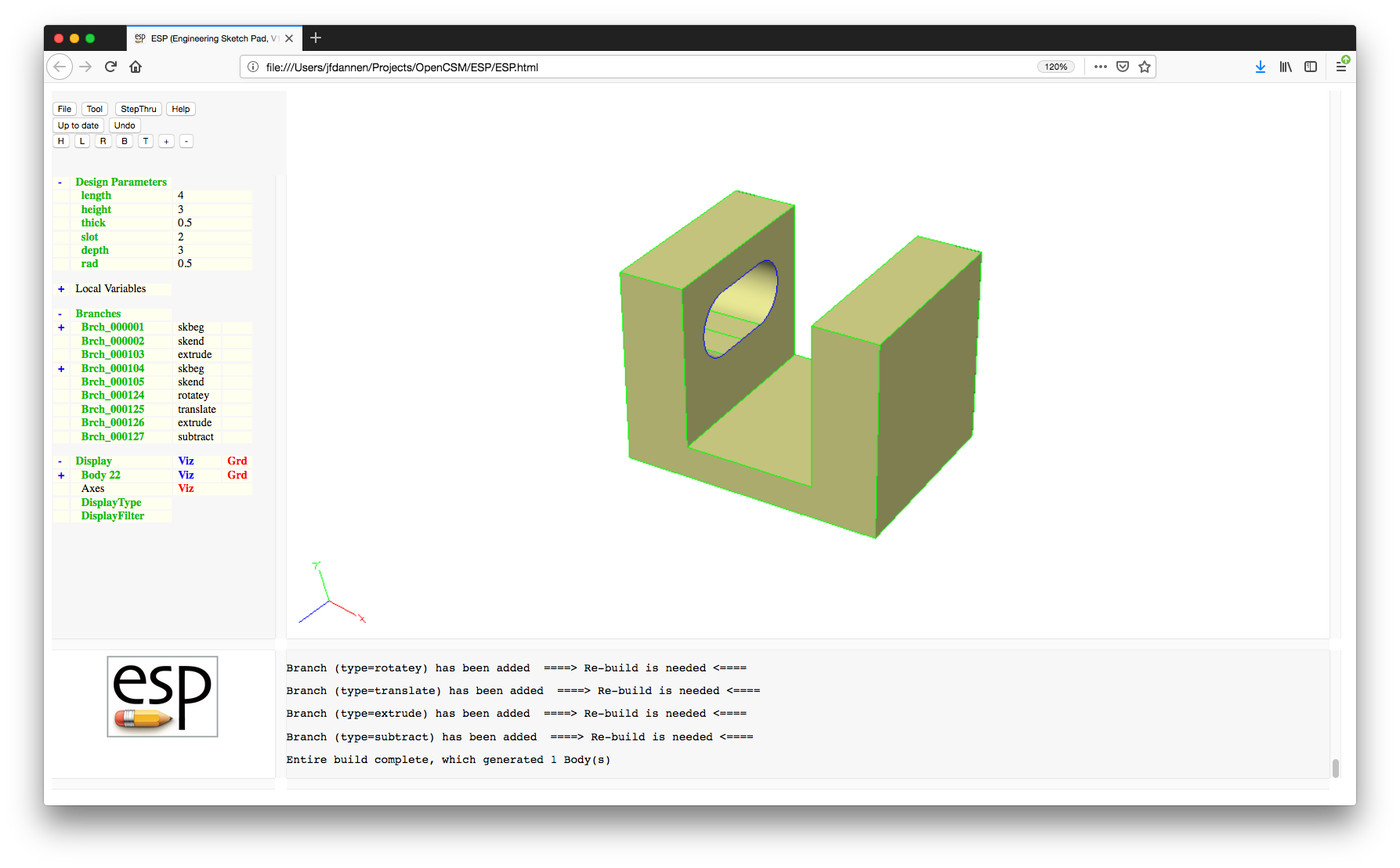

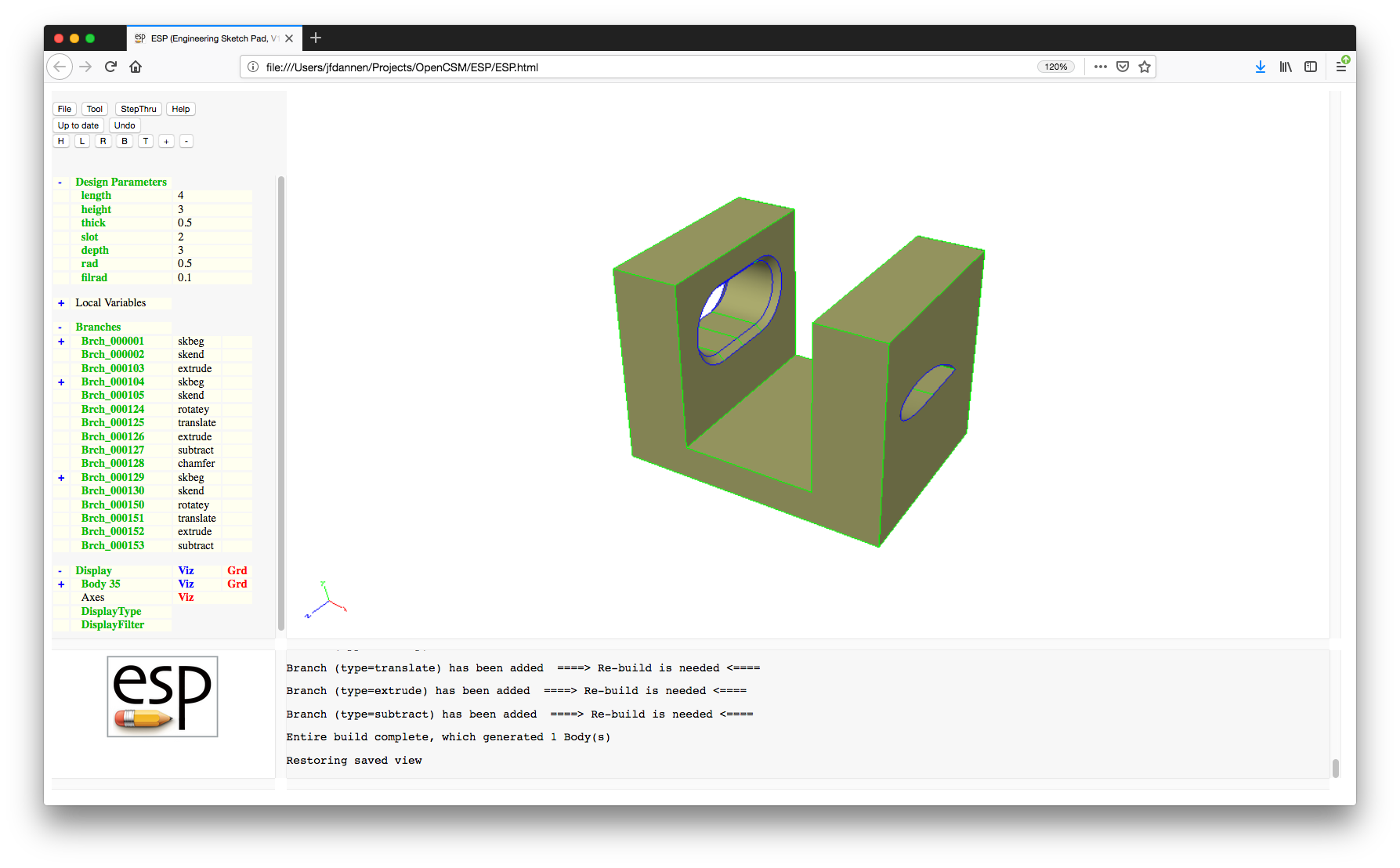

We are now going to extrude the sketch into a solid. This is

done by first creating a DesignParameter

named depth and giving it a default value

of 3. Then add an EXTRUDE Branch (by

pressing Branches in the TreeWindow), whose arguments

are dx=0, dy=0,

and dz=depth. This will extrude the sketch in the

"z" direction (out of the screen). Press to Re-build,

yielding:

As with most programs, it makes sense to periodically save your

work, so press File, Export FeatureTree, and save

the current model in a file named

"tutorial3". (Note that the

".csm" suffix will automatically be added for

you.)

To see the .csm file associated with the current

model, press the File and Edit: tutorial3.csm buttons. For now

you can ignore the warning. At the top of the file, all the

DesignParameters are defined (along with their current values).

This is followed by the Branches in the Feature Tree. Note the

the sketch starts with a SKBEG statement. This is

followed by a SKVAR statement that specifies the

initial locations of the various points in the sketch. (These

positions were automatically set up for you when you drew the

sketch). Following that, there is a series

of SKCON statements that define the various

constraints in the Sketcher. The first argument of

each SKCON statement is the constraint type (which

corresponds with the letters in the Sketcher), followed by the

point (or segment) number and the value; again these were

automatically set up for you when you drew the sketch and

constrained it. This is then followed by a series

of LINSEG Branches, which say that our current

sketch is made up of a series of line segments. Again the

number of the points to use in the LINSEG Branches

was set up automatically for you.

Press Cancel to exit the editor and return to the normal view.

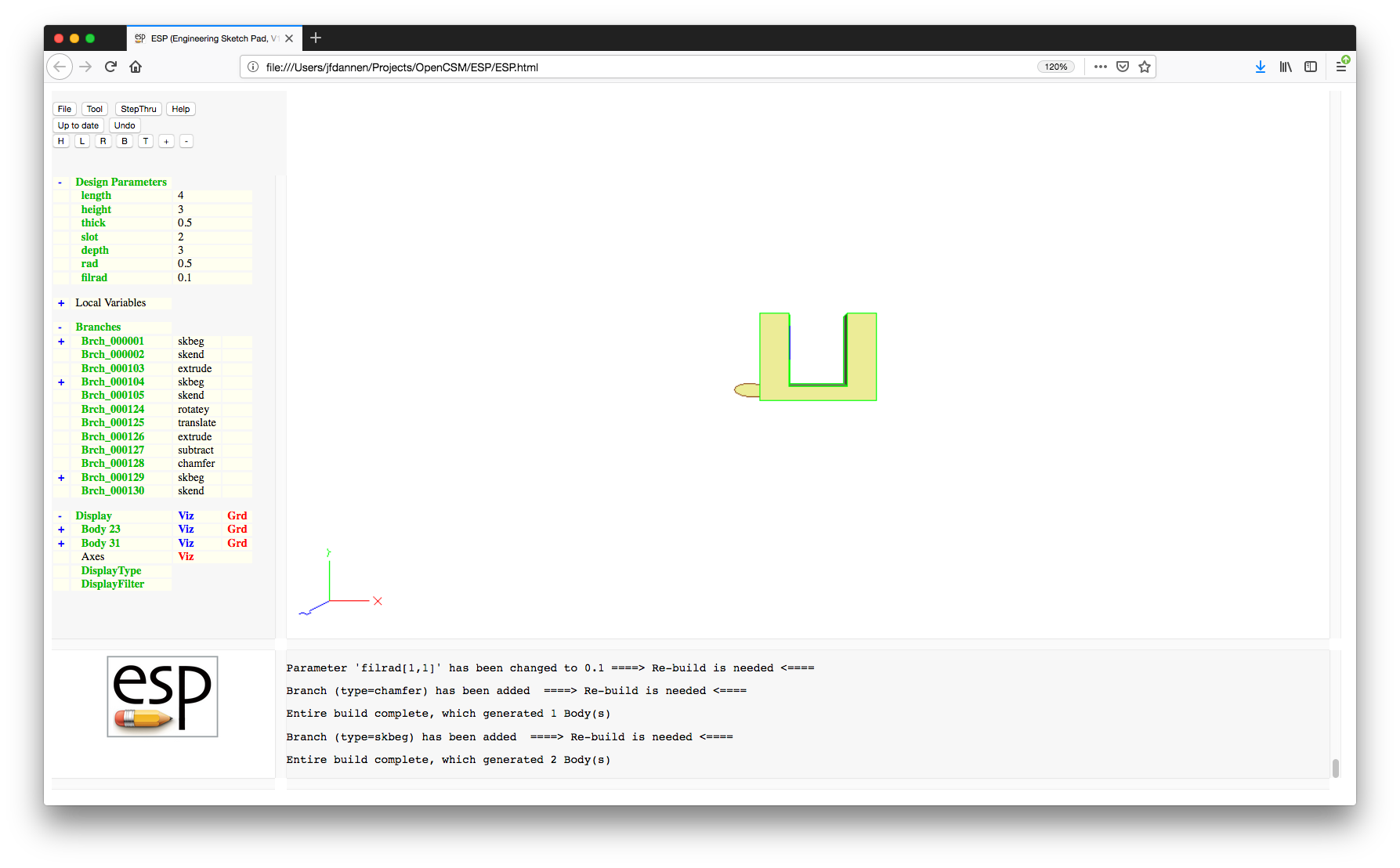

We are now going to create another sketch, which will be used

to cut a hole in the left upright of the bracket. This cut will

be parameterized with a DesignParameter named rad

whose value is 0.5. (You can create that now.)

Now we want to create a new sketch. We do this by adding a

SKBEG Branch (by pressing Branches in the

TreeWindow); set all its arguments to 0.

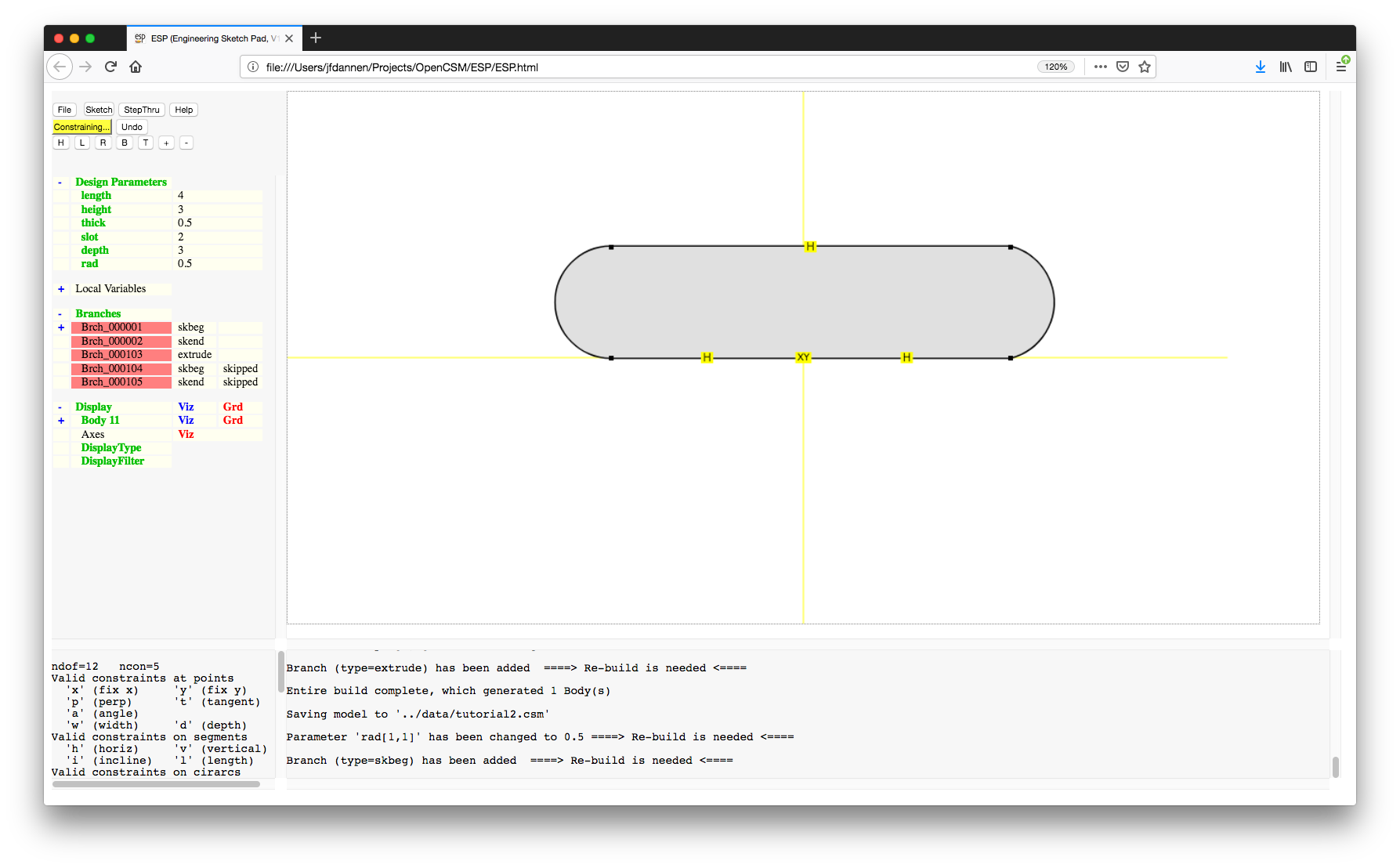

The sketch that we are going to create consists of a race-track-shape curve, as shown in:

This is done with the following actions. Draw a horizontal segment off to the right (make sure the line from the last point is drawn in orange) and press L (or click the mouse) to create the first horizontal segment. Then move the mouse up and press the C key to create a circular arc segment. When you have done that, the segment that you just created turns red and follows the cursor; move the cursor and see how it changes. Once it is located at approximately the correct location, press the mouse button. Then sketch the horizontal line segment to the left, a circular arc on the left end, and finally a line segment back to the original point.

You might be wondering why the bottom of the racetrack was

created with two LINSEGs. The reason is that we

are ultimately going to want to center the sketch on the

left-leg of the bracket, so having a point at the "center" of

the sketch will be convenient.

We are now going to constrain the sketch as follows:

rad;rad;rad (that is, you set the radius of the

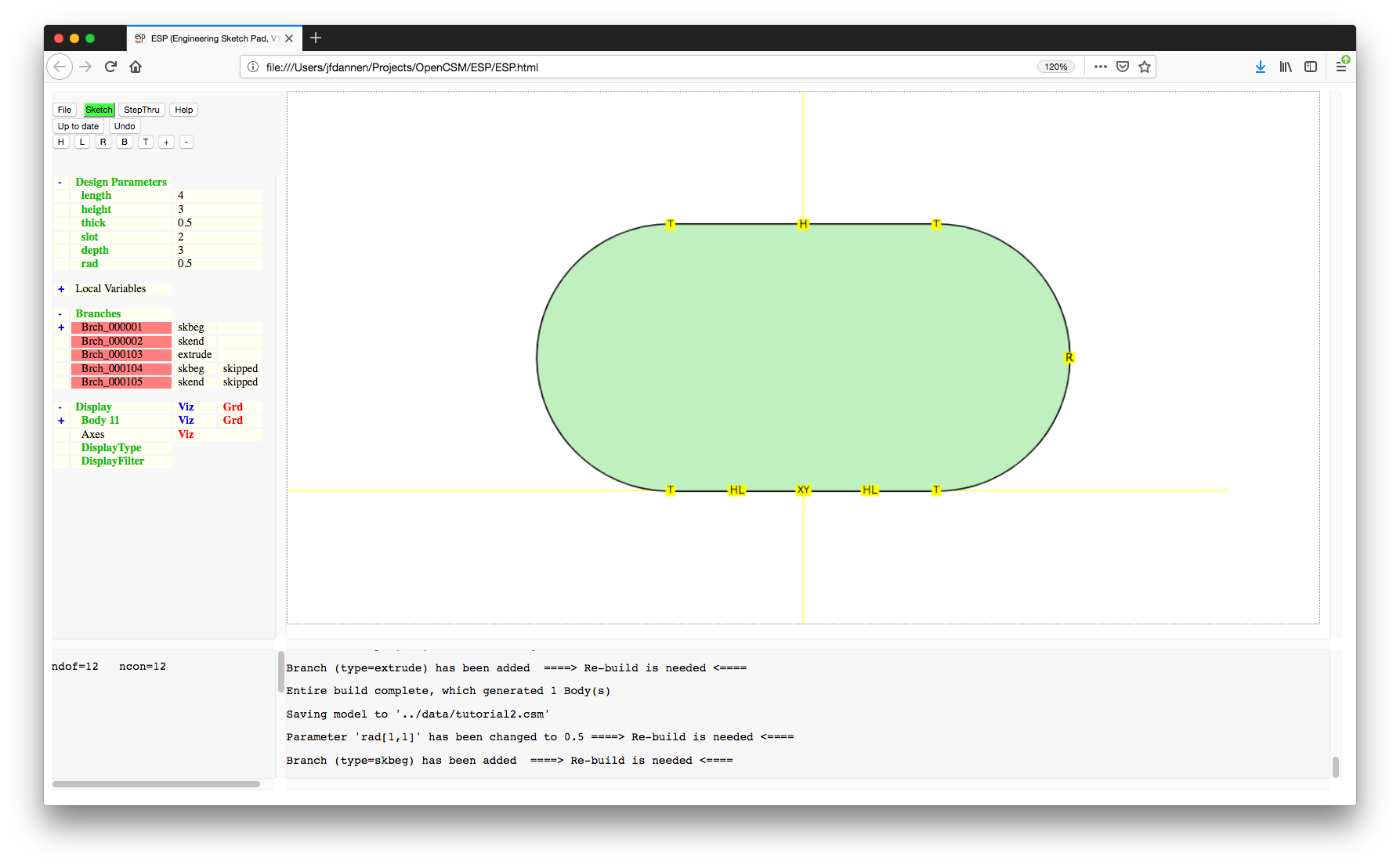

circular arc);Press to Solve, zoom in (using the + button) and center the sketch in the window (using the H) button, yielding:

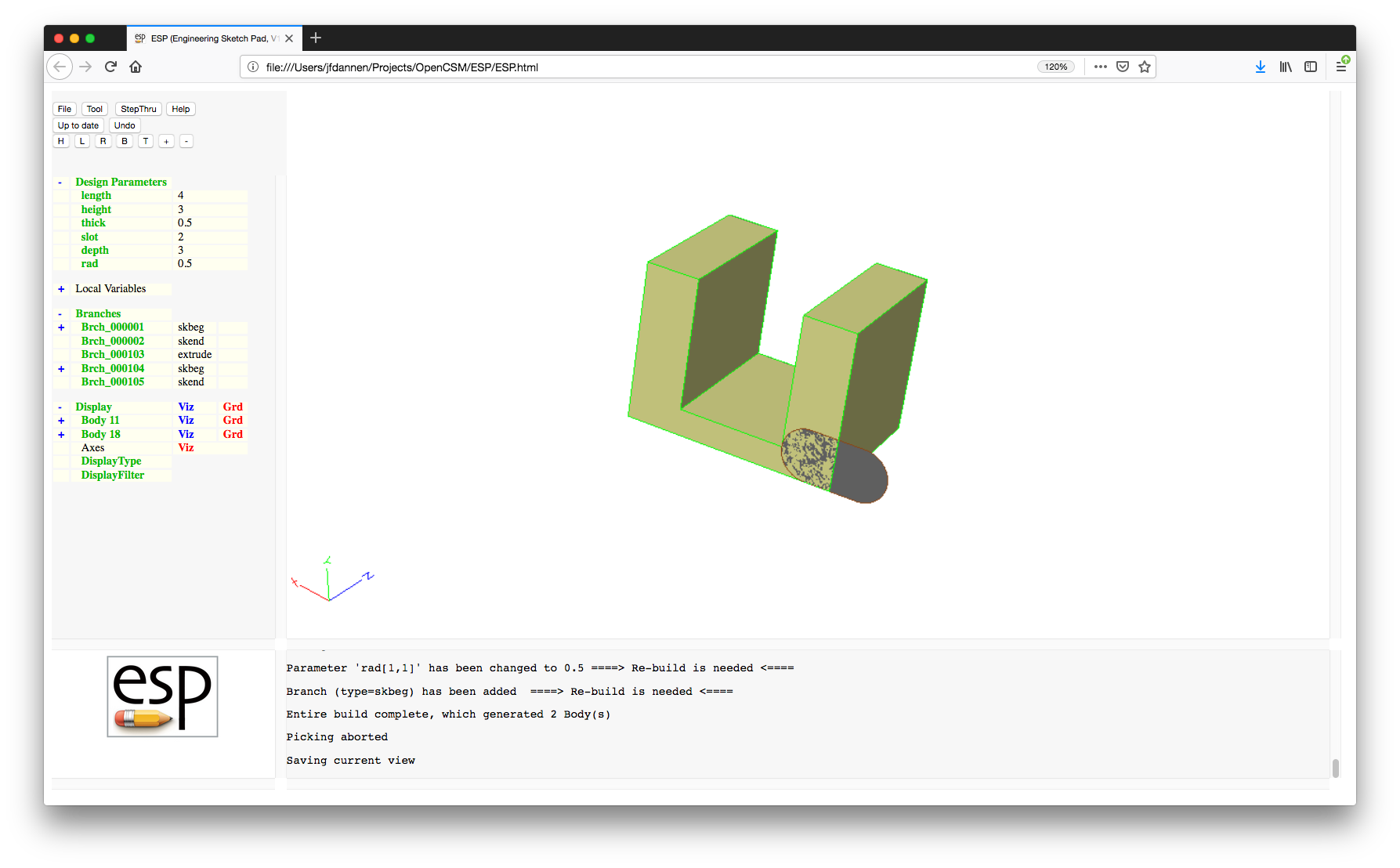

Sketch and Save and Press to Re-build. If you turn the configuration around, you will see the sketch at the back left bottom corner, as in:

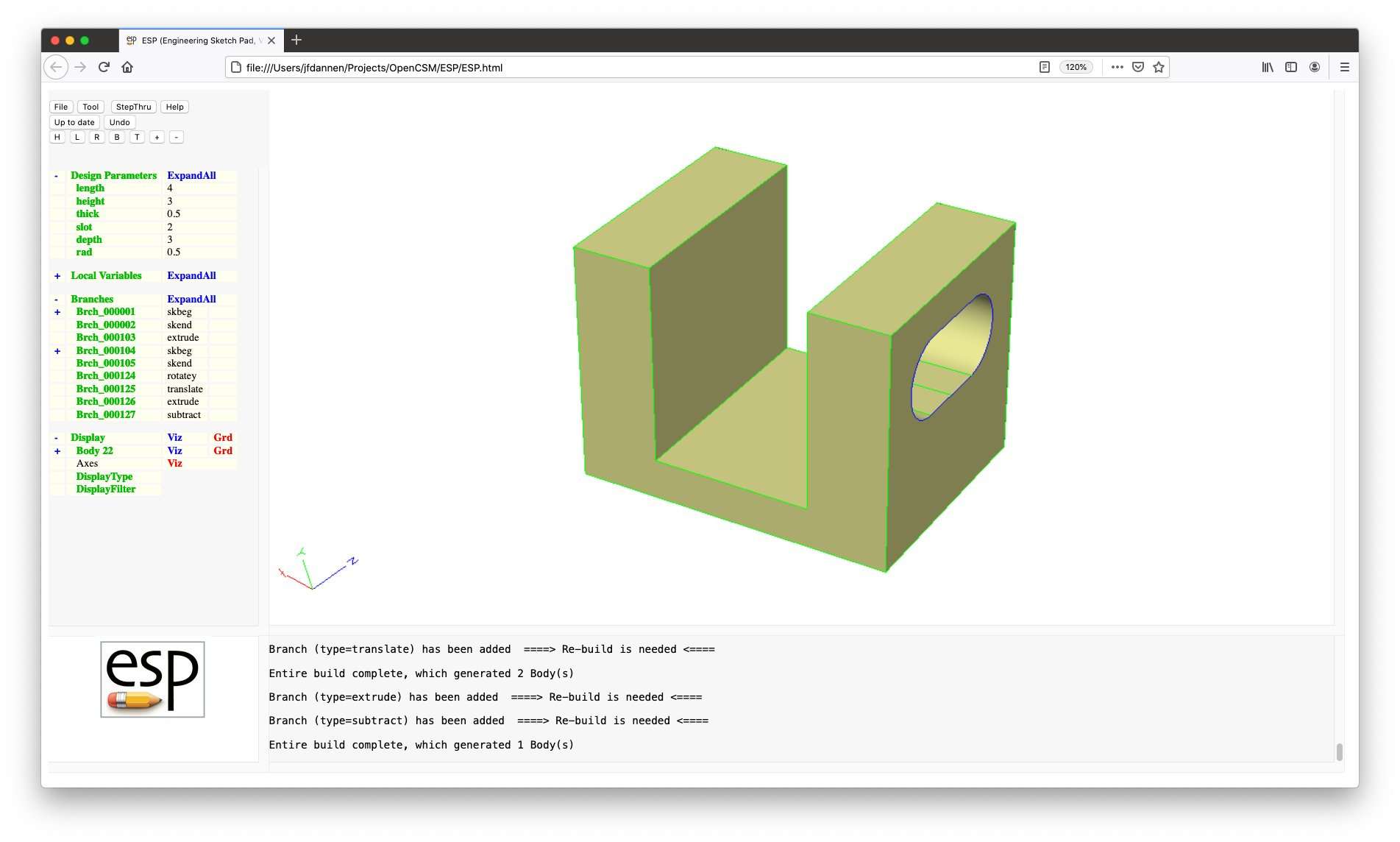

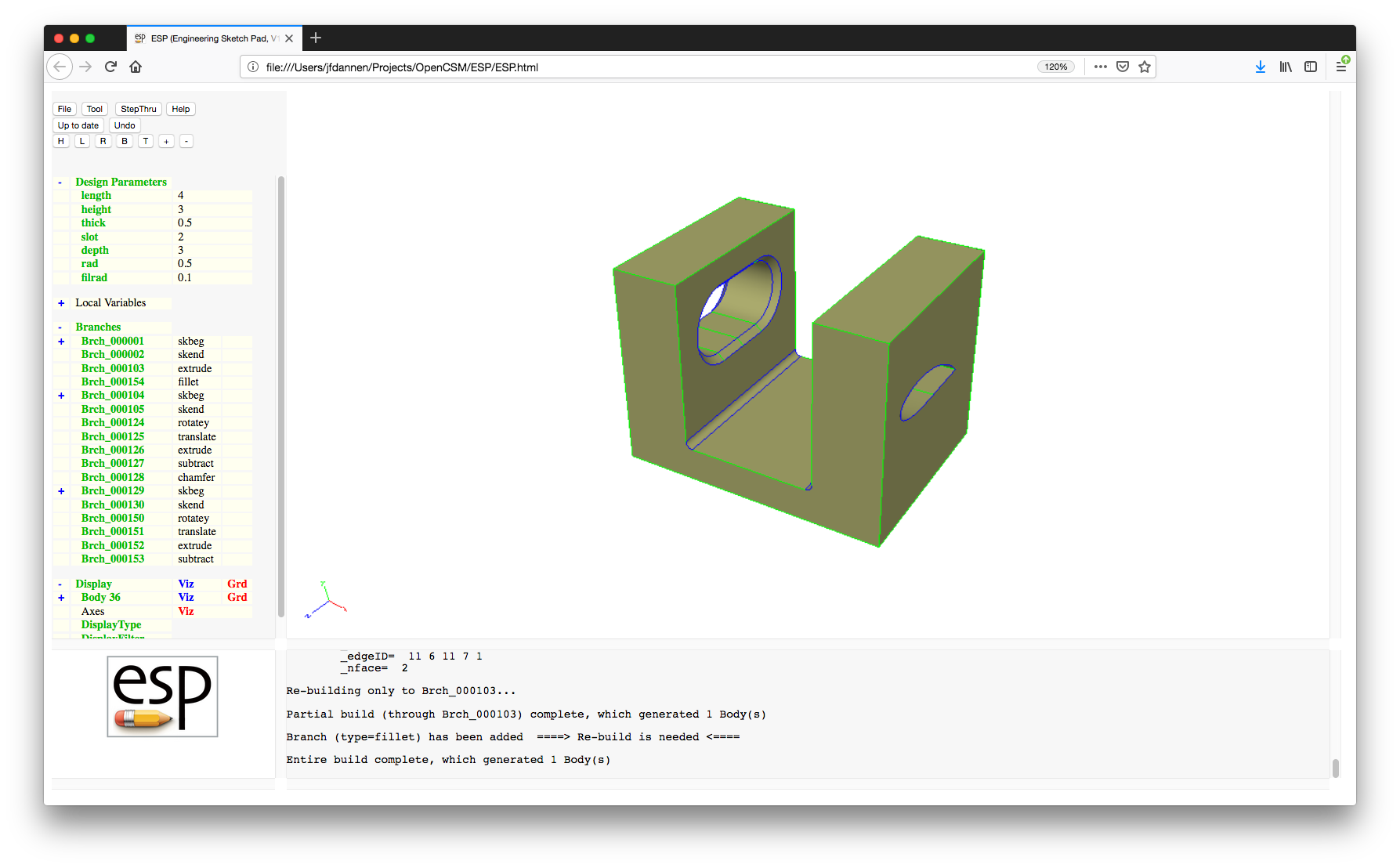

We want to rotate this to be parallel with the y-z

plane by adding a ROTATEY Branch (with

arguments 90, 0,

0), move it to its proper location by adding

a TRANSLATE Branch (with arguments

0, height-3*rad,

and depth/2). If you Press to Re-build you

will see that the sketch is now properly positioned. We can

then add an EXTRUDE Branch (with

arguments length/2, 0,

and 0) and finally subtract that new volume by

adding a SUBTRACT Branch (with the default

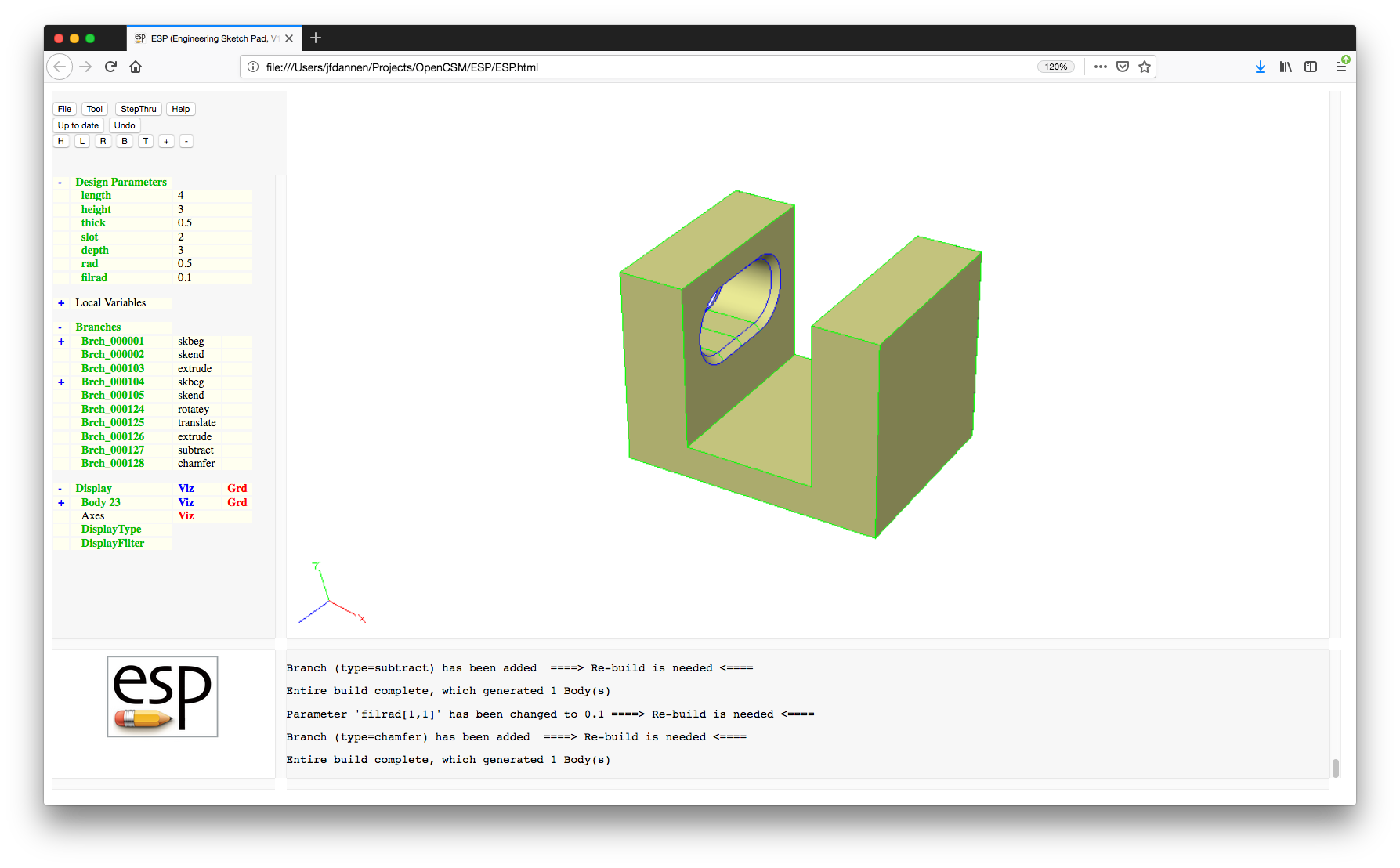

arguments). If you Press to Re-build, you should get:

One of the problems with using the interactive sketcher is that

the only way of saving an interactively-drawn sketch is to use Export

FeatureTree, but that option removes all your formatting

and all the comments that you have already spent time to put in

your model file. (You could also create a constrained sketch

using SOLBEG/SOLEND and then using statements such

as LINSEG or CIRARC directly. This

technique is not covered in this tutorial.)

To demonstrate adding a sketch to a model, we are going to make

a parameterized wedge. Start with an empty ESP by

pressing File and New.

To create a parameterized sketch of a triangle, do the following:

SET Branch (by pressing Branches

and then selecting SET).

The $pmtrName is length and

the exprs is 4;SET Branch so

that height is 3;SKBEG Branch that starts

at 0, 0, 0, and

draw the following:

The "length" of the horizontal segment is length

and the "length" of the vertical segment

is height. Press to Solve,

then Sketch, then Save, then Press to

Re-build. You should now see the following:

Notice that the Body is drawn in pink, meaning that it is a SheetBody (that is, a Body with Face(s) that does not enclose a volume).

Next we are going to save this as a user-defined component

(UDC). For now, think of a UDC as a file that can be included

in another file. To save this, press File and

then Export FeatureTree and use the name

triangle.udc. You will get a warning about losing

formatting, etc.; this is okay, so just press OK.

Now we are actually going to create the model (that is,

the .csm) file by selecting File

and Edit: <new file>. Enter the following in the

editor:

# wedge

# written by ...

DESPMTR depth 2.0

UDPRIM $/triangle

EXTRUDE 0 0 depth

END

Line 4 defines a DesignParameter (as we have seen

before). Line 6 is new; the UDPRIM statement

tells the program to "include" the

file triangle.udc at this point. This is followed

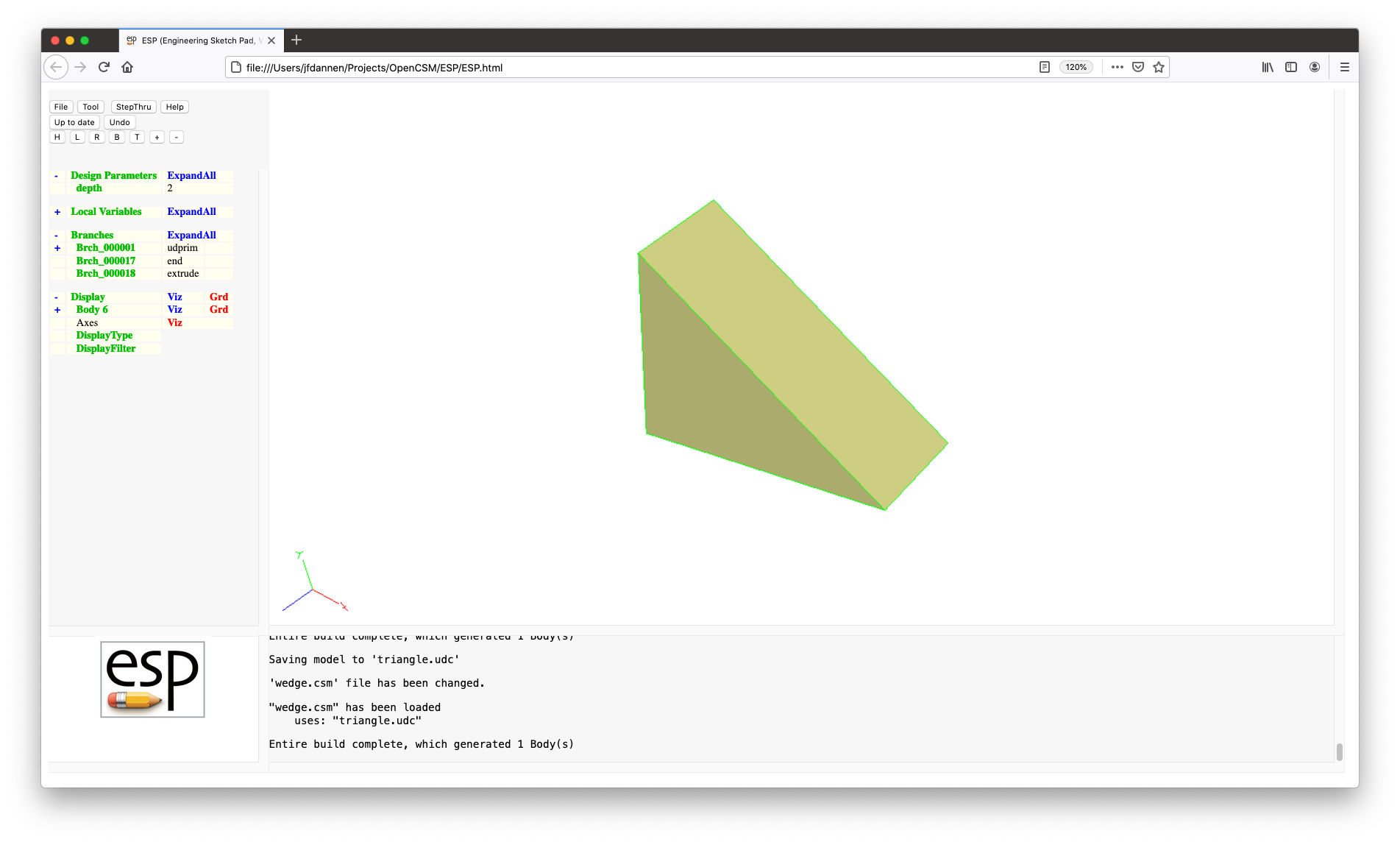

in line 8 by an EXTRUDEion in the z direction.

Press Save in the editor, and use the

name wedge. You should now see a 3D wedge on your

screen. Note that the Faces are now yellow since this is now a

SolidBody (that is, it encloses a volume).

If you change the value of the depth

DesignParameter and Press to Re-build, you will see the

depth of the wedge has changed. Now we want to

make length and height

DesignParameters too. To do this, we will need to edit

wedge.csm to be:

# wedge

# written by ...

DESPMTR length 4.0

DESPMTR height 3.0

DESPMTR depth 2.0

UDPRIM $/triangle

EXTRUDE 0 0 depth

END

Press Save. Notice that the configuration is not

automatically re-built since we have more than one file in the

session. Now we will edit triangle.udc and remove

the two SET statements near the top.

Again Save.

Finally, when you press Press to Re-build you will see a

fully parametric wedge. Try changing the DesignParameter

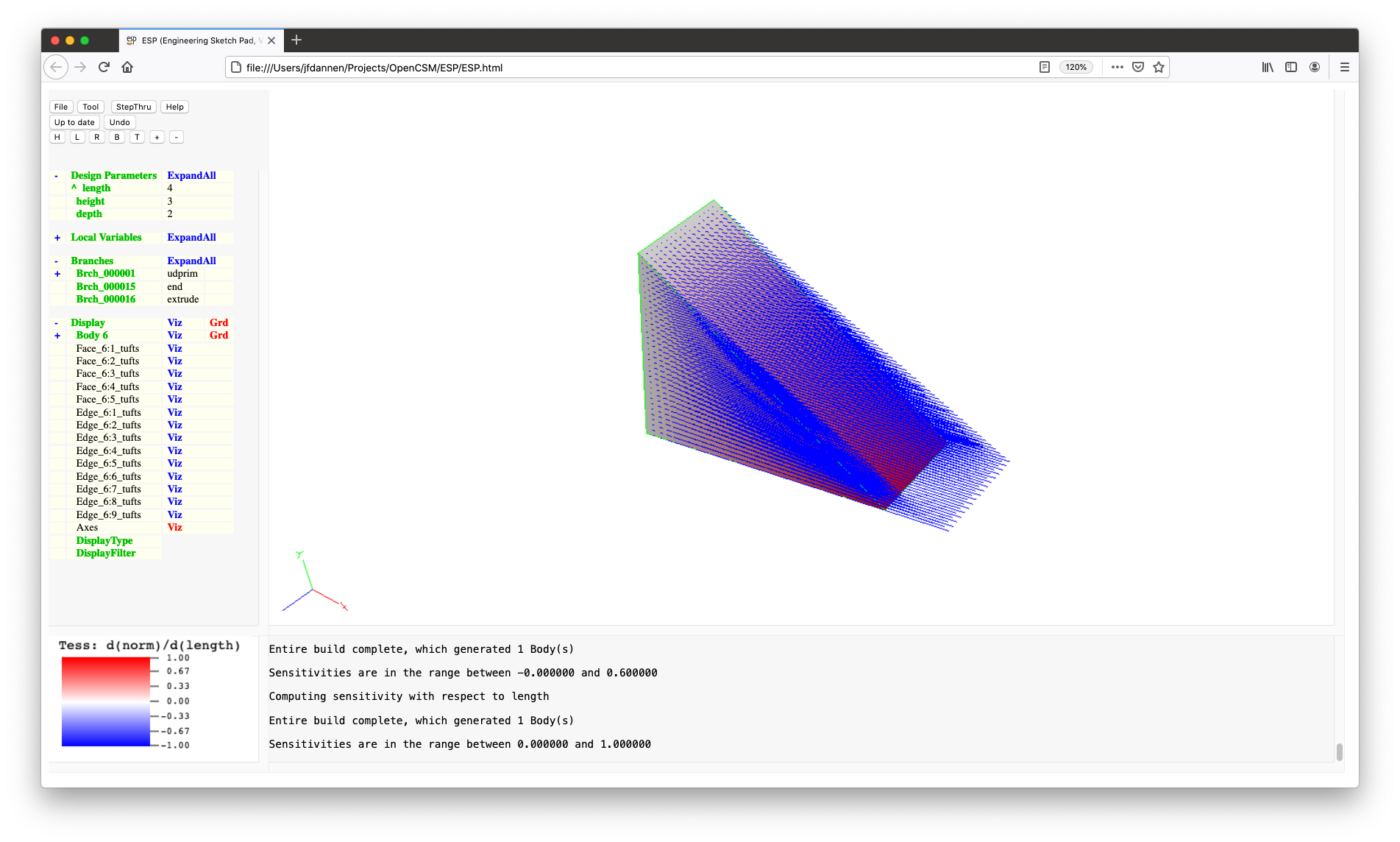

and/or get the sensitivities (which, you may recall, is done by

editing a DesignParameter and then choosing either Compute

geom sens or Compute tess sens. Here is what the

tessellation sensitivities look like with respect to

the length.

The next thing we are going to do is to make a copy of

our ../data/tutorial2.csm file, and call

it temp.csm. To do this:

../data/tutorial2.csm

(or ..\data\tutorial2.csm on Windows); and

temp.csm.

After you have done that, we will make our sketch of the cross-section of the tire. This is done by pressing File and then New (thereby removing from memory anything we have already done).

We are going to need a few DesignParameters for our sketch.

But for now, we are going to make them LocalVariables

with SET statements. (The reason for doing this

is because we are really going to want to have the

DesignParameter in the main script, and not in the sketch UDC

that we will now be building.)

Using Branches, create the following SET statements:

tire:wid_outer with the

value 12.0;tire:wid_inner with the

value 10.0;tire:fillet with the

value 1.0;tire:diam_outer with the

value 30.0; andtire:diam_inner with the

value 22.0.Press to Re-build so that ESP now knows

about these DesignParameters. You can also

press ExpandAll to the right of LocalVariables to

check the spelling of the variables that you just set.

Now make the sketch (by adding a SKBEG Branch),

with the

arguments 0, tire:diam_inner/2,

0, and 1, that

looks like:

The constraints associated with this sketch are:

tire:wid_inner/2;(tire:diam_outer-tire:diam_inner)/2;tire:fillet;tire:wid_outer/2; and90.Then Sketch, Save, (ignore the warning)

and Press to Re-build. In order to save our work,

use File, Export FeatureTree and

enter temp_sketch.udc as the filename.

Now we want to include this sketch in our bigger model file.

To do this, File and Open and

choose temp. (If you followed the

directions above, you should now see the same model that you

had at the end of Tutorial 2.)

After changing the name of the file in the first line (which is not actually needed, but which is a best practice), we are going to change our definitions of the DesignParameters (which are in lines 5 through 7), to:

DESPMTR tire:wid_outer 12.0 # outer width of tire

DESPMTR tire:wid_inner 10.0 # inner width of tire

DESPMTR tire:fillet 1.0 # fillet rad of tire

DESPMTR tire:diam_outer 30.0 # outer diam of tire

DESPMTR tire:diam_inner 22.0 # inner diam of tire

The only other thing we need to do is to change the definition

of the cross-section. Change the first BOX

statement (line 21) to read:

UDPRIM $/temp_sketch

When you Save out of the code editor, you will get an

error (MessageWindow will end with ||), telling you that something

went wrong. (What went wrong is that the SET

statements in the UDC are trying to set a new value for a

DesignParameter). It will also seem to "lock up" the GUI. To

clear this lock, press Re-building... and ignore the

warning.

Now edit temp_sketch.udc and remove

the SET statements near the top (since they will

be DesignParameters in temp.csm).

Press Save and Press to Re-build and you should

now see your tire with an updated cross-section.

But, you will notice that notice that the MessageWindow has

turned yellow, indicating that there was an error encountered.

If you double-click on the yellow window, the code editor will

automatically open up to the offending line. In this case, we

no longer have a parameter named tire:width; it

has been renamed to tire:wid_outer. Make the

change, Save, and Press to Re-build.

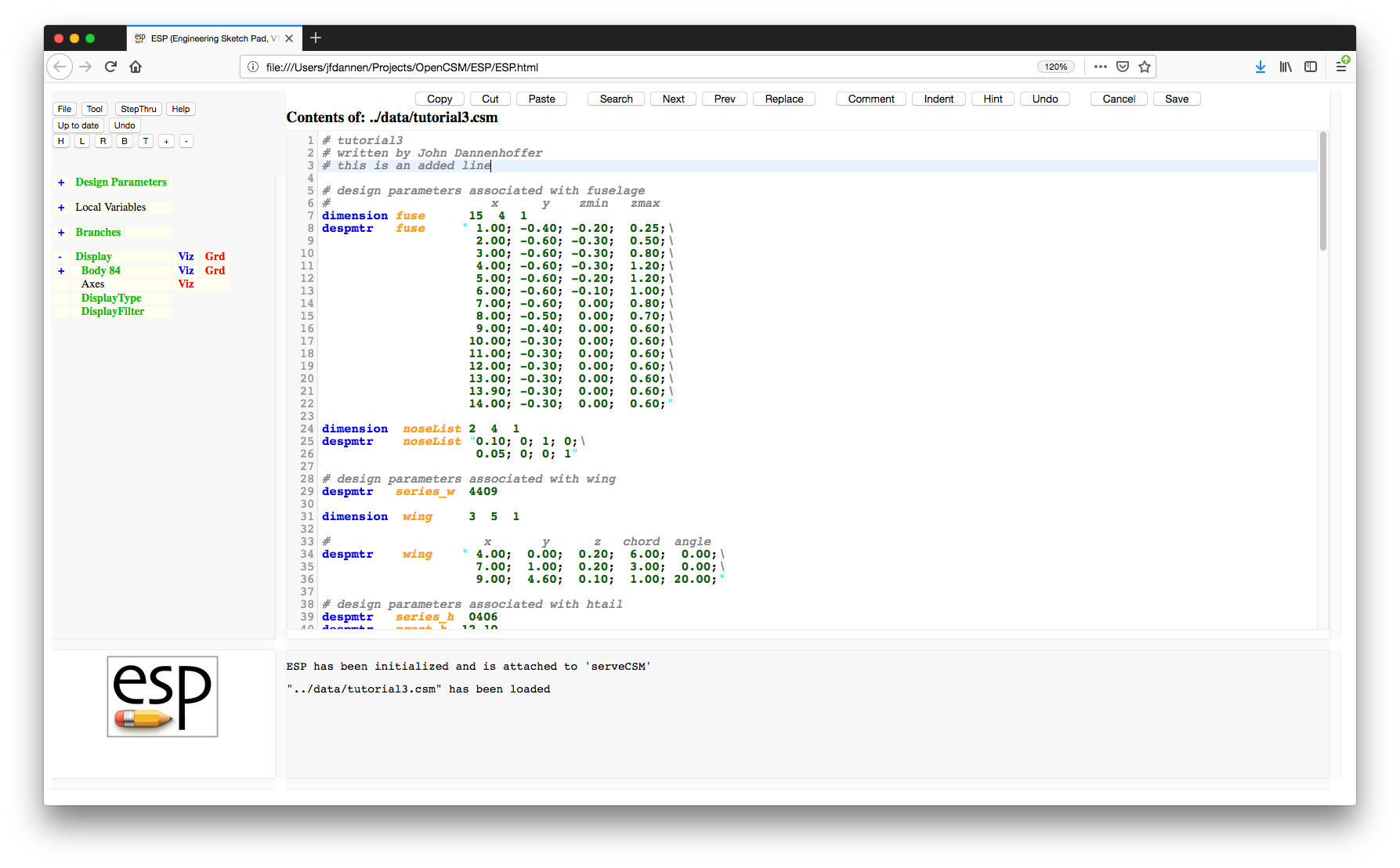

The next thing we are going to do is to add spokes to our

configuration. At this time, File and Open the

model ../data/tutorial3

(or ..\data\tutorial3). Now File

and Edit: ../data/tutorial3.csm.

To add the spokes, the following changes were made:

CFGPMTR spoke:num 10 # number of spokes

DESPMTR spoke:rim 1.0 # rim left after spokes cutout

DESPMTR spoke:rad 0.2 # radius of each spoke

IFTHEN spoke:num GT 0

ENDIF

define an IFTHEN block so

that the spokes will only be added if the user supplies a

positive number of spokes;

SET rmin hole:diam_circ/2+hole:rad+spoke:rim

SET rmax tire:diam_inner/2-disk:chamfer-spoke:rim

define the minimum and maximum radii of

the spokes;

CYLINDER -disk:width 0 0 +disk:width 0 0 rmax

SUBTRACT

make a CYLINDER and SUBTRACT it

from the overall "SolidModel";

SELECT FACE @nbody-1 0 # comes from cylinder

ATTRIBUTE _color $cyan

color the newly created Faces cyan. Note

that the Faces that we want to color actually come from

the CYLINDER, so we must SELECT

using the @nbody-1 Body. Also, we want all

Faces that came from the CYLINDER, so we use

a _faceID of 0;

CYLINDER 0 rmin-0.1 0 0 rmax+0.1 0 spoke:rad

and Attributed in

lines 98 and 99:

ATTRIBUTE myPart $spoke

ATTRIBUTE _color $cyan

Note that we slightly adjusted the

extents of the CYLINDER by 0.1

to make sure we would get clean Boolean operations;UNIONed with the rest of the

configuration in line 101

UNION

RESTOREd in line

103:

RESTORE SolidModel

and then a smaller CYLINDER

is INTERSECTed with it in lines 104 and 105:

CYLINDER -disk:width 0 0 +disk:width 0 0 rmin

INTERSECT

Again, the exposed Faces are Attributed in lines 106 and

107:

SELECT FACE @nbody-1 0 # comes from cylinder

ATTRIBUTE _color $cyan

UNIONed

with the rest of the configuration in line 108:

UNION

spoke:num-1 spokes (in lines 111

through 113):

CYLINDER 0 rmin-0.1 0 0 rmax+0.1 0 spoke:rad

ATTRIBUTE myPart $spoke

ATTRIBUTE _color $cyan

ROTATEX each into its final

position (in line 115):

ROTATEX 360*ispoke/spoke:num 0 0

and UNION each into

the rest of the configuration (in line 116):

UNION

andSTOREd in

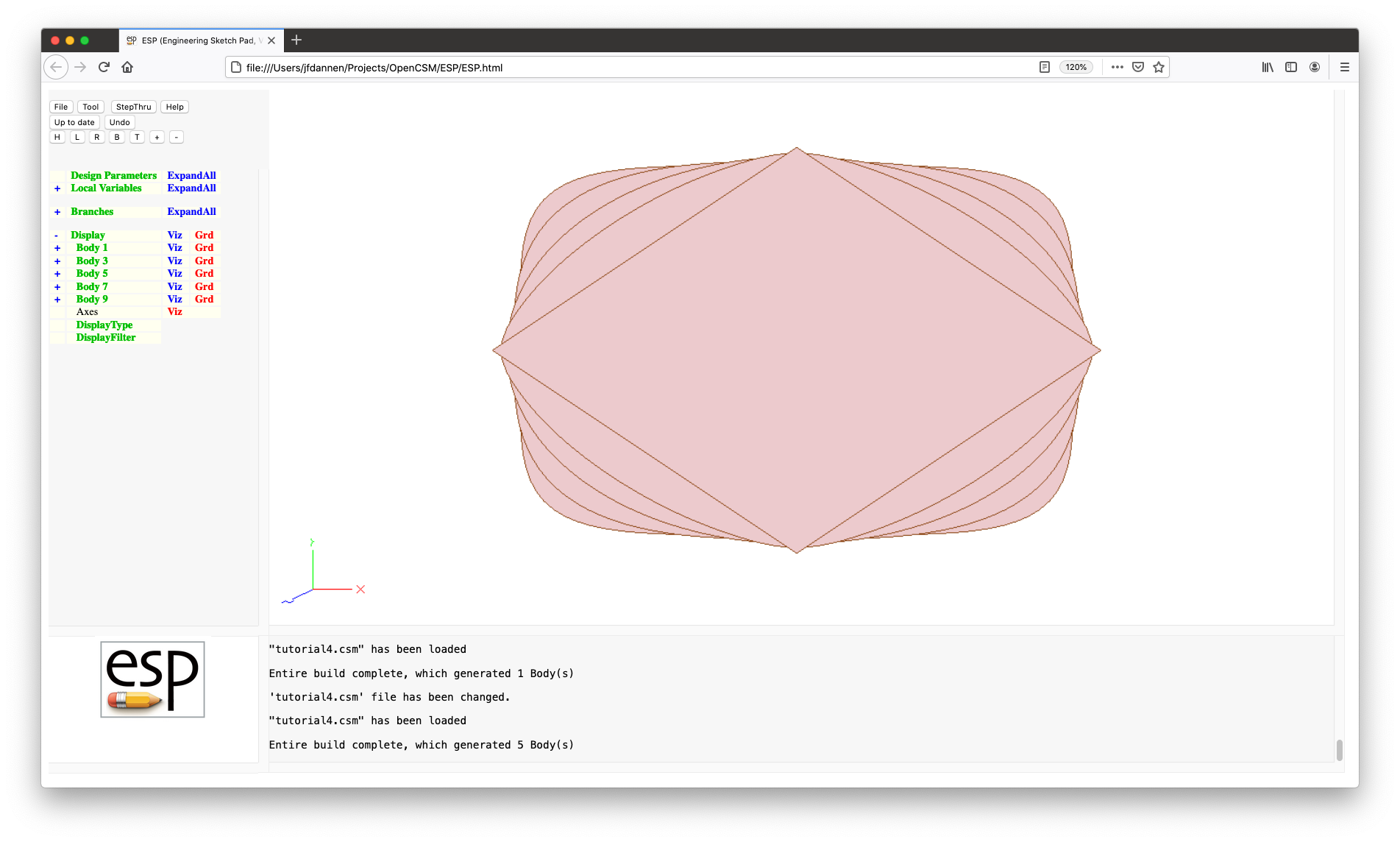

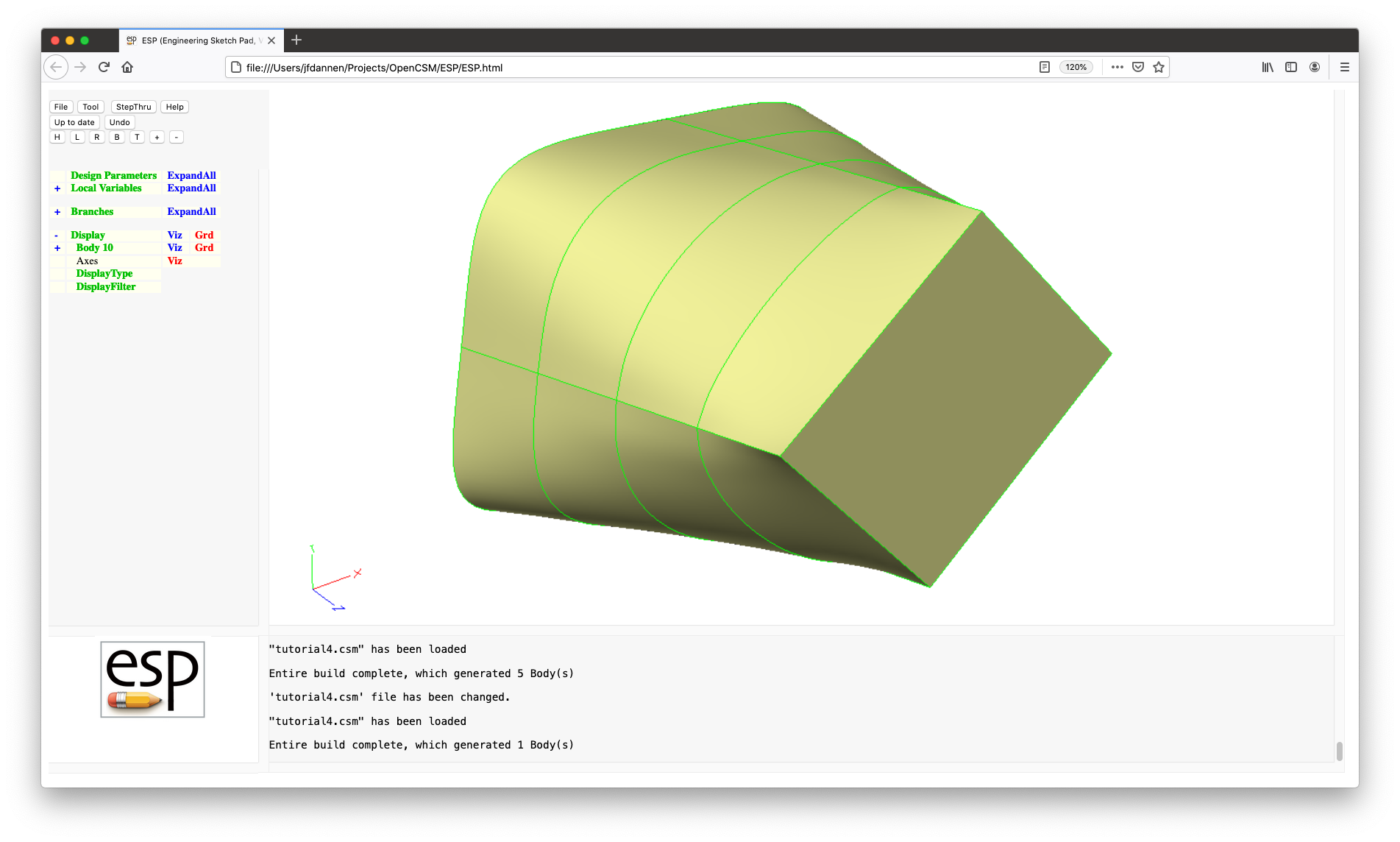

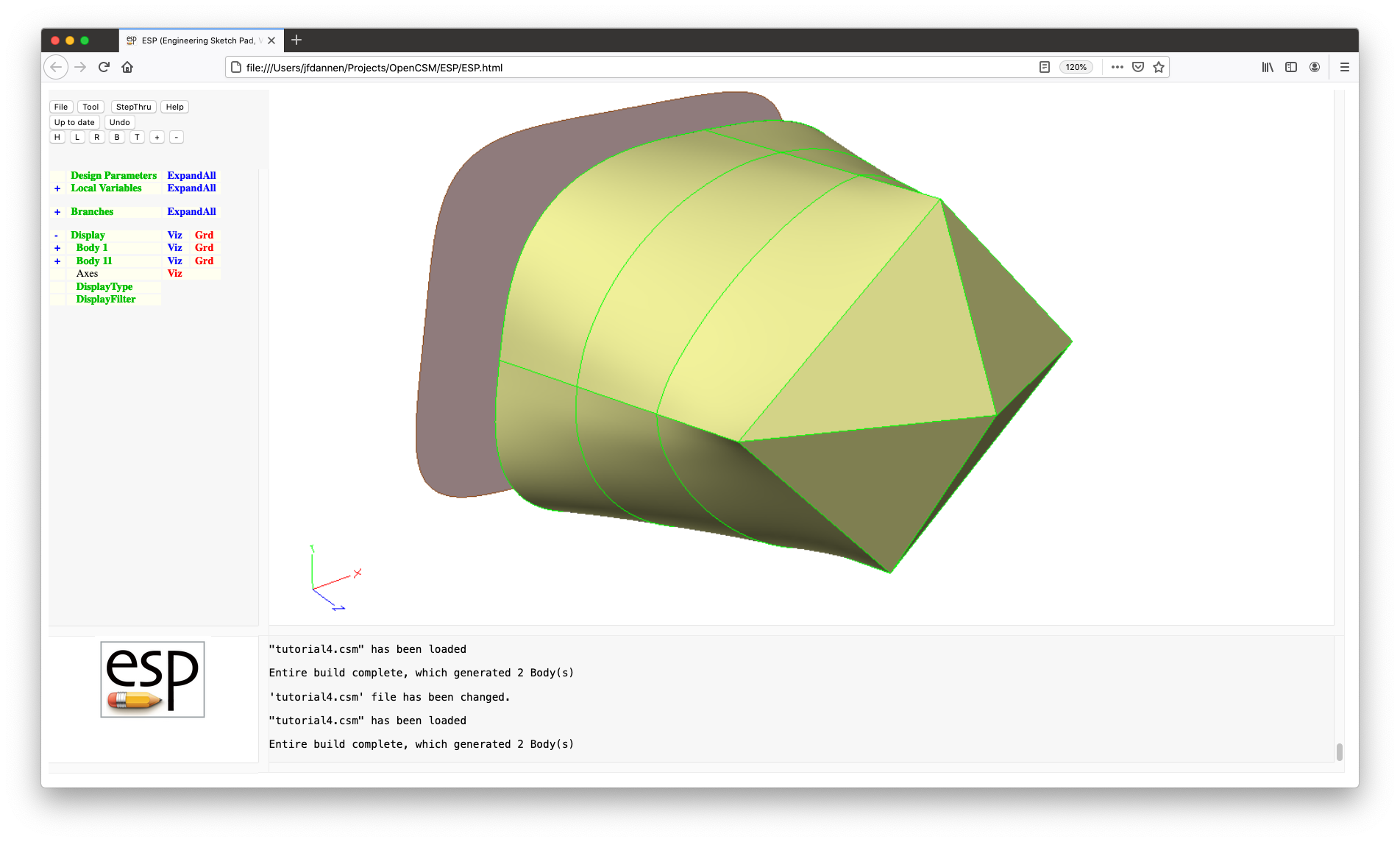

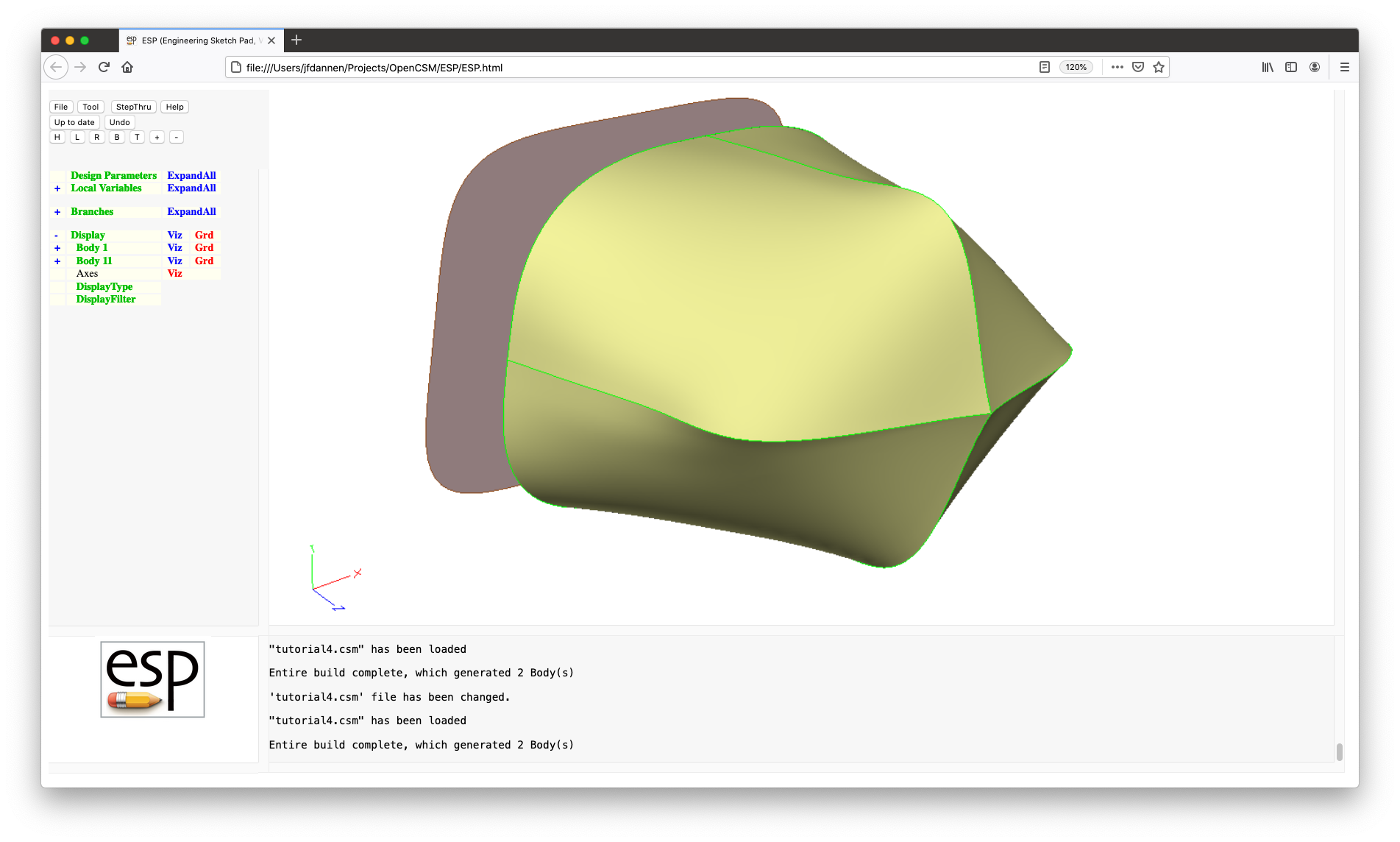

"SolidModel 0" and a copy of it is left on the Stack.In this fourth tutorial, we are going to focus on Bodys that

are made by growing from lower-dimensional Bodys. Specifically

we are going to look at EXTRUDE

and REVOLVE, which we have already seen, and then

two new important construction techniques: RULE

and BLEND.

All of these techniques can be used to make a WireBody out of a series of NodeBodys, or a SheetBody out of a series of WireBodys, or a SolidBody out of a series of SheetBodys.

Before continuing, it is instructive to define what we mean by the various Body types:

POINT command;BOX command, or by one of the airfoil

generators for the case where the thickness is zero, or by

one of the user-defined primitives (such

as bezier or freeform);BOX command, by the

sketcher, or by one of the user-defined primitives (such

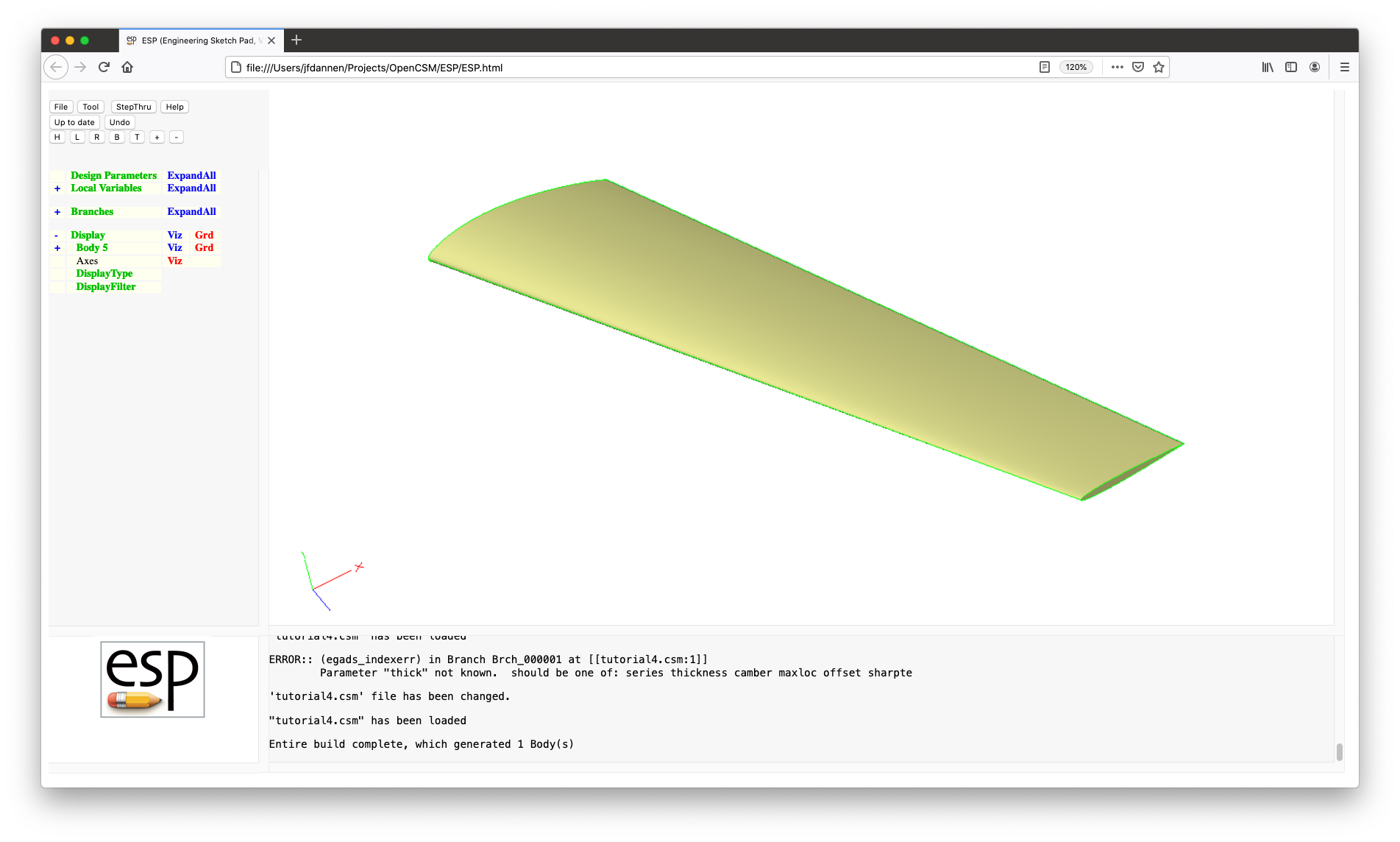

as the airfoils generators); andESP model are SolidBodys.Let us start with a simple rectangle, which can easily be made

with the BOX command. Press File,

then New, then Edit <new file> and put the

following in the editor:

BOX 1.0 4.0 0.0 2.0 3.0 0.0

EXTRUDE 0.0 1.0 4.0

END

and Save to the file temp. The first line

makes a 2-by-3 SheetBody that lies in the x-y plane and whose

lower left corner is at (1.0,4.0,0.0). The second

line EXTRUDEs the SheetBody into a SolidBody by

implicitly making a second copy that is at (0.0,1.0,4.0)

relative to the original SheetBody and then connecting the

SheetBodys.